Professional Documents

Culture Documents

4.VFD Spec. Rev.1

Uploaded by

wado11100%(1)100% found this document useful (1 vote)

446 views35 pagesVariable Speed Drive Specification

Original Title

4.VFD SPEC. REV.1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVariable Speed Drive Specification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

446 views35 pages4.VFD Spec. Rev.1

Uploaded by

wado11Variable Speed Drive Specification

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 35

16-QMP-05-3B

02 12.04.12 CLIENT COMMENTS INCORPORATED

AND REISSUED FOR USE

AKJ BPN TBY

01 29.03.12 CLIENT COMMENTS INCORPORATED

AND REISSUED FOR USE

AKJ ARUS TBY

00 21.02.12 ISSUED FOR USE AKJ ARUS TBY

Rev. Date Description Prpd. Chkd. Appd.

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR

HV VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 1 of 30

CHAPTER 4

TECHNICAL SPECIFICATION

FOR

HV VARIABLE FREQUENCY DRIVE

SYSTEM

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 2 of 35

1. Scope

The equipment listed below shall be supplied in accordance with the requirements specified in this

document, equipment data sheet, specification applicable codes and standards and other documents

attached/ referred herein.

Sl.

No.

Quantity STATION Description

1. 2 SET KHOPOLI

6.6kV, 3phase, minimum 18 pulse variable speed drive (VSD)

system suitable for 2 Nos. New Pump Motor of 2750kW

(Estimated rating) and 1 No. Existing 750kW (Refer Attach Motor

Data Sheet for Detail) including Dry type VSD transformer.

VSD Set/System shall be complete with the following as per

attached system configuration:

1. One No. Synchronous Panel.

2. One No. Common Drive Logic Panel.

3. One Set. of Down Stream Breakers Panel Board

(Consists of 9 Nos. of Breakers).

4. Interconnecting Power & Control Cables required for the

above VSD System.

5. 3 Nos. of Local Control panels.

6. Addition/ Modification of Existing 6.6kV Switchboard.

7. Any required change in control scheme.

Note:

Both VFDs shall have option for cross-selection of motor

according to the pump which is under operation as per attached

system configuration.

Same VFD shall be suitable for both rating of motor i.e. 2750kW &

750kW.

2

1 SET

For each

rating

-

Special Tools and Tackles required for the erection, testing,

commissioning, operation and maintenance of Complete System

at Khopoli.

3

1 SET

For each

rating

-

Recommended Commissioning Spare Parts for Complete System

at each location Khopoli.

4

1 SET

For each

rating

-

Mandatory Spares as per vendor recommendation for Complete

System at each location Khopoli.

5

1 SET

For each

rating

-

Recommended 2 year operation & maintenance Spare

(Vendor to submit unit rate separately for the same)

Notes:

1. Vendor to visit site (At Khopoli) before submitting offer and analyze required 6.6kV switchgear

modification/addition as per attached system configuration and indicate the same in their offer. All

the required modifications/additions due to addition of VFD system in the 6.6kV switchboard are in

the scope of vendor. Vendor to check and indicate interface requirement with UCP Panel and

Station PLC. All interface requirements and any changes in control scheme are in the scope of

vendor.

2. Vendors scope of work includes design, engineering, manufacturing, shop testing, inspection of

bought out items and supply of all electrical equipments.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 3 of 35

3. Pumps shall be fed from VSD system which includes input converter transformer. Protection and

Metering for VSD system shall be as per attached specifications for VSD system and referred codes

and standards.

4. VSD panel shall be located in the sub-station. Vendor to indicate requirement of Air-conditioned

room for the same (If any). However, equipment shall be suitable for operation even during failure of

Air-Condition.

5. With reference to limits of harmonics as per IEEE 519, the harmonics are to be controlled at 6.6kV

bus. The overall power factor of the drives at 100% load shall not be less than 0.99

6. Any other accessory, fixing hardware, switches etc. which shall be required for satisfactory operation

and completeness shall be provided by vendor.

7. Type test certificates and utility consumption list shall be submitted with the offer.

8. Inspection and Testing at works shall be as per VSD specification.

9. Final Documentation:

A. Vendor to furnish Hard Copy and electronic files of all the documents indicated for final

documentation in addition of hard copy.

B. Vendor to furnish all drawings and documents either in MS Word, MS Excel, Autocad, Microstation

stored in electronic media.

C. Final documentation shall be provided along with hard copies in compact disc compatible with

standard PC based application.

D. All operating and maintaining instructions in electronic media or in scanned images converted in

electronic media.

Final documentation shall be provided in CD with proper index along with hard copies.

ORDER OF PRECENDENCE:

1. Statutory Rules and Regulations

2. This Requisition

3. Equipment Data Sheet

4. Standard specification

5. Codes and Standards

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 4 of 35

1.0 SCOPE

These specification covers design, manufacturing, testing at works, packing and

supply of High Voltage (6.6KV), AC Variable Frequency Drive system along with

bypass isolators. The VFD system shall be compatible with Squirrel Cage

Induction Motor as specified in specification no. 9579-02-TS-101 and complete

with converter, converter input transformer (if required), DC link reactor with

associated auxiliaries, harmonic filters (if required), isolators, field mounted local

control panel etc. as detailed below.

2.0 GENERAL

The Vendor shall be responsible for engineering and functioning of the complete

system, meeting the requirement of this specification and data sheets. This shall

include but not be limited to inverter sizing, input transformer sizing, transformer

impedance selection, vector group, input and output harmonic filter(if required)

design and sizing, output dv/dt filter sizing, isolator rating, motor cable selection/

sizing and motor sizing / selection.

3.0 SITE CONDITIONS

3.1 The VFD and all other associated equipments shall be suitable for operating

satisfactorily in humid and highly corrosive atmosphere prevailing in refineries

and other petroleum installations.

Ambient temperature: 5 to 50

0

C.

Humidity: 95%

Altitude: less than 1000m above MSL.

3.2 The AC drive (with or without in built converter transformer) & isolators shall be

installed indoors in a non-hazardous room, as specified in data sheet. Motor shall

be installed outdoors in hazardous area as specified in datasheet. The vendor

shall furnish the required clearances in VFD room including layout, earthing

requirement and the required capacity of AC, if any, for efficient and reliable

operation of the VFD.

3.3 VFD system shall be designed for continuous duty as per nameplate rating under

the specified ambient conditions.

4.0 APPLICABLE CODES AND STANDARDS

4.1 The equipment shall comply with the requirements of latest revision of following

standards issued by BIS (Bureau of Indian Standards), unless otherwise specified.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 5 of 35

The offered equipment shall comply with latest editions of following standards.

The vendor shall clearly bring out in the offer the applicable standard for every

feature of the offered component, if different from the following standards.

IS-3700 : Essential ratings and characteristic of semi-conductor devices

IS-3715 : Letter symbols for semi-conducting devices

IS-4411 : Code of designation of semi-conducting devices

IS-5001 : Guide for preparation of drawings for semi-conductor devices

IS-5469 : Code of practice for the use of semi-conductor junction devices

IS-6297 : Transformers and indicators for electronic equipment

IS-8789 : Performance parameters for motors

IS-12729 : Switchgear and control gear for voltages exceeding 1000V- General

requirements

IS-13408 : Code of practice for the selection, installation and maintenance of

electrical apparatus for use in potentially explosive atmospheres

IEC 146 : Semi Conductor converters

IEC 297 : Dimension of panels and racks

IEC 326 :General requirements and measuring methods for printed wiring

boards

IEC 352 : Solder less wrapped connection

IEEE 444 : Protection standards for converters

IEEE 519 : Harmonic control & reactive compensation of static power

converters

DIN 41488 : Electrical engineering dimensions

In case Indian standards are not available for any particular equipment,

standards issued by IEC/BS/VDE/ IEEE/NEMA/UL/FM/CE or equivalent agency

shall be applicable.

