Professional Documents

Culture Documents

Hydrophobic, Antireflective, Self Cleaning, and Antifogging Sol Gel Coatings An Example of Multifunctional Nanostructured Materials For Photovoltaic Cells 2010 Chemistry of Materials

Uploaded by

Esau AguillónOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hydrophobic, Antireflective, Self Cleaning, and Antifogging Sol Gel Coatings An Example of Multifunctional Nanostructured Materials For Photovoltaic Cells 2010 Chemistry of Materials

Uploaded by

Esau AguillónCopyright:

Available Formats

pubs.acs.

org/cm Published on Web 07/15/2010 r2010 American Chemical Society

4406 Chem. Mater. 2010, 22, 44064413

DOI:10.1021/cm100937e

Hydrophobic, Antireflective, Self-Cleaning, and Antifogging Sol-Gel

Coatings: An Example of Multifunctional Nanostructured Materials for

Photovoltaic Cells

Marco Faustini,

Lionel Nicole,

Cedric Boissiere,

Plinio Innocenzi,

Clement Sanchez,

and David Grosso*

,

Chimie de la Mati ere Condens ee de Paris, UMR UPMC-CNRS 7574, Universit e Pierre et Marie Curie

(Paris 6), Coll ege de France, 11 place Marcelin Berthelot, 75231, Paris, France, and

Laboratorio di Scienza

dei Materiali e Nanotecnologie (LMNT), CR-INSTM, Universit a di Sassari, Palazzo Pou Salid Piazza

Duomo 6, 07041 Alghero SS, Italy

Received April 3, 2010. Revised Manuscript Received June 1, 2010

Antireflective, photocatalytic (self-cleaning), water repellent, and high water-wetting (anti fogging)

properties were combined for the first time into a sol-gel coating deposited onto glass substrates.

Such an original multifunctional coating was obtained by sol-gel liquid deposition of two successive

oxide layers. The first coating is composed of a hybrid methyl-functionalized nanoporous SiO

2

material that exhibits high transparency, high water resistance, close to null water adsorption, and

fairly high mechanical stability (transversal Young Modulus: 1.5 GPa). Thickness and refractive index

can be controlled by selecting proper chemical and processing conditions so as to adjust the anti-

reflectivity properties. The second layer is an ultrathin crystalline TiO

2

nanoperforated layer that was

deposited on top of the previous antireflective layer. Its thickness and refractive index were adjusted

around 12 nm and n 1.8 respectively. This hard TiO

2

top layer acts as a protecting barrier toward

mechanical aggressions and assures high water wetting (antifogging) and photocatalysis (self-

cleaning) at the surface. Indeed, this bilayer systemshows an excellent capability to photodecompose

organic species that were adsorbed into the Anti-Reflective (AR) layer porosity. We show that the

decomposition of model pollutants takes place inside and on the surface of the layer, which is likely

due to diffusion of the pollutants toward TiO

2

and/or diffusion of the radical species toward the

pollutants. These systems are easy to produce on a large scale at lowcost and exhibit high mechanical

and chemical durability. They are thus serious candidates to be used as antireflective, self-cleaning

coatings for photovoltaic cells.

1. Introduction

Many efforts have been dedicated to the development

of novel technologies associated to photovoltaic cells with

the aimof increasingthe energetic yields of suchgreenenergy

production devices. Whatever the type of technology to

photogenerate electricity (silicon based or Dye-sensitive

Solar Cells (DSC)), there is a need to obtain sustainable

optical coatings to allow the maximum solar emission to

reach the exiton generating semiconductor junction. Apply-

ing an Anti-Reflective (AR) layer, with an optimized refrac-

tive index and thickness, on top of a glass top cover of the

device can partly solve this issue.

1-3

Most of the time, the

coatings are primarily porous silica-based material offering

tunable refractive indexandthickness withexcellent adhesion

to the glass surface.

4,5

Unfortunately, pure SiO

2

porous

coatings are not stable in water since they are sufficiently

soluble to be progressively dissolved by rain. This process

is augmented by the presence of the porosity that drama-

tically increases the surface area of the material.

6

In addi-

tion, these pores have hydrophilic surfaces and are small

enough to be filled-up with water at relatively low humi-

dity through capillary condensation leading to a dramatic

effect on the optical properties and thereby increasing the

refractive index and provoking a significant reduction of

the antireflective properties. Meanwhile, the presence of

accessible pores in the nanometer range favoring the

adsorption of pollutants from the out-door environment;

the latter causes higher adsorption of contaminants that

again lead to a rise of the AR layer refractive index and

thus to the loss of its optical function. Water up-take can

be considerably reduced by making the pores hydropho-

bic through the use of alkyl functionalized silica precursors.

7

*To whom correspondence should be addressed. E-mail: david.grosso@

upmc.fr. Fax: 33 (0) 1 44 27 47 69. Phone: 33 (0) 1 44 27 15 30.

(1) Kermadi, S.; Agoudjil, N.; Sali, S.; Tala-Ighil, R.; Boumaour, M.

Thin Films Porous Mater. 2009, 609, 221.

(2) San Vicente, G.; Morales, A.; Gutierrez, M. T. Thin Solid Films

2001, 391, 133.

(3) Wang, X.; Shen, J. J. Sol-Gel Sci. Technol. 2009, online published

(4) Das, S.; Roy, S.; Patra, A.; Kumar Biswas, P. Mater. Lett. 2003, 57,

2320.

(5) Wu, G.; Wang, J.; Shen, J.; Yang, T.; Zhang, Q.; Zhou, B.; Deng,

Z.; Bin, F.; Zhou, D.; Zhang, F. J. Non-Cryst. Solids 2000, 275, 169.

(6) Chowdhury, S. R.; Peters, A. M.; Blank, D. H.A.; ten Elshof, J. E.

J. Membr. Sci. 2006, 276, 276.

Article Chem. Mater., Vol. 22, No. 15, 2010 4407

On the other hand, contamination cannot be avoided

except if the porosity is made non-accessible to pollutants

by applying a hermetic barrier layer. Another alternative

solution would be to integrate a photocatalyst species to

the optical layer whose role would be to clean the porosity

through in situ decomposition of the potential organic

contaminants upon natural sunlight activation. One of

the most efficient materials for such a purpose is TiO

2

anatase which exhibits a total cutoff at wavelength below

350 nm. It has already proven its efficiency in self-clean-

ing window glasses.

8,9

However, problems exist because

of its high refractive index (i.e., n = 2.5), which will

dramatically reduce the AR properties of the layer. To

reduce n, TiO

2

can be nanoparticles embedded into the

AR layer network. In this case, the porosity must be

increased so as to counter balance the increase in material

optical density, inducing a mechanical weakening and a

greater contamination through adsorption in the pores.

