Professional Documents

Culture Documents

Mix Design by Is Code

Uploaded by

Abhilash PillaiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mix Design by Is Code

Uploaded by

Abhilash PillaiCopyright:

Available Formats

Introduction

The concrete is widely used construction material. The main ingredient of the concrete is cement,

aggregates, water and admixtures. Due to the varying properties of the materials used in

concrete, the design of concrete is not an easy task. The various methods of mix design are

applied for determining the qualities & quantity of concrete. The objective of designing a mix is

to produce a concrete of required strength, durability and workability as economically as

possible. In our country, generally Indian Standard Institution (ISI) concrete design method is

preferred and hence has been discussed. The use of Indian standard institution (ISI) concrete

design method is illustrated with the aid of an example.

The selection of suitable ingredients of concrete and determining their relative amounts with the

objective of producing a concrete of the required, strength, durability, and workability as

economically as possible, is termed the concrete mix design. The proportioning of constituents of

concrete is governed by the performance of concrete in the plastic and the hardened states. The

concrete cannot be properly placed and compacted if the plastic concrete is not workable.

The compressive strength of hardened concrete depends upon many factors, e.g. quality and

quantity of cement, water and aggregates; batching and mixing; placing, compaction and curing.

The actual cost of concrete is related to the cost of materials required for producing a minimum

mean strength called characteristic strength which is specified by the structure engineer. This

depends on the quality control measures, but it is a fact that the quality control adds to the

concrete cost. The extent of quality control is often an economic compromise, and depends on

the size and type of job. The cost of labor depends on the workability of mix, e.g., a concrete mix

of inadequate workability may result in a high cost of labour to obtain a degree of compaction

with available equipment. So it is obligatory to resort to mix design for high rise/ strength

structures.

Requirements of Concrete Mix Design

The requirements which form the basis of selection and proportioning of mix ingredients are:

a)The minimum compressive strength required from structural point of view.

b) The adequate workability necessary for full compaction

c) Maximum water-cement ratio and/or maximum cement content to give adequate durability for

site conditions

d) Maximum cement content to avoid shrinkage cracking due to temperature in mass concrete.

Factors Affecting the Choice of Mix Proportions

The various factors affecting the mix design are:

Compressive Strength

It is one of the most important properties of concrete and influences many other

describable properties of the hardened concrete. The mean compressive strength required

after 28 days, determines the nominal water-cement ratio of the mix. The other factor

affecting the strength of concrete are age, cured and degree of compaction.

Workability

The degree of workability required depends on three factors i.e. size of the section, the

amount of reinforcement, and the method of compaction to be used. For the narrow and

complicated section with numerous corners or inaccessible parts, the concrete must have

a high workability so that full compaction can be achieved.

Durability

The durability of concrete is its resistance to the aggressive environmental conditions.

High strength concrete is generally more durable as compared to low strength concrete.

When the high strength is not required but the conditions of exposure are severe in such

situations, high durability is vital. To meet the durability requirement, the mix design is

the necessity.

Maximum nominal size of aggregate

The compressive strength tends to increase with the decrease in size of aggregate whereas

the workability of concrete increases with increase in maximum size of the aggregate

Grading and type of aggregate

The grading of aggregate influences the mix proportions for a specified workability and

water-cement ratio. Coarser the grading, leaner will be mixed which can be used. An

important feature of a satisfactory aggregate is the uniformity of the grading which can be

achieved by mixing different size fractions.

Quality Control

The degree of control can be judged statistically by the variations in test results. The

variation in strength results is due to lack of control of accuracy in batching, mixing,

placing, curing and testing. The lower the difference between the mean and minimum

strengths of the mix lower will be the cement-content required. The factor controlling this

difference is called as quality control.

Mix Proportion designations

The common method of expressing the proportions of ingredients of a concrete mix is in

the terms of parts or ratios of cement, fine and coarse aggregates e.g. a concrete mix of

proportions 1:2:4 means that the mix contains one part of cement, two parts of fine

aggregate and four parts of coarse aggregate. The proportions are either by volume or by

mass. The water-cement ratio is usually expressed in mass.

