Professional Documents

Culture Documents

Risk Assessment Template 1.2

Uploaded by

Jorge Humberto Herrera100%(1)100% found this document useful (1 vote)

411 views5 pagesRISK IDENTIFICATION,ASSESSMENT and mitigation TEMPLATE Mr. R.M. Gupta (M. Pharm.), is a free lancer consultant for US DMF, COS, ANDA, ACTD, CTD, eCTD and other regulatory submissions. The present protocol is a very basic version. The same may be customized as per specific requirements.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRISK IDENTIFICATION,ASSESSMENT and mitigation TEMPLATE Mr. R.M. Gupta (M. Pharm.), is a free lancer consultant for US DMF, COS, ANDA, ACTD, CTD, eCTD and other regulatory submissions. The present protocol is a very basic version. The same may be customized as per specific requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

411 views5 pagesRisk Assessment Template 1.2

Uploaded by

Jorge Humberto HerreraRISK IDENTIFICATION,ASSESSMENT and mitigation TEMPLATE Mr. R.M. Gupta (M. Pharm.), is a free lancer consultant for US DMF, COS, ANDA, ACTD, CTD, eCTD and other regulatory submissions. The present protocol is a very basic version. The same may be customized as per specific requirements.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

Perfect Pharmaceutical Consultants Pvt. Ltd.

Copyright Perfect Pharmaceutical Consultants Pvt. Limited

RISK IDENTIFICATION,ASSESSMENT & MITIGATION

TEMPLATE

Mr. R.M. Gupta (M. Pharm.), is a free lancer consultant for US DMF, COS,

ANDA, ACTD, CTD, eCTD and other regulatory submissions.

guptarmg1952@gmail.com

He is associated with Perfect Pharmaceutical Consultants Pvt. Limited and

Global Institute of Regulatory affairs (Pune, India)

Abstract: The risk involved in pharmaceutical manufacturing is largely

associated with:

1. Poorly written SOP, incomplete knowledge of the

process/machines/materials /areas/services

2. Unauthorized changes in process, incomplete vendor audits, changes in

source of raw materials

3. Incomplelete specifications of Raw materials/Finished Goods,

4. unwarranted procedures

5. Unknown personnel disabilities

6. Improper training, system failures,

7. Lack of validation activities, Lack of organizational harmony

8. Job dissatisfaction, poor maintenance, interference of the management

with critical functions such as quality assurance, quality control, purchase

and production,

9. Faulty organization structure, lack of management commitment for

quality,

10. Poor man and material flow, Poor environmental control

11. Poor control on process water

12. Inappropriate cleaning procedures for the equipments,

13. Lack of sanitation and hygiene

14. Poor control on rodents/insect/worming and birds, undue filth and

microbial contamination, undue cross contamination.

Risk Control involves proper identification, classification, mitigation and

prevention of root cause of the probable errors. The present protocol is a very

basic version. The same may be customized as per specific requirements. The

readers are invited to post their queries at guptarmg1952@gmail.com

Perfect Pharmaceutical Consultants Pvt. Ltd.

Copyright Perfect Pharmaceutical Consultants Pvt. Limited

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No

Effective Date Review Date

Drafted by Approved by

Released by

Page No

1of 4

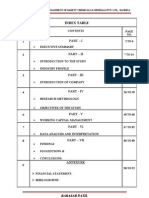

INDEX:

ID Contents Page No

1.0 Responsibilities

2.0 Objective

3.0 Scope

4.0 Risk Identification

5.0 Risk Assessment and Investigations

6.0 Risk Mitigation and prevention

7.0 Summary and Conclusion

1.0 RESPONSIBILITIES:

Sector Responsibilities

Risk Assessment Officer To identify the risk

Manufacturing In charge To report all deviations and unwarranted results in production

Maintenance In charge To report equipment limitations and deficiencies

Quality Control In charge To test the products

Quality Assurance To control the entire process and to mitigate the situation

2.0 OBJECTIVE: This is applicable to all functional areas including RM and FP Storage,

Manufacturing, Packaging, Maintenance procedures, Cleaning Procedures, receipt, storage

and release or approval of the materials. It is applicable to entire procedures as well as their

subparts.

..

