Professional Documents

Culture Documents

Construction - Overview of CFS Apps in BLDG Const - 2010 Update

Uploaded by

Авирмэдийн ГэрэлболдOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Construction - Overview of CFS Apps in BLDG Const - 2010 Update

Uploaded by

Авирмэдийн ГэрэлболдCopyright:

Available Formats

Cold-Formed Steel Profile (Updated in 2010)

I N T R O D U C T I O N

Cold-formed steel is widely used in buildings,

automobiles, equipment, home and office

furniture, utility poles, storage racks, grain bins, highway prod-

ucts, drainage facilities, and bridges. Its popularity can be attrib-

uted to ease of mass production and prefabrication, uniform qual-

ity, lightweight designs, economy in transportation and handling,

and quick and simple erection or installation.

In building construction, cold-formed steel products can be classi-

fied into three categories: members, panels, and prefabricated as-

semblies. Typical cold-formed steel members such as studs, track,

purlins, girts and angles are mainly used for carrying loads while

panels and decks constitute useful surfaces such as floors, roofs

and walls, in addition to resisting in-plane and out-of-plane sur-

face loads. Prefabricated cold-formed steel assemblies include roof

trusses, panelized walls or floors, and other prefabricated struc-

tural assemblies. Cold-formed steel possesses a significant market

share because of its advantages over other construction materials

and the industry-wide support provided by various organizations

that promote cold-formed steel research and products, including

codes and standards development that is spearheaded by the

American Iron and Steel Institute (AISI).

Cold-Formed Steel

possesses a signifi-

cant market share....

This article presents the profile of cold-formed steel in building

construction through a historical review of the development of the

AISI Cold-Formed Steel Specification and related standards, dis-

cusses the major cold-formed steel applications in building con-

1

Cold-Formed Steel Profile (Updated in 2010)

struction, and introduces organizations that play important roles

in the cold-formed steel industry.

C O D E S & S T A N D A R D S

D E V E L O P M E N T - A

H I S T O R I C A L R E V I E W

Cold-formed steel applications

can be traced back as early as

the 1850s in both the United

States and Great Britain. In the late 1920s and early 1930s, cold-

formed steel entered the building construction arena with prod-

ucts manufactured by a handful of fabricators. Although these

products were successful in performance, they faced difficulties

with acceptance for two reasons: (1) there was no standard design

methodology available, and (2) cold-formed steel was not in-

cluded in the building codes at that time. Many of the cold-formed

steel applications were unable to be used due to the lack of design

methodology and product recognition.

To face this challenge, AISI convened a technical committee in

1938, known as the Committee on Building Codes, with the mis-

sion of developing a specification for the design of cold-formed

steel structures. Research work was conducted at Cornell Univer-

sity, led by Professor George Winter. In 1946, the first Specification

for the Design of Light Gage Steel Structural Members was published,

and in 1949, the first Design Manual was available for use by de-

sign engineers. After the publication of the second edition in 1956,

the Specification was formally adopted by the building code body,

opening the door towards greater acceptance of cold-formed steel

products. To increase the market share of cold-formed steel, AISI

has been continually providing research funding to broaden the

design coverage, improve the design technology, and cultivate a

cold-formed steel research and design community.

After the publication of the

second edition in 1956, the

Specification was formally

adopted by the building code

body, opening the door to-

wards acceptance of cold-

formed steel products.

With the establishment of the North American Free Trade Agree-

ment (NAFTA) in 1990, it became clear that codes and standards

would be at the frontlines in eliminating the trade barrier and

2

Cold-Formed Steel Profile (Updated in 2010)

promoting the usage in steel in North America. In 1995, AISI initi-

ated the development of a unified cold-formed steel specification

among NAFTA countries. After 10 years of mutual effort, the first

edition of the North American Specification for the Design of Cold-

Formed Steel Structural Members was published in 2001. This

document was immediately adopted by the 2003 International

Building Code (IBC) and was recognized by the American Na-

tional Standards Institute (ANSI) as the National Standard in the

United States, by the Canadian Standards Association (CSA) in

Canada, and by Camara Nacional de la Industria del Hierro y del

Acero (CANACERO) in Mexico. This unified Specification raised

cold-formed steel design technology to the same level among all

NAFTA countries, allowing faster introduction of new technolo-

gies and opening up the marketplace for a wide variety of cold-

formed steel products and derivatives such as steel framing and

steel decks, as well as design aids and educational materials.

North American Specification

and Commentary

In the early 1990s, as the residential construction industry ex-

panded and lumber prices escalated, the steel industry recognized

a new potential market for cold-formed steel applications. A Resi-

dential Advisory Group was formed in 1991 to explore the ave-

nues for penetrating this potential market. In the mid-1990s, the

first edition of the Prescriptive Method for One- and Two-Family

Dwellings was published and adopted into the CABO One- and

Two-Family Dwelling Code. In 1996, the Residential Advisory

Group was reorganized into the North American Steel Framing

Alliance (NASFA). In 1998, NASFA was renamed the Steel Fram-

ing Alliance (SFA) and expanded its focus to cover the light com-

mercial market as well. Also in 1998, in its role as an ANSI-

accredited standards development organization, AISI launched

the Committee on Framing Standards with a mission to eliminate

regulatory barriers and increase the reliability and cost competi-

tiveness of cold-formed steel framing in residential and light

commercial building construction through improved design and

Cold-Formed Steel Framing Standards

3

Cold-Formed Steel Profile (Updated in 2010)

installation standards. As a result, additional ANSI-approved de-

sign standards, such as the Standard on Cold-Formed Steel Fram-

ingGeneral Provisions, Truss Design and Header Design, were

developed and published in 2001. These standards, as well as the

expanded and updated Prescriptive Method, were adopted by the

2003 International Building Code, and have been recognized by

ANSI as American National Standards. In 2004, these standards

were updated, and new ANSI-approved Standards on Cold-Formed

Steel FramingLateral Design and Wall Stud Design were com-

pleted. In 2007, the Limit States Design (LSD) method was incor-

porated into the cold-formed steel framing standards, which en-

abled those standards to be adopted in Canada and Mexico as

North American standards.

A detailed summary of specification and standard development

by AISI is provided in Appendix 1.

ORGA NI Z A T I ONS

R E L A T E D T O

C OL D- F OR ME D S T E E L

To expand the cold-formed steel

market, steel manufacturers and

suppliers have formed several

organizations to develop and improve cold-formed steel products,

provide services to the user group, and promote and expand

manufacturers product lines. These organizations include:

American Iron and Steel Institute (AISI): The American Iron and

Steel Institute's history spans almost 100 years. AISI is recognized

as a leader in the cold-formed steel industry, engaging in a wide

variety of collective and collaborative activities. This role allows

AISI to play a pivotal role in expanding and growing the markets

for steel applications. In addition to advancing the case for steel in

the marketplace as the preferred material of choice, AISI also

serves as the voice of the North American steel industry in the

www.steel.org

4

Cold-Formed Steel Profile (Updated in 2010)

public policy arena and plays a lead role in the development and

application of new steels and steelmaking technology.

