Professional Documents

Culture Documents

Ale Et Al-Trends of LSDS Strength Results LLDPE-HDPE-paper-rev.b

Uploaded by

Jose Ale0 ratings0% found this document useful (0 votes)

74 views12 pagesThe mining industry is developing at a fast pace in the South America region. A geotechnical characterization of the geomembrane-soil interface must be conducted. Results show a consistent trend in the residual shear strength envelops of different types of geomembranes.

Original Description:

Original Title

Ale Et Al-trends of LSDS Strength Results LLDPE-HDPE-paper-rev.b

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe mining industry is developing at a fast pace in the South America region. A geotechnical characterization of the geomembrane-soil interface must be conducted. Results show a consistent trend in the residual shear strength envelops of different types of geomembranes.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views12 pagesAle Et Al-Trends of LSDS Strength Results LLDPE-HDPE-paper-rev.b

Uploaded by

Jose AleThe mining industry is developing at a fast pace in the South America region. A geotechnical characterization of the geomembrane-soil interface must be conducted. Results show a consistent trend in the residual shear strength envelops of different types of geomembranes.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 12

1

Trends of Large Scale Direct Shear Strength Results for

LLDPE-HDPE Geomembrane/Soil Interfaces

Jos Ale; MSc., AMEC, Peru*

jose.ale@amec.com, +51-989806112

Martn Rodriguez; MSc., AUSENCO, Peru

Claudio Romn, AMEC, Chile

Humberto F. Preciado; PhD., P.E., AMEC, Peru

Marsy Sanchez, AMEC, Peru

Abstract

The mining industry is developing at a fast pace in the South America region, and demands the

construction of important and larger mining structures such as: tailings impoundments, heap leach pads,

rock waste facilities, etc. Heap leach pads by design, must contain leached mineral solutions through

properly designed engineered liner systems. As part of the geotechnical design of a heap leach pad, a

geotechnical characterization of the geomembrane-soil interface must be conducted. This characterization

is performed by large scale direct shear (LSDS) testing, using confinement pressures which simulate the

weight of the ore stacking in the leach pad. The type of geomembrane mainly used in the mining industry

is the high and linear low density polyethylene (HDPE and LLDPE, respectively), single side textured

(SST), and of variable thickness (1.5 and 2.0 mm, mostly).

Many authors have studied the response of geomembrane-soil interface (Koener et al., 2005;

Koerner et al. 2007; Thiel, 2009; Parra et al., 2010), and analyzed their strength envelopes considering

linear and nonlinear geometries (Parra et al., 2012). This paper compiles LSDS test results performed in

Peru, and other data available in the existing literature, and analyzes their trends and range of values.

Results from HDPE and LLDPE single side textured geomembranes are presented, with the textured side

in contact with the underlying soil, and using confinement pressures of up to 800 kPa, which are

equivalent to about 45 meters of ore stacking. The results show a consistent trend in the residual shear

strength envelops of different types of geomembranes, regardless of gradation of the soil. For high

pressures, this trend could be non-linear. In the low pressures interval, the values of adhesion range from

10 to 40 kPa, and angles of internal friction range from 11 to 21 for HDPE interfaces, and adhesion

between 10 and 35 kPa, and angles of internal friction between 15 and 29 for LLDPE interfaces.

Additionally, the shear strength values of the interface are higher in geomembrane samples manufactured

in recent years, potentially indicating an upward trend based on improvements in polymer technology.

Formatted: Indent: Left: 0", Hanging: 0.59"

Field Code Changed

2

Introduction

The mining industry is developing at a fast pace in the South America region, and demands the

construction of important and larger mining structures such as: tailings impoundments, heap leach pads,

rock waste facilities, etc. The correct geotechnical design of these structures is extremely important due to

their large size and the implications deriving from their potential failure,

Heap leach pads by design, must contain leached mineral solutions through properly designed

engineered liner systems. The proper design of these systems requires proper characterization of the

interface strength properties between geomembrane and soil. This characterization is performed by large

scale direct shear (LSDS) testing, using confinement pressures which simulate the weight of the ore

stacking in the leach pad.

