Professional Documents

Culture Documents

Quality Assurance Plan For Erection

Uploaded by

sushant_jhawerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality Assurance Plan For Erection

Uploaded by

sushant_jhawerCopyright:

Available Formats

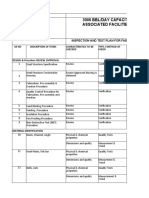

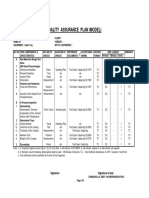

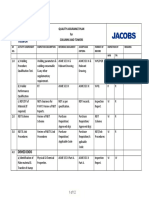

Quality assurance plan (stracture)

sr

no Attributes Characcteristics

Type method of

check

Extent of

work

Reference

document

Acceptance

norms

1 Raw materiala. surface condition &dimension visual 100% as par drg Free from rust

Plate Measurement Sketch Pitting,scale

section crack,lamination

angle

channel

Etc

2 In process a. welding procedure specification Reviw 100% ASME sec ASME sec

b.procedure qualification record To quilify visual 100% ASME sec ASME sec

c.marking,cutting & Measurement 100% as par drg as par drg

edge preperation

d.Weld fit up visual 100% PQR PQR

e. Weld surface flaws visual 100% AWSDI Free from under

cuts

f. weld size Measurement sample Drg/sketch Drg/sketch

3 Final a.dimension Measurement 100% Drg/sketch Drg/sketch

inspection b.surface preperation & painting bY alcometer 100% Drg/sketch Drg/sketch

Quality plan no Signature

Date Name

Rev no

Prepared

by

Checked &

approved by

Format of

record Agency Remark

Inspaction report V V C

crack,lamination

WPS Format V V C

PQR Format V V C

Inspaction report V V C

V V C

Inspaction report V V C

Inspaction report V V C

Inspaction report V V C

Inspaction report V V C

P=performer c=customer

w=witness V=SEF

R=review record

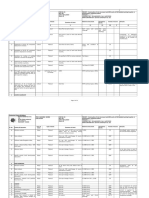

Quality assurance plan (Erection of machinery)

sr

no Attributes Characcteristics

Type method

of check

Extent of

work

Reference

document

Acceptanc

e norms

1 Foundation check a.level/centerline of foundation Measurement 100% Drg/sketch Drg/sketch

b.Nos/Dia/Length of anchor bolts Measurement 100% Drg/sketch Drg/sketch

2 Lifting tackles a.Check for wt of equipment T.C. 100% T.C. T.C.

3 Inspection of a. For any damage Visual 100% SpecificationSpecification

equipment b.Free shaft rotation Visual 100% SpecificationSpecification

4 Hole in base plate a. Size/Taps Visual 100% Drg/sketch Drg/sketch

5 During erection a.Level/Elevation of base frame Measurement 100% Drg/sketch Drg/sketch

b.Bolt checking Visual/measure 100% Drg/sketch Drg/sketch

c.Grouting of base frame Visual 100% Drg/sketch Drg/sketch

d.orientation of equipment Measurement 100% Drg/sketch Drg/sketch

e.Elevation / level of equipment Measurement 100% Drg/sketch Drg/sketch

f.Shim size Measurement 100% Drg/sketch Drg/sketch

g.Distance between coupling Measurement 100% Drg/sketch Drg/sketch

h.Alignment Visual 100% Drg/sketch Drg/sketch

6 After erection a.Auxiliary connection Visual 100% Drg/sketch Drg/sketch

b.Running test Visual 100% SpecificationSpecification

Quality plan no Signature

Date Name

Rev no

Prepared

by

Checked &

approved

by

Format of record Agency Remark

Inspaction report V V C

Inspaction report

T.C.

