Professional Documents

Culture Documents

Cost Escalation Factors

Uploaded by

MuslimkarimjeeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cost Escalation Factors

Uploaded by

MuslimkarimjeeCopyright:

Available Formats

COST ESCALATION FACTORS

Managing large construction projects must have good coordination between the human and non

human resources.

For a project to get approval from the deciding authority in an organization, It has to be within the

budget. The Project team is under pressure to estimate with an optimistic attitude (Akinci and

Fischer, 2004 pp. 6776.) so that it gets approval. This is very common if the project is funded by

public funds.

Some of the reasons for cost escalation in a project are:

Procurement Approach How the procurement team approaches procurement of certain items like

cement and steel can make a difference.

Project Schedule Change When budgeting the materials or services are based on the current time

and if the project takes time to take off (Callahan, 1998, pp. 1-59), these prices may no longer valid

and hence your original budget could be under. A typical example is the steel price in Kenya. This is

controlled by two main factors, the Dollar exchange rate and the price of raw material. Most steel

manufacturers would not like to maintain their prices for more than a month.

Unforeseen conditions As in the current construction project I am managing, the hardcore level

was deeper then what was designed which increase the excavation costs. This was due to preparing a

tender document before completion of geotechnical tests.

How do we control and plan for cost escalations:

1. We plan the procurement that is identify what is required when. Then look at the price

trend for lets say the past year. This allows us to know by what percentage the price has

been going up and the plan the purchase accordingly. If the price went up by 10% in last 12

months, we cost the purchase within the next year at 10% higher than the current market.

2. Contracts with Suppliers for Large critical items in the current project, we had contracts

with the cement and steel suppliers to supply the full required quantity over the construction

period at an agreed price. The Steel manufacturer agreed to maintain the price but asked for

a 30% deposit so that he can procure the raw material. This allowed us sustain a constant

price throughout the project.

Of course there is a contingency on the bottom figure.

To share an experience, When we were budgeting for the factory civil works, the consultants had

indicated that it could be completed in about Kshs. 1.2Billion. When the local consortium came up

with an engineers estimate it was around 2.1Billion and after floating the tenders, we received an

average bid of 2.2Billion. This was because the budget was prepared in 2006 but the tenders floated

in 2009. The exchange rate for US$ went up by more than 25% during that time and inflation was at

almost 7%. A lot of factors had changed in the 3 years.

Reference

Akinci, B., and Fischer, M. (1998)Factors affecting contractors risk of cost overburden. J. Manage.

Eng., 14(1)

Callahan, J. T. (1998) Managing transit construction contract claims,Transportation Research Board,

Transportation cooperative research program synthesis 28, National Academy Press, Washington,

D.C.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 11.schedule GDocument18 pages11.schedule Gjubail13100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- EPC Project Management PDFDocument28 pagesEPC Project Management PDFRuna Jully100% (1)

- Concepts in Workflow Release StrategyDocument21 pagesConcepts in Workflow Release Strategyarturmb1593No ratings yet

- ADB Procurement - Selection of Consultant - FinalDocument124 pagesADB Procurement - Selection of Consultant - FinalSE PIUNo ratings yet

- SAEP 1610 (Oct 2017)Document9 pagesSAEP 1610 (Oct 2017)nadeem shaikhNo ratings yet

- Method StatementDocument15 pagesMethod StatementMuslimkarimjeeNo ratings yet

- Matindok Gas Development Project Control ProcedureDocument21 pagesMatindok Gas Development Project Control ProcedureAnas PratamaNo ratings yet

- Validation Report and Protocol - Rev3bDocument48 pagesValidation Report and Protocol - Rev3bMuslimkarimjeeNo ratings yet

- The Next Frontier - Unlocking Value With Tail-Spend ManagementDocument9 pagesThe Next Frontier - Unlocking Value With Tail-Spend ManagementManvi Pareek100% (1)

- Ebook Ebook PDF Selling and Sales Management 11th Edition PDFDocument41 pagesEbook Ebook PDF Selling and Sales Management 11th Edition PDFtimothy.studdard10497% (30)

- RFB Procurement-Of-Ct Scan Final-10102023 - 6771583572218279Document111 pagesRFB Procurement-Of-Ct Scan Final-10102023 - 6771583572218279MuslimkarimjeeNo ratings yet

- Mobilization Checklist 1Document3 pagesMobilization Checklist 1MuslimkarimjeeNo ratings yet

- ITT No. 101043 Instruction Document Including Draft ContractDocument44 pagesITT No. 101043 Instruction Document Including Draft ContractMuslimkarimjeeNo ratings yet