5.0 GENERAL REQUIREMENTS

5.1 The offered equipment shall be brand new with state of art technology and proven

field track record. No prototype equipment shall be offered.

5.2 The VFD model offered shall be from the existing VFD model series in the regular

manufacturing range of the manufacturer. Along with the offer the Vendor should

submit the supply record and satisfactory performance record for 8000 Hr

running of the VFD supplied in India or abroad in a hydrocarbon industry

(Preferably in a petroleum oil pipeline).

5.3 Vendor shall ensure availability of spare parts and maintenance support services

for the offered equipment for at least for 15 years from the date of supply. The

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 6 of 35

offered VFD manufacturer should have their maintenance service & spares supply

network in India to provide quick maintenance service & Spares supply support.

The vendor shall indicate the source for supply of spares & Maintenance service

location in India.

5.4 Vendor shall ensure proper coordination with the driven equipment supplier in

selection / sizing of offered variable frequency drive system.

6.0 TECHNICAL REQUIREMENT

6.1 Performance Requirement

6.1.1 The system shall be fully digital, Microprocessor based, energy efficient, and shall

provide very high reliability, high power factor, low harmonic distortion and low

vibration and wear and noise. It shall be easy to install in minimum time and

expense and no special tools shall be required for routine maintenance.

6.1.2 The system shall be designed to deliver the motor input current and torque for the

complete speed torque characteristics of the driven equipment, with maximum

input supply voltage variation of +10% and frequency variation of +3%. The

system shall be suitable for the load characteristics and the operational duty of

the driven equipment.

6.1.3 It shall be capable of withstanding the thermal and dynamic stresses and the

transient mechanical torque, resulting from short circuit. Any damage resulting

from such a short circuit or internal fault shall be limited to the component

concerned.

6.1.4 The drive system shall be designed to operate in one or more of the following

operating modes as to suit characteristics of the driven equipment or specified in

the data sheet:

a. Variable torque changing as a function of speed i.e. speed squared

b. Constant torque over a specific speed range.

c. Constant power over a specific speed range where the torque decreases when

speed increases.

d. Any other as specified in data-sheet

6.1.5 The drive controller shall be equipped with microprocessor based digital regulator

with programmable functions. The power control regulator logic shall provide for

an acceleration / deceleration current limit curve and shall be capable of field

adjustments without shutting the system down. Linear acceleration and

deceleration shall be separately programmable from 0.1 second to 20 second.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 7 of 35

6.1.6 The system shall be suitable for single quadrant operation and the speed variation

shall be within range 10-110% with speed set accuracy of +1% of rated maximum

speed and steady state regulation of +0.5% of rated speed.

The total harmonic distortion (THD) of the voltage and current at inverter output

shall be as per IEC 61800-4 and it shall be considered in the design of the motor.

6.1.7 Harmonics at the supply side of the drive system i.e. at primary of the main input

transformer shall be restricted within the maximum allowable levels of current

and voltage distortion as per recommendations in the latest edition of IEEE-519.

Harmonic studies shall be conducted with maximum and minimum system fault

level, cable capacitance, system equipment reactance etc. The studies shall

highlight but not be limited to maximum load current, expected resonant

frequencies, need of harmonic filters, sequence of switching of filters, voltage wave

form etc.

6.1.8 Unless otherwise specified, the overload capacity of the controller shall be 150% of

rated current of motor for one minute for constant torque applications, and 115 %

of rated current for one minute for variable torque applications at rated voltage. If

the motor load exceeds the limit, the drive shall automatically reduce the

frequency and voltage to the motor to guard against overload. If load demand

exceeds the current limit for more than 1 minute, the drive shall shut down to

prevent over heating of the motor and damage to the drive.

6.1.9 During operation, the system shall be capable of developing sufficient torque

under all load conditions to respond to a 20% alteration in speed set point within

a time limit up to 60 seconds.

6.1.10 The integrator action of the speed set point alteration shall be independently

adjustable for both an upward and a downward alteration. The minimum time

interval between set point adjustments by the distributed control system shall be

considered as 10 seconds.

6.1.11 The drive shall trip in case the speed exceeds 110% of the maximum operational

speed or reduces to 95% of the minimum operational speed for more than 10

seconds.

6.1.12 Maximum noise level from the drive at 1-meter distance, under rated load with all

normal cooling fans operating shall not exceed 85 dBA.

6.1.13 Variable frequency drive shall be arranged so that it can be operated in an open

circuit mode, disconnected from the motor for startup adjustments and

troubleshooting / maintenance.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 8 of 35

6.1.14 VFD should have by-pass system for running of motor on DOL in case of any

problem in VFD. By-pass system should be provided with 3 vacuum contactors of

6.6 KV voltage level & suitable current rating corresponding to Motor & VFD

rating. All the three contactors shall have Mechanical & Electrical interlocks. Also,

Contactors should have Electrical interlock with VFD. Vendor is to furnish the

detailed scheme, catalogue & datasheet of contactor, interlock details etc. with

VFD for owner approval.

6.1.15 Voltage at Motor Neutral shall be maintained at ground potential for the total

operating condition.

6.1.16 Motor space heater supply for approximate rating of 240 V, 400 Watts is to be

provided in VFD Panel interlocked with VFD Run command i.e. when Motor is

running, motor space heater shall be OFF and when Motor is stopped, motor

space heater shall be ON. In case of bypass mode operation of Motor, a contact

shall be taken from Bypass Mechanism so that logic for Space heater is ensured

i.e. heater is ON when Motor is stopped and vice-versa.

6.2 Control Requirement

6.2.1 The system shall operate on constant v/f supply with required boost capability in

low frequency mode of operation.

6.2.2 Short time voltage dips up to 20% of nominal voltage (e.g. in case of a large motor

start up connected to the same bus as VFD) shall not cause the control system to

stop functioning and shall not trip the drive system.

6.2.3 The system shall also be equipped with a facility which will restart the system in

case of voltage dip over 20% of power interruptions for min. 2 seconds, with

recovery of the voltage to its nominal value, with a facility to block the automatic

restart if required by the operator. Upon restart the converter shall be capable of

synchronizing onto a rotating motor and develop full acceleration torque within 10

seconds.

6.2.4 The system shall be suitable for number of starts as per the specifications of the

Motor in chapter-3.

6.2.5 The power controller shall be controlled to always start the motor in the forward

direction. Logic shall be provided to prevent the motor from being started in the

reverse direction.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 9 of 35

6.2.6 The drive motor shall be speed controlled corresponding to 4-20 mA or 0-10V

reference input signal, the drive shall automatically run at constant speed as at

80-110% of the last speed reference available prior to the loss of signal.

6.2.7 It shall be possible to vary the speed of the drive in either Local or Remote mode.

Local / Remote selection shall be from VFD panel unless otherwise specified.

a. With the selector switch in Local mode, the operator shall be able to set the

speed through keypad, mounted on front of the drive panel.

b. With the selector switch in Remote mode, speed of the motor shall be

controlled from a 4-20 mA signal, from owners PLC/SCADA system. The

relationship between the speed, torque and the reference signal (4-20mA)

within the operational speed shall be linear. Necessary equipment required for

interfacing with PLC/SCADA shall also be provided in the drive panel.