The second possibility is to successively deposit both

materials in the desired structure to obtain independent

bilayer systems. Combination of TiO

2

and SiO

2

in the

same coating either under mixed phases

10

or under in-

dependent stack layers

2,3,5,11

obtained through physical

deposition or sol-gel liquid deposition techniques has

recently been reported for different types of optical

applications. None of these solutions combined hydro-

phobicity of the inner porosity together with photocata-

lytic activity located only at the surface, and a perfect

control of both layer porous structure and refractive

index. In the present work, we describe the preparation,

the structure, and the properties of bilayer systems com-

posed of an ultrathin Photo-Active (PA) TiO

2

coating

onto the surface of an Anti-Reflective (AR) hybrid silica-

based layer. The thickness of the top TiO

2

PA layer must

be extremely thin, and its refractive index must be as close

as possible to the refractive index of the AR layer so as to

preserve as much as possible the optical properties. In

addition, it is necessary to reduce the thickness of the AR

layer to compensate for the presence of the PA layer.

The AR layer is constituted of a calcined methyl-

functionalized SiO

2

matrix, exhibiting hydrophobic poro-

sity with pores in the range of several nm in diameter. It

has been prepared by dip-coating glass substrates into a

sol-gel solution containing partly hydrolyzed and con-

densed Tetraethoxysilane (TEOS) and Methyltriethoxy-

silane (MTEOS) precursors in the presence of (PEO-PPO-

PEO) Pluronic F127 block copolymer porogene. After

thermal stabilization, the PAlayer was deposited onto the

previous layer by the same liquid deposition method, but

using TiCl

4

precursor and PB-b-PEO block copolymer.

Thicknesses were adjusted between 50 and 160 nm for the

AR layers and around 15 nm for the PA layer.

12

The re-

fractive index of the AR layer could be adjusted between

1.16 and 1.33 by varying the F127 content, but it was fixed

here at around 1.22 (see Experimental Section). The refrac-

tive index of the PA coating was reduced to around 1.8

through the creation of homogeneous and ordered void

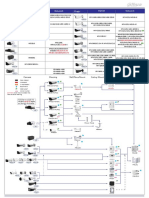

nanoperforations into the material. The scheme of the bi-

layer system is shown in Figure 1. The top layer could be

seenas anultrathinmembrane containing20nmindiameter

perforations organized into a hexagonal structure.

13

Struc-

tural and chemical characterizations were performed using

Environmental Ellipsometric Porosimetry (EEP) techni-

ques, Grazing Incidence X-ray analyses at low and wide

angles (GI-SAXS and GI-WAXS), electronic and near-

field microcopies, FTIR, and UV-visible transmittance.

The bilayer system shows close to 4% increase in trans-

mittance compare to the bare substrate at adjustable wave-

length range, excellent water repellence, good mechanical

properties, self-cleaning properties, and a stability over

9 months immersion into water (longest tested period).

These properties match perfectly with the requirements

for the final cover of out-door solar cells; however, it also

can be applied for other types of optical devices requiring

inner hydrophobicity, anti fogging because of high sur-

face energy, antireflectivity, and photo activity integrated

properties.

2. Experimental Section

Chemicals. Absolute ethanol was purchased from Normapur

while TiCl

4

, TEOS (TetraEthOxySilane) and MTEOS (Methyl-

TriEthOxySilane) precursors were purchased from Aldrich. F127

Pluronic (EO

106

-PO

70

-EO

106

) and P3017-BdEO PB-b-PEO (poly-

butadiene-b-polyethyleneoxide, MWPB=5500g mol

-1

, MWPEO=

5000 g mol

-1

) were purchased from Aldrich and Polymersource

respectively.

Anti Reflective Films. AR films were prepared from solutions

composed of TEOS/MTEOS/F127/HCl/H

2

O/EtOH with respec-

tive molar ratio of 0.5:0.5:0.006:0.005:5:40. MTEOS and TEOS

were first dissolved in the solution composed of EtOH, HCl

(2M) and H

2

O before addition of F127; the solution was stirred

for at least 2 h before deposition. Films were prepared on silicon

and glass microscope slide substrates (n = 1.49 at 700 nm) by

dip coating at room temperature and at low relative humidity

(RH<5%). The thickness of ARfilms was tuned using different

Figure 1. Scheme of the bilayer systemcomposed of the thick ARunder-

neath layer covered by the nanoperforated ultrathin PA layer.

(7) Krzyzak, M.; Frischat, G. H.; Hellmold, P. J. Sol-Gel Sci. Technol.

2007, 41, 99.

(8) Kesmez, O.; Erdem Camurlu, H.; Burunkaya, E.; Arpac, E. Sol.

Energy Mater. Sol. Cell. 2009, 93, 1833.

(9) Zhao, X.; Zhao, Q.; Yu, J.; Liu, B. J. Non-Cryst. Solids 2008, 354,

1424.

(10) Brinker, C. J.; Harrington, M. S. Sol. Energy Mater. J. 1981, 5, 159.

(11) Zhang, X. T.; Fujishima, A.; Jin, M.; Emeline, A. V.; Murakami, T.

J. Phys. Chem.B 2006, 110-50, 25142.

(12) Faustini, M.; Louis, B.; Albouy, P. A.; Kuemmel, M.; Grosso, D.

J. Phys. Chem.C 2010, 114, 7637.

(13) Kuemmel, M.; Allouche, J.; Nicole, L.; Boissiere, C.; Laberty, C.;

Amenitsch, H.; Sanchez, C.; Grosso, D. Chem. Mater. 2007, 19,

3717.

4408 Chem. Mater., Vol. 22, No. 15, 2010 Faustini et al.

withdrawal rates (1, 2, and 4 mm s

-1

) keeping all other dip coat-

ing conditions fixed. After coating, hybrid films were immedi-

atly calcinated underneath a curing IR lamp at 450 C for 10 min.

Photo Active Films. PA were obtained from fresh solutions

composed of TiCl

4

/PB-PEO/H

2

O/EtOH in the following res-

pective molar proportions: 1:0.002:42:160. A first solution A was

prepared by mixing the PB-b-PEO in the water and in 3/4 of the

amount of ethanol. Solution Awas aged at 70 Cfor 2 h until the

complete dissolution of the PB-b-PEO and then cooled down at

room temperature. A second solution B containing TiCl

4

and

the remaining ethanol were added to the cooled solution A before

being stirred at room temperature for 30 min. PA films were

deposited on top of the AR layers by dip coating using a with-

drawal speed of 1.5 mm s

-1

and at a temperature of 40 C, and

relative low humidity. The as-formed bilayer system was then

heated at 500 C for 5 min to ensure crystallization of the TiO

2

top layer. Film samples were labeled as ARX, for the Anti Ref-

lective single layer systems and ARXPA for the Anti Reflective

and Photo Active bilayer systems. X stands for the dip-coating

withdrawal speed in mm s

-1

used to prepare the AR layer. Single-

side coated samples were obtained by cleaning one side of the

substrate prior to heat treatment using a dry tissue imbibed with

ethanol.