Inspaction report

Inspaction report

Inspaction report

Inspaction report V V C

Inspaction report V V C

Inspaction report V V C

Inspaction report

Inspaction report V V C

Inspaction report V V C

Inspaction report

Inspaction report V V C

Inspaction report V V C

Inspaction report V V C

P=performer c=customer

w=witness V=SEF

R=review record

Quality assurance plan (Piping)

sr no Attributes Characcteristics

Type

method of

check

Extent of

work

Reference

document

Acceptanc

e norms

Format of

record Agency

1 Raw material a. surface condition & visual 100% as par drg Free from rust Inspaction report V

Pipe dimension Measurement Sketch Pitting,scale

Flanges crack,lamination

Tee

Reducer

Elbow

Etc

2 In process a. welding procedure specification Reviw 100% ASME sec ASME sec WPS FormatV

b.procedure qualification record To quilify 100% ASME sec ASME sec PQR FormatV

c.marking,cutting& edge preperation Dimension 100% Drg/sketch Drg/sketch Inspaction report V

d.Weld fit upvisual 100% PQR PQR V

e. Weld jointsvisual 100% Drg/sketch Free from under Inspaction report V

cuts,blow hole

f,D.P. test With D.P. Drg/spec. Drg/spec. Inspaction report V

g.Radiography Film shot Film as par standard Film record V

3 Final inspection a.dimension Measurement 100% Drg/sketch Drg/sketch Inspaction report V

b.Hydro test visual 100% Drg/sketch Drg/sketch Inspaction report V

Line cleaningvisual 100% Drg/spec. Drg/sketch Inspaction report

P=performer

Quality plan no Signature w=witness

Date Name R=review record

Rev no

Prepared

by

Checked &

approved

by

Remark

V C

V C

V C

V C

V C

V C

V C

V C

V C

V C

c=customer

V=SEF

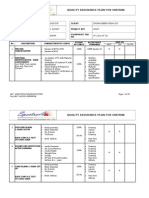

Quality assurance plan (Tanks)

sr.no Attributes Characcteristics

Type

method of

check

Extent of

work

Reference

document

Acceptanc

e norms

Format of

record Agency

1 Material a. surface condition &dimension visual 100% as par drg Free from rust Inspaction report V

identification Measurement Sketch Pitting,scale

Plate crack,lamination

section b.Mechanical/chemical properties Mechanical As par

angle chemical test standard Drg/sketch Test certificate/

channel Checked test report

Pipe,flanges

Etc

2 In processa. welding procedure specification Reviw 100% ASME sec ASME sec WPS FormatV

b.procedure qualification record To quilify visual 100% ASME sec ASME sec PQR FormatV

c.marking,cutting & visual 100% Drg/sketch Drg/sketch Inspaction report V

edge preperation

d.Weld fit upvisual 100% PQR PQR Inspaction report V

e. Weld surface flaws visual 100% AWSDI Free from under Inspaction report V

cuts

f. weld size Measurement sample Drg/sketch Drg/sketch Inspaction report V

g.D.P. test With D.P. Drg/spec. Drg/spec. Inspaction report V

3 Final a.dimension Measurement 100% Drg/sketch Drg/sketch Inspaction report V

inspectionb.Hydro test with water 100% Drg/sketch no leak allowed Inspaction report V

P=performer

Quality plan no Signature w=witness

Date Name R=review record

Rev no

Prepared

by

Checked &

approved

by

Remark

V C

V C

V C

V C

V C

V C

V C

V C

V C

V C

c=customer

V=SEF

You might also like

- Microsoft Word - Structural Steel SpecDocument26 pagesMicrosoft Word - Structural Steel SpecSaradhiJannNo ratings yet

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz KabirNo ratings yet

- 'Hydrostatic ProcedureDocument7 pages'Hydrostatic ProcedureYuwantoniAlNo ratings yet

- Chemical Reactors and Reactions Test MethodDocument63 pagesChemical Reactors and Reactions Test Methodsushant_jhawer100% (1)

- ItpDocument2 pagesItpVinay YadavNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Visible Penetrant Examination Using The Water-Washable ProcessDocument6 pagesVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Is 7307Document22 pagesIs 7307ponmanikandan1100% (1)

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 pagesInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoNo ratings yet

- Welding Procedure Specifica Tion (WPS) : I I I IDocument5 pagesWelding Procedure Specifica Tion (WPS) : I I I ITrinh DungNo ratings yet

- ITP For Steel StructureDocument3 pagesITP For Steel Structuretrey100% (4)

- Debate Lesson PlanDocument3 pagesDebate Lesson Planapi-280689729No ratings yet

- QAP StructureDocument2 pagesQAP Structureayoki100% (1)

- Itp For Structural Steel WorkDocument12 pagesItp For Structural Steel Worknguyen thangNo ratings yet