6.2.8 The required provision for the interface with remote PLC/SCADA located at control

room shall be through hardwiring of interface signals (DI/DO/AI/AO) with

potential free contacts and transducers. Also, provision for MODBUS

communication (RS 485) from VFD to Owners control panel shall be made

available. Vendor shall provide protocol details, mapping and addresses to be

taken by Owners panel.

6.3 Panel Construction

6.3.1 The drive shall be suitably housed in sheet steel panels fabricated with 2 mm

thick cold rolled sheet steel. The panel shall be suitable for indoor installation. The

panel shall be free standing, dust and vermin proof with degree of enclosure

protection as IP-4X. The maximum and minimum operating height shall be 1800

mm and 300 mm respectively.

6.3.2 The cable entry shall be from the bottom of the panel and bolted un-drilled gland

plate shall be provided. Clamp type terminals shall be used for connection of all

wire up to 10 mm

2

and terminal for higher sizes shall be bolted type suitable for

cable lugs. Minimum space for power cable termination shall be 600 mm clear

from bottom of the cable gland plate.

6.3.3 Bus bars shall be of electrolytic copper/aluminium, colour coded separately for AC

and DC system. All the live parts shall be sleeved / shrouded to ensure complete

safety to personnel intending to carry out routine inspection by opening the panel

doors. All the equipment inside the panel and on the doors shall be provided with

suitable nameplate.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 10 of 35

6.3.4 The panel shall include suitable semi conducting power devices (Diodes /

IGBT/IGCT/SGCT)

modules with protective devices, reactors (if required), filters (if

required), control circuit, control accessories, indication and annunciation etc. The

construction of the panel shall provide effective protection against electromagnetic

emissions and shall be the design requirement of integrated standards.

6.3.5 Upstream breaker ON/OFF/TRIP indications and remote breaker closing and trip

push button shall be provided on the front door.

6.3.6 Safety interlock shall be provided so that power cabinet cant be opened unless the

upstream breaker is disconnected, safety-grounding switch is closed and DC link

capacitor is discharged.

6.3.7 All the switches, component and accessories, which are essential for normal and

emergency operation, shall be mounted on the door and shall be operable

externally. All the analogue instruments, where provided, shall be switchboard

type, back connected, 96 mm x 96 mm. Scale shall have red mark indicating

maximum permissible operating rating.

6.3.8 Panels except power cell chamber shall be provided with illuminating lamp with

switch and fuse. 5/15A, 240V power socket with switch and fuse shall be

provided. Each panel shall have space heater with switch fuse/MCB and variable

setting thermostat.

6.3.9 Copper earth bus of minimum size 30 x 6 mm upto short circuit withstand

capacity of 31.5 KA and 50 x 6 mm for a short circuit withstand capacity above

31.5 KA shall be provided in the panel with provision for connection to Owners

plant earth grid. All the non-metallic components / parts shall be connected to the

main earth bus bar. Separate earth bus bar and stud for electronic control system

shall be provided.

6.3.10 All the metal parts shall be treated so as to ensure efficient anti-corrosive

protection. Hardwares shall be zinc passivated or electro-galvanized. Panel

enclosure and structure supports shall be thoroughly cleaned and degreased to

remove mill scale and rust etc. External surface shall be prepared for final

painting shade of RAL 7032 (Siemens grey) as per DIN.

6.3.11 All panels shall be of same height so as to form a uniform line-up, to give good

aesthetic appearance.

6.3.12 All the control wiring shall be enclosed in plastic / metal channel. Each wire shall

be identified at both ends by self-sticking wire marker tapes or PVC ferrules.

Power and control wiring inside the panel shall be done with BIS approved, PVC

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 11 of 35

insulated, fire retardant, copper conductor wire 1.5 mm

2

size wire shall normally

be used provided the control fuse rating is 10 Amps or less and 2.5 mm

2

size for

control fuse rating 16 A & above for electrical circuits and 0.5 mm

2

for electronic

circuits. All wires shall be ferruled and terminals shall be properly numbered,

minimum 20% spare terminal shall be provided.

6.3.13 All electronic modules and components shall be accessible from front of panel

only. Modular assemblies for both the system control electronic equipment and

power electronic equipments shall be used.

6.3.14 All low voltage compartment and cabling shall be electrically and physically

separated from the high voltage compartment.

6.3.15 Suitable removable type hooks shall be provided for lifting the panel.

6.3.16 Suitable transparent insulating material shall be used for covering live

components.

6.3.17 Drive keypad, operator control panel required for control, monitoring and

measurements shall be supplied and installed outside the panel on the front door.

It shall be accessible for operation without opening the front door and shall be

non-removable type.

6.3.18 All equipment shall be complete with cable glands, lugs etc. and cable glands shall

be double compression type.

6.3.19 DC link capacitor and pre-charging and discharging circuit shall preferably be

mounted in the rear of the panel.

6.4 Cooling

6.4.1 The drive panel shall be naturally air cooled as per manufacturers standards. If

unavoidable, forced type-cooling system shall be provided. Vendor shall ensure

that the panel dimensions and flow paths have been designed for continuous

running at the specified ambient without over hearting & suggest the cooling

system to be provided in VFD room considering heat generation in VFD & 50 deg

Cent ambient temp.

6.4.2 For fan cooled drives, redundant cooling fans (N+1) shall be provided. In case

the redundant fan is not possible to be mounted, same shall be supplied

loose.

6.4.3 Necessary starter shall be provided with in the VFD panels for the Ventilation fans

and any other auxiliary motors etc. The system provided shall be interfaced with

drive starting and shut down such that safety interlocks such as Start Permissive

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 12 of 35

from cooling system to drive and trip signal from cooling system to drive in case of

cooling system failure etc. shall be incorporated in the overall sequence logic.

6.5 Equipment / Component Specification

6.5.1 Motor

The motor shall be designed, constructed and tested in accordance with the

owners specification / data sheet (refer specification no. 9579-02-TS-101) for high

voltage induction motor, in addition to the following requirements:

a. The motor shall be suitable for operation with a solid state power supply

consisting of an adjustable frequency inverter for speed control and DOL.

b. The motor shall be suitable for the current waveforms produced by the power

supply including the harmonics generated by the drive.

c. The motor shall be designed to operate continuously at any speed over the

range (10-110%) of rated speed unless otherwise specified in data sheet.

d. The permitted voltage variation should take into account the steady state

voltage drop across the AC drive and all other system components upstream

of the motor.

e. The motor shall be constructed to withstand torque pulsations resulting from

harmonics generated by the solid-state power supply.

f. The motor insulation shall be designed to accept the applied voltage

waveform, within the Vpeak and dv/dt limits as per IEC-61800-4.

g. The drive manufacturer shall be solely responsible for proper selection of the

motor for the given load application and the output characteristics of the

drive.

For detailed motor specification and data sheet refer specification no. 9579-02-TS-

101.

6.5.2 Converter Transformer

a) The converter transformer, if provided, shall be copper wound dry type.

Insulation class of dry type transformer shall be H with temperature rise of

body limited to 75C. Dry type transformer shall preferably be mounted inside

the drive system panel. The impedances of converter input transformers with

more than one secondary winding for minimum 18 pulse systems shall be

selected to ensure equal load / current sharing between the secondary

windings, the converters and the motor windings under all operational

conditions including starting and restarting.

b) The transformation ratio, impedances, taps and secondary voltage shall be

chosen by the drive vendor to optimize system performance.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 13 of 35

c) The transformer shall be designed, manufactured and tested in accordance

with latest applicable Indian standards or equivalent international standards.

d) Transformer for operation with converters shall be suitable for operation with

non-sinusoidal wave shape and DC components under normal and abnormal

conditions of the system without exceeding the temperature.