Film structure was investigated using Field Emission Gun

Scanning Electron Microscopy (SEM-FEG) Zeiss Ultra 55,

Transmission Electron Microscopy (TEM) JEOL Jem 100CX,

and Atomic Force Microscopy (AFM) Veeco DI-CPII in non-

contact mode using MPP11123 phosphorus doped silicon probes

from Veeco. Grazing Incidence Small-Angle X-ray Scattering

(GISAXS-Rigaku S-max 3000 equipped with a microfocus source

=0.154 nm and a 2D Gabriel type detector place at 1480 mm

fromthe sample) was used to assess the structure of the films and

the period of the array of PA layer nanoperforations at an angle

of incidence of 0.21. The transmitted and specular reflected

beams were masked by a vertical beam-stop. Diffraction pat-

terns were analyzed using Igor software.

14

Ellypsometry mea-

surements were performedona UV-visible (from240 to1000 nm)

variableanglespectroscopicellipsometer (VASE-2000UWoollam),

and the data analyses were performed with the Wvase32 soft-

ware using Cauchy models for both layers. EEPwas investigated

through capillary condensation of water or toluene into the

porosity using an atmospheric control chamber designed by

SOPRA-LAB.

19

Photoactivity of the systems was investigated

by following the refractive index of the layer, contaminated with

Lauric acid, uponUVirradiation. Lauric acidwas chosenas model

pollutant because it contains hydrophilic and hydrophobic

groups found in most organic species. In addition, its carboxy-

late head and its hydrophobic alkyl tail allowstrong interactions

to form independently with the TiO

2

(Lewis acid) surface and

the hydrophobic inner porosity of the underneath layer, respec-

tively. Finally, if one wants to record the mass loss that is only

due to photcatalysis with the present elliposmetry setup, the orga-

nic pollutant must absolutely be poorly volatile. The porosity

was filled up by impregnation with Lauric acid from a concen-

trated solution in ethanol. The Lauric acid was deposited by dip-

coating at 2 mms

-1

the sample into the solution while the filling

of the pores was allowed by impregnation inside the porosity

because of evaporation-induced capillary filling. The extra

Lauric acid deposited on the surface was eliminated using a soft

tissue. In this conditions, ellipsometry analysis revealed that the

whole porosity was filled with the pollutant while no pollutant

layer remains on the surface. The polluted sample was then pla-

ced in air at 5 cm under a UV-lamp (365 nm/24W), and optical

density was recorded every minute using the previous ellipso-

metry conditions over a period of 3 days. The UV/vis absorption

spectra were recorded by using a UVIKON XL SECOMAM

(UVK-Lab) spectrometer directly on the one side coated glass

samples. The background was recorded in air only.

Fourier TransformInfrared (FTIR) analysis has been perfor-

med using a Bruker Vertex70 V spectrophotometer. The optical

bench and the sample compartment have been kept in vacuum

during the measurement at a pressure lower than 0.5 hPa. The

measurements in the middle infrared region have been done

using a Globar source, a KBr beamsplitter, and a RT-DLaTGS

detector averaging 256 scans with 4 cm

-1

of resolution. The mea-

sures in the far-infrared (FIR) region have been performed using

a Globar source, a Si beamsplitter, anda RT-DTGS-FIRdetector.

The spectra have been recorded in transmission, in the 600-

100 cm

-1

range by averaging 32 scans with 4 cm

-1

of resolution.

A silicon wafer has been used as substrate to measure the back-

ground; the baseline has been calculated by a rubberband algo-

rithm (2 iterations, 64 baseline points) (OPUS 7.5 software).

3. Results and Discussion

Figure 2 displays the SEM cross-section image of a typi-

cal AR2PA (see Experimental Section for detailed prepa-

ration) bilayer system where both AR and PA layers can

be independently identified. Indeed, the AR underneath

layer has a thickness of several tens of nanometers (difficult

to precisely assess as a result of the tilting angle) and is com-

posed of randomly ordered pores of around a few nano-

meters indiameter. The topTiO

2

layer has athickness around

10 nm and presents the characteristic nanoperforations

of 20 nm in diameter organized into an hexagonal-type

compact structure. An ellipsometry investigation of the

AR2PAbilayer systemconfirms that both layers could be

independently fitted between 400 and 1000 nm using a non-

absorbing Cauchy layer model. Thickness and refractive

index at 700 nm were found to be respectively 82 nm and

1.22 for the ARlayer and 16 nmand 1.75 for the PAlayer,

confirming the presence of porosity in both layers. Optical

properties of the AR layer were similar before and after

the deposition of the PA layer, suggesting that no Ti-oxo-

cluster entered the AR layer porosity upon the second

Figure 2. SEM image of the AR2PA bilayer system composed of the

thick AR underneath layer covered by the nanoperforated ultrathin PA

layer (scale bar = 100 nm).

(14) Babonneau, D.; Camelio, S.; Lantiat, D.; Simonot, L.; Michel, A.

Phys. Rev.B 2009, 80, 155446.

Article Chem. Mater., Vol. 22, No. 15, 2010 4409

dip-coating process. This impermeability could be attri-

buted to the hydrophobic porosity and to the lowconnec-

tivity with the environment (further confirmed by ellipso-

metry) and also to the fact that PB-b-PEO/Ti-oxo-cluster

hybrid micelles are too large to diffuse inside the porosity.

Indeed, PB-b-PEO in EtOH/H

2

O media forms micelles

with the PB in the core and PEO at the shell. Polar PEO

units are hydrophilic and have the ability to form strong

coordination bonds with Ti (IV) metallic center through

interaction between the free electron pairs of Oatoms and

the vacant d-orbitals of Ti atoms (Lewis acid/base pair).

The Ti-oxo-clusters are then expected to remain in the

PEO environment together with water. Recent studies

15

show that hybrid Ti-oxo-clusters micelles from a similar

PB-b-PEO have an hydrodynamic diameter around 50 nm

which are much larger than the pores of the ARlayer. They,

and their associated coordinated titanium intermediates,

do not penetrate the ARlayer and remainat the surface to

form the nanoperforated PA coating upon thermal treat-

ment. The topography of the bilayer system surface has

been also confirmed by TEM, SEM, and AFM investiga-

tions as shown in Figures 3.