Over the last half century, AISI has developed and maintained the

North American Specification for the Design of Cold-Formed Steel

Structural Members, which provides fundamental design method-

ology for all cold-formed steel members in construction. Since

1990, a series of cold-formed steel framing standards have been

developed. These standards have established a solid foundation

for the cold-formed steel framing industry. In addition, AISI has

published and maintained a number of cold-formed steel design

manuals and design guides.

In 2008, AISI announced the establishment of the AISI Steel Mar-

ket Development Institute (SMDI) with the mission to advance

the competitive use of steel through a market-driven strategy that

promotes cost-effective, steel-based solutions. SMDI operates as a

business unit of AISI.

Metal Building Manufacturers Association (MBMA): MBMA was

formed by metal building manufacturers and suppliers in 1956.

MBMA members represent the majority of the total metal building

systems built in the United States.

www.mbma.com

To ensure the good quality of metal building systems, MBMA re-

quires its member companies to be accredited by the International

Accreditation Services (IAS) through the Inspection Programs for

Manufacturers of Metal Building Systems (AC472). In addition,

MBMA periodically updates its Metal Building System Manual and

5

Cold-Formed Steel Profile (Updated in 2010)

Metal Roofing System Design Manual to assist architects and engi-

neers in selecting metal building systems.

With advanced computer design tools, metal building systems

have been expanded from simple building configurations such as

warehouses and factory buildings to applications with varying

architectural appearances found in churches, schools, shopping

centers, and office buildings. Metal buildings and roofing systems

are increasingly being recognized as reliable, aesthetically pleas-

ing, and cost-effective building alternatives.

Metal Building for a

Education Facility

Steel Deck Institute (SDI): Founded in 1939 by the manufacturers of

steel decks and associated products, the Steel Deck Institute has

played an important role in providing uniform industrial stan-

dards for engineering, manufacturing and field installation of

steel decks. Representing Majority of the steel decks produced in

the United States, SDI member companies produce cold-formed

steel decks with various configurations for different types of ap-

plications.

www.sdi.org

Technical information published by SDI includes the SDI Design

Manual for Composite Decks, Form Decks and Roof Decks; Roof Deck

Construction Handbook; Diaphragm Design Manual; and the SDI

Manual of Construction With Steel Deck.

Steel Stud Manufacturers Association (SSMA): The SSMA was

formed in 1999 through a merger of the Metal Lath and Steel

Framing Association Division of the National Association of Ar-

chitectural Metal Manufacturers and the Metal Stud Manufactur-

ers Association. The products produced by SSMA member com-

panies include studs, tracks, and steel framing accessories such as

cold-rolled channels and flat straps. In 2001, SSMA published its

first product catalog using a unified designation for both stud and

track sections, which greatly simplified product identification for

www.ssma.com

6

Cold-Formed Steel Profile (Updated in 2010)

both contractors and design professionals. SSMA also publishes

technical notes and CAD Details on cold-formed steel framing.

Steel Framing Alliance (SFA): The SFA, previously known as the

North American Steel Framing Alliance, was established in 1998

to enable and encourage the practical and widespread use of cold-

formed steel framing in the residential market. Since then, it has

expanded its scope to include commercial and institutional mar-

kets. The SFA is a leading organization for promoting steel studs

and related products by providing builders and engineers with

cost-effective alternatives. On the technical front, SFA has sup-

ported many research and development initiatives, and has pub-

lished a series of issue papers and builder guides/ The SFA has

also published design guides on fire-resistance and acoustic rat-

ings, and on thermal design and code compliance.

www.steelframingalliance.com

Metal Construction Association (MCA): The MCA was formed in

1983 by entities engaged in manufacturing, engineering, selling

and installing metal products. Its mission is to expand the usage

of metal in construction through marketing, innovation, and edu-

cation. MCA organizes the annual industry event called METAL-

CON, which provides a showcase for manufacturers and a learn-

ing opportunity for consumers and design professionals. In addi-

tion, MCA manages a metal roofing certification program to pro-

mote the widespread use of appropriate metal roofing products

that have met the designated quality standards. The organization

also publishes a series of metal wall and roof design and selection

guides.

www.metalconstruction.org

www.mhia.org

Rack Manufacturers Institute (RMI): The RMI was formed in 1958 by

rack manufacturer companies, and is currently affiliated with the

Material Handling Industry of America (MHIA). The member

companies of the RMI produce cold-formed steel industry racks

that are classified as either stationary or portable racks. Different

7

Cold-Formed Steel Profile (Updated in 2010)

from other cold-formed steel members, storage rack members con-

tain slots (openings) for connecting members flexibly. In addition

to considering the North American Cold-Formed Steel Specification,

storage racks are designed to follow the Specifications developed

by RMI, such as the Specification for the Design and Utilization of

Industrial Portable Storage Rack; Specification for the Design,

Testing and Utilization of Industrial Steel Storage; Specification

for the Use of Industrial and Commercial Steel Storage Racks-

Manual of the Safety Practices/A Code of Safety Practices.

Metal Roofing Alliance (MRA): The MRA is a coalition of metal roof-

ing manufacturers, paint suppliers and coaters, dealers, metal in-

dustry associations, and roofing contractors. The mission of the

MRA is to promote metal roofing products by demonstrating to

both consumers and installers the outstanding value and the su-

perior longevity that a metal roof provides. The MRA provides

information, resources, and the Find a Contractor function via its

website to introduce consumers to the benefits of metal roofing.

http://www.metalroofing.com/

Wei-Wen Yu Center for Cold-Formed Steel Structures (CCFSS): Estab-

lished at the University of Missouri-Rolla (UMR) in 1990 under

the leadership of Professor Wei-Wen Yu and the sponsorship of

the American Iron and Steel Institute, the Center provides inte-

grated services related to cold-formed steel research and educa-

tion. CCFSS organizes a biennial International Specialty Confer-

ence on Cold-Formed Steel Structures, which showcases the

worldwide state-of-the-art practices in cold-formed steel research

and technology. Many innovative ideas and design provisions

presented through the International Specialty Conferences have

been adopted by design specifications and standards. CCFSS also

organizes a biennial cold-formed steel design short course and

offers online courses for design professionals, researchers and col-

lege students. The Center also maintains a technical library of

cold-formed steel-related research publications and research

www.ccfssonline.org

8

Cold-Formed Steel Profile (Updated in 2010)

documents from around the world. This information can be ac-

cessed via the Centers website at www.ccfssonline.org. The Cen-

ters technical bulletins provide valuable information to the cold-

formed steel community. Currently, the Center is co-sponsored by

AISI and other industrial organizations.