6.5.3 Power Converter

a. The static power converter shall consist of a line side converter for operation as

a rectifier and a load side power converter for operation as a fully controller

inverter. Power converter shall be fast switching, most efficient and low loss

type.

b. The converter shall be co-ordinated with the transformers. The converter shall

be able to withstand a three phase short circuit current until interrupted by

normal breaker operation.

c. Adequate short circuit and over voltage protection shall be provided for the

converter and inverter system.

d. All power converter devices shall include protective devices, snubber networks

and dv/dt networks as required.

e. The current rating of the converters semi-conductor components shall not be

less than 120% of the nominal current flowing through the elements at full

load of the VFD through the whole speed range. If the parallel connection of

semi conductor is applied, the above current rating shall not be less than

140% of the above values.

f. All power diodes shall be of silicon type with minimum VBO rating at 2.5 times

the rated operating voltage.

g. The power converter circuit shall be designed so that motor can be powered at

its full nameplate rating continuously without exceeding its rated temperature

rise nor reducing its service factor due to harmonic currents generated by the

inverter operation.

h. The conversion devices and associated heat sinks shall be assembled such that

individual devices can be replaced without requiring the use of any special

precautions / tools.

i. The cooling system of the electronic components, if provided, shall be

monitored and necessary alarms shall be provided to prevent any

consequential damage to the power control devices.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 14 of 35

j. All power controller devices shall be protected with high speed semiconductor

grade fuse. I

2

t particulars of the power controller devices and the fuses shall be

supplied along with the calculations in support of the selection of fuses.

k. Offered system shall also take in account the distance between drive panel and

motor and system shall include all material and accessories to make system

suitable for a distance of 350 m unless otherwise specified in the data sheet.

6.5.4 Output filter

Vendor shall ensure that converter design is in such a way that both voltage and

current harmonics are within the limits as specified in IEEE-519. Output filter

shall be provided, if required. Output filter capacitors shall be provided with

discharge circuits to ensure that all residual stored charge is reduced to less than

50 V DC within 30 seconds after a loss of AC voltage. All capacitor shall be

maintenance free and self-healing type.

The VFD system shall inherently protect motor from high voltage dv/dt stress,

independent of cable length to motor. Output filter shall be an integral part of the

VFD system and included within the VFD enclosure.

6.5.5 DC Link Reactor (For CSI drive)

Smoothing reactors for the DC link shall be designed to sufficiently decouple the

rectifier and inverter portion of the converter and to limit fault currents in this

circuit.

Unless otherwise specified, the reactor shall be air-cooled or fan cooled typed

located within the panel.

Reactor shall be suitable for operation with the non-sinusoidal current wave

shapes and DC components under all operational conditions of the system without

exceeding its temperature limits.

6.6 PROTECTION, CONTROL METERING AND INDICATION / ANNUNCIATION

REQUIREMENTS

6.6.1 The manufacturer shall provide all the necessary system control, protection, alarm

equipment and metering for the entire drive system and its auxiliary equipment

and its description shall be furnished along with the offer including the details of

the system built-up.

6.6.2 Automatic sequence control shall include start-up of cooling system, auxiliary

system of the motor, interlock checking, automatic start and run-up of drive,

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 15 of 35

planned and emergency shutdown. The same shall be processed through

microprocessor based system.

6.6.3 All protection, metering, indication, alarm, annunciation and fault diagnostic as

required, shall be available at PLC over communication network (RS-485).

Necessary communication module shall be provided in VFD accordingly.

6.6.4 Operator Control Panel.

a. Each drive shall be equipped with a front mounted operator control panel

consisting of a backlit alphanumeric display and a keypad with keys for

parameterization and adjusting parameter which shall not be limited to start /

stop, local / remote, auto / manual, increase / decrease, menu navigation and

protection and measurement parameter selection etc. Display shall consist of

minimum 2 lines of 16 characters- LCD type.

b. All parameters names, fault messages, warnings and other information shall

be displayed in complete English words or Standard English abbreviations to

allow the user to understand what is being displayed without the use of a

manual or cross-reference table. This shall also be used for the modification of

all electrical values, configuration parameters, drive menu parameters,

application and activity function access, faults, local control, adjustment

storage, self test and diagnostics. Keypad shall be operable with password for

changing the protection setting, safety interlock etc. However the parameters

such as measurements, setting, mode of drive etc. shall be allowed to be

viewed without any password.

c. Operator console shall have facility / port to connect external hardware such

as Lap-Top etc. Console shall have facility for upload and download of all

parameter settings from one drive to another identical drive for start up and

operation.

d. Drive system control shall also have facility to receive tripping signal from

upstream breaker for tripping and also provision for closing upstream breaker

after all required process parameters are achieved.

e. User-friendly software for operation and fault diagnostic shall be loaded in the

drive system panel before commissioning.

6.6.5 Protective features

The system offered shall incorporate adequate protective features, properly

coordinated for the drive control and for motor but not limited to the following:

i) Converter transformer: short circuit, over current, earth fault & winding

temperature high

ii) Incoming and outgoing line surge protection with suitably designed surge

diverter.

iii) Under / over voltage protection

iv) Phase loss, phase reversal protection

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 16 of 35

v) Programmable over current protection and under load protection

vi) Inverter fault.

vii) Over frequency/speed operation.

viii) Ventilation loss.

ix) Over temperature of equipment

x) Specific motor protection, including motor winding, bearing temperatures,

over current, overload, negative phase sequence, locked rotor and earth

fault protections etc.

xi) System earth fault protection.

xii) Speed reference loss

6.6.6 Control

The following minimum controls shall be provided as a part of the Operator

Control Panel or through separate switches on the front panel door.

i) Start / stop(in local/remote mode)

ii) Speed control (Raise / lower)

iii) Acknowledge/Accept/ Test Push Button for annunciation

iv) Auto / Manual / Test Mode select

v) Emergency stop

vi) Trip-Remote Breaker

vii) Local Remote

viii) Sequential Switching of filters

6.6.7 Indications

Vendor shall provide indications as required for normal operation and for easy

maintenance, which shall not be limited to the following indications.

i) Motor running

ii) Motor stopped

iii) VFD System Fault

iv) System ready to start

v) Motor zero speed

vi) AC mains ON

vii) Motor over speed

viii) VFD ON

ix) Remote breaker trip

x) Owners speed reference fail

xi) Input Isolator ON

xii) Input Isolator OFF

xiii) Output Isolator ON

xiv) Output Isolator OFF

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 17 of 35

xv) Bypass Isolator ON

xvi) Bypass Isolator OFF

xvii) Motor Space heater ON

xviii) Motor Space heater OFF

xix) Rectifier output ON

xx) Motor Zero Speed

Above indications may be provided as a part of the operator control panel, i.e. door

mounted keypad or through indicating lamps / LEDS in VFD/Isolator Panel.

Potential free contacts of items i-iv shall be wired separately for remote indications

in Owners SCADA systems.

6.6.8 Metering

Digital display of the following parameters shall be as a part of the Operator

Control Panel, selectable by the operator.

i) Input AC voltage

ii) Input AC frequency

iii) Input AC Current

iv) Output voltage

v) Output current VFD

vi) Output frequency

vii) Motor speed

viii) Hour Run

ix) Necessary transducer shall be provided with 4-20mA output for indicating

motor speed and motor current in Owners SCADA system.

x) KW monitoring

xi) KWh monitoring

xii) Power factor

xiii) Drive Thermal State

6.6.9 Audio-visual annunciations

a. Audio-visual window annunciations shall be provided on the front of the panel.

