Professional Documents

Culture Documents

Thermoelectric Waste Heat Recovery

Uploaded by

Sant NientCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Thermoelectric Waste Heat Recovery

Uploaded by

Sant NientCopyright:

Available Formats

Thermoelectric Waste Heat Recovery Program for

Passenger Vehicles, 2012 Vehicle Technologies

Program Annual Merit Review

PI: Douglas T. Crane

Presenter: John W. LaGrandeur

Amerigon

May 18, 2012

This presentation does not contain any proprietary, confidential or otherwise restricted information

Project ID # ACE080

1 Thermoelectric Waste Heat Recovery

Program for Passenger Vehicles, 18

May, 2012

BSST Program Overview

Timeline

Program Start Date: Oct 04

Program End date: Sept 11

Percent Complete: 100%

2

Thermoelectric Waste Heat Recovery Program for

Passenger Vehicles, 18 May, 2012

Barriers

Economic manufacture of TE engines

and TEG subsystem

Vehicle system integration for optimum

usage of TE power

Vehicle TEG system on-cost

Budget

Total Project spend: $ 11,874,538

DOE Share: $ 7,156,109

Contractor Share: $ 4,718,429 (39.7%)

FY2011 $ -

Funding Received:

Partners

Project Lead: BSST

OEM Partners: BMW & Ford

Tier 1 Partners: Faurecia, Visteon

University/Fedl Lab Caltech, JPL, NREL

Partners: Virginia Polytechnic

Targets

FE Improvement: 10%

Phase 5 Objectives

Improve cylindrical TEG prototype

manufacture with improved tooling and

subassembly component manufacture

Integrate TEGs into BMW and Ford vehicles

for road testing

Address series production manufacturability/

usability issues with the cylindrical TEG

3

Thermoelectric Waste Heat Recovery Program for

Passenger Vehicles, 18 May, 2012

BSST 2011 Program Milestones

4

Thermoelectric Waste Heat Recovery Program for

Passenger Vehicles, 18 May, 2012

Date Milestone Actual

May 7 Complete TEG build and test at

BSST

Completed

June 11 Complete engine/TEG dyno testing

at NREL

Completed

August 15 Deliver TEGs for BMW and Ford

Vehicle installations

Completed

October 15 Substantially complete TEG system

evaluation in BMW and Ford

vehicles

Completed

Approach: Improve TEG prototype

manufacture

5

Thermoelectric Waste Heat Recovery Program for Passenger

Vehicles, 18 May, 2012

The liquid cooling tube

alignment along the

length of the gas HEX

(through many, collinear

TE engines) was difficult

to align

Proposed solutions:

Carefully control the gas

HEX OD and utilize

tooling to precisely locate

successive TE engines in

the direction of flow

Approach: Integrate TEGs into BMW and

Ford vehicles for road testing

TEG atmospheric control (maintenance of O2 depleted atmosphere) was a

high priority

Solution: Install gas ports in outer shell (hermetic enclosure) with pressure

sensor to check and refill Argon gas as required

6

Thermoelectric Waste Heat Recovery Program for Passenger

Vehicles, 18 May, 2012

Approach: Address manufacturability/usability

issues with the cylindrical TEG

The Phase 5 TEG provides a proof of concept for stack-arranged

TE engines in a cylindrical form factor.

The current design has an inappropriate power form (high

current, low voltage) and will be difficult to manufacture due to

the complex liquid cooling circuit, number of parts and large

hermetically enclosed volume.

The next generation TEG will retain a cylindrical form factor and

stack-designed TE engines but be comprised of a number of

smaller cartridges.

7

Thermoelectric Waste Heat Recovery Program for Passenger

Vehicles, 18 May, 2012

Accomplishment: Improve TEG prototype

manufacture

8

Thermoelectric Waste Heat Recovery Program for

Passenger Vehicles, 18 May, 2012

Two Phase 5 Cylindrical TEGs were built using improved tooling and subassembly components

The TEGs were tested on the bench at Amerigon-Irwindale and in a peak performance test

produced over 700 watts as a result of improving interfaces, thermal and electrical.

The hot side TE material temperature reached ~ 500C and the TEG has exhibited stable

performance for > 6 months.

Accomplishment: Integrate TEGs into BMW and

Ford vehicles for road testing

9

Thermoelectric Waste Heat Recovery Program for

Passenger Vehicles, 18 May, 2012

TEGs were installed in the

BMW X6 and Ford Lincoln

MKT.

The Ford installation is

pictured at right.

Powertrain coolant was

circulated through the TEGs

A resistive load was used to

consumeTEG power

TEG Integration

on Lincoln MKT

Accomplishment: Road test TEGs in BMW and Ford

vehicles

Thermoelectric Waste Heat Recovery Program for Passenger

Vehicles, 18 May, 2012 10

The BMW X6

was put into

service in July

2011.

TEG power

measured in the

X6 is shown at

right.

Accomplishment: Road test TEGs in BMW and Ford

vehicles

11

Thermoelectric Waste Heat Recovery Program for Passenger

Vehicles, 18 May, 2012

The Ford Lincoln

MKTwas put into

service in August

2011.

TEG power

measured in the

MKT for a 65

mph cruise

condition is

shown at right.