The TEM image (Figure 3a) shows the TiO

2

hexagonal

network, which is darker because of its higher density.

The SiO

2

-based layer can be seen through the perforations

in light gray color. No high resolution or EDX analysis

could be performed because of the diffusion of the elec-

tronic beamthrough the AR layer. The SEM-FEG image

of the surface (Figure 3b) confirms the structure observed

by TEM. The smaller holes, that are visible through the

perforations, belong to the underneath AR layer. The per-

forated topography of the surface is confirmed by AFM

topography (Figure 3c). An additional analysis of the

AR2PAbilayer systemstructure is obtained by GI-SAXS

and GI-WAXS. Figure 4 displays the GI-SAXS 2D

pattern and the GI-WAXS diagram obtained after radial

integration of the exposed image plate. In the GI-SAXS

pattern, thenanoperforationorganizationinto2Dhexagonal-

like structure leads to the presence of the two character-

istics diffraction rods at a d-spacing of 28 nm (together

with their faint harmonic as seen onthe intensity profile in

the y direction (inset Figure 4a)) which corresponds to the

(10) planes. The rods are created by the confinement of

the diffraction waves into the PA thin layer, and the fact

that they are elongated in the vertical direction (normal to

the surface) suggests the presence of a single layer of

nanoperforation motifs distributed with a similar trend

on the whole irradiated surface of the sample. The porous

texture of the bottom AR layer should provide a faint

diffusion ring at greater q-value (marked by white dashed

line on the pattern). Such a low intense signal is, however,

not observed even on the single AR layer as a result of

the poor degree of pore ordering. The WAXS diagram in

Figure 4b presents a wide and low intense diffraction

signal centered at 2=24.8, confirming the crystallinity

of the TiO

2

membrane. Deducing the particle size by app-

lying the Scherrer formula to this diffraction is not appro-

priate because of the grazing incidence geometry by which

the whole width of the sample is irradiated and partici-

pates in the construction of the diffraction. A diffraction

band, corresponding to the more intense (101) peak of the

TiO

2

anatase, is created instead of a real exploitable peak

(see Figure 4 inset). One must point out here that irradi-

ated films that are dimensionally longer lead to a wider

diffraction band. Here a 7 mm wide sample film and a

distance of 60 mm from the detector was used. It seems

that the signal is composed of two overlapping but slightly

shifted peaks. The diffraction band contains two reinfor-

cements below and above 2 =24.8 that correspond to

the same anatase phase but are likely due to the higher

quantity of material present at the edge of the sample

because of typical edge dewetting effects intrinsically

associated to the liquid deposition techniques. The low

intensity is due to the very lowquantity of TiO

2

present on

the surface. Crystallization of the PA layer into anatase

has been confirmed by the far-infrared absorption spec-

tra in the 510-200 cm

-1

range (see Figure 5). The spec-

trum is formed by two intense and well-defined absorp-

tion bands, peaking around 436 and 267 cm

-1

. These

vibrational modes are due to transverse optical (TO) E

u

phonons in tetragonal anatase with two TiO

2

units per

primitive cell.

16,17

Figure 3. (a) TEM, (b) SEM, and (c) AFM images of the AR2PA bilayer system showing the presence of the 20 nm in diameter nanoperforations at the

surface.

(15) Kuemmel, M.; Sm

att, J.; Boissiere, C.; Nicole, L.; Sanchez, C.;

Linden, M.; Grosso, D. J. Mater. Chem. 2009, 19, 3638.

(16) Gonzalez, R. J.; Zallen, R.; Berger, H. Phys. Rev. B 1997, 55, 7014.

(17) Pecharroman, C.; Grac

ia, F.; Holdago, J. P.; Ocana, M.; Gonzalez-

Elipe, A. R.; Bassas, J.; Santiso, J.; Figueras, A. J. Appl. Phys. 2003,

93, 4634.

4410 Chem. Mater., Vol. 22, No. 15, 2010 Faustini et al.

As expected and already observed with the present

nanoperforated TiO

2

top layer in a previous study,

18

the

deposition of a drop of water on top of the bilayer surface

leads to the complete wetting with a contact angle inferior

to 10, confirming the antifogging property of the layer.

Such a property is due to the high surface energy of TiO

2

.

EEPis a recent and very efficient technique to assess the

porosity of an optical coating by probing the adsorption/

desorption and capillary condensation of selected vapors

inside the film. First, the experiment was performed on

the AR layer using water vapor. The sample was exposed

to increasing and decreasing relative vapor pressure (0<

P/P

0

< 1), and the evolution of refractive index was re-

corded every P/P

0

=0.02. The refractive index was found

to vary from 1.23 to 1.25 when exposed from 0 to 100%

relative humidity (data not shown), suggesting that less

than 5% of the porosity can be filled up with condensed

water while the rest of the porosity remains empty even at

saturated humidity. As already mentioned previously,

this behavior is likely due to the presence of residual

methyl groups making the surface of the pores hydro-

phobic. The same film was then aged for 9 months in

deionized water, and the same water repellent behavior

was observed. The AR layer refractive index and thick-

ness were not modified by the latter treatment, suggesting

that the methyl-containing silica framework does not

dissolve even after a long period into water. In a second

EEP experiment, non-polar toluene vapor was used as

adsorbate. In this case, the adsorption/desorption iso-

therm shows a toluene capillary condensation into the

pores suggesting that the porosity is open to the atmos-

phere. Figure 6a shows a progressive increase of the refrac-

tive index of the AR layer with increasing toluene vapor

pressure. Capillary condensation for a given P/P

0

value

can be related to a specific pore dimension and morpho-

logy.

19

In this case, the pore size distribution in Figure 6b)

has been obtained from the Kelvin equation using the

model describing interconnected pores (cylindrical model)

and using the physical and chemical characteristics of

toluene.

19

It confirms that a population of pores having

diameters below 10 nm are present in the structure. Such

a finding is in agreement with the microscopic analysis

where pores of various dimensions but below10 nminsize

could be depicted. The desorption branch shows a sudden

decrease of the refractive index below 50% that corres-

ponds to the desorption of the toluene. This is character-

istic of the bottle neck effect, where smaller intercon-

necting windows assures accessibility to the pores. An

important point to underline here is that only non-polar

liquids, such as toluene, can condense inside the pores in

the studied conditions, which proves that the interface of

the pores must be hydrophobic. This hydrophobicity must

be associated with uncompleted thermal decomposition

of the methyl groups on the surface of the pores, which

will be confirmed later by FTIR investigation. For com-

parison, the same filmbut free of methyl groups, prepared

with 100% TEOS as precursor, shows high hydrophili-

city.