This paper describes the geotechnical design of a heap leach pad with emphasis on the liner

system design, which covers laboratory testing and geotechnical analysis.

Since these structures are very important due to their large size and their susceptibility in case of failure, it

is necessary to develop a detailed geotechnical design.

Heap leach pads by design, must contain leached mineral solutions through properly designed engineered

liner systems. This paper describes the design from the geotechnical point of view of a heap leach pad

with emphasis in the liner system design, which covers laboratory testing and geotechnical analysis.

Heap Leach Geotechnical Design

The geotechnical design of a heap leach pad includes the completion of many geotechnical analysis and

characterizations of the materials which include: slope stability and stress-strain.

The slope stability analysis is performed considering circular, non-circular and translational slip

surfaces. The circular and non-circular slip surface analyses evaluate stability associated with

homogeneous and non-homogeneous soil conditions, respectively. Translational or compound slip surface

analyses evaluate the possibility of landslides through the liner system of the leach pad.

The stress-strain analysis is usually required when the factor of safety of slope stability analysis

has a low value, either static or seismic conditions.

The geotechnical design of a heap leach pad includes the completion of many geotechnical analysis and

characterizations of the materials which form part of this important structure.

The geotechnical analyses performed generally are slope stability and stress-strain. The slope

stability analysis is performed considering circular and non-circular slip surfaces. The non-circular

analysis evaluates the possibility of landslides through the liner system of the leach pad.

Comment [h1]: Aqu podramos hablar de casos

de fallas que se han dado por interface en algunos

proyectos y que resalte la importancia de una

apropiada caracterizacin.

Formatted: Heading 1

Formatted: Normal

3

Liner System of Heap Leach Pad

In South AmericaPeru, the heap leach pads usually have usually a conventional liner system, consisting of

a soil liner (low permeability soil) covered by a geomembrane which in turn is covered by a gravelly

material (overliner) as shown in Figure 1.

The soil liner has to be clayey and its hydraulic conductivity must be less than 5x10

-6

cm / s. The

geomembrane is commonly made of polyethylene of high and low density (HDPE and LLDPE,

respectively). These structures usually use geomembrane of a textured side and a smooth side (single side

textured, SST), where the textured side faces the clay soil liner and the smoth side faces the gravelly over

liner material.. The gravelly material generally has to have draining characteristics, and should not punch

the liner under confinement, which can reach pressures up to 4000 kPa.

Figure 1: Conventional Liner System

In cases where there is no clay material or where this cannot be placed (steep slopes), soil liner

can be replaced by a geosynthetic material calledclay liner (GCL), as shown in Figure 2. The GCL

consists of a layer of bentonite confined by two layers of geotextile (woven or nonwoven). This

geocomposite has a hydraulic conductivity of about 10

-9

cm / s.

Figure 2: GCL Liner System

Formatted: Centered

4

Geotechnical Characterization of Liner System

General

This paper will focus on the geotechnical characterization of the first type of lining mentioned in the

previous section.conventional liner system. In this type of lining liner, can be seen that there are two

interfaces: geomembrane/soil-liner and geomembrane/overliner. Many authors have studied the behavior

of geosynthetic interfaces (Koener et al., 2005; Koerner et al. 2007; Thiel, 2009; Parra et al., 2010) and

analyzed their linear and nonlinear geometry (Parra et al ., 2012). However

Geomembrane/Soil Interfaces Analyses

In the case of a heap leach pad, the geotechnical characterization of the interfaces is carried out by

performing direct shear tests on a large scale box, following the methodology of ASTM 5321 standard.

These tests can be performed including all the materials that form the lining system: gravelly material,

geomembrane and clayey soil. The shear strength values obtained by this test depend of on the resistance

values of the geomembrane/gravel and geomembrane/clay interfaces (two variables).

Parra et al. (2010) studied the difference of values of the large scale direct shear (LSDS) test

results considering the presence and the absentce of a gravelly material (overliner) on the geomembrane.