- Pt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and ErectionDocument5 pagesPt-bm-g00-Dc-00101 Inspection and Test Plan For Piping Fabriction and Erectioneldobie3100% (1)

- Back Gouging ProcedureDocument8 pagesBack Gouging Proceduremahi1437100% (1)

- Samples ITPDocument4 pagesSamples ITPHassan SajidNo ratings yet

- N0200003 - NEW-F201-0 - Inspection & Test PlanDocument3 pagesN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliNo ratings yet

- Projected Costs of Generating Electricity (EGC) 2005Document233 pagesProjected Costs of Generating Electricity (EGC) 2005susantojdNo ratings yet

- Inspection and Test Plan For Storage TankDocument6 pagesInspection and Test Plan For Storage Tankpluton1954No ratings yet

- FQP GeneralDocument21 pagesFQP GeneralgaladrialNo ratings yet

- Deliverables List Feed Vs Detail EngineeringDocument9 pagesDeliverables List Feed Vs Detail Engineeringsushant_jhawer100% (5)

- Quality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Document10 pagesQuality Assurance Plan For Unitank:: QAP/AAV/MFG/00107/UT Crown Beers India LTD: AAVI-GA-003, R0, 210507 00107Narayana Mugalur100% (1)

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTDocument5 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3) Welding & NDTVKT TiwariNo ratings yet

- Weld SummaryDocument85 pagesWeld SummarywalitedisonNo ratings yet

- 8 Field Quality PlanDocument18 pages8 Field Quality Plangeorge_hem100% (1)

- Blank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)Document1 pageBlank Sample WPS Form (GMAW & FCAW) Welding Procedure Specification (WPS)GMNo ratings yet

- Spark Testing FormDocument1 pageSpark Testing FormMark Kevin Bechayda100% (1)

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- Larsen & Toubro Limited: Inspection and Test Plan For Under Ground PipingDocument4 pagesLarsen & Toubro Limited: Inspection and Test Plan For Under Ground PipingBhavani PrasadNo ratings yet

- Precision Storage Vessels PVT LTD: Pressure Test ReportDocument2 pagesPrecision Storage Vessels PVT LTD: Pressure Test ReportSenthil Kumaran100% (1)

- FQP 2Document25 pagesFQP 2Kuldeep ChakerwartiNo ratings yet

- F-Liquid Penetran Exam ReportDocument24 pagesF-Liquid Penetran Exam Reportzat572000No ratings yet

- Field Quality Plan For LgfsDocument7 pagesField Quality Plan For LgfsUday PratapNo ratings yet

- Rotary Dryer CalculationDocument5 pagesRotary Dryer Calculationsushant_jhawer100% (2)

- Steam Control and Condensate Drainage For Heat Exchangers: GeneralDocument6 pagesSteam Control and Condensate Drainage For Heat Exchangers: Generalsushant_jhawerNo ratings yet

- IRN-8108577716-432-01-RIL-Audco-17 Jan 2014Document1 pageIRN-8108577716-432-01-RIL-Audco-17 Jan 2014MuralitclNo ratings yet

- Welder ID Card BRE KarahaDocument5 pagesWelder ID Card BRE KarahaHerruSetiawan100% (1)

- Arte PoveraDocument13 pagesArte PoveraSohini MaitiNo ratings yet

- How To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Document15 pagesHow To Make Weld Map, Shop Weld Plan, WPS, PQR & WPQ For A Static Pressure Vessel (Part-3)Mohamed Atef100% (1)

- Fit Up ReportDocument41 pagesFit Up ReportFendik NewbieNo ratings yet

- Model Qap Cable TrayDocument2 pagesModel Qap Cable Trayveerendra100% (3)

- Edoc - Pub - Fire Hydrant Pump CalculationDocument3 pagesEdoc - Pub - Fire Hydrant Pump Calculationsushant_jhawerNo ratings yet

- Revised IMIR ReportDocument2 pagesRevised IMIR ReportSimbu ArasanNo ratings yet

- PQR (Hdpe)Document3 pagesPQR (Hdpe)abdo elmokademNo ratings yet

- Section 2 QAP, Cable TrayDocument3 pagesSection 2 QAP, Cable TrayveerendraNo ratings yet