19

Mechanical properties of the hybrid AR film were

investigated by analyzing the evolution of film thickness

in the range of toluene relative pressure for which capil-

lary condensation has occurred (P/P

0

>0.6). Using the

Kelvin-Laplace equation given in ref 19 to fit the capillary

stress relaxation of the film, we deduced the transverse

Figure 4. (a) GI-SAXS pattern and (b) GI-WAXS diagram obtained for a typical AR2PA bilayer system.

Figure 5. Far infrared absorption spectrum of a titania monolayer obta-

ined on a AR2PA system.

(18) Jarn, M.; Brieler, F.; Kuemmel, M.; Grosso, D.; Linden, M. Chem.

Mater. 2008, 20, 1476.

(19) Boissiere, C.; Grosso, D.; Lepoutre, S.; Nicole, L.; Brunet-Bruneau,

A.; Sanchez, C. Langmuir 2005, 21, 12362.

Article Chem. Mater., Vol. 22, No. 15, 2010 4411

Young Modulus (E) to be around 1.5((0.3) GPa. As the

maximum film contraction observed upon capillary con-

densation is about 3%of the filminitial thickness, we can

conclude that the mesoporous hybrid AR layer is behav-

ing mechanically very much like mesoporous purely inor-

ganic ceramics.

19

Thus, organic functions introduced into

the silica network are mainly located at the interface of

the silica walls and do not weaken the silica framework

beyond an acceptable point for the AR coating applica-

tion. In addition, the bilayer system was resistant to

cleaning with a soft tissue soaked either by water, ethanol,

or acetone. The complete removal of the bilayer coating

was achieved only after 5 cycles of aging 5 min in a con-

centrated KOH solution followed by rubbing with a dry

tissue, confirming its relatively good mechanical stability.

Figure 7 shows the infrared absorption spectrum in the

4000-900 cm

-1

range of a MTEOS-TEOS hybrid film

that has been treated at 450 C for 10 min and immedi-

ately increased to 500 C for 5 min. The spectrum shows

an intense absorption band peaking at 1050 cm

-1

that is

assigned to Si-O-Si antisymmetric stretching, which

indicates the formation of the silica network. On the other

hand this network appears well condensed because no

signals due to silanols at 910 cm

-1

(Si-OH stretching),

and 3300 cm

-1

(O-H stretching) can be observed. Two

small bands at 3657 and 3765 cm

-1

are assigned to the pre-

sence of tween (geminal) and isolated silanols, respectively,

which are the residual of the condensation of silanol chains.

This is in accordance with previous findings and is a good

indication of the state of the surface upon condensation.

On the other hand, the spectrum gives also some impor-

tant information: no signals due to absorbed water are

present, neither at 1640 cm

-1

nor at 3200 cm

-1

(O-Hstret-

ching), and a strong sharp signal at 1280 cm

-1

indicates

the presence of CH

3

groups in the film. The FTIR data

indicates therefore that the film structure is formed by a

well condensed silica network which is modified via the

covalent Si-C bonds with methyl groups mainly located

at the surface of the pores.

20-22

The fact that methyl

groups were not fully decomposed at such high tempe-

rature is not yet fully understood but is likely due to the

confinement and fast thermal treatment. The presence of

these hydrophobic species avoids the absorption of water

or other hydrophilic moieties from the external environ-

ment within the film.

Figure 7. FTIR absorption spectra of a MTES-TEOS hybrid film after

thermal treatment.

Figure 6. (a) Evolution of refractive index of the ARlayer (AR2 sample) upon exposure to increasing and decreasing toluene vapor pressure. (b) Pore size

distribution deduced from the adsorption curve.

Figure 8. Evolution of refractive index with UVirradiation time for both

single AR (AR2 sample) layer and AR-PA bilayer (AR2PA sample)

systems contaminated with Lauric acid.

(20) Innocenzi, P. J. Non-Cryst. Solids 2003, 316, 309.

(21) Malfatti, L.; Kidchob, T.; Falcaro, P.; Costacurta, S.; Piccinini,

M.; Cestelli Guidi, M.; Marcelli, C.; Corrias, A.; Casula, M.;

Amenitsch, H.; Innocenzi, P. Microporous Mesoporous Mater.

2007, 103, 113.

(22) Falcaro, P.; Grosso, D.; Amenistch, H.; Innocenzi, P. J. Phys.

Chem. B 2004, 108, 10942.

4412 Chem. Mater., Vol. 22, No. 15, 2010 Faustini et al.

Photocatalytic efficiency of both single AR layer and

AR2PA bilayer systems was investigated by ellipsometry

in situ during UV irradiation. The hydrophobicity of the

pore permits to fill them up with Lauric acid pollutants.

The contaminated system was then placed below a UV-

lamp, and the variation of refractive index was recorded

every minute by ellipsometry over a period of 3 days (see

Figure 8). The initial thickness and refractive index of the

AR layer before impregnation were 130 nm and 1.23, res-

pectively. After impregnation with Lauric acid, the thick-

ness does not change while the refractive index increases

up to 1.43, suggesting that a fair proportion of the poro-

sity volume was contaminated. While the AR2PA bilayer

system regained its initial porous state after 2 days of

irradiation, the TiO

2

free system has eliminated only less

than 50% of its contamination by natural non-catalyzed

UV decomposition for the same period, confirming the

photocatalytic role of the TiO

2

PA top layer. Even if

the TiO

2

is locatedoutside of the ARlayer, it provokes the

photodecomposition of the Lauric acid molecules located

inside the AR layer by ellipsometry, suggesting that con-

taminant species do not have to be in direct contact with

TiO

2

to be eliminated. In this conditions, the decreasing

of the refractive index is related to the decomposition of

the Lauric acid presumably associated to the formation of

OH

3

and O

2

3

radicals. The latter are produced as a result

of the electronic transfer operating between the TiO

2

semi-

conductor surface and the adsorbed water upon irradia-

tion. The products of the reaction between the radicals

and the Lauric acid become more and more volatile and

eventually evaporate fromthe film. For the bilayer geometry,

one may state that Lauric acid diffuses toward the TiO

2

rich zone (surface), where irradiation is optimal and where

the concentration of free radical is high. However, one

cannot neglect the possibility that even if highly unstable,

free radicals may have a sufficient lifetime to migrate inside

the AR layer to decompose the pollutants.