Information Required For Mix Design

For the design of concrete mix, the following information is required:

Grade of concrete

Degree of workability

Maximum temperature of fresh concrete

Type of cement

Minimum cement content

Maximum water cement ratio

Type of aggregates

Maximum nominal size of aggregate

Type of admixtures, if required

Level of quality assurance

Exposure condition

Method of placing

Degree of supervision

Target mean strength of concrete:-

In order that not more than the specified proportion of test result are likely to fall below the

characteristic strength, the concrete mix has to be proportioned for higher target mean

compressive strength f

ck

. The margin over characteristic strength is given by the following

relation

f

ck =

f

ck +

1.65 s

Where

f

ck=

target mean compressive strength at 28 days in N/mm

2

f

ck

= characteristic compressive strength at 28 days in N/mm

2

s= standard deviation (whose value is obtained from table 1 as per IS 10262:2009)

Selection of water cement ratio:-

From Figure 1 of IS: 10262-1982, the free water cement ratio required for the target mean strength can be

obtained.

Input Parameters

C1. Design Stipulation:

i.

Characteristics Compressive

Strength = 30 N/mm2

ii. Maximum Size of Aggregate = 20 mm

iii. Type of Aggregate = Angular

iv. Degree of quality = Good

v. Type of exposure = Extreme

vi. Slump = 100mm

C2. Test data for Materials

(i) Specific gravity of cement = 3.00

(ii) Specific gravity

Fine aggregate = 2.80

Coarse aggregate = 2.61

(iii) Cement used = OPC 43

(iv) Superplasticizer added = 0.40%

(iv)

Water Content Reduction due to

Superplasticizer = 17%

(v)

Fine aggregate confirming the table

4, IS 383 zone = 2

C3. Target mean strength

= 26.6N/mm2

C4. Water Cement ratio

= 0.29146465

From fig 1.IS

10262-1982

RESULT

Quantity of Concrete = 1 cubic meter

GRADE OFCONCRETE M20

GRADE OF CONCRETE M25

GRADE OF CONCRETE M30

Sr.

No

Material Name Without Superplasticizer With Superplasticizer

1 Cement (kg) 368 368

2 Fine Aggregate(kg) 687 687

3 Coarse Aggregate(kg) 1087 1087

4 Water(l) 197 163

5 Slump (mm) 100 100

6 W/C Ratio .53 .53

Sr.

No

Material Name Without Superplasticizer With Superplasticizer

1 Cement (kg) 411 411

2 Fine Aggregate(kg) 653 653

3 Coarse Aggregate(kg) 1084 1084

4 Water(l) 197 163

5 Slump (mm) 100 100

6 W/C Ratio 0.47 0.47

Sr.

No

Material Name Without Superplasticizer With Superplasticizer

1 Cement (kg) 487 487

2 Fine Aggregate(kg) 602 602

3 Coarse Aggregate(kg) 1068 1068

4 Water(l) 197 163

5 Slump (mm) 100 100

6 W/C Ratio 0.4 0.4

GRADE OF CONCRETE M35

Effect of superplastizer:-

These are the organic substance or mixture of organic and inorganic substance that allow the

reduction in water for the formation of concrete having same workability.

As superplasticizer is used the water content can be reduced up 20% and above but we can

change the percentage of superplastizer based on the trial which give us efficient mix

proportions.

CONCLUSION

Design mix for a site/construction results in economy.

By designing a mix, we can achieve the required compressive strength and workability by

consuming minimum quantity of concrete materials.

It is suggested that all the contractors/builders should get the design mix done for bringing quality

control in construction.

Sr.

No

Material Name Without Superplasticizer With Superplasticizer

1 Cement (kg) 566 566

2 Fine Aggregate(kg) 560 560

3 Coarse Aggregate(kg) 1042 1042

4 Water(l) 197 163

5 Slump (mm) 100 100

6 W/C Ratio 0.34 0.34

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Him 1Document6 pagesHim 1Abhilash PillaiNo ratings yet

- WWW - Madeeasy.in Admin UploadDocument MadeEasySol CE GATE 2013Document34 pagesWWW - Madeeasy.in Admin UploadDocument MadeEasySol CE GATE 2013Ponnada MarkandeyarajuNo ratings yet

- Crack WidthDocument1 pageCrack WidthAbhilash PillaiNo ratings yet

- Design of 6 Storey Building in EtabsDocument51 pagesDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- UntitledDocument1 pageUntitledAbhilash PillaiNo ratings yet

- AFFIDAVIT For Issue of Duplicate Degree CertificateDocument1 pageAFFIDAVIT For Issue of Duplicate Degree Certificatemsk4mech100% (1)