In the test, the overliner which must be in contact with the smooth side of the geomembrane was replaced

by rigid substrata (concrete). The results of this comparison for the case of an LLDPE geomembrane

showed that is more conservative consider the presence of a rigid substrata, as shown in Figure 3.

Figure 3: LSDS tests performed with Overliner and Rigid Substrata (Parra et al.,

2010)

Formatted: Highlight

Formatted: Highlight

5

Figure 4: LSDS tests performed with Overliner and Rigid Substratain Geomembrane

- Overliner and Geomembrane - Soil Liner Interfaces

Furthermore, comparing independently the results of LSDS test of the interfaces of the liner

system, it can be seen that the interface geomembrane/overliner (over the smooth side) has more shear

strength than the interface geomembrane/soil liner (in contact to the textured side) for the same LLDPE

1.5 mm geomembrane (Ale et al, 2010), as can be shown in Figure 4.

0

50

100

150

200

250

300

350

400

0 200 400 600 800

R

e

i

d

u

a

l

S

h

e

a

r

S

t

r

e

n

g

t

h

(

k

P

a

)

Normal Stress (kPa)

GM (smooth side) - Overliner

GM (textured side) - Soil Liner (SC)

GM (textured side) - Soil Liner (SC)

0

50

100

150

200

250

300

350

400

0 200 400 600 800

R

e

s

i

d

u

a

l

S

h

e

a

r

S

t

r

e

n

g

t

h

(

k

P

a

)

Normal Stress (kPa)

GM (smooth side) - Overliner

GM (textured side) - Soil Liner (SC)

GM (textured side) - Soil Liner (SC)

Formatted: Font: (Default) Tw Cen MT, Bold,

English (U.S.), Expanded by 0.25 pt

Formatted: Highlight

6

From this, the geotechnical characterization and shear strength of the liner system of a heap leach

pad depends of geomembrane/clay interface.

Review of LSDS Test Results

In the geotechnical design of a heap leach pad, the physical stability of the structure must be analyzed. In

the common practice, the slope stability analysis considering a non- circular sliding surface (through the

liner system) uses the residual values of the LSDS test in geomembrane-soil liner interface.

Taking into consideration this, results from 83 LSDS tests have been analyzed for LLDPE and

HDPE geomembranes, of 1.5 mm and 2.0 mm thick. All of these tests have been conducted in interfaces

with soil liner (clayey material). A compilation of the results of these tests is plotted in Figures 5, 6, 7 and

8. Table 1 shows the average trend of strength parameters of the plotted data, also, the upper and lower

boundaries for shear strength values, are shown.

These results are consistent with those reported by Koerner et al. (2005)..

As Koerner et al. (2005) showed, the friction angle values at interfaces of HDPE and LLDPE are

similar, which is confirmed in Table 1.

Figure 5: LSDS tests in LLDPE geomembrane, 2mm (residual values)

0

50

100

150

200

250

300

350

400

450

0 100 200 300 400 500 600 700 800

R

e

s

i

d

u

a

l

S

h

e

a

r

S

t

r

e

n

g

t

h

(

k

P

a

)

Normal Stress (kPa)

Adhesion = 27.9 kPa

Friction Angle = 19.2

R

2

= 0.82

Formatted: Font: Highlight

Formatted: Font: Highlight

Comment [h2]: Algo de diferencia que resaltar?

O solo confirma lo publicado por Koerner

Formatted: Font: (Default) Tw Cen MT, Bold,

Expanded by 0.25 pt, Highlight

7

Figure 6: LSDS tests in LLDPE geomembrane, 1.5mm (residual values)

Figure 7: LSDS tests in HDPE geomembrane, 2mm (residual values)

0

50

100

150

200

250

300

350

400

0 100 200 300 400 500 600 700 800

R

e

s

i

d

u

a

l

S

h

e

a

r

S

t

r

e

n

g

t

h

(

k

P

a

)

Normal Stress (kPa)

Adhesion = 24.4 kPa

Friction Angle = 15.8

R

2

= 0.79

0

50

100

150

200

250

300

350

400

450

0 100 200 300 400 500 600 700 800

R

e

s

i

d

u

a

l

S

h

e

a

r

S

t

r

e

n

g

t

h

(

k

P

a

)