Antireflective properties of both single AR layer and

both AR-PA bilayer systems were assessed by UV-visible

spectroscopy for different AR layer thickness. The per-

centages of transmitted light (transmittance) of AR, AR-

PA, and substrate systems are plotted in Figure 9 in the

visible wavelength range. In the inset table in Figure 9,

one observes that the refractive index of the AR layer of

the single and bilayer systems are close to 1.23 whatever

the thickness. The PA layer has a refractive index and

thickness close to 1.8 and 15 nm, respectively. As expec-

ted, the single ARcoatings with a refractive index close to

1.23 provide the characteristic increase in transmission of

around 4.5%, with a maximum transmission, correspon-

ding to the first harmonic of the interference, shifting to

higher wavelengths for higher thicknesses.

For the bilayer systems, the transmitted intensity is

considerably decreased at lower wavelengths as a result of

the anatase TiO

2

absorption below 350 nm. On the other

hand, one notices that the antireflective properties are

maintained in the visible range, reaching 3.5% gain at

maximal transmission, even if they are slightly lower than

that of the single AR layer systems. One can also observe

that the maxima are shifted to higher wavelength because

of the increase in optical path resulting from the presence

of the TiO

2

layer. The latter results confirm that the bilayer

Figure 9. UV-visible analysis intransmissionat 90 incident angle of the single layer (plainlines) andbilayer (dottedlines) systems depositedonone side of

the glass microscope slide substrate. Thickness and refractive index (measured by ellipsometry) of each system are reported in the joint table.

Article Chem. Mater., Vol. 22, No. 15, 2010 4413

systems has efficient AR properties, resulting from the

thinness and reduced refractive index of the PA top layer,

and that the wavelength of maximumtransmission can be

adjusted by the thickness of the AR layer.

4. Conclusions

We have confirmedthat antireflectivity, water-repellence,

high wetting behavior (antifogging), photocatalytic acti-

vity (improved self-cleaning ability), and relatively high

mechanical properties can be integrated into the same

sol-gel coating made of a methyl modified SiO

2

and TiO

2

bilayer. The localization of the hard semiconductive TiO

2

ultrathin layer at the surface of the ARhydrophobic silica

layer, provides (i) the surface high energy necessary for

high wetting, (ii) the direct exposure to radiation and

pollutants, and (iii) an improved resistance to abrasion.

Chemical precursors used to produce such materials are

relatively low cost while the dip-coating liquid deposition

process is highly suitable to large-scale production. The

systemshowed no alteration of the structure and the opti-

cal properties after 9 months immersion in water, making

these coatings serious candidates for use as antireflective,

self-cleaning top coating for photovoltaic cells.

Acknowledgment. D. Jalabert (Centre de Microscopie

Electronique dOrleans) is thanked for TEM analyses and

Dr. Vasana Maneeratana for the language corrections. The

authors also acknowledge funding provided by The TER-

AMAGSTOR program, the CNRS and the UPMC.

You might also like

- 500 Important Spoken Tamil Situations Into Spoken English Sentences SampleDocument7 pages500 Important Spoken Tamil Situations Into Spoken English Sentences SamplerameshdurairajNo ratings yet

- Maya Keyboard ShortcutsDocument0 pagesMaya Keyboard ShortcutsDaryl Gomez TimatimNo ratings yet

- Mitchell Heisman - Suicide NoteDocument1,905 pagesMitchell Heisman - Suicide Notejarmenl83% (24)

- Tennis BiomechanicsDocument14 pagesTennis BiomechanicsΒασίλης Παπατσάς100% (1)

- State of The Art Penelitian - Chat GPT 2023Document137 pagesState of The Art Penelitian - Chat GPT 2023restyNo ratings yet

- LIST Real Estate Contacts ListDocument4 pagesLIST Real Estate Contacts ListChauhan Harshit100% (1)

- ADDC Construction QuestionairesDocument19 pagesADDC Construction QuestionairesUsman Arif100% (1)

- Tutorials Origin Pro 9Document920 pagesTutorials Origin Pro 9h7q290587100% (1)

- Bill No. 1 - General Items PreliminariesDocument24 pagesBill No. 1 - General Items PreliminariesNorazreen NorAzharNo ratings yet

- Paper On SoilingDocument7 pagesPaper On SoilingSuchanond KaewjindaNo ratings yet

- Solar Energy Materials & Solar CellsDocument6 pagesSolar Energy Materials & Solar CellsSutha SenthilNo ratings yet

- TFC Polyamide Membranes Modified by Grafting of Hydrophilic Polymers - An FT-IR AFM TEM StudyDocument10 pagesTFC Polyamide Membranes Modified by Grafting of Hydrophilic Polymers - An FT-IR AFM TEM StudyAlisya AlyaNo ratings yet

- 1 s2.0 S2213343723000775 MainDocument14 pages1 s2.0 S2213343723000775 MainKashif ManzoorNo ratings yet

- Researchers Develop Antifouling Nanofiltration MembraneDocument2 pagesResearchers Develop Antifouling Nanofiltration MembraneLuis LicetNo ratings yet

- Sun 2020Document11 pagesSun 2020mepcNo ratings yet

- Composite Assignment-II EditrdDocument5 pagesComposite Assignment-II Editrdsai andeNo ratings yet

- Han 2017Document32 pagesHan 2017AbeeraShujatNo ratings yet

- Field Test of A Self Sintering Anti Soiling Thin Film Coating For Solar PVDocument8 pagesField Test of A Self Sintering Anti Soiling Thin Film Coating For Solar PVEbenezer ButarbutarNo ratings yet

- Transparent Metasurfaces Counteracting Fogging by Harnessing SunlightDocument42 pagesTransparent Metasurfaces Counteracting Fogging by Harnessing SunlightMilan PetrikNo ratings yet

- Stability of Polymeric Membranes To UV Exposure Before andDocument23 pagesStability of Polymeric Membranes To UV Exposure Before andDani Puji UtomoNo ratings yet

- Liquid Phase Production of Graphene by Exfoliation of Graphite in Surfactant/Water SolutionsDocument10 pagesLiquid Phase Production of Graphene by Exfoliation of Graphite in Surfactant/Water SolutionsOlga Viviana Cardenas LunaNo ratings yet

- Surface Coating: Toxicology Considerations in NanomedicineDocument3 pagesSurface Coating: Toxicology Considerations in NanomedicineMuhammad farhanNo ratings yet

- Alias, Harun, Latif - 2018 - Characterization and Performance of Porous Photocatalytic Ceramic Membranes Coated With TiO2 Via DifferentDocument19 pagesAlias, Harun, Latif - 2018 - Characterization and Performance of Porous Photocatalytic Ceramic Membranes Coated With TiO2 Via DifferentBFCNo ratings yet

- International Journal of Chemtech Research: Neetu SinghDocument5 pagesInternational Journal of Chemtech Research: Neetu Singhthai avvai100% (1)

- Guddal Glass Ceramic Wave Guides Fabrication and Properties IEEE 2010Document4 pagesGuddal Glass Ceramic Wave Guides Fabrication and Properties IEEE 2010Sriram GuddalaNo ratings yet