Cold-Formed Steel Engineers Institute (CFSEI): The membership of

the CFSEI (which was formerly known as the Light-Gauge Steel

Engineers Association) includes design engineers, manufacturers,

builders, and contractors in cold-formed steel construction. The

organization conducts educational seminars and develops a series

of technical notes that supplement cold-formed steel design stan-

dards and provide assistance to design engineers.

www.cfsei.org

Based on their functions, the organizations listed above can be

classified as follows:

a. Organizations emphasizing the promotion and technical de-

velopment of their product lines: AISI, MBMA, SFA, SDI,

SSMA;

b. Organizations emphasizing the promotion of steel products:

MCA, MRA;

c. Organizations emphasizing the technical issues related to

cold-formed steel: CCFSS, CFSEI.

The organizations can also be categorized according to their

products:

a. Building Systems: MBMA, SFA, RMI

b. Structural Members: SSMA

c. Steel Decks: SDI

d. Roof Panels: MCA, MRA

e. Wall Panels: MCA

f. Storage Racks: RMI

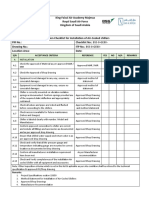

A summary of technical documents and standards published by

each organization is provided in Table 1.

9

Cold-Formed Steel Profile (Updated in 2010)

A D V A N T A G E S O F C O L D -

F O R M E D S T E E L

Cold-formed steel products are

shaped at ambient tempera-

tures from steel sheet, strip plate or flat bars by roll-forming ma-

chines, press brakes or bending brake operations. They can be

produced in large quantity and at high speed with consistent

quality. A typical automated rolling machine can run at a speed

range of 75-400 feet per minute, and the products can be as small

as a three-quarter inch wide cold-rolled channel section to as big

as a thirty-six inch wide roof deck section.

Roll Forming

Cold-formed steel possesses many advantages over other con-

struction materials:

1. Lightweight - Cold-formed steel components weigh ap-

proximately 35% to 50% less than their wood counterparts,

which means that they are easy to handle during construc-

tion and transportation.

2. High-strength and stiffness As a result of the cold-forming

process, cold-formed steel possesses one of the highest

strength-to-weight ratios of any building material. This

high strength and stiffness result in more design options,

wider spans and better material usage.

3. Fast and easy erection and installation Building components

made of cold-formed steel can be fabricated with high ac-

curacy in a plant and then assembled on job sites, which

greatly increases erection efficiency and ensures construc-

tion quality.

4. Dimensionally stable material - Cold-formed steel does not

expand or contract with moisture content. In addition, it

does not split or warp as time goes by. Therefore, it is di-

mensionally stable. Cracked gypsum sheathed walls, nail

head popping and other common problems with wood-

10

Cold-Formed Steel Profile (Updated in 2010)

framed structures can be virtually eliminated in buildings

with cold-formed steel stud walls.

5. No formwork needed The use of cold-formed steel decks

eliminates the formwork for pouring concrete floor. In ad-

dition, composite action between the steel deck and con-

crete increases floor strength and stiffness.

6. Durable material - Cold-formed steel is durable because it is

resistant to termites and rotting. In addition, galvanized

cold-formed steel products provide long-term resistance to

corrosion.

7. Economy in transportation and handling - Lightweight cold-

formed members or panels are easy to handle and trans-

port. In addition, they can be nested and bundled, reduc-

ing the required shipping and storage space.

8. Non-combustible material - Steel is a non-combustible mate-

rial and will not contribute fuel to the spread of a fire. This

results in better fire resistance and lower insurance premi-

ums.

9. Recyclable nature - Steel is North Americas No. 1 recycled

construction material, with a minimum 25% recycled con-

tent. Steel products used in construction are infinitely re-

cyclable, with no degradation in structural properties. It

can be recycled and reused. Steel-framed housing dramati-

cally reduces the amount of trees consumed for residential

construction, thus conserving one of nature's most pre-

cious resources.

10. Energy efficiency A variety of color options for metal roofs

and panels provides consumers with many choices to se-

lect products that save energy. For low-heating degree

day climates (such as Miami), high-emissive white or light

painted Galvalume

TM

roofs display solar reflectance of at

least 65% and thermal emittance of 80 percent. This results

in reducing air conditioning costs and the smog and pollu-

tion that are created by the production of that energy. For

11

Cold-Formed Steel Profile (Updated in 2010)

high-heating degree-day climates, on the other hand, heat

gain can be obtained by using low-emissive unpainted

Galvalume

TM

roof and wall products, which reduce the

load on the buildings heating system and save energy.

A P P L I C A T I O N S O F C O L D -

F O R M E D S T E E L

In building construction,

cold-formed steel products

are mainly used as

structural members, diaphragms, and coverings for roofs, walls

and floors. There are varieties of cold-formed shapes available as

structural members, which include open sections, closed sections,

and built-up sections. Cee-, zee-, double channel I-sections, hat,

and angle sections are open sections while box sections and pipes

are closed sections. The built-up members are formed by connect-

ing two or more cold-formed steel members together, such as an I-

section member built up by connecting two channel sections back-

to-back. These structural shapes can be used in buildings as eave

struts, purlins, girts, studs, headers, floor joists, braces, and other

building components. Various shapes are also available for wall,

floor, and roof diaphragms and coverings.

Profile of Structural Members

Profile of Cold-Formed Steel Panels

Metal Building Construction

In pre-engineered metal buildings, the entire building structure is

made from steel products, and approximately 40-60% of the total

steel used is cold-formed steel. A typical metal building system

consists of primary rigid frames, secondary members, cladding,

and bracing. The primary rigid frames are usually built up using

welded plates with sizes optimized to satisfy the design require-

ments. The secondary members, such as purlins and girts, support

the roof and wall coverings and provide lateral stability to the

primary rigid frame members. The cold-formed metal roof and

wall panels are often used as building claddings. They transfer the

loads (such as wind and snow) to the secondary members and

Metal Building Anatomy

12

Cold-Formed Steel Profile (Updated in 2010)

provide the integrity of the whole building. Straps or rods are of-

ten used as bracing members that maintain the building stability

in the direction perpendicular to the primary rigid frames. They

are also often used in end-walls for stability.

Metal Building System

MBMA publishes an annual business review on its website that

includes the total sales of its member companies, new construc-

tion square footage, steel shipments, and market share.

Wall Construction

Cold-formed steel products are used for wall coverings and wall

framing.