All annunciations as required for normal and satisfactorily operation of the

drive system shall be included as per vendor standards. These annunciations

can be part of operator console panel.

b. Vendor shall include audio-visual alarm as required for normal operation and

maintenance of the system but not be limited to the following.

i) Rectifier fuse failure

ii) Main AC failure

iii) Inverter fuse failure

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 18 of 35

iv) Inverter overload

v) Inverter high temperature

vi) Cooling system failure

vii) Motor failed to start

viii) Transformer failure

ix) Communication and measurement system unhealthy

x) Motor Temperature High

xi) Harmonic Filters Monitoring

Common potential free contacts shall be provided for above annunciations and

these shall be wired up to terminal block for owners use for remote alarm and

monitoring.

Alarm accept / reset push button is to be provided on the front door of the panel.

6.7 Fault Diagnostic

Fault diagnostic shall be built into the system to supervise the operation and

failure of the system. The information regarding failure of any of the system

including shut down of the system shall be available for a period of minimum 7 4

days (96 hours) after a shut down even though no supply would be available to

the system. The system may be totally de-energized for maintenance or otherwise.

It shall be possible to retrieve the record of events prior to tripping of the system

or de-energization. Auxiliary supply to the system components or to the

electronics (firmware) for the diagnostics / display shall be taken care by the

manufacturer for this purpose.

6.8 External Power supply for auxiliary and Control Circuit

Auxiliary power supply for devices external to VFD module, space heater supply

for motor, VFD panel space heater, auxiliary power supply for transformers,

cubicle lamps etc. shall operate on 240 volts single phase AC provided by Owner.

All control circuit shall operate at 110V DC (Provided by owner).

Vendor shall include supply of all control transformers, protective devices,

required accessories etc. and any other control supply voltage as required for the

system shall be derived from the power supply made available by owner.

6.9 Reliability features

The expected lifetime of the drive system shall be 20 years. The system including

all individual components forming part of the system shall have an availability of

minimum 0.997 and a minimum MTBF of 40,000 Hours.

6.10 Maintenance features

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 19 of 35

The controller design shall incorporates the following maintenance features:

- Modular construction.

- All components shall be easily accessible.

- Standard diagnostics to aid maintenance personnel. These shall include LED

or alphanumeric displays, test or measurement points.

6.11 Painting

All metal surfaces shall be thoroughly cleaned and degreased. Fabricated

structure shall be pickled and then rinsed to remove any trace of acid. The under

surface shall be prepared by applying a coat of paint and coat of yellow zinc

chromate primer. After preparation of the under surface, the board shall be spray

painted with two coats of final paint. Colour shade shall be RAL 7032 (Siemens

grey) as per DIN.

The finished panels shall be dried in stoving ovens in dust free atmosphere. Panel

finish shall be free from imperfection like pin holes, orange peels, runoff paints

etc. All unpainted steel parts shall be cadmium plated or suitably treated to

prevent rust formation.

7.0 CDL PANEL AND SYNCHRONOUS PANEL

CDL or Common Drive Logic Panel functions as a common interface between

VFD1, VFD2, Upstream and Downstream Breakers, Unit Control Panel (UCP)-A,B

& C and Synchronous Panel.

Main Functions of the CDR Panel are:

Controls the VFD Start-up & Shutdown Sequence.

Receives Commands & Provides Feedback to UCP and Station PLC

Controls the downstream breaker line-up as per the VFD & Motor combination

selection.

Helps in Breaker Control during Synchronous change-over.

Synchronous panel takes voltage sample from downstream breaker of each VFD,

Upstream breaker of bypass and synchronize the VFD output with mains.

8.0 INSPECTION, TESTING AND ACCEPTANCE

8.1 All tests shall be carried out at the manufacturers works under his care and

expense. The tests shall be witnessed by an inspector of Owner or of an agency

authorized by the owner. Prior notice of minimum 4 weeks shall be given to the

inspector for witnessing the tests.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 20 of 35

8.2 The routine test shall be conducted on all the drive system. However type test

shall be performed on one system of each rating and type. For the purpose of

testing, drive system shall include input transformer, switchgears, converter,

filters etc. as defined in clause 1.0.

8.3 The Routine and Type tests to be performed on the drive system shall be as

follows:

8.3.1 Routine tests

a. Visual Inspection

It involves checking of the various equipments / components fault diagnostic

unit, wiring, terminals, earthing ratings etc. in line with the approved drawings

and visual inspection shall not be limited to the following:

i) Dimensions and door layout vis--vis the approved drawings.

ii) Degree of Protection of Cubicles.

iii) Simulation facility of control signals for testing purposes.

iv) Memory function of fault diagnostic.

v) Interface capability

vi) Voltage / current rating of power semi conductor elements.

vii) Cable termination size and number of terminals, cable supporting etc.

viii) Accessibility of components.

ix) External signals and indication / alarm signals on converter.

x) Earthing of cubicles and cubicle doors.

b. Insulation test

c. Checking of auxiliary devices

d. Checking the protective devices

e. Checking of control and functional requirements

f. Automatic restart / re-acceleration

g. Test capability to restart the system and resynchronize converter onto running

motor after a voltage interruption.

h. Light load and functional test

i. Load Duty test

8.3.2 Type Tests

a. Efficiency

b. Temperature rise

c. Torque pulsation

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 21 of 35

d. EM Immunity

e. EM Emission

f. Line side voltage and current distortion content

g. Power factor

h. Audible noise

i. High voltage test on transformer

j. Speed loop test capability to ride through voltage less than 80%.

k. Total Harmonic Distortion at input side

l. Allowable full load current Vs Speed

m. Dynamic Performance

n. Current limit and Current loop test

Type test certificate from Independent Testing Agency for similar equipment can

be accepted for a, b, c, d & e as mentioned above.

8.3.3 Additional tests on transformers/other auxiliaries shall be carried out as per the

applicable codes/standards.

9.0 CERTIFICATIONS

The Variable Frequency Drive shall have test certification from internationally

recognized test house i.e. CE/UL/FM/IEC/CSA/NEMA or equivalent. The VFD

and associated equipment shall have test certificates issued by recognized

independent test house (CIMFR/BASEEFA/LCIE/UL/FM or equivalent). All

indigenous motors shall conform to Indian Standards and shall be certified by

Indian testing agencies. All motors (indigenous and imported) shall also have valid

statutory approvals as applicable for the specified location.

10.0 PACKING AND DESPATCH

The equipment shall be divided into several shipping sections for protection and

ease of handling during transportation. The equipment shall be properly packed

for transportation by ship / rail or trailer. The equipment shall be wrapped in

polyethylene sheets before being placed in wooden crates / cases to prevent

damage to the finish. Crates / cases shall have skid bottoms for handling. Special

notations such as Fragile, The side up, Weight, Owners particulars, PO Nos.

etc. shall be clearly marked on the package together with other details as per

purchase order.

The equipment may be stored outdoors for long periods before installation. The

packing should also be suitable for outdoor storage areas with heavy rains / high

ambient temperature unless otherwise agreed.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 22 of 35

11.0 Software of PLC of VFD

A copy of PLC software of the VFD along with any hardware / software key is to be

provided on DVD / CD on placement of purchase order as a backup for

maintenance of the VFD.

License software (both run time and works) to be supplied.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 23 of 35

13.0 DRAWINGS AND DOCUMENTATION

Following drawings and documents in English language shall be furnished as per

the schedule mentioned hereunder. It is mandatory for vendor to take approval of

all post PO documents/drawings before proceeding with manufacturing of VFD

and its By-pass system.