- Kenya-LandAct No6of2012Document90 pagesKenya-LandAct No6of2012MuslimkarimjeeNo ratings yet

- WEDA 30 (50Hz)Document1 pageWEDA 30 (50Hz)MuslimkarimjeeNo ratings yet

- 1089 GEEA Revised PDD CleanDocument50 pages1089 GEEA Revised PDD CleanMuslimkarimjeeNo ratings yet

- Brief Company Profile Projects and LicensesDocument13 pagesBrief Company Profile Projects and LicensesMuslimkarimjeeNo ratings yet

- Dynamics NAV 5.0 White Paper Warehouse Management SystemDocument51 pagesDynamics NAV 5.0 White Paper Warehouse Management SystemMuslimkarimjeeNo ratings yet

- Identifying Project StakeholdersDocument2 pagesIdentifying Project StakeholdersMuslimkarimjeeNo ratings yet

- Financial Control in African Countries: Objectives and ModelsDocument25 pagesFinancial Control in African Countries: Objectives and ModelsdailyNo ratings yet

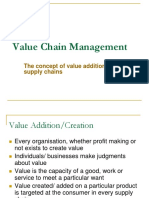

- Value Chain Management: Adding Value in Supply ChainsDocument23 pagesValue Chain Management: Adding Value in Supply ChainsANo ratings yet

- Lesson 3 Customer ValueDocument35 pagesLesson 3 Customer ValueShannen SambaleNo ratings yet

- Application AI For Pressure Vessel FabricationDocument2 pagesApplication AI For Pressure Vessel FabricationWinsonLimHuiWahNo ratings yet

- Monograph # 2Document9 pagesMonograph # 2Rabia YasmeenNo ratings yet

- Supply Chain Management T1-T4Document8 pagesSupply Chain Management T1-T4Krystelle MayaNo ratings yet

- Terms of Reference: Package No. TIIGP2-VIE-C01: Detailed Design and Support ConsultantDocument22 pagesTerms of Reference: Package No. TIIGP2-VIE-C01: Detailed Design and Support ConsultantHong Lam ThaiNo ratings yet

- Newport Utilities ReportDocument12 pagesNewport Utilities ReportWVLT NewsNo ratings yet

- Guidelines For Completing The Individual Financial StatementDocument19 pagesGuidelines For Completing The Individual Financial StatementRyan X RoseNo ratings yet

- Three Buying Situations 1. New Task 3. Modified Rebuy 2. Straight RebuyDocument11 pagesThree Buying Situations 1. New Task 3. Modified Rebuy 2. Straight RebuyPhuc Huynh PhucNo ratings yet

- PMBOK Processes From A Historian Point of ViewDocument1 pagePMBOK Processes From A Historian Point of ViewRanjith KumarNo ratings yet

- Comprehensive Exam Handling StepsDocument99 pagesComprehensive Exam Handling Stepsabdelrahman.hashem.20No ratings yet

- Experienced Procurement Specialist ResumeDocument2 pagesExperienced Procurement Specialist ResumeJOSEPH GODWINNo ratings yet

- Simulated Real Estate Business Plan and Operational DocumentsDocument17 pagesSimulated Real Estate Business Plan and Operational Documentsnirajan parajuli100% (1)

- Burj Khalifa ProcurementDocument9 pagesBurj Khalifa Procurementdenmanzano0426No ratings yet

- PPF Guidelines and Proposal TemplateDocument7 pagesPPF Guidelines and Proposal TemplateButch D. de la CruzNo ratings yet

- 2023 BSTD Grade 10 Week 7 Market EnvironmentDocument6 pages2023 BSTD Grade 10 Week 7 Market Environmentadelaidemkondiwa1No ratings yet

- Uniform Guidelines For BlacklistingDocument7 pagesUniform Guidelines For BlacklistingKaJong JaclaNo ratings yet

- Minerals and Mining BrochureDocument12 pagesMinerals and Mining BrochureDédia BangaliNo ratings yet

- INDUSTRIAL MARKETING - HAWALDAR (For Test Only Chap1,2,3,4,6,7)Document166 pagesINDUSTRIAL MARKETING - HAWALDAR (For Test Only Chap1,2,3,4,6,7)ravichitlangia28100% (6)

- Functions in Contract ManagementDocument5 pagesFunctions in Contract ManagementRAJSHREE MAURYANo ratings yet

- Government Gazette Vol. 27 18-3-2022 FINALDocument32 pagesGovernment Gazette Vol. 27 18-3-2022 FINALMUTANGA BASILNo ratings yet