- Teng 2021Document11 pagesTeng 2021tire farrokhzadNo ratings yet

- Fouling-Resistant Coatings For Reverse Osmosis Membranes: Gas and Liquid Permeation Studies On Morphology and Mass Transport EffectsDocument9 pagesFouling-Resistant Coatings For Reverse Osmosis Membranes: Gas and Liquid Permeation Studies On Morphology and Mass Transport Effectssyed_ahmed_71No ratings yet

- Nature Energy 2, Article Number 17009 (2017)Document7 pagesNature Energy 2, Article Number 17009 (2017)elderwanNo ratings yet

- Desalination: Zhi Chien NG, Woei Jye Lau, Ahmad Fauzi IsmailDocument11 pagesDesalination: Zhi Chien NG, Woei Jye Lau, Ahmad Fauzi IsmailSK SahooNo ratings yet

- Coatings 12 00502Document15 pagesCoatings 12 00502phum 1996No ratings yet

- Optical and Morphological Characterization of Photocatalytic TiO2 Sol-Gel Thin FilmsDocument13 pagesOptical and Morphological Characterization of Photocatalytic TiO2 Sol-Gel Thin FilmsjvalverdegarciaNo ratings yet

- Thin Solid FilmsDocument8 pagesThin Solid FilmsLarissa Nunes da CostaNo ratings yet

- Zhao2019 Article GrapheneOxideQuantumDotsEmbeddDocument11 pagesZhao2019 Article GrapheneOxideQuantumDotsEmbeddbazediNo ratings yet

- Bacterial Inactivation by TiO2-Coated MembranesDocument10 pagesBacterial Inactivation by TiO2-Coated MembraneshusseinhshNo ratings yet

- Advances in Polymeric Nanofiltration Membrane - A ReviewDocument56 pagesAdvances in Polymeric Nanofiltration Membrane - A ReviewPolanqNo ratings yet

- GJESM Volume 8 Issue 4 Pages 485-502Document18 pagesGJESM Volume 8 Issue 4 Pages 485-502GJESMNo ratings yet

- Progress in Organic Coatings: SciencedirectDocument11 pagesProgress in Organic Coatings: SciencedirectOmar MorteoNo ratings yet

- The Nature of The Glass Fibre Surface and Its Effect in The Water Absorption of Glass Fibre Epoxy Composites. The Use of Fluorescence To Obtain Information at The Interface (L)Document11 pagesThe Nature of The Glass Fibre Surface and Its Effect in The Water Absorption of Glass Fibre Epoxy Composites. The Use of Fluorescence To Obtain Information at The Interface (L)Navid HoseiniNo ratings yet

- Wettability Behavior of XLPE Nanocomposite With Surface Modified NanofillerDocument7 pagesWettability Behavior of XLPE Nanocomposite With Surface Modified NanofillerAnuar AtanNo ratings yet

- Lascaud 2017Document8 pagesLascaud 2017Luisa CenchaNo ratings yet

- Chantarat 2013Document5 pagesChantarat 2013IpungNo ratings yet

- Mcquade2018 cracksACSOmega PDFDocument6 pagesMcquade2018 cracksACSOmega PDFTapati DuttaNo ratings yet

- Sciadv Abm4149Document12 pagesSciadv Abm4149vikrant.20chz0003No ratings yet

- 20 Surface Modification of Plastics: Kenth S. JohanssonDocument45 pages20 Surface Modification of Plastics: Kenth S. JohanssonLuis Alberto Escalante PradoNo ratings yet

- Influence of Water On Damage, Mech Behavior of Single Hemp Yarn CompositesDocument9 pagesInfluence of Water On Damage, Mech Behavior of Single Hemp Yarn Compositessanchana velalaganNo ratings yet

- Improved Permeation, Separation and Antifouling Performance of Customized Polyacrylonitrile Ultrafiltration MembranesDocument13 pagesImproved Permeation, Separation and Antifouling Performance of Customized Polyacrylonitrile Ultrafiltration MembranesBeril NavinNo ratings yet

- Advances in Nanocomposite Membranes: EditorialDocument3 pagesAdvances in Nanocomposite Membranes: EditorialTamara WahidNo ratings yet

- Membranes 13 00654Document27 pagesMembranes 13 00654Dr.Ghada MohammedNo ratings yet

- Anti-Biofouling Coating by Wrinkled, Dual-Roughness Structures of Diamond-Like Carbon (DLC)Document8 pagesAnti-Biofouling Coating by Wrinkled, Dual-Roughness Structures of Diamond-Like Carbon (DLC)sithvincentNo ratings yet

- Sol-Gel Solar CellDocument5 pagesSol-Gel Solar CellJosé Carlos GBNo ratings yet

- Water-Tree Degradation in Power Cable Insulation - Understanding and PreventionDocument4 pagesWater-Tree Degradation in Power Cable Insulation - Understanding and PreventionNoé Rafael Colorado SósolNo ratings yet

- 0.76% Absolute Efficiency Increase For Screen-Printed Multicrystalline Silicon Solar Cells With Nanostructures by Reactive Ion EtchingDocument7 pages0.76% Absolute Efficiency Increase For Screen-Printed Multicrystalline Silicon Solar Cells With Nanostructures by Reactive Ion EtchingMohsen GoodarziNo ratings yet

- Materials Today: Proceedings: Deepanjana Adak, Raghunath Bhattacharyya, Hiranmay Saha, Pradipta Sankar MaitiDocument5 pagesMaterials Today: Proceedings: Deepanjana Adak, Raghunath Bhattacharyya, Hiranmay Saha, Pradipta Sankar MaitiAAKIB QURESHINo ratings yet

- Wang 2016 - Journal of Membrane ScienceDocument10 pagesWang 2016 - Journal of Membrane ScienceGipsy Abril Peña RamirezNo ratings yet

- Nanorecubrimiento Compuesto Hidrofóbico Con Propiedades Autolimpiantes para La Protección Del MarmolDocument11 pagesNanorecubrimiento Compuesto Hidrofóbico Con Propiedades Autolimpiantes para La Protección Del MarmolDaily GallegosNo ratings yet

- Giuri2016-Glucose MAPIDocument10 pagesGiuri2016-Glucose MAPIelderwanNo ratings yet

- Texture Analysis of Hydrophobic Polycarbonate and Polydimethylsiloxane Surfaces Via Persistent HomologyDocument15 pagesTexture Analysis of Hydrophobic Polycarbonate and Polydimethylsiloxane Surfaces Via Persistent HomologyJoeNo ratings yet