Normal Stress (kPa)

Adhesion = 35.0 kPa

Friction Angle = 22.1

R

2

= 0.84

8

Figure 8: LSDS tests in HDPE geomembrane, 1.5mm (residual values)

The available data from LSDS tests in HDPE geomembranes are much less than those from

LLDPE ones, because in the recent times, use of LLDPE geomembrane is has been more recommended

by designerswidespread due to. For this reason, the values data shown in Table 1, those offor

LLDPE (75 tests) are may be more reliable representative than those of HDPE (8 tests). Figure 9 shows

all values listed in Table 1.

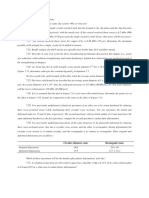

Table 1: Trends of Shear Strength Parameters from LSDS tests

Geomembrane

Shear Strength Parameters

Average Maximum Minimum

Adhesio

n

(kPa)

Friction

Angle ()

Adhesio

n

(kPa)

Friction

Angle ()

Adhesio

n

(kPa)

Friction

Angle ()

LLDPE, 2.0 mm 27.9 19.2 34.0 24.0 15.0 15.0

LLDPE, 1.5 mm 24.4 15.8 35.0 20.0 15.0 12.0

0

50

100

150

200

250

300

350

400

0 100 200 300 400 500 600 700 800

R

e

s

i

d

u

a

l

S

h

e

a

r

S

t

r

e

n

g

t

h

(

k

P

a

)

Normal Stress (kPa)

Adhesion = 45.7 kPa

Friction Angle = 17.3

R

2

= 0.88

9

HDPE, 2.0 mm 35.0 22.1 40.0 26.0 26.0 19.0

HDPE, 1.5 mm 45.7 17.3 53.0 19.0 35.0 16.0

Figure 9: Trends of Shear Strength Parameters from LSDS tests

Influence of Shear Strength of Liner System in theon Slope Stability

In order to analyze the influence of shear strength of interfaces in on the physical stability of a heap leach

pad, a hypothetic case is conducted by limit equilibrium method (Spencer method), considering a heap

height of 100 m, and the slope of liner system varying between 0% and 4%, as shown in Figure 910. The

analyses were performed inputting average, maximum and minimum shear strength parameters for a

LLDPE geomembrane of 2 mm thick. Table 2 summarizes the results of all of these analyses.

0

5

10

15

20

25

30

0 10 20 30 40 50 60

Adhesion

Friction Angle

LLDPE, 2.0 mm

LLDPE, 1.5 mm

HDPE, 2.0 mm

HDPE, 1.5 mm

LLDPE average

HDPE average

Formatted: Centered

10

Figure 109: Hypothetic Heap Leach Analyzed

Table 2: Factors of Safety for Slope Stability in using 2 mm LLDPE Geomembrane, 2

mm

Slope

Shear Strength Parameters

Average Maximum Minimum

Factor of Safety Factor of Safety Factor of Safety

0% 1.73 1.93 1.52

1% 1.71 1.89 1.51

2% 1.70 1.88 1.49

3% 1.69 1.87 1.46

4% 1.67 1.86 1.45

Conclusions

From this article, the following conclusions can be obtained.

The shear strength of the smooth-side-geomembrane/overliner interface is larger than that of the

textured-side-geomembrane/soil-liner interface.

The physical stability in the block-slip surface or translational failure mode of the heap leach pad

depends on the shear strength of the interface geomembrane/soil-liner rather than the

geomembrane/overliner interface.

The LLDPE geomembranes are the most recommended by designers in recent times.

The residual values of shear strength from LSDS tests, are commonly used in the geotechnical

characterization of the liner system.

Formatted: Font: 11 pt, Not Bold, Font color:

Auto, Highlight

Formatted: Font: 11 pt, Not Bold, Font color:

Auto, Highlight

Formatted: Highlight

Formatted: Font: 11 pt, Not Bold, Font color:

Auto, Highlight

11

All correlation coefficients have acceptable values, 0.82, 0.79, 0.84 and 0.88 for geomembranes

of 2mm-LLDPE, 1.5mm-LLDPE, 2mm-HDPE, and 1.5mm-HDPE, respectively.