3.0 SCOPE:

To provide procedure for identification, classification, mitigation and prevention of risk

during manufacturing of ..at .

..

Perfect Pharmaceutical Consultants Pvt. Ltd.

Copyright Perfect Pharmaceutical Consultants Pvt. Limited

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No

Effective Date Review Date

Drafted by Approved by

Released by

Page No

2 of 4

Risk Control involves proper identification, classification, mitigation and

prevention of root cause of the probable errors.

4. RISK IDENTIFICATION:

Elements Description Observations

4.1 Identify the SOP

associated with risk

Provide SOP Title and Clause No which is

to be assessed for risk

4.2 State Likelihood of

Risk Occurrence

State the probability of the event occurring

as most likely, some times, Rarely.

4.3 Provide details on

Raw Data Collected

for risk analysis

Collect the raw data which is to be

analyzed for risk assessment

4.4 Identify Major

System / Component

/ Functional Area /

Subsystem affected

Identify the major system / component and

the pertinent subsystem or component based

on the process in which the risk event has

occurred.

4.5 Rate the severity of

Risk

Rate the risk as High, Medium or Low,

derived from likelihood and severity ( Very

Critical, Critical, Minor )

4.6 Assign the priority QA Manager/Production

,Manager/Regulatory Manager/Marketing

Manager to assign priority to the risk

4.7 (Category) Identify the risk as: Gross cGMP

Violation/Minor GMP Violation.

4.8 Assign Specific ID Assign specific ID to each risk

Perfect Pharmaceutical Consultants Pvt. Ltd.

Copyright Perfect Pharmaceutical Consultants Pvt. Limited

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No

Effective Date Review Date

Drafted by Approved by

Released by

Page No

3 of 4

5. RISK ASSESSMENT AND INVESTIGATION.

5.1 Define the Risk Gives detailed statement of the risk

involved with the procedure

5.2 Define the Impact of

risk

Sates the consequence of the event on

quality and yield of the product. You may

also describe average and worse case

consequences.

5.3 State the Major

Products affected

Provide Name of the Products with batch

No

5.4 Analyze the impact

of risk on quality

and efficacy of the

product

Briefly describes the impact on

chemical/physical/microbiological

properties of the drug/product.

If required identify the impact on impurity

profiling , assay and stability of the product

5.5 Stare Time

Sensitivity of the

risk

Estimates the relative urgency for

identification and management of risk

involved.

5.6 State Severity of risk

control

State the severity or the potential impact of

the risk. on product quality, yield and on

timelines

.

5.7 Identify the Other

Affected Areas

Identify any other subsystem or subsequent

processing steps which may get affected by

the risk.

Perfect Pharmaceutical Consultants Pvt. Ltd.

Copyright Perfect Pharmaceutical Consultants Pvt. Limited

Company Logo RISK IDENTIFICATION, ASSESSMENT & MITIGATION

TEMPLATE

Template No

Effective Date Review Date

Drafted by Approved by

Released by

Page No

4 of 4

6. RISK MITIGATION AND PREVENTION

6.1 Define the Variation

to be done in SOP

Describe what variations will be required in

the process to minimize the risk

6.2 State Risk Handling

Plans

Briefly describes plans to nullify the risk. .

6.3 State Risk

Monitoring Activity

Describe the plan/in process tests to monitor

the risk

6.4 Risk Control Review Review the few batches for efficacy of risk

control measures

6.5 Specify the Periodic

Review program for

risk control

Provide the frequency or exact dates for

reviewing the risk control activities

6.6 Risk Reported By Records name and phone number of

individual who reported the risk.

6.7 Risk Closing

Rationale

Reason for closing the risk.