Wall Coverings. Wall panels are widely used as wall cover-

ing for metal buildings and office buildings. With technol-

ogy improvement, wall panels can be made with a variety

of shapes and textures, such as embossed, granular-

finished metals, to meet structural and architectural re-

quirements. Insulated wall panels can greatly simplify the

construction process and achieve significant cost savings.

Wall Panel

Wall Framing. In a metal building, C- or Z-shaped cold-

formed steel girts are often used to provide lateral support

to the metal wall panels. They are normally connected to

the rigid frame at each end and are suspended from the

roof eave purlins for vertical support.

Cold-formed steel stud wall framing has been widely used

in commercial buildings for both exterior and interior wall

construction. For exterior applications, steel stud wall

framing is often used as a backup system for brick veneer,

stucco, and exterior insulating finishing systems (EIFS).

For interior applications, steel stud wall framing is used to

Typical Wall Framing

13

Cold-Formed Steel Profile (Updated in 2010)

support the partition walls, shaft walls, ceilings, and duct

enclosures.

Stud wall framing is a system with studs connected to top

and bottom tracks and braced with cold-rolled channel

bridging or flat strap bracing. The stud wall system can be

used to carry the floor load (load bearing wall), to divide

building space (partition wall), to resist the lateral load

such as wind or seismic load (curtain wall), or to provide

lateral stability for the building (shear wall). In the last

decade, stud wall framing has seen a significant increased

usage in residential and light commercial load-bearing

construction.

Floor Construction

In floor construction, floor decks, steel joists (studs) and trusses

are often used as floor coverings, diaphragms and floor framing,

respectively.

Floor Deck. Cold-formed steel decks are widely used in

commercial and institutional building construction. They

are made by forming cold-formed steel sheet into corru-

gated profiles, which greatly increases the bending capac-

ity of the sheet steel and results in a very high strength-to-

weight ratio. One of the great advantages of using steel

deck in building construction is that it can function as a

working platform and serve as a stay-in-place form that

carries construction loads and concrete weight during

construction, and as a permanent part of load resistance

system in service. There are two types of floor decks: form

deck and composite deck. While both types are widely

used in building construction, the composite decks usually

provide means such as embossments to interlock the deck

Floor Deck

14

Cold-Formed Steel Profile (Updated in 2010)

to the concrete so that higher shear resistance can be

achieved. The composite decks usually possess higher

strength and are capable of achieving a longer span.

Multi-function steel decks, such as a cellular deck, can

carry electrical wires and communication cables, as well as

heating and air conditioning ducts.

Floor Framing. Cold-formed steel can also be used as a part

of sub-floor structures. They usually consist of C-shaped

cold-formed joists or cold-formed steel trusses spaced at 16

in. or 24 in. on center and braced with diagonal or horizon-

tal bridging at 8- to 10-feet on center. Either concrete or

plywood floors can be installed on top of the cold-formed

steel sub-floor.

The cold-formed sub-floor structures are used in light

commercial structures such as apartments, educational

buildings, and single-family homes.

Floor Joist

Roof Construction

Roof Panels. Cold-formed steel roof panels function as

structural components, resisting wind uplift and snow

load, and maintaining the integrity of the building under

lateral wind and seismic loads. They also fulfill appealing

architectural requirements. The roof panels can be fastened

to the purlins as in a through-fastened roof system, or be

connected to purlins with concealed sliding clips as in a

standing seam roof system. The standing seam roof system

can accommodate roof panel movement due to tempera-

ture changes, which makes standing seam roof panels ef-

fective weather-resistant products. The standing seam roof

panels are not only used in new buildings, but are also

Metal Roof

15

Cold-Formed Steel Profile (Updated in 2010)

widely used in the renovation and restoration of existing

buildings.

Cold-formed steel roof decks can serve as part of the roof

sub-structure, resisting roof diaphragm forces and sup-

porting roofs with insulation and waterproofing mem-

brane. Steel roof decks are usually 1" or 3" deep, depend-

ing on the span requirement.

Roof Framing. Cold-formed steel can also serve as the roof

sub-structure in the form of roof purlins or roof trusses. In

a metal building, Z-shaped and C-shaped roof purlins are

usually used to support the roof panels and to transfer the

roof wind and snow loads to the primary frames, while

providing lateral stability to the primary frame members.

Cold-formed steel trusses are used in residential and light

commercial buildings. They can be made from regular C-

section studs or from other proprietary shapes. Cold-

formed steel trusses provide the same span capabilities

and design flexibilities as wood trusses, yet they are lighter

and more dimensionally stable than wood trusses. Most of

the cold-formed steel roof trusses are pre-engineered and

prefabricated with the help of computer software, which

makes it possible to accommodate various roof configura-

tions and layouts. This design flexibility makes cold-

formed steel trusses ideal for almost any building type, in-

cluding residential, commercial, institutional, educational

and industrial structures.

Roof Trusses

Cold-formed steel will continue to be

a viable material in building con-

struction because of its unique

R E S E A R C H A N D

A C C O M P L I S H M E N T S

16

Cold-Formed Steel Profile (Updated in 2010)

characteristics and advantages. However, to maintain and in-

crease market share, the steel industry must focus in the long-term

on enhancing design, improving manufacturing processes and

innovating new construction technologies.

Research and Accomplishments. To keep cold-formed steel design

at the cutting-edge of technology and to be competitive in the

codes and standards arena, research work continues to be carried

out through AISI committees, partner associations, and affiliated

research institutes. The following are some of the highlights of

ongoing and accomplished (completed?) research and standards

development:

Direct Strength Method (DSM). This is a design methodology

that has been adopted by the North American Cold-Formed Steel

Specification as an alternative method to the traditional effec-

tive width design approach. The DSM does not require effec-

tive width calculations or iterations, but instead uses gross

properties and the elastic buckling behavior of the cross-

section to predict the member strength. With the assistance of

computer software, this design procedure is applicable to

cold-formed steel prismatic members with virtually any cross-

section configuration and will result in a more reliable and re-

alistic design. Research work has extended this design method

to perforated members such as studs with web openings or

rack structural members with patterned cutouts. The DSM for

shear has been completed at the University of Sydney.

Seismic Design. To facilitate cold-formed steel design in high

seismic areas, a North American Standard for Cold-Formed Steel

Framing - Lateral Design has been developed by the AISI Com-

mittee on Framing Standards (COFS). A Standard for Seismic

Design of Cold-Formed Steel Structural Systems-Special Bolted

Moment Frames has been published by the AISI Committee on

Specifications (COS). The 2008 edition addresses cold-formed

steel structural design with an emphasis on bolted moment

17

Cold-Formed Steel Profile (Updated in 2010)

frames formed by cold-formed steel channel beams with tubu-

lar columns.

