Professional Documents

Culture Documents

Assignment 3 SCM

Uploaded by

drahmedneo0%(4)0% found this document useful (4 votes)

2K views3 pagesSCM assignment 3 problems

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSCM assignment 3 problems

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0%(4)0% found this document useful (4 votes)

2K views3 pagesAssignment 3 SCM

Uploaded by

drahmedneoSCM assignment 3 problems

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

Skycell, a major European cell phone manufacturer, is making

production plans for the coming year. Skycell has worked

Skycell has worked its customers

(the service providers) to come up with

forecasts of monthly requirements (in thousands of phones) as Month

shown in Table 8-9. Jan

Manufacturing is primarily an assembly operation, Feb

and capacity is governed by the number of people on the Mar

production line. The plant operates for 20 days a month, Apr

eight hours each day. One person can assemble a phone May

every 10 minutes. Workers are paid 20 euros per hour and Jun

a 50 percent premium for overtime. The plant currently Jul

employs 1,250 workers. Component costs for each cell Aug

phone total 20 euros. Given the rapid decline in component Sep

and finished-product Oct

prices, cartrying inventory from one Nov

month to the next incurs a cost of 3 euros per phone per Dec

month. Skycell currently has a no-layoff policy in place'

overtime is limited to a maxiillum of 20 hours per month

per employee. Assume that Skycell has a starting inventory

of 50,000 units and wants to end tlee year with the same

level of inventorY.

a. Assuming no backlogs, no subcontracting,

and no new

hires, what is the optimum production schedule? What is

the annual cost of this schedule?

Is there any value for management to negotiate an

increase of allowed overtime per employ." p., month

from 20 hours to 40?

Reconsider parts (a) and (b) if Skycell srarts with only

1,200 employees.

Reconsider parts (a) and (b) if Skycell

starts with 1,300 employees.

what happens to the value of

additional overtime as the workforce size decreases?

consider part (a) for the case in which Skycell aims for a

level production

schedule such that the quantity produced

each month does not exceed the average demand over the

next 12 months (1 ,241,667) by 50,000 units. Thus, monthly production

including overtime should be no more than

1,291,667 . what would be the cost of this level production

schedule? what is the value of overtime flexibiity?

Demand

1000

1100

1000

1200

1500

1600

1600

900

1100

800

1400

1700

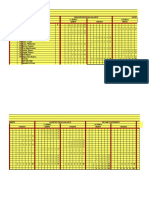

Period Hired workforce overtime Inventory Stochout subcontracts Production Demand

0

You might also like

- Assignment 1 Aggregate Planning ProblemsDocument4 pagesAssignment 1 Aggregate Planning ProblemsZiaNo ratings yet

- Skycell Cell Phone Production PlanningDocument3 pagesSkycell Cell Phone Production PlanningwillNo ratings yet

- DsvesrvceswcdsacDocument1 pageDsvesrvceswcdsacBagasNo ratings yet

- H L W O I S C P: ECLT5940/SEEM5880 Supply Chain Management These Problems Were Taken From Chapter 08 of The TextbookDocument4 pagesH L W O I S C P: ECLT5940/SEEM5880 Supply Chain Management These Problems Were Taken From Chapter 08 of The Textbookhilda isnani a.s100% (1)

- Monthly demand and production forecastDocument10 pagesMonthly demand and production forecastHau HuynhNo ratings yet

- Exercise Aggregate PlanningDocument1 pageExercise Aggregate PlanningIIMnotesNo ratings yet

- Homework 3Document1 pageHomework 3Nishtha KaushikNo ratings yet

- Exercise Solutions:: Chapter 8: Aggregate Planning in A Supply ChainDocument6 pagesExercise Solutions:: Chapter 8: Aggregate Planning in A Supply ChainSkyeNo ratings yet

- Case Study: Mintendo Game Girl: 1.decision VariablesDocument5 pagesCase Study: Mintendo Game Girl: 1.decision Variablesstevenwang0180% (1)

- Solver Aggregate Planning Example inDocument5 pagesSolver Aggregate Planning Example inGopichand AthukuriNo ratings yet

- Homework 2 Solutions for IE 3860 Spring 2014Document12 pagesHomework 2 Solutions for IE 3860 Spring 2014Eber Mancipe100% (1)

- Aggregate Planning: Demand ForecastDocument9 pagesAggregate Planning: Demand ForecastRashadafanehNo ratings yet

- Pom Sol 10Document5 pagesPom Sol 10amritranjan123_34249No ratings yet

- Mintendo Game GirlDocument2 pagesMintendo Game GirlZarak MirNo ratings yet

- Toys CaseDocument4 pagesToys Caseshashi_rajaNo ratings yet

- Aggregate Planning Classroom ProblemsDocument9 pagesAggregate Planning Classroom ProblemsDarwin FishNo ratings yet