S.

N.

Drawing/ Document Time of submission No.

of

sets

1

Technical particulars/ catalogues for the

offered system and the detailed

description

To be submitted

Two

2 Block diagram of the system Along with the technical bid Two

3

Complete technical details of each

equipment / component

Along with the technical bid Two

4 GA layout showing overall dimensions Along with the technical bid Two

5

Single line diagram and control schematic

showing equipment rating

Along with the technical bid Two

6

The detailed scheme, catalogue &

datasheet of isolator, interlock details with

VFD

Along with the technical bid Two

7 List of spares for 2 years of maintenance Along with the technical bid Two

8

Reference list along with PO copies and

performance certificates from end user in

India only to whom such system (VFD of

same make & similar design for same or

higher rating) has been supplied.

Along with the technical bid Two

9

Detail of cooling system to be provided in

VFD room

Along with the technical bid Two

10

Copy of drive system certifications as per

clause no. 8.0

Along with the technical bid Two

11

Details of after sales (Service) network in

India with addresses, contact numbers,

manpower details and level of expertise (in

terms of drive rating etc.) available.

Along with the technical bid Two

12

BOM of cables in case converter

transformer is mounted outside VFD

Panel

Along with the technical bid Two

13

Block diagram of the system

On placement of purchase order

Two

14

Complete technical details of each

equipment / component

On placement of purchase order

Two

15

G.A. layout showing overall dimensions

On placement of purchase order

Two

16

Single line diagram and control schematic

showing equipment rating , interlocks,

control and power cable scheduling etc.

On placement of purchase order

Two

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 24 of 35

17

Protection co-ordination diagram

On placement of purchase order

Six

18

Torque / speed/ current / power factor of

the system

On placement of purchase order

Six

19

Foundation/mounting drawing of VFD,

Transformer, Bypass Isolator etc.

On placement of purchase order

Six

20

Special installation requirements for the

VFD system and cables

On placement of purchase order

Six

21

Operation and Maintenance manuals

On placement of purchase order

Three

22

Terminal details for wiring to external

station control panel including Potential

free contacts, DI, DO, AI & AOs

separately.

On placement of purchase order

Three

23

QAP for all independent equipments for

VFD system.

On placement of purchase order

Three

24

Detailed document on control philosophy

On placement of purchase order

Six

25

Detailed Single Line Diagram Along with the technical bid Two

26

Suggestive Sub-station Equipment Layout Along with the technical bid Two

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 25 of 35

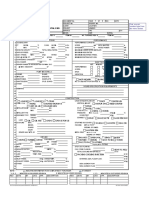

14.0 DATA SHEET FOR HV VARIABLES SPEED DRIVES

DATA FURNISHED BY OWNER

Sl.

no

FEATURES Description

1. BASIC REQUIREMENTS

i. Required rated output capacity : * (As per motor ratings / Pump

Load)

ii. Torque requirement : As per pump requirement

iii. Load/driven equipment details : Horizontal Centrifugal pumps

iv. Load torque details : Centrifugal pumps

v. Drive system : One drive for each pump

vi. Reacceleration of motor : As per Operational requirements of

Pump specifications

2. SITE CONDITIONS

a) Location : As per SOR

b) Design Ambient temperature : 5- 50

0

C

c) Altitude : Less than 1000m above mean sea

level

d) Humidity (max) : 95%(relative)

e) Location : Indoor

f) Installation area for VFD : Indoor

g) Installation area for motor &

LCP

: Hazardous zone-2, gas group-

IIA/IIB, Temperature class-T3,

Tropical, dusty, corrosive.

3 INPUT POWER SUPPLY

SYSTEM CONDITIONS

a) No. of phases : Three

b) AC input voltage : 6.6KV

c) Voltage fluctuation : 10%

d) Rated frequency : 50 Hz

e) Frequency fluctuation : 3%

f) System fault level : 25 KA (1 sec.)

4 SYSTEM REQUIREMENTS

a) Speed range required : As per Pump requirement

b) Speed reference signal : 4-20mA

c)

Operation in case of loss of

reference signal

: Last speed reference/ a set speed

lower than previous reference /

either of above as per manufactures

standard.

d) Acceleration time : As per clause 6.1.5

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 26 of 35

Sl.

no

FEATURES Description

e) Deceleration time : As per clause 6.1.5

f) Communication facility between

Owners control system and

drive

: Required

g) Harmonic study : Required

h) Braking : Flux braking/ DC injection

braking/ either of the above

i) Converter transformer :

Dry type

j) Output voltage of VFD system : 6.6KV, three phase (without using

any output transformer)

k) Type of converter/rectifier : Minimum 18 Pulse

l) Harmonic filters on supply bus : Vendor shall ensure that converter

design is in such a way that both

harmonics V&I harmonics are

within limits as specified in IEEE-

519

m) Power factor improvement

feature as part of harmonic

filters

: Vendor shall ensure that converter

design is in such a way, so that

minimum PF at input of each VFD

is 0.99 lag for the varying load of

10% to 110%

5 CONTROL LOCATION

a) Local/Remote operation : Required

b) Local/Remote selector switch

location

: At VFD panel

c) Speed raise/Lower signal : At VFD panel

d) Distance of VFD panel from

Motor

: 350m (maximum)

6 COMMUNICATION

On communication network

(compatible RS 485 port) the

following details shall be

available

a) Protection features : Yes

b) Indication : Yes

c) Metering : Yes

d) Annunciation : Yes

e) Diagnostic : Yes

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 27 of 35

15.0 TECHNICAL DATA TO BE FURNISHED BY MANUFACTURER

(To be submitted separately for each location)

1. Make : Siemens / ABB / Rockwell / Yaskawa /

Hitachi

2. Model No. : *

3. Rating of drive panel

a) Output in amperes : * (to be provided)

b) Rating expressed at

(torque)

: *

c) Rating declared at

(temp.)

: 50 Deg C

d) Switching frequency at

declared rating

: * Hz

4. Applicable code / standards : CSA,UL,IEC,NEMA,ANSI,IEEE,CE/equivalent

5. Drive type : CSI/VSI

6. Speed range : 10% to 110% of rated motor speed

7. Speed reference signal type : 4-20mA

8. Input power supply ratings : 3 Phase 6.6Kv

9. Voltage : 6600 V + 10%

10. Frequency : 50 Hz + 3%

11. Output voltage at 10%

input voltage full speed, full

load

: 6600 v

12. Overload capability of

converter

a) 115% In( for variable

torque) for

: *

13. Overall efficiency of drive

(excl. motor) at

a) 100% load : *

b) 75% load : *

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 28 of 35

c) 50% load : *

14. Overall power factor of drive

(excl. motor) at

:

a) 100% load : *

b) 75% load : *

c) 50% load : *

15. AC Output :

a) Rated frequency range : *

b) Accuracy of frequency : *

16. Dynamic response :

a) Speed fluctuation band : *

b) Speed recovery time after

100% torque step

: *

17. Waveform distortion factor

(% harmonics) in output /

input waveform.