- CSWIP - WIS5-90516b PART 1Document24 pagesCSWIP - WIS5-90516b PART 1Ehsan KhanNo ratings yet

- 2.8.2. Indicative QAP - ColumnsDocument12 pages2.8.2. Indicative QAP - ColumnsAshish Dhok0% (1)

- Inspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksDocument3 pagesInspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksjitendraNo ratings yet

- Welding Procedure Specification (WPS) FormDocument2 pagesWelding Procedure Specification (WPS) FormEarl Harbert0% (2)

- DR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07Document13 pagesDR 10.01 Instructions For Non-Destructive Testing of Welds REV 05 2011-07SasaNo ratings yet

- Project Internal Audit Procedure: SheetalkumarDocument4 pagesProject Internal Audit Procedure: SheetalkumarTwin BullsNo ratings yet

- Birla Copper WPS For Tube To Tubesheet Welding MOC - CSDocument2 pagesBirla Copper WPS For Tube To Tubesheet Welding MOC - CSJitu Padhiyar PadhiyarNo ratings yet

- 66 KV Single Core XLPE Power Cable PDFDocument11 pages66 KV Single Core XLPE Power Cable PDFRani VjNo ratings yet

- Manufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsDocument4 pagesManufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsBhanu Pratap ChoudhuryNo ratings yet

- Wps Mig PDF FreeDocument3 pagesWps Mig PDF Freehanz bermejoNo ratings yet

- B H e L Limited RTDocument13 pagesB H e L Limited RTbhavin17850% (2)

- WPQ TemplateDocument1 pageWPQ Templatejoshrathburn1980No ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDDocument10 pagesFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- QAP ITP Bhogat - REV-01Document8 pagesQAP ITP Bhogat - REV-01Ramkunwar YadavNo ratings yet

- Ug PipingDocument1 pageUg PipingVinoth KumarNo ratings yet

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- Is - 2062Document10 pagesIs - 2062Jagjeet SinghNo ratings yet

- Company ProfileDocument18 pagesCompany ProfileAjay Singh LucknowNo ratings yet

- Welding Procedure Specification (WPS) & Procedure Hp-Bolir Esr0040020qmo4279a-2507 - 0BXDocument62 pagesWelding Procedure Specification (WPS) & Procedure Hp-Bolir Esr0040020qmo4279a-2507 - 0BXkingstonNo ratings yet

- TGN-BC-01 Tack Welding of Reinforcement BarDocument8 pagesTGN-BC-01 Tack Welding of Reinforcement Barnaseema1No ratings yet

- Ask Team To Add Company Logo Her "Shri Ganesh Engineering"Document4 pagesAsk Team To Add Company Logo Her "Shri Ganesh Engineering"manoj thakkar100% (1)

- Itp CibasDocument24 pagesItp CibasIzzadAfif1990No ratings yet

- Concrete FDN Insp. Checklist Rev1 On 26-12-2012Document1 pageConcrete FDN Insp. Checklist Rev1 On 26-12-2012sushant_jhawerNo ratings yet

- Edoc - Pub - Foundation Design Philosophy For Rotating EquipmenDocument8 pagesEdoc - Pub - Foundation Design Philosophy For Rotating Equipmensushant_jhawerNo ratings yet

- Dennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale OperationsDocument25 pagesDennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale Operationssushant_jhawerNo ratings yet

- Design of Pressure Drop Flow MeterDocument6 pagesDesign of Pressure Drop Flow Metersushant_jhawerNo ratings yet

- Basic Engineering Package - Ideal ApproachDocument2 pagesBasic Engineering Package - Ideal Approachsushant_jhawerNo ratings yet

- Green Field Building-ConstructionDocument7 pagesGreen Field Building-Constructionsushant_jhawerNo ratings yet

- Heat Exchanger Failure Analysis: Case HistoryDocument1 pageHeat Exchanger Failure Analysis: Case Historysushant_jhawerNo ratings yet

- Multi AgitatorDocument9 pagesMulti Agitatorsushant_jhawerNo ratings yet

- Control Valve PartDocument4 pagesControl Valve Partsushant_jhawerNo ratings yet

- Role of Micro-Financing in Women Empowerment: An Empirical Study of Urban PunjabDocument16 pagesRole of Micro-Financing in Women Empowerment: An Empirical Study of Urban PunjabAnum ZubairNo ratings yet