- Ass 8 AnsDocument4 pagesAss 8 AnsAshish BhallaNo ratings yet

- Solutions of Chapter-5Document20 pagesSolutions of Chapter-5Puneet Mehta0% (2)

- Home Assignment - RevisedDocument4 pagesHome Assignment - RevisedLê Quỳnh Anh100% (1)

- Planeacion ProduccionDocument6 pagesPlaneacion ProduccionJimena OchoaNo ratings yet

- Month Demand January 1,000 February 1,100 March 1,000 April 1,200 May 1,500 June 1,600 July 1,600 August 900 September 1,100 October 800 November 1,400 December 1,700Document4 pagesMonth Demand January 1,000 February 1,100 March 1,000 April 1,200 May 1,500 June 1,600 July 1,600 August 900 September 1,100 October 800 November 1,400 December 1,700Sthepani7No ratings yet

- C6 - Aggregate Planning - ExcercisesDocument16 pagesC6 - Aggregate Planning - ExcercisesTÂM MAINo ratings yet

- ABC Monthly Demand ForecastDocument8 pagesABC Monthly Demand ForecastNita AnitasariNo ratings yet

- Tesco GSCMDocument6 pagesTesco GSCMadmbad2No ratings yet

- This Study Resource WasDocument6 pagesThis Study Resource WasTÂM MAINo ratings yet

- 1 Ch1 QuestionsDocument2 pages1 Ch1 QuestionsE100% (1)

- Group 6 - Aggregate Plan - Report - WordDocument11 pagesGroup 6 - Aggregate Plan - Report - WordNguyễn Bích NgọcNo ratings yet

- UnitronDocument9 pagesUnitronIvan Naufal PriadyNo ratings yet

- Monthly demand cellphones thousands optimizeDocument5 pagesMonthly demand cellphones thousands optimizePravina MoorthyNo ratings yet

- Assignment Sir Tariq QuesDocument4 pagesAssignment Sir Tariq QuesSahar Batool QaziNo ratings yet

- Heizerom10ism14 141023093356 Conversion Gate02Document19 pagesHeizerom10ism14 141023093356 Conversion Gate02WiRda BustamamNo ratings yet

- CASE Mintendo Game GirlDocument3 pagesCASE Mintendo Game Girlkenned220% (5)

- Sources/ $/ton Mile Tons Coordinates Markets: Buffalo Memphis St. Louis Atlanta Boston Jacksonville Philadelphia New YorkDocument2 pagesSources/ $/ton Mile Tons Coordinates Markets: Buffalo Memphis St. Louis Atlanta Boston Jacksonville Philadelphia New YorkNithya RathnaNo ratings yet

- Application of Marginal Costing in Decision Making-Questions Example 1: Make or BuyDocument3 pagesApplication of Marginal Costing in Decision Making-Questions Example 1: Make or BuyDEVINA GURRIAHNo ratings yet

- Exc CH 5Document34 pagesExc CH 5Syafiah Khairunnisa33% (3)

- Chapter 8 Answers To ExercisesDocument12 pagesChapter 8 Answers To ExercisesSaroj Kumar RaiNo ratings yet

- Business Exam SolutionsDocument15 pagesBusiness Exam SolutionsClement DonovanNo ratings yet

- Exercise-5 - Genta Yusuf Madhani - 1201174352 PDFDocument17 pagesExercise-5 - Genta Yusuf Madhani - 1201174352 PDFGentaYusufMadhaniNo ratings yet

- Operations Management FormulasDocument1 pageOperations Management FormulasNavi SinghNo ratings yet

- MECH 6076 Quiz II Supply Chain Modeling and OptimizationDocument3 pagesMECH 6076 Quiz II Supply Chain Modeling and OptimizationCostina Luc0% (1)

- RVC Assignment 1Document10 pagesRVC Assignment 1ynegiNo ratings yet

- Supply Chain ManagementDocument12 pagesSupply Chain ManagementRazib Razon100% (1)

- MPC Process Time Horizons and Phases ExplainedDocument9 pagesMPC Process Time Horizons and Phases ExplainedHuy TranNo ratings yet

- BUS 822 - Assignment-20 Aggregate PlanningDocument19 pagesBUS 822 - Assignment-20 Aggregate Planningcoolguys235No ratings yet

- Cool Wipes - Case Summary: AssumptionsDocument15 pagesCool Wipes - Case Summary: AssumptionsNeeraj SNo ratings yet

- Supply Chain Management (Sabirzianov Azat)Document12 pagesSupply Chain Management (Sabirzianov Azat)АзатNo ratings yet