- Chemical Engineering Science: X article explores electrophoretic coating to improve oxygen fluxDocument8 pagesChemical Engineering Science: X article explores electrophoretic coating to improve oxygen fluxAnita BudiNo ratings yet

- Characterization of Structure and Corrosion Resistivity of P 2010 Progress IDocument9 pagesCharacterization of Structure and Corrosion Resistivity of P 2010 Progress INurhanifa AidyNo ratings yet

- Cellulose Nanofibers ThesisDocument5 pagesCellulose Nanofibers ThesisVicki Cristol100% (2)

- Masturi JPCS 2018Document6 pagesMasturi JPCS 2018masturiNo ratings yet

- Literature ReviewDocument5 pagesLiterature ReviewImtiaz KhanNo ratings yet

- References For Introduction Writing - 2022 - JMSDocument12 pagesReferences For Introduction Writing - 2022 - JMSBest HopeNo ratings yet

- Self Cleaning Membrane For Water TreatmentDocument14 pagesSelf Cleaning Membrane For Water TreatmentmadhuNo ratings yet

- Bacterial Inactivation and Organic Degradation Using TiO2-Coated MembranesDocument10 pagesBacterial Inactivation and Organic Degradation Using TiO2-Coated MembranesVũ Hải NamNo ratings yet

- High Oxygen Barrier Polyethylene Films: ArticleDocument13 pagesHigh Oxygen Barrier Polyethylene Films: ArticleAngga PrasetyoNo ratings yet

- Pathways For The Degradation of Organic Photovoltaic p3ht PCBM Based DevicesDocument7 pagesPathways For The Degradation of Organic Photovoltaic p3ht PCBM Based DevicesNevena CelicNo ratings yet

- Zeolite Adsorbers For Molecular Contamination Control in SpacecraftDocument14 pagesZeolite Adsorbers For Molecular Contamination Control in SpacecraftEdoardo AlbertiNo ratings yet

- Clay-Containing Polymer Nanocomposites: From Fundamentals to Real ApplicationsFrom EverandClay-Containing Polymer Nanocomposites: From Fundamentals to Real ApplicationsNo ratings yet

- NSF GuidelinesDocument62 pagesNSF GuidelinescskhNo ratings yet

- Indice de DesgasteDocument2 pagesIndice de DesgasteEsau AguillónNo ratings yet

- HEAT REFLECTING PAINTS REVIEWEDDocument13 pagesHEAT REFLECTING PAINTS REVIEWEDEsau AguillónNo ratings yet

- Materiales Aislantes e ImpermeabilizantesDocument8 pagesMateriales Aislantes e ImpermeabilizantesEsau AguillónNo ratings yet

- Testing Coatings For Abrasion and WearDocument3 pagesTesting Coatings For Abrasion and WearEsau AguillónNo ratings yet

- Modals Ilovepdf Compressed PDFDocument22 pagesModals Ilovepdf Compressed PDFAlfonso Chan MayNo ratings yet

- Page 33, Woodruff Keys - RevisedDocument1 pagePage 33, Woodruff Keys - RevisedEsau AguillónNo ratings yet

- Xray DiffractionDocument7 pagesXray DiffractionEsau AguillónNo ratings yet

- Ridge regression biased estimates nonorthogonal problemsDocument14 pagesRidge regression biased estimates nonorthogonal problemsGHULAM MURTAZANo ratings yet

- True/False/Not Given Exercise 5: It Rains On The SunDocument2 pagesTrue/False/Not Given Exercise 5: It Rains On The Sunyuvrajsinh jadejaNo ratings yet

- White Paper Without Track ChangesDocument7 pagesWhite Paper Without Track Changesapi-609064761No ratings yet

- ARES SC4 Service Manual (HP-300UA)Document20 pagesARES SC4 Service Manual (HP-300UA)mike_net8903No ratings yet

- 10risk Assessment and ComahDocument25 pages10risk Assessment and ComahHansraj RahulNo ratings yet

- Applying Value Engineering to Improve Quality and Reduce Costs of Ready-Mixed ConcreteDocument15 pagesApplying Value Engineering to Improve Quality and Reduce Costs of Ready-Mixed ConcreteayyishNo ratings yet

- My Medications ListDocument5 pagesMy Medications Listhussain077No ratings yet

- The Relevance of Vivekananda S Thought IDocument16 pagesThe Relevance of Vivekananda S Thought IJaiyansh VatsNo ratings yet

- Design of PID controllersDocument4 pagesDesign of PID controllersFseha GetahunNo ratings yet

- Pembangkit ListrikDocument2 pagesPembangkit ListrikDede MulyamanNo ratings yet

- Buddhism Beyond ReligionDocument7 pagesBuddhism Beyond ReligionCarlos A SanchesNo ratings yet

- Medium Strength High Conductivity MaterialsDocument37 pagesMedium Strength High Conductivity MaterialsNut AssanaiNo ratings yet

- Treasure Island Summary c#1-7Document4 pagesTreasure Island Summary c#1-7Great Wall Of FactsNo ratings yet

- 2 Profile OMORIS - Presentation 2020-2Document20 pages2 Profile OMORIS - Presentation 2020-2lemuel bacsaNo ratings yet

- Time and Work Assignments PDFDocument8 pagesTime and Work Assignments PDFpavan0% (1)

- Lectura Isaac NewtonDocument2 pagesLectura Isaac NewtonCESAR MAURICIO RODRIGUEZNo ratings yet

- Civil ServiceDocument46 pagesCivil ServiceLester Josh SalvidarNo ratings yet

- Dahua Pfa130 e Korisnicko Uputstvo EngleskiDocument5 pagesDahua Pfa130 e Korisnicko Uputstvo EngleskiSaša CucakNo ratings yet

- Pemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganDocument6 pagesPemanfaatan Limbah Spanduk Plastik (Flexy Banner) Menjadi Produk Dekorasi RuanganErvan Maulana IlyasNo ratings yet

- Cricothyroidotomy and Needle CricothyrotomyDocument10 pagesCricothyroidotomy and Needle CricothyrotomykityamuwesiNo ratings yet

- Synopsis - AVR Based Realtime Online Scada With Smart Electrical Grid Automation Using Ethernet 2016Document19 pagesSynopsis - AVR Based Realtime Online Scada With Smart Electrical Grid Automation Using Ethernet 2016AmAnDeepSinghNo ratings yet

- Specifications Sheet ReddyDocument4 pagesSpecifications Sheet ReddyHenry CruzNo ratings yet

- Elements of Plane and Spherical Trigonometry With Numerous Practical Problems - Horatio N. RobinsonDocument228 pagesElements of Plane and Spherical Trigonometry With Numerous Practical Problems - Horatio N. RobinsonjorgeNo ratings yet