Professional Documents

Culture Documents

PGT25 G4 02-04-2010

Uploaded by

Sumanth Karanam0 ratings0% found this document useful (0 votes)

224 views2 pagesPGT25+G4 is a 34 MW gas turbine that draws its high efficiency and light weight from GE's Aeroderivative Technology and its ruggedness from heavy duty gas turbine designs. The gas generator is based on the proven LM2500+ with minor enhancements to increase the flow and temperature capabilities. The power turbine is a 6100 RPM machine proven in the PGT25 + and capable of direct coupling to the driven equipment for simplicity and improved efficiency and maintenance.

Original Description:

Original Title

PGT25_G4_02-04-2010

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPGT25+G4 is a 34 MW gas turbine that draws its high efficiency and light weight from GE's Aeroderivative Technology and its ruggedness from heavy duty gas turbine designs. The gas generator is based on the proven LM2500+ with minor enhancements to increase the flow and temperature capabilities. The power turbine is a 6100 RPM machine proven in the PGT25 + and capable of direct coupling to the driven equipment for simplicity and improved efficiency and maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

224 views2 pagesPGT25 G4 02-04-2010

Uploaded by

Sumanth KaranamPGT25+G4 is a 34 MW gas turbine that draws its high efficiency and light weight from GE's Aeroderivative Technology and its ruggedness from heavy duty gas turbine designs. The gas generator is based on the proven LM2500+ with minor enhancements to increase the flow and temperature capabilities. The power turbine is a 6100 RPM machine proven in the PGT25 + and capable of direct coupling to the driven equipment for simplicity and improved efficiency and maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

PGT25+G4

The latest in Aeroderivative Technology for On- and Offshore

Mechanical Drive and Power Generation applications

The PGT25+G4 is a 34 MW gas turbine that draws its high efciency and light weight from GEs aeroderivative

technology and its ruggedness from heavy duty gas turbine designs. Its high reliability and availability are

the result of its evolution from the proven LM2500+ and PGT25+ models, as well as advanced materials used

in GE aircraft engines, and heavy duty gas turbine technology.

The gas generator is based on the LM2500+ with minor enhancements to increase the ow and temperature

capabilities, while the power turbine is a 6100 RPM machine proven in the PGT25+ and capable of direct

coupling to the driven equipment for simplicity and improved efciency and maintenance. The annular

combustor is that of the LM2500+ with slight modications to impart higher ring temperature capability,

reduce the maintenance cycle time, and keep NOx at LM2500+ levels even at higher ring temperatures.

The enhanced PGT25+G4 package offers improved integration of auxiliaries, reduced installation and

commissioning time, and easy maintenability. Upgrade kits are also available for the the installed base

of PGT25+ units to increase output power by 10%.

GE Oil & Gas

g

Key characteristics

34 MW output power & high efciency

from minor enhancements of proven

technology

High reliability & availability traced to

LM2500+ and PGT25+ legacy designs

Fuel exibility natural gas, ethane,

syngas, medium BTU gas, liquid fuel,

dual fuel (natural gas or liquid)

Low emissions; DLE with gas or dual

fuel

Pipeline

LNG

Gas reinjection and storage

Offshore applications

Renery & Petrochemical

GE imagination at work

g

Applying proven, advanced

technologies to deliver greater value

Gas Generator

The PGT25+G4 gas generator is based on

the proven LM2500+ upgraded for increased

ow. The limited design changes include:

Minor blade and stationary vane airfoil

modications for increased ow

Minor blade cooling improvements and

material upgrades proven in aircraft

engines for higher temperature capability

Adjustment of compressor discharge seal

area for optimum rotor thrust balance

Combustor upgrades for DLE applications to reduce maintenance downtime

The frames, HP compressor front and aft cases, sump hardware, and main shaft

bearing conguration all remain unchanged.

Power Turbine

The power turbine design is that of the PGT25+ and applies additional cooling

technology based on GEs heavy duty gas turbine experience for higher HSPT

reliability. Its features include:

Aerodynamic blading design for high efciency at both design point and

reduced speed

6100 RPM shaft speed for direct coupling with driven equipment for simplicity,

and enhanced plant efciency and reliability

Cartridge philosophy extends maintenance intervals, cuts costs and increases

availability

Optimized cooling ows and the latest generation of seals increase

component life and maintains efciency at its peak

GENERAL SPECIFICATIONS

- Output Power (nat. gas) 34 MW

- Efciency (DLE) 41%@ iso cond.