- Building g5Document45 pagesBuilding g5ammarsteel68No ratings yet

- Re BuyerDocument20 pagesRe BuyerElias OjuokNo ratings yet

- DLL - English 5 - Q3 - W8Document8 pagesDLL - English 5 - Q3 - W8Merlyn S. Al-osNo ratings yet

- Sample TRM All Series 2020v1 - ShortseDocument40 pagesSample TRM All Series 2020v1 - ShortseSuhail AhmadNo ratings yet

- MT Im For 2002 3 PGC This Is A Lecture About Politics Governance and Citizenship This Will HelpDocument62 pagesMT Im For 2002 3 PGC This Is A Lecture About Politics Governance and Citizenship This Will HelpGen UriNo ratings yet

- Civil Engineering Literature Review SampleDocument6 pagesCivil Engineering Literature Review Sampleea442225100% (1)

- Normal Consistency of Hydraulic CementDocument15 pagesNormal Consistency of Hydraulic CementApril Lyn SantosNo ratings yet

- 103-Article Text-514-1-10-20190329Document11 pages103-Article Text-514-1-10-20190329Elok KurniaNo ratings yet

- General Introduction: 1.1 What Is Manufacturing (MFG) ?Document19 pagesGeneral Introduction: 1.1 What Is Manufacturing (MFG) ?Mohammed AbushammalaNo ratings yet

- Philippine Rural Development Project: South Luzon Cluster C Ommunication Resourc ES Management WorkshopDocument45 pagesPhilippine Rural Development Project: South Luzon Cluster C Ommunication Resourc ES Management WorkshopAlorn CatibogNo ratings yet

- System of Linear Equation and ApplicationDocument32 pagesSystem of Linear Equation and Applicationihsaanbava0% (1)

- Program Need Analysis Questionnaire For DKA ProgramDocument6 pagesProgram Need Analysis Questionnaire For DKA ProgramAzman Bin TalibNo ratings yet

- Concise Beam DemoDocument33 pagesConcise Beam DemoluciafmNo ratings yet

- Rubric For Audio Speech DeliveryDocument2 pagesRubric For Audio Speech DeliveryMarie Sol PanganNo ratings yet

- AURTTA104 - Assessment 2 Practical Demonstration Tasks - V3Document16 pagesAURTTA104 - Assessment 2 Practical Demonstration Tasks - V3muhammaduzairNo ratings yet

- Ccie R&s Expanded-BlueprintDocument12 pagesCcie R&s Expanded-BlueprintAftab AlamNo ratings yet

- Assembly and RiggingDocument52 pagesAssembly and RiggingPokemon Go0% (1)

- WT&D (Optimization of WDS) PDFDocument89 pagesWT&D (Optimization of WDS) PDFAbirham TilahunNo ratings yet

- Denial of LOI & LOP For Ayurveda Colleges Under 13A For AY-2021-22 As On 18.02.2022Document1 pageDenial of LOI & LOP For Ayurveda Colleges Under 13A For AY-2021-22 As On 18.02.2022Gbp GbpNo ratings yet

- Age and Gender Detection Using Deep Learning: HYDERABAD - 501 510Document11 pagesAge and Gender Detection Using Deep Learning: HYDERABAD - 501 510ShyamkumarBannuNo ratings yet

- Résumé Emily Martin FullDocument3 pagesRésumé Emily Martin FullEmily MartinNo ratings yet

- Blackstone The Dash Model #1610 Owner's ManualDocument53 pagesBlackstone The Dash Model #1610 Owner's ManualSydney Adam SteeleNo ratings yet

- Registration Form - Synergies in Communication - 6th Edition - 2017-Drobot AnaDocument3 pagesRegistration Form - Synergies in Communication - 6th Edition - 2017-Drobot AnaAna IrinaNo ratings yet

- SQL TestDocument10 pagesSQL TestGautam KatlaNo ratings yet

- ShopDrawings - Part 1Document51 pagesShopDrawings - Part 1YapNo ratings yet

- SAP Environment, Health, and Safety (EHS)Document13 pagesSAP Environment, Health, and Safety (EHS)SAFETY VOFPLNo ratings yet