Wind Load Effects on Metal Roofing. A series of wind tunnel

tests and electromagnetic uplift simulations have been carried

out by MBMA with co-sponsorship by AISI, MCA and Factory

Mutual Global (FM Global). The objective of this research is to

study how metal roofs respond to instantaneous wind load

and determine a correlation factor which can be applied to

roof panel uniform static air pressure tests while taking wind

load dynamic effects into consideration. The outcome of this

research has resulted in improved design provisions for metal

roof systems.

Building Performance. Over the years, the North American steel

industry has committed to enhancing building performance

through the improved performance of cold-formed steel products.

Some examples include:

Cool Metal Roofing. Formed by AISI, MBMA, MCA, the Na-

tional Coil Coaters Association (NCCA) and Zinc Aluminum

Coaters Association (ZAC), the Cool Metal Roofing Coalition

sponsored research to evaluate the energy efficiency of metal

roofs. The objective of this research was to formulate and vali-

date design tools for predicting metal roof energy efficiency

during the cooling and heating seasons. The metal panels,

each with different coatings, were compared with each other

and with asphalt shingle roofs in different geographical re-

gions to determine their energy efficiency. Department of En-

ergy computer models were used to show the annual energy

savings of metal roofing products. The Cool Metal Roofing

Coalition also provides technical information and educational

materials, and promotes metal roofing as a green building

product due to its energy efficiency, durability, recyclability

and low weight.

18

Cold-Formed Steel Profile (Updated in 2010)

Durability of Steel Faming. Coordinated by the International

Lead and Zinc Research Organization (ILZRO), a five-year

study of steel framing viability under different climatic condi-

tions has been carried out by the National Association of

Home Builders (NAHB). The on-site monitoring of steel fram-

ing was carried out at Miami, FL; Leonardtown, MD; Long

Beach Island, NJ; and Hamilton, Ontario in Canada. The test

results indicated that for cold-formed steel with minimum

coating weight (G60), the estimated life expectancies ranged

from 235 to more than 841 years, with an average of 490 years

for all of the samples at all of the locations. The research has

substantiated that metallic-coated metal studs are long-lasting

and corrosion-resistant.

Fire Endurance and Acoustic Performance of Steel Framing. A

design guide that collects a series of fire endurance and sound

transmission data for residential and light commercial steel

framing (steel-framed?) wall and floor systems has been de-

veloped through the joint efforts of the Steel Framing Alliance

(SFA) and the Canadian Steel Construction Council (CSCC). In

addition, a Residential Steel Framing Builders Guide for Fire and

Acoustic Details has been developed by the National Associa-

tion of Home Builders Research Center, Inc. and sponsored by

The U.S. Department of Housing and Urban Development

(HUD) and the Steel Framing Alliance. These documents pro-

vide valuable information for design engineers and architects

in selecting steel framing walls and floor systems.

Construction Safety. To address the ironworkers concern about

traction on lubricated steel decking and roofing surfaces, the

OSHA/SENRAC Steel Coalition was established with its member

associations of AISI, MBMA, MCA, SDI, NCCA, and Steel Joist

Institute (SJI) in 1996. After more than eight years of research and

experimentation, a Voluntary Lubricant Compliance Program

(VLCP) was developed which recommends that participants use

19

Cold-Formed Steel Profile (Updated in 2010)

highly evaporative lubricants during the manufacturing of roof

and deck products. This VLCP provides an innovative and re-

sponsible approach to mitigating potential risks of slip and fall

accidents on steel decking and roofing.

Manufacturing and Construction. Metal buildings and cold-formed

products have evolved over the years. A streamlined price esti-

mating, designing and manufacturing process has greatly in-

creased the productivity and product quality. In addition, ad-

vanced computerized design tools provide flexibility so that metal

buildings and light-framed cold-formed steel buildings can be

rapidly designed to meet architectural requirements.

To meet the demand for more steel framing construction workers,

the SFA has developed a series of How To educational materials

for frame workers, plumbers and electricians. To encourage build-

ers to use cold-formed steel framing, many manufacturers provide

customized price estimates and framing design services. In addi-

tion, many panelized wall and floor products are being developed

by manufacturers to speed up and simplify the construction proc-

ess.

As a result of the steel industrys efforts, the building construction

industry is benefiting from new design, manufacturing and con-

struction technologies.

S U M M A R Y

Cold-formed steel has become a competitive build-

ing material as a result of industry-wide efforts. To

ensure sustained market growth for cold-formed steel in building

construction, AISI and the Steel Market Development Institute

will continue to play an important role to increase collaboration

between different organizations, to improve the design specifica-

tion, and to enhance the image and awareness of cold-formed

steel in the marketplace. The American Iron and Steel Institute has

20

Cold-Formed Steel Profile (Updated in 2010)

been and will remain at the forefront of developing codes and

standards to pave the way for cold-formed steel to enter a new

era.

R E F E R E N C E S

1. George Winter (1959), Development of Cold-Formed

Light Gage Steel Structures, a paper presented at the

Pittsburgh Regional Technical Meeting of the American

Iron and Steel Institute, 1959.

2. Wei-Wen Yu, Don S. Wolford, and Albert L. Johnson

(1996), Golden Anniversary of the AISI Specification, Re-

cent Research and Developments in Cold-Formed Steel

Design and Construction, Proceedings of the 13

th

Interna-

tional Specialty Conference on Cold-Formed Steel Structures,

1996.

3. Wei-Wen Yu (2000), Cold-Formed Steel Design, Wiley, 2000.

4. MBMA, 2002 MBMA Business Review, www.mbma.com.

5. MBMA, Effective Design Techniques, www.mbma.com.

6. MBMA (1998), An Integrated Design Approach Offers

Flexibility, Economy, Durability An Evaluation of Metal

Building Systems, Architectural Record, February 1998.

7. American Iron and Steel Institute, slide show, A Look at

Cold-Formed Steel Structures.

8. Larry Williams (2003), Steel Framing: A Look Back Brings

Forward Motion.