: *

(Number of harmonics and magnitude of each harmonic generated shall be

furnished)

18. Output short ckt. Capability

and duration

: *

19. Controls At Drive level

(Please answer as provided /

not provided

a) System start : *

b) System stop : *

c) Speed raise : *

d) Speed lower : *

e) Drive frequency setting : *

h) Remote bkr.trip : *

i)Electronic Ramp function : *

j) Speed and current

controller

: *

k) Drive ready to start signal : *

l) Ammeter : On digital operator or separate digital type

m) Speed indicator : On digital operator or separate digital type

20. a)Diodes / IGBT : *

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 29 of 35

/IGCT/SGCT configuration

Number and Ratings

b)Total No. of diodes / IGBT

/IGCT / SGCT

Number and Ratings

: *

21. Cooling system :

i) Type : Fan forced cooling

ii) Redundancy in cooling

units

: *

22. a)Type of feed-back for

speed control

: Open loop Vector

b)Speed control accuracy : *

23. List of controls provided at

the front of panel (As per

specification)

: Yes / No

24. List of status measuring

devices provided at the front

of panel (as per specification

: Yes / No

25. List of status indication and

annunciation provided (as

per specification)

: Yes / No

26. Type of electronic card

mounting arrangement

: *

27. DIMENSION

a) Length : *

b) Height : *

c) Depth : *

d) Weight of cubicle : *

(Dimensional details of all panels shall be furnished).

28. Degree of protection for

enclosure

: * (Minimum IP 4X)

29. Paint shade : As per specification

30. Heat output of Panel : *

31. Whether Air conditioning is

required for these panels

: *

32. Control supply voltage and

Aux. Power requirement

: 415 V, 3 phase, 4 Wire

33. Converter Transformer (If :

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 30 of 35

applicable)

a) Make : *

b) Type of transformer : Dry type

c) KVA Rating : *

d) Voltage ratio : *

e) Vector group : *

f) Taps : *

g) Insulation class : F (Min) for dry type transformer.

f) Impedance : *

g) Efficiency : > 98%

h) Weight : *

i) Winding RTDs /

Thermistors

: Minimum 1 per phase

g) Overall dimension

(L&BXH)

: *

h) Transformer accessories : *

* data to be filled up & furnished with the offer

Note:

1. If synchronous and de-synchronous transfers are required it shall be in "bumpless

close transition" only. Open transition is not acceptable.

2. Motor to be protected from all the electrical faults by VFD when it is in VFD mode and

by "DOL Feeder" when it is in DOL mode.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 31 of 35

16.0 COMPLIANCE / EXCEPTIONS AND DEVIATIONS FOR OFFERED VFD

NAME OF BIDDER:

Bidder to stipulate here exceptions and deviations to Bidding Document, if any,

separately for technical clauses in respect of the specifications.

Sl.

No.

Clause

No.

Accepted

(Tick one)

Deviation proposed by Bidder if No for column no. 3

1 2 3 4

1. 1.0 Yes / No

2. 2.0 Yes / No

3. 3.0 Yes / No

4. 4.0 Yes / No

5. 5.0 Yes / No

6. 6.0 Yes / No

7. 7.0 Yes / No

8. 8.0 Yes / No

9. 9.0 Yes / No

10. 10.0 Yes / No

11. 11.0 Yes / No

12. 12.0 Yes / No

13. 13.0 Yes / No

14. 14.0 Yes / No

Note:

1. If the space is not sufficient, separate sheets to be attached as per this format.

2. Bidder to note that clause no. 16.0 has been included in the Bidding document solely

for the convenience of the Bidder so as to facilitate them to list out the deviations /

exceptions both of technical and commercial nature from / to the bidding document.

Owner will not recognise any deviations / exception (s) in respect of the specifications

which is not listed at clause no. 16.0.

3. Offers without fully filled clause no. 16.0 may be summarily rejected.

(SIGNATURE OF BIDDER)

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 32 of 35

15.0 List of the VFD Manufacturer or their Indian Representative

Sl No VFD Manufacturer

Indian Office / Representative

1(a)

1(b)

Siemens

Pittsberg

USA

Siemens

Nasik, India

Siemens Ltd.

IIADT

Post Box 85

Thane Belapur Road

Thane 400601

Maharashtra

2 Asea Brown Boveri

Turgi

Swizerland

Asea Brown Boveri Limited,

Drive Division

Kosbahalli road,

Nelemangla

Bangalore

Karnataka

3 Rockwell Automation

Cambridge

Canada

Rockwell Automation India Pvt Ltd

A-66, Sector-64

Noida-201301

UP

4 Yaskawa Electric Corporation

YUKUHASHI

Japan

Larsen & Toubro Ltd

Control & automation Business Unit

Automation campus

A-600, TTC Industrial Area

Shil-Mahape Road

Navi Mumbai - 400710

5 HITACHI

NOTE: Make of 6.6kV Downstream Breaker Panel, CDL Panel and Synchronization Panel

shall be Siemens/ABB/Schneider Electric/L&T.

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 33 of 35

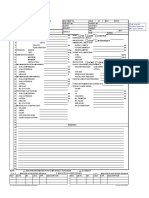

TECHNICAL DATA SHEET

FOR EXISTING

HT MOTOR AT KHOPOLI

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 34 of 35

PARAMETERS DESCRIPTION

Motor Condition Existing

Duty Centrifugal Pump

Output, kW 750

Volts, V 6600

Phases 3

Locked Rooter Torque 90% of F.L. torque

Enclosure TEFV

Frame XD40010

Poles 2

Speed, RPM 2988

Full Load Current, Amp 76.5

Frequency, Hz 50

Temperature Rise 75

O

C by resistance

Starting Current 636% of F.L. Current

Protection IPW55

Cooling Air-Cooled

Mounting Foot

Pull Out Torque 250% of Full Load Torque

Stator Winding Diamond Coils Star Connected

Net Weight, kg. 4875

Bearing (DE/NDE) Roller/Ball & Roller

Direction of Rotation Clock-Wise

Starting DOL

Lubrication Shell Alvania 3

Main Terminal Arrangement

No. of terminals 3 entry from below Peebles

flameproof containing Phase Segregated

type 15A

Connections (Terminals/Phase) U V W/L1 L2 L3

Space Heater Rating 240W, 240V, 1 Phase FLP terminal box

Stator Winding RTDs

Six platinum Resistors, wired to separate

terminal box

BASEEFA Certificate No. EX811075

Insulation Class F

Stator Connection Star

Power Factor 0.89

16-QMP-05-3B

W

o

r

d

Triune Energy Services Pvt. Ltd.

New Delhi

TECHNICAL SPECIFICATION FOR HV

VARIABLE FREQUENCY DRIVE

SYSTEM

Std. / Doc. Number Rev.

9579-02-TS-102 0

Sheet 35 of 35

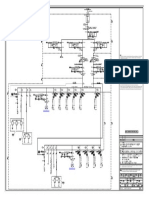

SYSTEM CONFIGURATION:

Proposed

(2750KW)

Proposed

(2750KW)

Existing

(750KW)

You might also like

- Sizing of Cable Tray Rev. D PDFDocument13 pagesSizing of Cable Tray Rev. D PDFAlvin SmithNo ratings yet

- Sizing Calculation: Selection of UPS 3 Phase or 1 PhaseDocument18 pagesSizing Calculation: Selection of UPS 3 Phase or 1 PhasedhruvNo ratings yet

- Control Cable Schedule (A) - Armoured Cable, (F) - Flexible Cable, (S) - Cable With Screen. KWPCL/DRG/CS/018 Rev. 1 Sheet 1 of 3Document3 pagesControl Cable Schedule (A) - Armoured Cable, (F) - Flexible Cable, (S) - Cable With Screen. KWPCL/DRG/CS/018 Rev. 1 Sheet 1 of 3ARIJIT KUNDUNo ratings yet

- Design Criteria ElectricalDocument38 pagesDesign Criteria ElectricalPramod B.Wankhade100% (4)