- Syllabus BookDocument38 pagesSyllabus BookSrinivas GarapatiNo ratings yet

- UntitledDocument1 pageUntitledAbhilash PillaiNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- TVS Apache RTR 180 Service ManualDocument25 pagesTVS Apache RTR 180 Service ManualSandino JoseNo ratings yet

- Tomescu PDFDocument353 pagesTomescu PDFLuís Farias100% (3)

- RC Beam Deflection and Stress AnalysisDocument4 pagesRC Beam Deflection and Stress AnalysisMaxNo ratings yet

- Skinput Technology Unlocks Human Body as Input SurfaceDocument2 pagesSkinput Technology Unlocks Human Body as Input SurfaceNISHANo ratings yet

- Name: Fatema Saeed Grade Level:: Lesson Plan TemplateDocument3 pagesName: Fatema Saeed Grade Level:: Lesson Plan Templateapi-340688378No ratings yet

- Alexander DisciplineDocument7 pagesAlexander DisciplinePatricia TagartaNo ratings yet

- VT2009B Eng 02 953680Document2 pagesVT2009B Eng 02 953680gabrieltracto100% (1)

- Sensitivity Analysis: Enter Base, Minimum, and Maximum Values in Input CellsDocument5 pagesSensitivity Analysis: Enter Base, Minimum, and Maximum Values in Input CellsSajid IqbalNo ratings yet

- AerialSolution - 280 - Brochure - LT - New Design - Final - LRDocument20 pagesAerialSolution - 280 - Brochure - LT - New Design - Final - LRRover DmsNo ratings yet

- Liquefaction AnalysisDocument16 pagesLiquefaction AnalysisKristi Engineering Services Pvt. Ltd.No ratings yet

- CS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Document23 pagesCS5371 Theory of Computation: Lecture 1: Mathematics Review I (Basic Terminology)Kamal WaliaNo ratings yet

- Structural Design of Penstock - Criteria: Indian StandardDocument21 pagesStructural Design of Penstock - Criteria: Indian StandardAlok KumarNo ratings yet

- StudenttextDocument15 pagesStudenttextapi-195130729No ratings yet

- 1 - Introduction - Derivatives GreeksDocument50 pages1 - Introduction - Derivatives GreeksThomas GallantNo ratings yet

- Wind Load Sheet by Abid SirDocument4 pagesWind Load Sheet by Abid SirMohammad KasimNo ratings yet

- Valve Selection Guide For WWTPDocument11 pagesValve Selection Guide For WWTPsf wNo ratings yet

- Quiz6 AnswerDocument8 pagesQuiz6 AnswerTrí Tạ MinhNo ratings yet

- Operations Management 1St Edition Cachon Test Bank Full Chapter PDFDocument36 pagesOperations Management 1St Edition Cachon Test Bank Full Chapter PDFwayne.martin885100% (11)

- Visual Studio C++ TutorialDocument324 pagesVisual Studio C++ TutorialFahadNo ratings yet

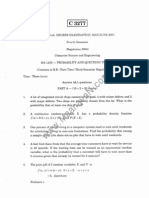

- PQT MJ07Document6 pagesPQT MJ07Raguraman BalajiNo ratings yet

- Shape and angle detective game for kidsDocument21 pagesShape and angle detective game for kidsbemusaNo ratings yet

- 24Document3 pages24sdssdNo ratings yet

- 10.8 Special Polar GraphsDocument16 pages10.8 Special Polar GraphsIlias NihaNo ratings yet

- Vector Integration - GATE Study Material in PDFDocument10 pagesVector Integration - GATE Study Material in PDFTestbook BlogNo ratings yet

- Navisworks BasicTrainingDocument54 pagesNavisworks BasicTrainingMadhankumarNo ratings yet

- The Windows Process Journey v6 0 Aug2023 1691726739Document53 pagesThe Windows Process Journey v6 0 Aug2023 1691726739blakboukiNo ratings yet

- Simulation and Implementation of Servo Motor Control With Sliding Mode Control (SMC) Using Matlab and LabviewDocument30 pagesSimulation and Implementation of Servo Motor Control With Sliding Mode Control (SMC) Using Matlab and Labviewmjohn87No ratings yet

- Raman BandsDocument2 pagesRaman Bandspreyas1No ratings yet

- Filter 7Document480 pagesFilter 7Pranjal TripathiNo ratings yet