9. Related Industry Websites:

a. American Iron and Steel Institute: www.steel.org

b. Metal Building Manufacturers Association: www.mbma.com

c. Steel Deck Institute: www.sdi.org

d. Steel Stud Manufacturers Association: www.ssma.com

e. Steel Framing Alliance: www.steelframing.org

f. Wei-Wen Yu Center for Cold-Formed Steel Structures:

www.ccfssonline.org

21

Cold-Formed Steel Profile (Updated in 2010)

22

g. Cold-Formed Steel Engineers Institute: www.cfsei.org

h. Metal Construction Association: www.metalconstruction.org

i. Metal Roofing Alliance: www.metalroofing.com

j. Cool Metal Roofing Coalition: www.coolmetalroofing.com

k. Rack Manufacturers Institute:

www.mhia.org/psc/PSC_Products_Racks.cfm

Cold-Formed Steel Profile (Updated in 2010)

TABLE 1 TECHNICAL DOCUMENTS ON COLD-FORMED STEEL DESIGN AND CONSTRUCTION

Organization Publication Name

AISI 1. AISI Cold-Formed Steel Design Standards:

AISI S100, North American Specification for the Design of Cold-Formed Steel Structural Members

AISI S110, Standard for Seismic Design of Cold-Formed Steel Structural SystemsSpecial Bolted Moment

Frames

AISI S200, North American Standard for Cold-Formed Steel FramingGeneral Provisions

AISI S201, North American Standard for Cold-Formed Steel FramingProducts Standard

AISI S202, Standard for Cold-Formed Steel Framing Code of Standard Practice

AISI S210, North American Standard for Cold-Formed Steel FramingFloor and Roof System Design

AISI S211, North American Standard for Cold-Formed Steel FramingWall Stud Design

AISI S212, North American Standard for Cold-Formed Steel FramingHeader Design

AISI S213, North American Standard for Cold-Formed Steel FramingLateral Design

AISI S214, North American Standard for Cold-Formed Steel FramingTruss Design

AISI S230, North American Standard for Cold-Formed Steel Framing Prescriptive Method for One- and Two-

Family Dwellings

2. AISI Test Standards for Cold-Formed Steel Members, Connections and Assemblies

AISI S901, Rotational-Lateral Stiffness Test Method for Beam-to-Panel Assemblies

AISI S902, Stub-Column Test Method for Effective Area of Cold-Formed Steel Columns

AISI S903, Standard Methods for Determination of Uniform and Local Ductility

AISI S904, Standard Test Methods for Determining the Tensile and Shear Strength of Screws

AISI S905, Test Methods for Mechanically Fastened Cold-Formed Steel Connections

AISI S906, Standard Procedures for Panel and Anchor Structural Tests

AISI S907, Test Standard for Cantilever Test Method for Cold-Formed Steel Diaphragm

AISI S909, Standard Test Method for Determining the Web Crippling Strength of Cold-Formed Steel Beams

AISI S910, Test Method for Distortional Buckling of Cold-Formed Steel Hat Shaped Compression Members

AISI S911, Method for Flexural Testing Cold-Formed Steel Had Shaped Beams

AISI S912, Test Procedure for Determining a Strength Value for a Roof Panel-to-Purlin-to-Anchorage Device

Connection

AISI S913, Test Standard for Hold-Downs Attached to Cold-Formed Steel Structural Framing

23

Cold-Formed Steel Profile (Updated in 2010)

AISI S914, Test Standard for Joist Connectors Attached to Cold-Formed Steel Structural Framing

3. Cold-Formed Steel Design Manual

4. Cold-Formed Steel Framing Design Guide

5. Steel Stud Brick Veneer Design Guide

6. Direct Strength Method Design Guide

7. Design Guide for Cold-Formed Steel Purlin Roof Framing Systems

8. Various Research Reports (go to www.steel.org and refer to the Quick Link: Research Reports on the AISI

Codes and Standards page under Steel Markets: Construction.)

MBMA 1. Metal Building System Manual

2. Metal Roofing Systems Design Manual

3. Energy Design Guide for Metal Building Systems

4. Fire Resistance Design Guide for Metal Building Systems

5. Seismic Design Guide for Metal Building Systems

6. Various Brochures

SDI 1. Design Manual for Composite Decks, Form Decks and Roof Decks

2. Roof Deck Construction Handbook

3. Diaphragm Design Manual

4. SDI Manual of Construction with Steel Deck

5. Composite Steel Deck Design Handbook

6. Standard Practice Details

CFSEI 1. Design Guide: Cold-Formed Steel Framed Wood or Steel Sheathed Shear Wall Assemblies

2. Technical Note Series:

D001-07, Durability of Cold-Formed Steel Framing Members

D100-08, Corrosion Protection of Screw Fasteners

24

Cold-Formed Steel Profile (Updated in 2010)

D200-07, Corrosion Protection For Cold-Formed Steel Framing In Coastal Areas

F100-09, Design of Clip Angle Bearing Stiffeners

F140-10, Welding Cold-Formed Steel

F300-09, Pneumatically Driven Pins For Wood Based Panel Attachment

G000-08, Cold-Formed Steel Design Software

G100-07, Using Chapter F of the North American Specification for the Design of CFS Structural Members

G100-08, Design Aids and Examples for Distortional Buckling

G100-09, Designing CFS Using the Direct Strength Method

G800-07a, ASTM Standards For Cold-Formed Steel

G801-08, ASTM A1003 - No Cause for Rejection

G900-08, Design Methodology for Hole Reinforcement of CFS Bending Members

L000-08, Changes from the 1997 UBC to the 2006 IBC for Lateral Design with Cold-Formed Steel Framing

L001-09, Design of Diagonal Strap Bracing Lateral Force Resisting Systems for the 2006 IBC

L200-09, Roof Anchorage Forces: MWFRS or C&C

L300-09, Design of End Posts for Diaphragm Shear Walls: A Perspective

T001-09, Suggested Cost Effective CFS Fire and Acoustic-Rated Assemblies for Multi-Unit Structures

W100-08a, Single Slip Track Design

W101-09, Common Design Issues for Deflection Track

W200-09, Header Design

3. Technical Notes - Produced by the former Light Gauge Steel Engineering Association (LGSEA)

360, Acoustic Insulation and Sound Transmission in Cold-Formed Steel Construction

420, Fire-Rated Assemblies for Cold-Formed Steel Construction

542, Introduction to Curtain Wall Design Using Cold-Formed Steel

550, Design Values For Vertical and Horizontal Lateral Load Systems

551d, Design Guide: Construction Bracing of Cold-Formed Steel Trusses

551e, Design Guide: Permanent Bracing of Cold-Formed Steel Trusses

551f, Specifying Pre-Engineered Cold-Formed Steel Floor and Roof Trusses

552, Cold-Formed Steel Joists

544, Design of By-Pass Slip Connectors in Cold-Formed Steel Construction

556a-4, Shear Transfer at Top Plate: Drag Strut Design

556a-6, Vertical Lateral Force Resisting System: Boundary Elements

558b-1, Lateral Load Resisting Elements: Diaphragm Design Values

25

Cold-Formed Steel Profile (Updated in 2010)

559, Design Considerations for Flexural and Lateral-Torsional Bracing

560b-5, Fastener Corrosion

560c, Clinch (Integral) Fastening of Cold-Formed Steel

561c, Diaphragm Design with Pneumatically Driven Pins

562, Powder-Actuated Fasteners in Cold-Formed Steel Construction

565c, Screw Fastener Selection for Light Gauge Steel Framing

565d, Screws For Attachment of Steel-To-Wood and Wood-To-Steel

1010b, Inspection Checklist for Structural CFS Framing (pocket size)