7. SUMMARY AND CONCLUSIONS:

Risk Assessment Authorization Page

Prepared By Checked By Approved By Released By

You might also like

- Pharm Phlash Cards Pharmacology Flash Cards 2nd EditionDocument466 pagesPharm Phlash Cards Pharmacology Flash Cards 2nd EditionDerricka Crosby100% (1)

- 1 - Introduction To Computerized Systems Validation - For ReviewDocument41 pages1 - Introduction To Computerized Systems Validation - For Reviewpate malabananNo ratings yet

- Qualification - Validation CPOB 2018 PDFDocument145 pagesQualification - Validation CPOB 2018 PDFmela milaniNo ratings yet

- Auditing Guide: Active Pharmaceutical Ingredients Committee (APIC)Document26 pagesAuditing Guide: Active Pharmaceutical Ingredients Committee (APIC)Ngoc Sang HuynhNo ratings yet

- VAL 135 Risk Assessment For Computer Validation Systems Sample - SandraDocument3 pagesVAL 135 Risk Assessment For Computer Validation Systems Sample - SandraSandra Silva100% (1)

- 2.4 Cleanrooms and Air Quality - A Risk-Based ApproachDocument13 pages2.4 Cleanrooms and Air Quality - A Risk-Based ApproachJorge Humberto HerreraNo ratings yet

- A-Mab Case Study Version 2-1Document278 pagesA-Mab Case Study Version 2-1Davion Stewart100% (1)

- Writing An Effective 483 ResponseDocument27 pagesWriting An Effective 483 ResponseJanna Hendrix Babson100% (1)

- Validation Master PlanDocument37 pagesValidation Master PlanOsama Mahmoud0% (1)

- QRMDocument110 pagesQRMRoberto RamosNo ratings yet

- CSV Risks Requirements Tests and TraceabilityDocument44 pagesCSV Risks Requirements Tests and TraceabilitymonsepackNo ratings yet

- MR-Mastering BatchRecord ReviewDocument54 pagesMR-Mastering BatchRecord ReviewLien HongNo ratings yet

- Sample - VAL004 Req For Val Plans Protocols 7 Mar 06Document3 pagesSample - VAL004 Req For Val Plans Protocols 7 Mar 06nagarajs50No ratings yet

- QualityRiskManagement QAS10-376Rev2 27082012Document27 pagesQualityRiskManagement QAS10-376Rev2 27082012Jorge Humberto HerreraNo ratings yet

- FDA Sterile Product Manufacturing GuidelinesDocument63 pagesFDA Sterile Product Manufacturing GuidelinesSmartishag Bediako100% (2)

- Computer System Validation in The Perspective of TDocument7 pagesComputer System Validation in The Perspective of Tttugce29No ratings yet

- Validation Master Plan 9 25 16Document13 pagesValidation Master Plan 9 25 16Itzel Acosta SalgadoNo ratings yet

- ECA Design Controls Drug Device Combination Live Online TrainingDocument6 pagesECA Design Controls Drug Device Combination Live Online TrainingDarla Bala KishorNo ratings yet

- Qualification of Equipment - A Risk-Based ApproachDocument6 pagesQualification of Equipment - A Risk-Based ApproachJorge Humberto Herrera100% (9)

- Protocol Development and Acceptance CriteriaDocument43 pagesProtocol Development and Acceptance CriteriaJorge Humberto HerreraNo ratings yet

- QRM SOP Issue# 01 ApprovedDocument9 pagesQRM SOP Issue# 01 ApprovedibrahimgomaaNo ratings yet

- Quality Assurance (QA) Management Procedures: By: Pharma Tips - Views: 14415 - Date: 06-May-2012Document6 pagesQuality Assurance (QA) Management Procedures: By: Pharma Tips - Views: 14415 - Date: 06-May-2012SrinivasNo ratings yet

- Deviation & OOSDocument56 pagesDeviation & OOSRakeshNo ratings yet

- Risk Assessment in Automated Manufacturing Practices 2Document0 pagesRisk Assessment in Automated Manufacturing Practices 2venki_beeNo ratings yet

- 16.0 Re-Validation / RequalificationDocument3 pages16.0 Re-Validation / RequalificationBhavik YadavNo ratings yet

- A Case Study in Quality Risk ManagementDocument30 pagesA Case Study in Quality Risk Managementrodcam1No ratings yet

- Validation Master PlanDocument3 pagesValidation Master PlanPrince MoniNo ratings yet

- Cleaning ValidationDocument6 pagesCleaning Validationanandhra2010No ratings yet

- Practical Approaches to Method Validation and Essential Instrument QualificationFrom EverandPractical Approaches to Method Validation and Essential Instrument QualificationNo ratings yet