- Chapter 3: Process and Capacity AnalysisDocument15 pagesChapter 3: Process and Capacity AnalysisAnugragha SundarNo ratings yet

- ACCT 505 Managerial Accounting - DevryDocument4 pagesACCT 505 Managerial Accounting - Devrychana980100% (5)

- Opdrag: Inhandigingsdatum:: Assignment: Submission DateDocument5 pagesOpdrag: Inhandigingsdatum:: Assignment: Submission DateVeronica NhlapoNo ratings yet

- MRP Chapter 14 ProblemsDocument3 pagesMRP Chapter 14 ProblemsRadinne Fakhri Al WafaNo ratings yet

- DocxDocument5 pagesDocxbbbbbNo ratings yet

- Chapter 9 Mintendo Game GirlDocument5 pagesChapter 9 Mintendo Game GirlANANG DWI CAHYADINo ratings yet

- Jones IronworksDocument1 pageJones Ironworkssachinrst100% (1)

- How government borrowing affects interest rates and investmentDocument2 pagesHow government borrowing affects interest rates and investmentMin Hsuan HsianNo ratings yet

- Case Study: Andrew–Carter, Inc. plant closure analysisDocument6 pagesCase Study: Andrew–Carter, Inc. plant closure analysisfer cags100% (2)

- TIET Patiala Department of Mechanical EngineeringDocument2 pagesTIET Patiala Department of Mechanical Engineeringkunal gargNo ratings yet

- BudgetDocument9 pagesBudgetDrBharti KeswaniNo ratings yet

- 30784rtpfinalnov2013 5Document0 pages30784rtpfinalnov2013 5kamlesh1714No ratings yet

- August 2007 CPPADocument19 pagesAugust 2007 CPPAAhmed Raza MirNo ratings yet

- A Capacity Planning Assignment 2016 Bassam Senior Modified SolutionDocument10 pagesA Capacity Planning Assignment 2016 Bassam Senior Modified SolutionAhmad Ayman FaroukNo ratings yet

- Egyptian Labour EconomicsDocument6 pagesEgyptian Labour EconomicsdrahmedneoNo ratings yet

- WHO Model List of Essential MedicinesDocument45 pagesWHO Model List of Essential MedicinesVarun HVNo ratings yet

- Assessment Criteria Key Questions Regarding Collected DataDocument1 pageAssessment Criteria Key Questions Regarding Collected DatadrahmedneoNo ratings yet

- Designing Great VisualizationsDocument17 pagesDesigning Great Visualizationsjuhaem100% (1)

- UW Health strategic plan refocus and renewDocument7 pagesUW Health strategic plan refocus and renewdrahmedneoNo ratings yet

- Data Visualization and The Rationalization of SeeingDocument13 pagesData Visualization and The Rationalization of SeeingdrahmedneoNo ratings yet

- Emotional Impact of Proximity Techniques in VisualizationDocument16 pagesEmotional Impact of Proximity Techniques in VisualizationdrahmedneoNo ratings yet

- Monitoring and Evaluation Training CurriculumDocument89 pagesMonitoring and Evaluation Training CurriculumdrahmedneoNo ratings yet

- Why Model? Insights from Joshua M. EpsteinDocument5 pagesWhy Model? Insights from Joshua M. EpsteinLautaro Simón Ramírez CifuentesNo ratings yet

- TB Important Topics For MRCPCH Part 1Document1 pageTB Important Topics For MRCPCH Part 1drahmedneoNo ratings yet

- The Model Thinker Prologue, Introduction and Chapter 1Document32 pagesThe Model Thinker Prologue, Introduction and Chapter 1sdenkaspNo ratings yet

- PonderDocument1 pagePonderdrahmedneoNo ratings yet

- UNHCR Medical Doctor PositionDocument2 pagesUNHCR Medical Doctor PositiondrahmedneoNo ratings yet

- Mercy Strategic PlanDocument8 pagesMercy Strategic PlandrahmedneoNo ratings yet

- Ahmed Mohamed Seliem ResumeDocument2 pagesAhmed Mohamed Seliem ResumedrahmedneoNo ratings yet

- Suggestions To Improve US Healthcare SystemDocument8 pagesSuggestions To Improve US Healthcare SystemdrahmedneoNo ratings yet

- Reading Reflections Chapter 1Document1 pageReading Reflections Chapter 1drahmedneoNo ratings yet

- Phase 2 German BakeryDocument16 pagesPhase 2 German BakerydrahmedneoNo ratings yet

- Reading Reflections Chapter 1Document1 pageReading Reflections Chapter 1drahmedneoNo ratings yet