1010c, Inspection Checklist for Structural CFS Framing (full size)

MCA 1. Single or Dual Level Roll Former Operation and Maintenance Manual

2. Smooth-Faced Uninsulated Metal Wall Panels

3. Metal Roof Design for Cold Climates

4. Performed Metal Wall Specification Guidelines

5. Selection Guidelines for Metal Composite Foam Roof Panels

6. Other Various Technical Bulletins

SSMA 1. SSMA Product Technical Information

2. Cold-Formed Steel Details

3. Technical Notes:

Single Deflection Track Selection

Unsheathed Flange Bracing

Track Within A Track Deflection

Interior Non-Structural 30 Mil Framed Walls

Metric Conversion SSMA Tables

SFA 1. Design Guide for Cold-Formed Steel Beams with Web Penetrations

2. Thermal Design and Code Compliance for Cold-Formed Steel Walls

3. Low-Rise Residential Steel Construction Details and Guidelines (CD-ROM)

4. L-Shaped Header Field Guide

26

Cold-Formed Steel Profile (Updated in 2010)

27

5. Steel Floor Guide

6. Steel Wall Guide

7. Occupancy A (Assembly) Building: A Case Study

8. Other Various Market and Research Reports

RMI

1. Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks

2. Specification for the Design, Manufacture, and Installation of Industrial Steel Work Platforms

3. Design, Testing and Utilization of Welded-Wire Rack Decking

4. Stacker Rack Nomenclature

5. Testing Guidelines for Pallet Stacking Frames

Cold-Formed Steel Profile (Updated in 2010)

APPENDIX 1

CHRONICLED SUMMARY OF AISI COLD-FORMED STEEL STANDARDS

Year

Published

Significance

North American Specification for the Design of Cold-Formed Steel Structural Members:

1946 The first edition of the AISI Specification for the Design of Light Gage Steel Structural

Members was published

1949 The first edition of the AISI Light Gage Steel Design Manual was published.

1956 The AISI Design Manual with the AISI Specification was published, and the Specifi-

cation was adopted by the building code officials.

1960 &

1961

The basic safety factor was reduced from 1.85 to 1.65 in the Specification.

1962 Strength increase due to cold work of forming was recognized.

1968 Compression member lateral-torsional buckling consideration was added.

1980 Specification scope was extended to cover cold-formed steel up to one inch in

thickness, and was expanded to include plate and bar steels, as well as sheet

steels.

1986 The unified approach was adopted for determining the cold-formed member

strength in considering local buckling.

1991 The first edition of LRFD Specification was published. The AISI Advisory Group

was renamed to Committee on Specifications for the Design of Cold-Formed Steel

Structural Members.

1996 The first edition of the combined ASD and LRFD Specification was published.

2001 The first edition of the North American Specification was published by AISI and

CSA.

2004 Supplement No. 1 to the 2001 Edition of the North American Specification was pub-

lished, which included the Direct Strength Method.

2007 2007 Edition of the North American Specification was published, and designated as

AISI S100.

Cold-Formed Steel Framing Standards

1996 The first edition of the Prescriptive Method for Residential Cold-Formed Steel Framing

was published by HUD.

1997 The second edition of the Prescriptive Method for Residential Cold-Formed Steel Fram-

ing was published by HUD and was adopted by IRC 2000.

2001 The following AISI standards were first published:

1. Standard for Cold-Formed Steel Framing Prescriptive Method for One- and

Two-Family Dwellings

2. Standard for Cold-Formed Steel Framing General Provisions

3. Standard for Cold-Formed Steel Framing Truss Design

4. Standard for Cold-Formed Steel Framing Header Design

2004 The following AISI standards were first published:

5. Standard for Cold-Formed Steel Framing Lateral Design

6. Standard for Cold-Formed Steel Framing Wall Stud Design

28

Cold-Formed Steel Profile (Updated in 2010)

29

2007 The following standards were published as 2007 editions, and new designations

were adopted:

AISI S200, North American Standard for Cold-Formed Steel FramingGeneral Provisions

AISI S201, North American Standard for Cold-Formed Steel FramingProducts Standard

AISI S210, North American Standard for Cold-Formed Steel FramingFloor and Roof System

Design

AISI S211, North American Standard for Cold-Formed Steel FramingWall Stud Design

AISI S212, North American Standard for Cold-Formed Steel FramingHeader Design

AISI S213, North American Standard for Cold-Formed Steel FramingLateral Design

AISI S214, North American Standard for Cold-Formed Steel FramingTruss Design

AISI S230, North American Standard for Cold-Formed Steel Framing Prescriptive Method

for One- and Two-Family Dwellings

Cold-Formed Steel Standard for Seismic Design

2008 The first edition of AISI S110, Standard for Seismic Design of Cold-Formed Steel Struc-

tural Systems-Special Bolted Moment Frames, was published.

2009 The Supplement to the 2008 edition of AISI S110, Standard for Seismic Design of

Cold-Formed Steel Structural Systems-Special Bolted Moment Frames, was published.

Cold-Formed Steel Test Standards

2008 A new designation for AISI test standards was adopted. The new standards S909-

S914 were added during 2002 and 2008. See Table 1 for complete list of the pub-

lished test standards.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- ETABS2013 Introductory TutorialDocument116 pagesETABS2013 Introductory Tutorialpradeepjoshi007No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 300 Solved Problems in Geotechnical EngineeringDocument0 pages300 Solved Problems in Geotechnical Engineeringmote3488% (17)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Cyclic Pushover Analysis Estimates Seismic Demands for BuildingsDocument14 pagesCyclic Pushover Analysis Estimates Seismic Demands for BuildingsАвирмэдийн ГэрэлболдNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Good ReferDocument18 pagesGood RefersathiyasuthanNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Push9 2012 PDFDocument8 pagesPush9 2012 PDFАвирмэдийн ГэрэлболдNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- An Investigation On The Accuracy of Pushover Analysis For Estimating The Seismic Deformation of Braced Steel FramesDocument9 pagesAn Investigation On The Accuracy of Pushover Analysis For Estimating The Seismic Deformation of Braced Steel Framesrahulgehlot2008No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- CFRP-Retrofitted Concrete Shear Walls Pushover TestsDocument16 pagesCFRP-Retrofitted Concrete Shear Walls Pushover TestsАвирмэдийн ГэрэлболдNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Leonardo Pinheiroa and Ricardo A. M. Silveira - Computational Procedures For Nonlinear Analysis of Frames With Semi-Rigid ConnectionsDocument30 pagesLeonardo Pinheiroa and Ricardo A. M. Silveira - Computational Procedures For Nonlinear Analysis of Frames With Semi-Rigid ConnectionsCristina VlaicuNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 2006 Structural Seismic Design Manual 1Document220 pages2006 Structural Seismic Design Manual 1vttrlc93% (14)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Engineering Failure Analysis: Gabriele Milani, Marco ValenteDocument33 pagesEngineering Failure Analysis: Gabriele Milani, Marco ValenteАвирмэдийн ГэрэлболдNo ratings yet