The residual shear strength of 2mm-LLDPE geomembrane varies from 15 to 34 kPa in adhesion

and from 15 to 24 in friction angle. The average shear strength parameters are adhesion of 27.9 kPa and

friction angle of 19.2.

The residual shear strength of 1.5mm-LLDPE geomembrane varies from 15 to 35 kPa in adhesion

and from 12 to 20 in friction angle. The average shear strength parameters are adhesion of 24.4 kPa and

friction angle of 15.8.

The residual shear strength of 2mm-HDPE geomembrane varies from 26 to 40 kPa in adhesion

and from 19 to 26 in friction angle. The average shear strength parameters are adhesion of 35 kPa and

friction angle of 22.1.

The residual shear strength of 1.5mm-HDPE geomembrane varies from 35 to 53 kPa in adhesion

and from 16 to 19 in friction angle. The average shear strength parameters are adhesion of 45.7 kPa and

friction angle of 17.3.

In a hypothetic case of a heap leach pad of 100 m height, the factors of safety varies between 1.67

and 1.73 in static conditions for average shear strength parameters with a variation of the slope of liner

system from 0% and 4%.

References

Ale, J., Clari, J. and Bonalumi, A. (2010). Diseo Geotcnico de Pilas de Lixiviacin. Proceedings of Congreso Argentino de

Mecnica de Suelos e Ingeniera Geotcnica 2010, Mendoza, Argentina.

xxx

ASTM D 5321. Standard test method for determining the coefficient of soil and geosynthetic or geosynthetic and geosynthetic

friction by the direct shear method. American Society for Testing and Materials, West Conshohocken, Pennsylvania,

USA.

Koerner, R.M. and Koerner G.R. (2005). Direct shear database of geosynthetic-to-geosynthetic and geosynthetic-to-soil

interfaces. GRI Report #30, Geosynthetic Institute 475 Kedron Avenue Folsom, PA 19033 USA.

Koerner, R.M. and Koerner G.R. (2007). Interpretation(s) of laboratory generated interface shear strength data. GRI White Paper

#10, Geosynthetic Institute 475 Kedron Avenue Folsom, PA 19033 USA.

Parra, D., Soto, C. and Valdivia, R. (2010). Soil liner-geomembrane interface shear strength using rigid substrata or overliner.

Proceedings of 9th International Conference in Geosynthetic, pp. 747-750.

Parra, D., Valdivia, R. And Soto, C. (2012).Parra xxxx Analysis of shear strength non-linear envelopes of soil-geomembrane

interface and its influence in the heap leach pad stability. Proceedings of Second Pan American Geosynthetics

Conference & Exhibition GeoAmericas 2012, Lima, Peru.

Thiel, R. (2009). Cohesion (or adhesion) and friction angle in direct shear tests.

Formatted: Font: 11 pt, Not Bold, Font color:

Auto, Highlight

Formatted: Font: 11 pt, Not Bold, Font color:

Auto, Highlight

Formatted: Spanish (Peru)

Formatted: Reference, Left, Indent: Left: 0",

Hanging: 0.59"

Formatted: English (U.S.)

Formatted: Spanish (Peru)

Formatted: Font: Italic

Formatted: Spanish (Peru)

Formatted: Font: (Default) Times New Roman,

Spanish (Peru)

Formatted: Spanish (Peru)

Formatted: Font: 9 pt, Italian (Switzerland)

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Not Bold

Formatted: Font: 9 pt, Italic

Formatted: Font: 9 pt

Formatted: Font: 9 pt

Formatted: Reference, Line spacing: single,

Pattern: Clear

Formatted: Font: Times New Roman, 9 pt,

Font color: Auto

Formatted: Font: Times New Roman, 9 pt,

Bold, Font color: Auto

12

xxx

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Anchorbolt (318 08)Document26 pagesAnchorbolt (318 08)Anonymous 9MDGo2jNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Design of Plate Girders As Per IS 800 2007-LSM - Unsupported - LatestDocument30 pagesDesign of Plate Girders As Per IS 800 2007-LSM - Unsupported - Latestmehdihasan80% (5)