- SCM ExamDocument9 pagesSCM ExamdrahmedneoNo ratings yet

- Water and Wastewater Technology: WATR 100 4.0 Units Wastewater Treatment I WATR 102 4.0 Units Sanitary ChemistryDocument2 pagesWater and Wastewater Technology: WATR 100 4.0 Units Wastewater Treatment I WATR 102 4.0 Units Sanitary ChemistryTarek Azziz LikhonNo ratings yet

- Special Services Invoice SummaryDocument1 pageSpecial Services Invoice SummaryTQ Home Services100% (1)

- Productivity, Efficiency and Economic Growth in Asia PacificDocument335 pagesProductivity, Efficiency and Economic Growth in Asia PacificZainudin Mohamed100% (1)

- Chapter 7 Problems: Problem #14 P. 7-57 Problem #15 P. 7-58Document3 pagesChapter 7 Problems: Problem #14 P. 7-57 Problem #15 P. 7-58Zyrene Kei ReyesNo ratings yet

- GBS750 Assignment 1Document7 pagesGBS750 Assignment 1Kasimba MwandilaNo ratings yet

- Kurt Weyland - The Rise of Latin America S Two Lefts Insights From Rentier State TheoryDocument20 pagesKurt Weyland - The Rise of Latin America S Two Lefts Insights From Rentier State TheorycacoNo ratings yet

- Ticketing HandbookDocument409 pagesTicketing HandbookRapsak50% (2)

- ABNT NBR 6330 2020 - General Purpose Carbon Steel Wire RodDocument12 pagesABNT NBR 6330 2020 - General Purpose Carbon Steel Wire RodElton Felipe Gularte dos SantosNo ratings yet

- Ukay-Ukay: The Philippine Culture As Sustainable FashionDocument11 pagesUkay-Ukay: The Philippine Culture As Sustainable FashionElNo ratings yet

- Producer Decision MakingDocument16 pagesProducer Decision Makingteme beyaNo ratings yet

- Relevant CostingDocument5 pagesRelevant CostingBeatriz Basa DimainNo ratings yet

- Digital Marketing Freelance OpportunitiesDocument1 pageDigital Marketing Freelance OpportunitiesSandeep JainNo ratings yet

- Research Project On Kross CycleDocument18 pagesResearch Project On Kross CycleRAJAN SINGHNo ratings yet

- A Detail Study On Implementation of Green Technology and Reverse Manufacturing Methods in Plastic Molding IndustryDocument7 pagesA Detail Study On Implementation of Green Technology and Reverse Manufacturing Methods in Plastic Molding IndustryInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Exercise No. 1:: Required: Journal Entries Using Two Methods of Recording Stock TransactionsDocument4 pagesExercise No. 1:: Required: Journal Entries Using Two Methods of Recording Stock TransactionsCarlos ReyesNo ratings yet

- BASF Catalysts - Leveraging Innovation to Serve Growing MarketsDocument18 pagesBASF Catalysts - Leveraging Innovation to Serve Growing Marketsccnew3000No ratings yet

- Prakas On Construction License - CambodiaDocument4 pagesPrakas On Construction License - CambodiaVP SadokaNo ratings yet

- C. Castro Company-Cdc 2018Document42 pagesC. Castro Company-Cdc 2018Gennelyn Lairise Rivera100% (1)

- Chapter 1Document94 pagesChapter 1Narendran SrinivasanNo ratings yet

- Understanding Supply Chain Finance (SCF)Document5 pagesUnderstanding Supply Chain Finance (SCF)ranga.ramanNo ratings yet

- A Project Report On The Study of Consumer Satisfaction: Submitted ToDocument35 pagesA Project Report On The Study of Consumer Satisfaction: Submitted ToAshuNo ratings yet

- Auditing IDocument58 pagesAuditing IBereket DesalegnNo ratings yet

- Create Invoice correction requestDocument7 pagesCreate Invoice correction requestdeepali ahireNo ratings yet

- TaxonomyDocument9 pagesTaxonomyMauricio KlasserNo ratings yet

- Bescom ProjectDocument62 pagesBescom ProjectRakeshNo ratings yet

- Design and Manufacturing of Zig-Zag Bar Bending MachineDocument58 pagesDesign and Manufacturing of Zig-Zag Bar Bending MachineSachin T100% (1)

- Auditing Theory Test Bank Escala - pdf-14-18Document5 pagesAuditing Theory Test Bank Escala - pdf-14-18randomlungs121223No ratings yet

- A Study of Consumers Behaviour Related To KTMDocument8 pagesA Study of Consumers Behaviour Related To KTMDiganta DaimaryNo ratings yet

- True False True: Stockholders' EquityDocument3 pagesTrue False True: Stockholders' EquityOMAYOMAYNo ratings yet

- Store Keeper Cover LetterDocument7 pagesStore Keeper Cover Letterfsv74mkj100% (1)