Compressor

- 17-stage axial ow

- Inlet guide vanes & adjustable

stator vanes on rst 7 stages

- Pressure ratio 24:1

Combustion & Emission Control

- Single annular combustion

chamber

- Dry Low Emission (DLE) system

- 25 ppm NOx (natural gas)

Turbine

- Two-stage HPT

- Two-stage HSPT (6100 RPM)

GE Oil & Gas

via Felice Matteucci, 2

50127 Florence - Italy

T +39 055 4272500

F +39 055 4232800

Nuovo Pignone S.p.A.

customer.service.center@ge.com

www.ge.com/oilandgas

COMK/MARK 901/II - Designed by: Studio Tre Fasi

Printed by: Sagraf - 01 - 2010

2010 General Electric Company

All Rights Reserved

You might also like

- Electrician Training - Troubleshooting and Fault FindingDocument11 pagesElectrician Training - Troubleshooting and Fault FindingOgunjimi Taofiki AdebisiNo ratings yet

- Rover V8 Fuel Injection SystemsDocument16 pagesRover V8 Fuel Injection SystemsClint Cooper100% (1)

- Seismic Acquisition and Processing BWDocument33 pagesSeismic Acquisition and Processing BWghassen laouiniNo ratings yet

- 9FA Failures in DabholDocument10 pages9FA Failures in Dabholsenthil031277100% (3)

- Turbina ms6001bDocument64 pagesTurbina ms6001bAangel HHernande100% (1)

- Frame 7EA 2021Document30 pagesFrame 7EA 2021Ender Galvis0% (1)

- Gek105054 File0007Document18 pagesGek105054 File0007outilprok22kNo ratings yet

- 4Q2005 7EA UsersGrpDocument19 pages4Q2005 7EA UsersGrpaxl1No ratings yet

- Manual Firstair FAS3-37 - FAS SC 7-37 - ArtNr. 195. 03701 - GBDocument80 pagesManual Firstair FAS3-37 - FAS SC 7-37 - ArtNr. 195. 03701 - GBEduardo ParraNo ratings yet

- Installation Guide For Instrument Cables, Conduits and Cable TraysDocument35 pagesInstallation Guide For Instrument Cables, Conduits and Cable TraysImran Mohiuddin100% (1)

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDocument3 pagesDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezNo ratings yet

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet RittirutNo ratings yet

- GE MS6001B - EmissionDocument33 pagesGE MS6001B - EmissionMohamad AfifNo ratings yet

- 3 - Gas Turbine Overview 8.09Document25 pages3 - Gas Turbine Overview 8.09Sujeet Kumar100% (1)

- Ger4250 LM2500G4Document12 pagesGer4250 LM2500G4Denis JimenezNo ratings yet

- GE Frame 6B - DixieDocument17 pagesGE Frame 6B - DixieClive Cadogan100% (1)

- Electronic engine control module circuit diagramDocument17 pagesElectronic engine control module circuit diagramelisei sorinNo ratings yet

- ACI 229 Enhanced CLSM 20160415 PDFDocument30 pagesACI 229 Enhanced CLSM 20160415 PDFerosNo ratings yet

- Lm6000 PF Plus Fact SheetDocument2 pagesLm6000 PF Plus Fact SheetNivaldo GarciaNo ratings yet

- Igv 7eaDocument2 pagesIgv 7eaSamir BenabdallahNo ratings yet

- GE Gas Turbines Were Basically Divided Into 3 DifferentDocument3 pagesGE Gas Turbines Were Basically Divided Into 3 Differentsaikrish36No ratings yet

- MS5001PA Gas Turbine Fact SheetDocument3 pagesMS5001PA Gas Turbine Fact SheetGustavo Palacios100% (3)

- Proven Upgrade SGT5-4000FDocument9 pagesProven Upgrade SGT5-4000FThanapaet Rittirut100% (1)

- GearboxDocument16 pagesGearboxMehul zareNo ratings yet

- GE Power Systems 7F Users Conference PresentationsDocument27 pagesGE Power Systems 7F Users Conference Presentationsatfrost4638No ratings yet

- Alstom Gas-Turbines-Technical-Performance PDFDocument2 pagesAlstom Gas-Turbines-Technical-Performance PDFPoull SteeadyNo ratings yet