- Properties of C-Purlins Adopted From Aisc Steel Construction Manual 13Th EditionDocument51 pagesProperties of C-Purlins Adopted From Aisc Steel Construction Manual 13Th EditionD MNo ratings yet

- Concrete Industrial Ground Floor Design To Tr34 Third EditionDocument2 pagesConcrete Industrial Ground Floor Design To Tr34 Third Editionadera1100% (1)

- Anchor Bolt and Shear Key DesignDocument3 pagesAnchor Bolt and Shear Key DesignsvgkraoNo ratings yet

- IS 4880-1 (1987) Code of Practice For Design of Tunnels Conveying Water, General DesignDocument7 pagesIS 4880-1 (1987) Code of Practice For Design of Tunnels Conveying Water, General DesignAlok Kumar0% (1)

- Canadian Foundation Engineering Manual 4th EdDocument503 pagesCanadian Foundation Engineering Manual 4th EdClaudia GonzalezNo ratings yet

- Irc SP.114.2018Document146 pagesIrc SP.114.2018Anonymous YHcvra8Xw6No ratings yet

- Science 10: Quarter 1 Earthquake EpicentersDocument24 pagesScience 10: Quarter 1 Earthquake Epicentersjelly marie flores100% (2)

- Rock Mass Characterization by High-Resolution SoniDocument17 pagesRock Mass Characterization by High-Resolution SoniJose AleNo ratings yet

- Best Practice and New Technology in Core Drilling, Logging and Fracture AnalysisDocument8 pagesBest Practice and New Technology in Core Drilling, Logging and Fracture AnalysisUnurbayar EnkhbaatarNo ratings yet

- Best Practice and New Technology in Core Drilling, Logging and Fracture AnalysisDocument8 pagesBest Practice and New Technology in Core Drilling, Logging and Fracture AnalysisUnurbayar EnkhbaatarNo ratings yet

- Two-Dimensional Non-Linear Dynamic Response of A Heap Leach Pad Located in Peru Perez & AleDocument6 pagesTwo-Dimensional Non-Linear Dynamic Response of A Heap Leach Pad Located in Peru Perez & AleJose AleNo ratings yet

- Characterization of Old Tailings Under Unsaturated Conditions AbstractDocument1 pageCharacterization of Old Tailings Under Unsaturated Conditions AbstractJose AleNo ratings yet

- Characterization of Old Tailings Under Unsaturated Conditions AbstractDocument1 pageCharacterization of Old Tailings Under Unsaturated Conditions AbstractJose AleNo ratings yet

- Dearman1974-Weathering Classification in The Characterisation of Rock For Engineering PurposesDocument10 pagesDearman1974-Weathering Classification in The Characterisation of Rock For Engineering PurposesJose AleNo ratings yet

- Geotechnical Characterization of Unsaturated Old Tailings For A Mining Plan Design - AbstractDocument1 pageGeotechnical Characterization of Unsaturated Old Tailings For A Mining Plan Design - AbstractJose AleNo ratings yet

- 16cyp - Abstract - Slope Design in An Open Pit Within A Tailings Storage Fac..Document2 pages16cyp - Abstract - Slope Design in An Open Pit Within A Tailings Storage Fac..Jose AleNo ratings yet

- Duklet1980-An Empirical Correlation To Predict Diamond Bit Drilling RatesDocument7 pagesDuklet1980-An Empirical Correlation To Predict Diamond Bit Drilling RatesJose AleNo ratings yet

- Ale Et Al-Trends of LSDS Strength Results LLDPE-HDPE-paper-rev.bDocument12 pagesAle Et Al-Trends of LSDS Strength Results LLDPE-HDPE-paper-rev.bJose AleNo ratings yet

- SPT Con Arcillas y LimosDocument4 pagesSPT Con Arcillas y LimosJose AleNo ratings yet