- Pharma Manufacturing BiotechDocument38 pagesPharma Manufacturing BiotechJorge Humberto HerreraNo ratings yet

- CAPA Change ManagementDocument22 pagesCAPA Change ManagementMuhammadAmdadulHoque100% (1)

- 2.2 Guia IspecDocument6 pages2.2 Guia IspecJorge Humberto HerreraNo ratings yet

- Good Distribution PracticesDocument9 pagesGood Distribution PracticesAnam AnnieNo ratings yet

- TEM-310 Impact Assessment Template For Equipment Utility and Computer SampleDocument2 pagesTEM-310 Impact Assessment Template For Equipment Utility and Computer SamplejamesyenchoNo ratings yet

- Sop For Technology TransferDocument3 pagesSop For Technology TransferDolly Bijani100% (3)

- Pharmacovigilance Inspection Program Guidance Medicine SponsorsDocument23 pagesPharmacovigilance Inspection Program Guidance Medicine SponsorsJasper Buss Hub100% (1)

- S 264 Validation Spreadsheet ApplicationsDocument14 pagesS 264 Validation Spreadsheet ApplicationsNeoNo ratings yet

- Application of Quality Risk Management To Pharmaceutical OperationsDocument13 pagesApplication of Quality Risk Management To Pharmaceutical Operationsshah777100% (2)

- Installation Qualification Sop No 0068Document3 pagesInstallation Qualification Sop No 0068Alanna RobinsonNo ratings yet

- Cleaning Validation Protocol PDFDocument17 pagesCleaning Validation Protocol PDFhauvu100% (1)

- Validation VMP Validation Master PlanDocument13 pagesValidation VMP Validation Master Plank.p.No ratings yet

- ValidationDocument5 pagesValidationjyothisahadevanNo ratings yet

- Good Documentation Practices - IVT - JVTDocument7 pagesGood Documentation Practices - IVT - JVTdcharliesNo ratings yet

- Site Validation Master Plan: Releasing Its Full PotentialDocument32 pagesSite Validation Master Plan: Releasing Its Full PotentialnophadonNo ratings yet

- Computersystemsvalidation BlogspotDocument7 pagesComputersystemsvalidation BlogspotNitin KashyapNo ratings yet

- Training in PharmaDocument4 pagesTraining in PharmaPrince MoniNo ratings yet

- Vendor Audit Checklist PDFDocument3 pagesVendor Audit Checklist PDFMaria Magdalena Palacios HernandezNo ratings yet

- Biocontamination Control for Pharmaceuticals and HealthcareFrom EverandBiocontamination Control for Pharmaceuticals and HealthcareRating: 5 out of 5 stars5/5 (1)

- Revalidation Assessment PDFDocument17 pagesRevalidation Assessment PDFrouss1906No ratings yet

- Praxis Spreadsheet-ValidationDocument67 pagesPraxis Spreadsheet-ValidationcpkakopeNo ratings yet

- Documentation: Good Manufacturing Practices Modul-3Document29 pagesDocumentation: Good Manufacturing Practices Modul-3ChristinaNo ratings yet

- 8.3 Operation Qualification Protocol For Dispensing BoothDocument4 pages8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- A Risk Based Approach To GMP TrainingDocument7 pagesA Risk Based Approach To GMP TrainingRafat AlghubariNo ratings yet

- VPP - ZetasizerDocument11 pagesVPP - ZetasizerprathimaNo ratings yet

- MET Sample Test ADocument28 pagesMET Sample Test AEdwin Arias Marin67% (3)

- Good Manufacturing Practices, Guidelines On ValidationDocument83 pagesGood Manufacturing Practices, Guidelines On ValidationPrince Moni100% (2)

- A Model: Solid Oral Hard Gelatin CapsuleDocument50 pagesA Model: Solid Oral Hard Gelatin CapsuleasamjengkolatNo ratings yet

- Contamination Control Compliance Program PDFDocument7 pagesContamination Control Compliance Program PDFDavid100% (1)

- Computerized System ValidationDocument14 pagesComputerized System ValidationEka OktawigunaNo ratings yet

- Working Capital Management PROJECT REPORT MBADocument90 pagesWorking Capital Management PROJECT REPORT MBABabasab Patil (Karrisatte)100% (14)