- Sb-Lm2500-Ind-303 R1Document11 pagesSb-Lm2500-Ind-303 R1Daniil SerovNo ratings yet

- Offshore Kurz SolarDocument28 pagesOffshore Kurz Solarstuntmanz100% (1)

- Gas Turbine Combustion SystemDocument14 pagesGas Turbine Combustion Systemrohit u100% (1)

- CatalogoTurbineaGas PDFDocument34 pagesCatalogoTurbineaGas PDFshihabjamaan0% (1)

- Til 1213 R1Document6 pagesTil 1213 R1Hernan GirautNo ratings yet

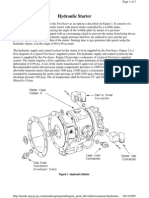

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- GEA31503e PGP Product E-Catalog 2015 R10Document47 pagesGEA31503e PGP Product E-Catalog 2015 R10juagamsar100% (1)

- GT Frame 9 ManualDocument102 pagesGT Frame 9 ManualSSC & GSC of LebanonNo ratings yet

- Gas TurbineDocument31 pagesGas TurbineŞansal Dikmener100% (1)

- Variable Inlet Guide Vane System: GE Power SystemsDocument4 pagesVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- H25-H15 CatalogueDocument12 pagesH25-H15 CatalogueTong Chaipanyakul100% (1)

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- MS5002Document8 pagesMS5002Fauzi Rasdi100% (5)

- MS5002EDocument8 pagesMS5002Eamir8100100% (1)

- Oman Energy Conference - World Record Gas Turbine Service ExperiencesDocument16 pagesOman Energy Conference - World Record Gas Turbine Service ExperiencesabelsgNo ratings yet

- TM2500 and TM2500+ Intro Pages-2Document24 pagesTM2500 and TM2500+ Intro Pages-2abelsg100% (2)

- Improving Power System Stability Through Integrated Power System Stabilizers - 100520Document25 pagesImproving Power System Stability Through Integrated Power System Stabilizers - 100520soumyanitcNo ratings yet

- Factsheet Industrial Trent 60 Us LowresDocument2 pagesFactsheet Industrial Trent 60 Us LowresAsri GaniNo ratings yet

- Ansaldo Energia AE94.2 Upgrading ProjectDocument20 pagesAnsaldo Energia AE94.2 Upgrading Projectvincent8295547100% (1)

- PFR vs. CSTR: Size and Selectivity: V R V RDocument6 pagesPFR vs. CSTR: Size and Selectivity: V R V RSerkan KayacanNo ratings yet

- Siemens Gas Turbine Product Range Comparison Chart 0-130 MWDocument2 pagesSiemens Gas Turbine Product Range Comparison Chart 0-130 MWdvcher78No ratings yet

- MS5002E NewDocument8 pagesMS5002E Newecs71100% (2)

- ASME Presentation Nov 2014 PDFDocument56 pagesASME Presentation Nov 2014 PDFdf_campos33530% (2)

- 7HA Gas Turbine: World's Largest, Most Efficient Gas Turbine in Its ClassDocument4 pages7HA Gas Turbine: World's Largest, Most Efficient Gas Turbine in Its Classjparmar100% (2)

- Gas Turbines Siemens Interactive PDFDocument22 pagesGas Turbines Siemens Interactive PDF'Izzad AfifNo ratings yet

- Siemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use OnlyDocument2 pagesSiemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use Onlythunder0% (1)

- DLN1+ Combustion Upgrade Solution: Fact SheetDocument1 pageDLN1+ Combustion Upgrade Solution: Fact SheetAhmad Riaz KhanNo ratings yet

- MOU (00) - Introduction LDocument37 pagesMOU (00) - Introduction LDRISSI100% (1)

- Scope of Supply GEF9Document144 pagesScope of Supply GEF9Her Phy ToNo ratings yet

- SB LM2500 Ind 312 R1Document7 pagesSB LM2500 Ind 312 R1Daniil SerovNo ratings yet

- Gas Turb CatDocument31 pagesGas Turb CatPablo Gutierrez100% (1)

- Lechler Brochure Tank Equipment Cleaning enDocument84 pagesLechler Brochure Tank Equipment Cleaning enAnonymous lswzqloNo ratings yet

- GEK101944Document8 pagesGEK101944Nouman Saeed100% (1)