- Push 30 2012 PDFDocument13 pagesPush 30 2012 PDFАвирмэдийн ГэрэлболдNo ratings yet

- Comparative Inelastic Pushover Analysis of Masonry FramesDocument9 pagesComparative Inelastic Pushover Analysis of Masonry FramesGeorge VarelisNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Push 16 2011 PDFDocument18 pagesPush 16 2011 PDFАвирмэдийн Гэрэлболд100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Push 29 2013 PDFDocument13 pagesPush 29 2013 PDFАвирмэдийн ГэрэлболдNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Push 13 2012 PDFDocument12 pagesPush 13 2012 PDFАвирмэдийн ГэрэлболдNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Push 14 2013 PDFDocument16 pagesPush 14 2013 PDFАвирмэдийн ГэрэлболдNo ratings yet

- Push 12 2013 PDFDocument20 pagesPush 12 2013 PDFАвирмэдийн ГэрэлболдNo ratings yet

- Push 15 2012 PDFDocument13 pagesPush 15 2012 PDFАвирмэдийн ГэрэлболдNo ratings yet

- Seismic Performance Study On RC Wall Buildings From Pushover AnalysisDocument7 pagesSeismic Performance Study On RC Wall Buildings From Pushover AnalysisАвирмэдийн ГэрэлболдNo ratings yet

- PushoverDocument2 pagesPushoverjustake100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- LectureDocument8 pagesLectureАвирмэдийн ГэрэлболдNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- SAP2000 - A To Z ProblemsDocument194 pagesSAP2000 - A To Z ProblemsKang'ethe GeoffreyNo ratings yet

- Higher Algebra - Hall & KnightDocument593 pagesHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- LectureDocument8 pagesLectureАвирмэдийн ГэрэлболдNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hemangioma CavernousDocument10 pagesHemangioma CavernousАвирмэдийн ГэрэлболдNo ratings yet

- Load Assumptions: Ground Floor LevelDocument4 pagesLoad Assumptions: Ground Floor Levelkiritoo kirigayaaNo ratings yet

- Timberline Prestique 30 Shingles CSI SpecificationDocument13 pagesTimberline Prestique 30 Shingles CSI SpecificationKevin LuNo ratings yet

- Knauf Regular Access PanelDocument2 pagesKnauf Regular Access PanelTa TinNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Productivity Norms For Civil WorksDocument189 pagesProductivity Norms For Civil Worksshoaib akhtarNo ratings yet

- Tradition and Innovation in Contemporary Romanian ArchitectureDocument5 pagesTradition and Innovation in Contemporary Romanian ArchitectureBiris GabrielNo ratings yet

- BT 3 - Vernacular TermsDocument3 pagesBT 3 - Vernacular TermsJustin Ramos GollosoNo ratings yet

- Concrete Failure MechanismsDocument43 pagesConcrete Failure MechanismsheminNo ratings yet

- 90 1 2010 2013addenda PDFDocument300 pages90 1 2010 2013addenda PDFDevendraNo ratings yet

- J2020b-Preparation of Low-Cost Foam Concrete Using Detergent-UETDocument10 pagesJ2020b-Preparation of Low-Cost Foam Concrete Using Detergent-UETafaq120No ratings yet

- Presentation Gene TGDocument40 pagesPresentation Gene TGsuvraNo ratings yet

- Repair of Cracks in Reinforced Concrete BeamsDocument2 pagesRepair of Cracks in Reinforced Concrete BeamssuryakantameNo ratings yet

- ECBC Implementation Experience - A Case Study on UPERC BuildingDocument21 pagesECBC Implementation Experience - A Case Study on UPERC BuildingAanchal MishraNo ratings yet

- Products Aquapas-Redispersible-PowdersDocument3 pagesProducts Aquapas-Redispersible-PowdersMauro RicoNo ratings yet

- Super Adobe ConstructionDocument3 pagesSuper Adobe ConstructionGilles GautierNo ratings yet

- BOQ CulvertDocument2 pagesBOQ CulvertDeepak_pethkar85% (13)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Sushanth-J Colony JAN-30-2023-EXCAVATION LAYOUT-1Document1 pageSushanth-J Colony JAN-30-2023-EXCAVATION LAYOUT-1srinivas pNo ratings yet

- Aluminum Box Section 80X50X4MM THK. Ms L Angle 35X35X3Mm Thk. 50Mm WidthDocument1 pageAluminum Box Section 80X50X4MM THK. Ms L Angle 35X35X3Mm Thk. 50Mm WidthSiva RajanNo ratings yet

- Construction Materials and Testing ModuleDocument66 pagesConstruction Materials and Testing Moduleacurvz2005No ratings yet

- SCZ/SKZ Cold Formed Steel Sheet PileDocument2 pagesSCZ/SKZ Cold Formed Steel Sheet PileLuis Valdivieso VidalNo ratings yet

- Stego Accessories Calculation of Temperature Control en 0911Document1 pageStego Accessories Calculation of Temperature Control en 0911AnnNo ratings yet

- Method Statement Retaining WallDocument3 pagesMethod Statement Retaining WallPravin Pelanisamy100% (1)

- Rehabilitation of Septic Tank WorksDocument4 pagesRehabilitation of Septic Tank WorksAbdi MusaNo ratings yet

- Asbestos Register Handover VersionDocument6 pagesAsbestos Register Handover Versionapi-336132958No ratings yet

- Perhitungan Cooling Load - by INDDocument6 pagesPerhitungan Cooling Load - by INDIrvan Abdul AzizNo ratings yet

- Unit 2 Lesson 1 Gravity Loads On StructuresDocument4 pagesUnit 2 Lesson 1 Gravity Loads On StructuresPrince AJNo ratings yet

- Commercial Building SpecsDocument15 pagesCommercial Building SpecsGeeryl TayoneNo ratings yet

- Pile - Dwall Capacity CalculationDocument5 pagesPile - Dwall Capacity CalculationAlhad Panwalkar100% (1)

- King - Load Bearing Straw Blalle ConstructionDocument26 pagesKing - Load Bearing Straw Blalle ConstructionJaba de SojaNo ratings yet

- 04 Inspection Checklist - Installation of Air-Cooled ChillersDocument2 pages04 Inspection Checklist - Installation of Air-Cooled ChillersBabar Shehzad100% (3)

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)