- Advancing Biopharmaceutical Process ControlDocument31 pagesAdvancing Biopharmaceutical Process ControlJorge Humberto HerreraNo ratings yet

- Capa Case StudyDocument9 pagesCapa Case Studykavya nainitaNo ratings yet

- Risk Assessment Template 1.2 PDFDocument5 pagesRisk Assessment Template 1.2 PDFGanesh KashinathNo ratings yet

- Risk Assessment in PharmaDocument2 pagesRisk Assessment in PharmaPrince MoniNo ratings yet

- User Requirements Template RAJADocument25 pagesUser Requirements Template RAJAdrs_mdu480% (1)

- Analytical Equipment Lifecycle ManagementDocument24 pagesAnalytical Equipment Lifecycle Managementtvijayak41No ratings yet

- Panasonic Quality Risk Management Manual: August 1, 2015Document15 pagesPanasonic Quality Risk Management Manual: August 1, 2015Yahya Kemal Kösali100% (1)

- ECA Deviation Management CAPADocument4 pagesECA Deviation Management CAPATaniparthy Madhusudhana ReddyNo ratings yet

- VAL-085 Process Validation Guideline SampleDocument2 pagesVAL-085 Process Validation Guideline SampleVizit31No ratings yet

- Process Control Systems GAMP 5 Software CategoriesDocument4 pagesProcess Control Systems GAMP 5 Software CategoriesApoloTrevinoNo ratings yet

- EU - Risk AssesmentDocument23 pagesEU - Risk Assesmentapi-3859063No ratings yet

- Good Storage PracticesDocument45 pagesGood Storage PracticesEko Murwanto100% (1)

- International Research Journal of Pharmacy: A Review On Concept of Cleaning Validation in Pharmaceutical IndustryDocument3 pagesInternational Research Journal of Pharmacy: A Review On Concept of Cleaning Validation in Pharmaceutical IndustryMohamed KamalNo ratings yet

- Overview of EU Funds For Research and InnovationDocument8 pagesOverview of EU Funds For Research and InnovationFacultad de Ingeniería U de ANo ratings yet

- Bio Similar SDocument12 pagesBio Similar SvivguyNo ratings yet

- Pharma Facilities EbookDocument17 pagesPharma Facilities EbookJorge Humberto HerreraNo ratings yet

- Natoli Whitepaper How To Choose The Right ToolingDocument2 pagesNatoli Whitepaper How To Choose The Right ToolingJorge Humberto HerreraNo ratings yet

- Pharma MFG Packaging EbookDocument23 pagesPharma MFG Packaging EbookJorge Humberto HerreraNo ratings yet

- Guidance For Industry: Investigating Out-of-Specification (OOS) Test Results For Pharmaceutical ProductionDocument17 pagesGuidance For Industry: Investigating Out-of-Specification (OOS) Test Results For Pharmaceutical Productionvyugue100% (1)

- WHO Non Sterile Process ValidationDocument15 pagesWHO Non Sterile Process Validationsubirme100% (1)

- Fault Tree Analysis (FTA)Document194 pagesFault Tree Analysis (FTA)LaciNo ratings yet

- q8, q9, q10 Question and AnswersDocument16 pagesq8, q9, q10 Question and AnswersJorge Humberto HerreraNo ratings yet

- Risk Management NASADocument256 pagesRisk Management NASAJorge Humberto HerreraNo ratings yet

- Solid Dose AdvancingDocument24 pagesSolid Dose AdvancingJorge Humberto HerreraNo ratings yet

- Limits Drug ProductDocument6 pagesLimits Drug ProductsanjeevbhatNo ratings yet

- GMPs For Phase1 - June 2008Document20 pagesGMPs For Phase1 - June 2008rattychattyNo ratings yet

- Q1a FdaDocument28 pagesQ1a FdaJorge Humberto HerreraNo ratings yet

- DoD TRA July 2009 Read VersionDocument129 pagesDoD TRA July 2009 Read VersionJorge Humberto HerreraNo ratings yet

- Afpam63 128Document187 pagesAfpam63 128Jorge Humberto HerreraNo ratings yet

- 2012 10 May Risk Based Approach C QDocument26 pages2012 10 May Risk Based Approach C Qvijayns_250355172No ratings yet