- LM2500 16th Stage Bleed Manifold KitDocument2 pagesLM2500 16th Stage Bleed Manifold KitDenis JimenezNo ratings yet

- Gea32081a LM6000 - Pa - Us - R1 - LRDocument1 pageGea32081a LM6000 - Pa - Us - R1 - LRErik Van GroningenNo ratings yet

- Compressor Power PointDocument28 pagesCompressor Power PointDiden Dz100% (1)

- Ansaldo Thomassen - CMU (2014)Document4 pagesAnsaldo Thomassen - CMU (2014)guerrezNo ratings yet

- MHPS GT F ClassDocument9 pagesMHPS GT F Classkp pkNo ratings yet

- GT26 Pulsation Supervision SystemDocument4 pagesGT26 Pulsation Supervision Systemkp pkNo ratings yet

- Fact Sheet: GE Energy EX2100e Excitation Control For Gas Turbine GeneratorsDocument2 pagesFact Sheet: GE Energy EX2100e Excitation Control For Gas Turbine Generatorsvcharles100% (1)

- Psib 20150212Document10 pagesPsib 20150212Léandre Ettekri NdriNo ratings yet

- MHPS D Class GT UpratesDocument6 pagesMHPS D Class GT Uprateskp pkNo ratings yet

- NIC 13.20 Rev.01Document15 pagesNIC 13.20 Rev.01Mahmoud Ahmed100% (1)

- GT Water WashDocument4 pagesGT Water WashPrasanna DhamodharanNo ratings yet

- Curved Data KEW PUMP KSSE 3 1Document1 pageCurved Data KEW PUMP KSSE 3 1Haryono SyalimNo ratings yet

- Cornell Notes 3Document3 pagesCornell Notes 3api-302904199No ratings yet

- Chemistry 3202 Reaction Rates and Equilibrium NotesDocument4 pagesChemistry 3202 Reaction Rates and Equilibrium NotesMorgan SearsNo ratings yet

- EHS Compliance Scope of Work for Ather EnergyDocument4 pagesEHS Compliance Scope of Work for Ather EnergyFazal AhmadNo ratings yet

- Paraloid km-334Document5 pagesParaloid km-334Naseer MianNo ratings yet

- Mi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsDocument2 pagesMi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsTuan Anh Le CongNo ratings yet

- Training Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IIDocument5 pagesTraining Document: 120 113 304 f Gilbarco GmbH + Co. KG Error Codes - Sandpiper IICharlie ShowNo ratings yet

- An overview of common vehicle indicatorsDocument9 pagesAn overview of common vehicle indicatorsNikhitaNo ratings yet

- Apd NG150Document5 pagesApd NG150Magaly PeraltaNo ratings yet

- Module 2Document79 pagesModule 2uditNo ratings yet

- Radiography Sai KripaDocument4 pagesRadiography Sai KripaSarthak EnterprisesNo ratings yet

- ComponentsDocument8 pagesComponentsprbthapa2055No ratings yet

- Data Sheet 2BH1 840: Side Channel BlowerDocument2 pagesData Sheet 2BH1 840: Side Channel BlowerPablo Andres Espin MartinNo ratings yet

- BLW29Document12 pagesBLW29glow4No ratings yet

- CT Essential Products EN PDFDocument159 pagesCT Essential Products EN PDFXavier DomenechNo ratings yet

- NeOz Energy Is The Foremost Oil and Gas Company Manufacturing Oil Drilling Tools Used For Various Stages of Drilling.Document15 pagesNeOz Energy Is The Foremost Oil and Gas Company Manufacturing Oil Drilling Tools Used For Various Stages of Drilling.Neoz EnergyNo ratings yet

- Vdocuments - MX - Api 612 Latest Edition 612 Latest Editionpdf Free Download Here Api Standard PDFDocument2 pagesVdocuments - MX - Api 612 Latest Edition 612 Latest Editionpdf Free Download Here Api Standard PDFNeeraj JangidNo ratings yet

- Exercise-01 Check Your Grasp: O CH HO HODocument7 pagesExercise-01 Check Your Grasp: O CH HO HOChesta MalhotraNo ratings yet

- HexaneDocument3 pagesHexaneIan RidzuanNo ratings yet

- Eco NicalDocument13 pagesEco Nicalluizfellipe95No ratings yet