- Electrical Design Basis - Rev 0Document17 pagesElectrical Design Basis - Rev 0DeepmalaJayeshNo ratings yet

- Chemical Injection SkidDocument1 pageChemical Injection SkidKalyankumar KrishnamoorthyNo ratings yet

- Project Management Book PDFDocument55 pagesProject Management Book PDFSerigne Mbaye Diop94% (16)

- Transportation System, Analysis and Modelling (CE-632) : Carried Out by Group-3Document15 pagesTransportation System, Analysis and Modelling (CE-632) : Carried Out by Group-3Naman Kumar100% (2)

- Imcc - EtsDocument7 pagesImcc - EtssutanuprojectsNo ratings yet

- Bus Duct Sizing CalculationDocument5 pagesBus Duct Sizing CalculationmohammadkassarNo ratings yet

- Instrumentation EarthingDocument13 pagesInstrumentation EarthingTrung TrầnNo ratings yet

- Transformer Sizing for Sewage Treatment PlantDocument4 pagesTransformer Sizing for Sewage Treatment Plantepe civilNo ratings yet

- 2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONDocument5 pages2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONkkumar_717405No ratings yet

- HPCL Black Oil Terminal Electrical SpecificationDocument109 pagesHPCL Black Oil Terminal Electrical SpecificationWhite HeartNo ratings yet

- Duct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor WestDocument12 pagesDuct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor Westwado11No ratings yet

- Duct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor WestDocument12 pagesDuct Pressure Drop Calculator - Bok - HQ - Ventilation - Eaf-1 - Eor Westwado11No ratings yet

- Tech. Specification For Battery ChargerDocument22 pagesTech. Specification For Battery ChargerPramod B.Wankhade100% (1)

- Drive Control Philosophy - C & IDocument11 pagesDrive Control Philosophy - C & Irpaliwal1967No ratings yet

- Ipbd Sizing r1Document6 pagesIpbd Sizing r1Rahul Srivastava100% (1)

- Jacobbs Ele Installations SpecsDocument33 pagesJacobbs Ele Installations Specssureshn829No ratings yet

- DG Sizing Calculation Rev00Document3 pagesDG Sizing Calculation Rev00epe civil100% (1)

- 41-HRSG Electrical Load ListDocument7 pages41-HRSG Electrical Load Listessameldin0% (1)

- 240V Ac Ups Sizing Calculation: Document TitleDocument6 pages240V Ac Ups Sizing Calculation: Document Titlephanendra2No ratings yet

- 12 - Loop Wiring DiagramsDocument161 pages12 - Loop Wiring Diagramsabid aliNo ratings yet

- 33 KV Control Relay Spec PDFDocument75 pages33 KV Control Relay Spec PDFMohanta Amrit100% (2)

- Ocl Ele Main SLD 1-11-2017 Main SLDDocument1 pageOcl Ele Main SLD 1-11-2017 Main SLDSanjay SahulNo ratings yet

- UPS Sizing Calculation - EmersonDocument5 pagesUPS Sizing Calculation - Emersonjugal8252No ratings yet

- 2485-0-El-Dl-001 (Electrical Load Summary List) Rev BDocument58 pages2485-0-El-Dl-001 (Electrical Load Summary List) Rev BRahul SrivastavaNo ratings yet

- E2308 - 305B - Wiring Diagram of PLC Panel - R0Document13 pagesE2308 - 305B - Wiring Diagram of PLC Panel - R0sujitNo ratings yet

- 5-Power & Control Cables PDFDocument11 pages5-Power & Control Cables PDFAnonymous ufMAGXcskMNo ratings yet

- Remote I/O Panel SpecificationDocument43 pagesRemote I/O Panel SpecificationToni100% (3)

- DG Spec Final ApprovalDocument41 pagesDG Spec Final Approvalapi-3854942100% (7)

- Power Plant Control and Instrumentation SpecificationDocument119 pagesPower Plant Control and Instrumentation SpecificationpingoliaNo ratings yet

- Vol-2-9-33kV Switchgear Technical SpecificationDocument10 pagesVol-2-9-33kV Switchgear Technical SpecificationTejaswi ShuklaNo ratings yet

- DP16004 YT10 90ZEN 140115 Elec - Power - Cable Sizing Calculation - Rev P1Document26 pagesDP16004 YT10 90ZEN 140115 Elec - Power - Cable Sizing Calculation - Rev P1rahul.srivastavaNo ratings yet

- Electrical Design SpecificationDocument28 pagesElectrical Design SpecificationMuthiah MuruganNo ratings yet

- C259 N00-X013 01 Electrical Specification For PackagesDocument27 pagesC259 N00-X013 01 Electrical Specification For Packagesvirgil guimanNo ratings yet

- Motor Data Sheet LT MOTORDocument12 pagesMotor Data Sheet LT MOTORHarshit GautamNo ratings yet

- Static Pressure Calculator r3Document3 pagesStatic Pressure Calculator r3arshi_yusufNo ratings yet

- MTO For Electrical Cable TrayDocument3 pagesMTO For Electrical Cable TrayhungleteNo ratings yet

- UPS Battery SizingDocument2 pagesUPS Battery SizingAbhijeet Durge100% (1)

- Solar Panelpanel Design (22.8.12)Document12 pagesSolar Panelpanel Design (22.8.12)Battinapati ShivaNo ratings yet

- Product Oriented Performance Based OrientedDocument43 pagesProduct Oriented Performance Based OrientedAlmira A. Mira-ato100% (1)

- Application Guide of VSD On A PumpDocument36 pagesApplication Guide of VSD On A PumpSyam TawakkalNo ratings yet

- Control Philosophy Rafha-18.11.2004Document14 pagesControl Philosophy Rafha-18.11.2004srigirisetty208No ratings yet

- MD1 0 e 182 06 00001 0Document6 pagesMD1 0 e 182 06 00001 0tvpham123No ratings yet

- VT CalculationDocument36 pagesVT Calculationmohammadkassar100% (1)

- VFD SpecificationDocument16 pagesVFD SpecificationkalpeshnishuNo ratings yet

- Generator Exhaust Pipe Diameter Calculations: Marina Towers L9959Document4 pagesGenerator Exhaust Pipe Diameter Calculations: Marina Towers L9959febousNo ratings yet

- Power Consumption & Heat Dissipation-COB#1-Rev1Document10 pagesPower Consumption & Heat Dissipation-COB#1-Rev1mnm_somuNo ratings yet

- LV Motor Data SheetDocument4 pagesLV Motor Data Sheetwado11No ratings yet

- EORP Power and Motor Control Centre Data SheetDocument22 pagesEORP Power and Motor Control Centre Data Sheetvaithy2011100% (1)

- PCC transformer sizing for largest motorDocument5 pagesPCC transformer sizing for largest motorArunava Basak100% (1)

- AbzenoDocument7 pagesAbzenojykhgpdrc5No ratings yet

- Instrument Cable SizingDocument2 pagesInstrument Cable Sizingsv_verma100% (1)

- Engineering Specification For MV SwitchgearDocument21 pagesEngineering Specification For MV SwitchgearSundaresan SabanayagamNo ratings yet

- Comment - Mouda - R0 - VFD Data SheetDocument34 pagesComment - Mouda - R0 - VFD Data SheetAshok reddyNo ratings yet

- Cable Sizing Calculation. Rev.1Document4 pagesCable Sizing Calculation. Rev.1jack jalaNo ratings yet

- VFDDocument9 pagesVFDVenkatesh RaoNo ratings yet

- Final Design Guide Logic DiagDocument16 pagesFinal Design Guide Logic DiagRajesh Ashtikar100% (3)