- Q1a FdaDocument28 pagesQ1a FdaJorge Humberto HerreraNo ratings yet

- ResearchSpotlight LNSresearchDocument12 pagesResearchSpotlight LNSresearchJorge Humberto HerreraNo ratings yet

- Essential Guide To RiskDocument15 pagesEssential Guide To RiskJorge Humberto HerreraNo ratings yet

- Process Safety and Environmental Protection: Baoyang DingDocument16 pagesProcess Safety and Environmental Protection: Baoyang DingVipul BhagatNo ratings yet

- Orange BookDocument18 pagesOrange BookWaseem Mohd0% (1)

- Torreya Global Pharma Industry Study October2017 PDFDocument97 pagesTorreya Global Pharma Industry Study October2017 PDFsouranilsenNo ratings yet

- 2.2 Plan of WorkDocument3 pages2.2 Plan of WorkSuresh RewarNo ratings yet

- Biological Properties of Lemongrass An OverviewDocument1 pageBiological Properties of Lemongrass An OverviewLilia RotariNo ratings yet

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocument9 pagesResearch Journal of Pharmaceutical, Biological and Chemical SciencesAtraoNo ratings yet

- Orig 1 S 000Document49 pagesOrig 1 S 000santhoshNo ratings yet

- REACT BroschureDocument84 pagesREACT BroschurekingjanuariusNo ratings yet

- Medication AdministrationDocument61 pagesMedication Administrationkerema BadasaNo ratings yet

- ASRA Guidelines Regional Anaesthesia in Anticoagulated PatientDocument10 pagesASRA Guidelines Regional Anaesthesia in Anticoagulated PatientRizg AlamriNo ratings yet

- Intravenous Bolus Administration Part II PDFDocument44 pagesIntravenous Bolus Administration Part II PDFAlaa MansourNo ratings yet

- Ciprofloxacin: Supervisedby: DR - Ali Salama Done By: A T H A L A H M A D 2 0 2 0 1 0 3 3 9Document10 pagesCiprofloxacin: Supervisedby: DR - Ali Salama Done By: A T H A L A H M A D 2 0 2 0 1 0 3 3 9wasan mousaNo ratings yet

- Effectiveness of Complementary and Self-Help Treatments For DepressionDocument13 pagesEffectiveness of Complementary and Self-Help Treatments For DepressionLiz RoxNo ratings yet

- 4TH Sem B.pharm Time TableDocument1 page4TH Sem B.pharm Time TableDAMBALENo ratings yet

- Cardiovascular: Original DescriptionDocument52 pagesCardiovascular: Original DescriptionMA ComputerNo ratings yet

- Project About Clinical Drug Development: BY Bharatwajan M Student From Presidency College, ChennaiDocument19 pagesProject About Clinical Drug Development: BY Bharatwajan M Student From Presidency College, ChennaiDineshNo ratings yet

- Data Pasien Potensi PRB Jan-Juni 2019Document212 pagesData Pasien Potensi PRB Jan-Juni 2019Adra AdeNo ratings yet

- Traditional Medicine About HerbsDocument25 pagesTraditional Medicine About HerbsJames MelwynNo ratings yet

- Dr. Vaibhav KulkarniDocument1 pageDr. Vaibhav KulkarniJake KNo ratings yet

- Robert G Gish CV October 2014Document228 pagesRobert G Gish CV October 2014Robert G. Gish, MDNo ratings yet

- Keo PropofolDocument4 pagesKeo PropofolNathali MorenoNo ratings yet

- Daunorubicin: Drug NameDocument7 pagesDaunorubicin: Drug NameEdgar Ledesma-MartínezNo ratings yet

- Drug Vs MedicineDocument2 pagesDrug Vs MedicineGillian Rose Bryant HernaezNo ratings yet

- Price List EthicalDocument2 pagesPrice List EthicalMuhammad Khairul AswinNo ratings yet

- Cms Sop FinalDocument65 pagesCms Sop FinalJennifer LopataNo ratings yet

- LMWH QML 06Document7 pagesLMWH QML 06pd7qmlNo ratings yet