- Expansive Soils Engineering Geological Mapping: Applied Method in Clayey Soils of Montevideo, UruguayDocument8 pagesExpansive Soils Engineering Geological Mapping: Applied Method in Clayey Soils of Montevideo, UruguayJose AleNo ratings yet

- Ale Et Al-Trends of LSDS Strength Results LLDPE-HDPE-paper-rev.bDocument12 pagesAle Et Al-Trends of LSDS Strength Results LLDPE-HDPE-paper-rev.bJose AleNo ratings yet

- Fracture Analysis of Wind Turbine Main Shaft: Engineering Failure Analysis December 2013Document12 pagesFracture Analysis of Wind Turbine Main Shaft: Engineering Failure Analysis December 2013FOOTBALL CRICKETNo ratings yet

- Numerical Evaluation of Damage Distribution Over A Slat Track Using Flight Test DataDocument9 pagesNumerical Evaluation of Damage Distribution Over A Slat Track Using Flight Test Datareek_bhatNo ratings yet

- CE6102 - 5 - Application of Newton Raphson Techniques To Elasto-Plastic Model With Constant Yield SurfacesDocument9 pagesCE6102 - 5 - Application of Newton Raphson Techniques To Elasto-Plastic Model With Constant Yield SurfacesandreashendiNo ratings yet

- Fatigue in Bamboo 2015Document6 pagesFatigue in Bamboo 2015Arifin Beddu TjandoNo ratings yet

- Amadei - Importance of Anisotropy When Estimating and Measuring In0-Situ Stresses in RockDocument33 pagesAmadei - Importance of Anisotropy When Estimating and Measuring In0-Situ Stresses in RockgianniorlatiNo ratings yet

- Volume Loss in Shallow TunnellingDocument14 pagesVolume Loss in Shallow TunnellingAida RafrinNo ratings yet

- Stability of Slender Columns PDFDocument70 pagesStability of Slender Columns PDFmagdy bakryNo ratings yet

- Design of Pile Foundation A Project RepoDocument67 pagesDesign of Pile Foundation A Project RepoSiddharth MoteriyaNo ratings yet

- Module 1 Assignment Questions PDFDocument5 pagesModule 1 Assignment Questions PDFSaravanakumar PNo ratings yet

- Lectures40 41 AnnotatedDocument29 pagesLectures40 41 AnnotatedBharath NallaNo ratings yet

- Prayer Room & Guard Room Structure With CalculationDocument42 pagesPrayer Room & Guard Room Structure With CalculationNazrinNo ratings yet

- Soil MechanicsDocument42 pagesSoil MechanicsbentapadaNo ratings yet

- Proceedings of The First PRC-US W Orkshop On Seismic Analysis and Design of Special BridgesDocument291 pagesProceedings of The First PRC-US W Orkshop On Seismic Analysis and Design of Special BridgesjbNo ratings yet

- Assignment 6 2023Document2 pagesAssignment 6 2023Linhan ChuNo ratings yet

- Design of RC Membrane ElementsDocument11 pagesDesign of RC Membrane ElementsRodain NajjarNo ratings yet

- Lecture-7-Practical Design To Eurocode 2Document71 pagesLecture-7-Practical Design To Eurocode 2jcunha4740No ratings yet

- Yield Line Analysis - 1Document19 pagesYield Line Analysis - 1Ahmed NabilNo ratings yet

- Analysis of ColumnDocument42 pagesAnalysis of ColumnJMANo ratings yet

- Geosynthetics Types and ApplicationsDocument50 pagesGeosynthetics Types and Applicationscivil vlits100% (1)

- Strength Evaluation of Interior Slab-Column Connections: Aci Structural Journal Technical PaperDocument9 pagesStrength Evaluation of Interior Slab-Column Connections: Aci Structural Journal Technical PaperangthiankongNo ratings yet

- Extracted Pages From Design of Steel Portal Frames For EuropeDocument1 pageExtracted Pages From Design of Steel Portal Frames For EuropeMoussaàb RedaouniaNo ratings yet