0

50

100

150

200

250

300

350

400

450

500

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300

Test Time (sec)

T

E

G

P

o

w

e

r

(

W

a

t

t

s

)

,

E

x

h

a

u

s

t

T

e

m

p

e

r

a

t

u

r

e

(

C

)

0

9

18

27

36

45

54

63

72

81

90

V

e

h

i

c

l

e

S

p

e

e

d

(

m

p

h

)

TEG Power

Exh. Temp. into TEG

Vehicle Speed

Bypass Opened

Bypass Closed

Accomplishment: Dynamometer test the TEG with

BMWs 6 cylinder engine

12

Thermoelectric Waste Heat Recovery Program for Passenger

Vehicles, 18 May, 2012

The TEG was tested

over steady state and

drive cycle conditions

at a designated NREL

Lab

In preparation for the

follow-on TEG

program testing over

US06 was performed.

0

50

100

150

200

250

300

0 200 400 600 800 1000 1200 1400

p

o

w

e

r

(

W

)

time (s)

US06 Driv Cycle Measured Dyno Results

coolant temp = 80C and coolant flow = 20 lpm

2 cycles run back to back with 60s idle in between

basic bypass valve strategy employed

0

100

200

300

400

500

600

0 200 400 600 800 1000 1200 1400

p

o

w

e

r

(

W

)

time (s)

US06 Drive Cycle Measured Dyno Results

coolant flow = 20 lpm

2 cycles run back to back with 60s idle in between

01/31/12

coolant temp = 80C

coolant temp = 55C

Collaborations

OEM leadership has been provided by

BMW from program inception and Ford

since Phase 3.

Tier 1 support in the design-in of the

cylindrical TEG for BMW and Ford

vehicles was provided by Faurecia.

TE Material characterization was provided

by Caltech and ZT Plus.

13

Thermoelectric Waste Heat Recovery Program for

Passenger Vehicles, 18 May, 2012

Future Work

A follow-on TEG program for passenger

vehicles began in October 2011. Objectives

include:

5% FE gain over the US06 drive cycle

Economic feasibility assessment for 100K/annum

TEG system manufacture

Amerigon partners include BMW and Ford, Caltech and

NREL.

14

Thermoelectric Waste Heat Recovery Program for

Passenger Vehicles, 18 May, 2012

Summary

Relevance

Exhaust gas waste heat conversion to electric power reduces fuel consumption and is aligned with the

increasing electrification of vehicles.

Approach/Strategy for Deployment

An approach focused on optimizing vehicle level system performance while reducing the amount of TE material

used to facilitate commercialization has been followed.

Technical Accomplishments and Progress

Two prototype cylindrical TEGs were manufactured and have provided stabile performance since July, 2011.

The TEGs operate with TE material temperatures reaching ~ 500C and have produced over 700 watts of

electrical power. Carefully controlled testing under NRELs cognizance was performed on an engine

dynamometer, and in bench testing at Amerigon the TEG computer performance model validated to within 5%

to 10%.

Collaborations and Coordination with Other Institutions

Faurecia, a Tier 1 global leader in exhaust systems, has joined BMW, Ford and BSST and is leading the TEG

subsystem integration into the exhaust system. In parallel, Amerigon/BSST, through a self funded collaboration

with OSU and Northwestern, has developed a pilot production facility ,ZT Plus ,for the manufacture of advanced

TE material.

Proposed Future Work/Proposed Future Activities

A follow on program has begun and Amerigon has made significant modifications to the TEG design to ready it

for commercialization in the latter half of this decade.

15

Thermoelectric Waste Heat Recovery Program for Passenger

Vehicles, 18 May, 2012

Acknowledgements

US Department of Energy: John Fairbanks

DOE NETL: Carl Maronde

BMW: Boris Mazar, Andreas Eder and Carsten

Spengler

Ford Motor Company: Clay Maranville, Dan Demitroff,

and Quazi Hussain

Faurecia Exhaust Systems: Rita Fehle, Robin Willats,

Boris Kienle, and Ed Kinnaird

Amerigon/BSST/ZT Plus: Steve Davis, Dmitri

Kossakovski, Eric Poliquin, Vladimir Jovovic, Joe

Dean & Lon Bell & the rest of the Amerigon Team

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Diff. EquationsDocument12 pagesDiff. EquationsSant NientNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- TEGDocument12 pagesTEGMiloslav Steinbauer100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- SfunctionsDocument210 pagesSfunctionsSunitha ReddyNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Possibilities For Admixing Gasification GasesDocument15 pagesPossibilities For Admixing Gasification GasesSant NientNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- BMW Utili Profili Termici GasDocument24 pagesBMW Utili Profili Termici GasSant NientNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Battery Thermal Management in EVs and HEVsDocument10 pagesBattery Thermal Management in EVs and HEVsSant NientNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Battery Thermal Management in EVs and HEVsDocument10 pagesBattery Thermal Management in EVs and HEVsSant NientNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Finned TubeDocument8 pagesFinned TubeSant NientNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- LaTeX - Symbols - AoPSWikiDocument4 pagesLaTeX - Symbols - AoPSWikiSant NientNo ratings yet

- Beamer GuideDocument225 pagesBeamer GuideAn-Sheng Jhang98% (41)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Chapter 3: Elements of Demand and SupplyDocument19 pagesChapter 3: Elements of Demand and SupplySerrano EUNo ratings yet

- Business Case - Uganda Maize Export To South SudanDocument44 pagesBusiness Case - Uganda Maize Export To South SudanInfiniteKnowledge33% (3)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Banas Dairy ETP Training ReportDocument38 pagesBanas Dairy ETP Training ReportEagle eye0% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

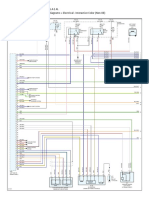

- Engine Controls (Powertrain Management) - ALLDATA RepairDocument4 pagesEngine Controls (Powertrain Management) - ALLDATA Repairmemo velascoNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Lorilie Muring ResumeDocument1 pageLorilie Muring ResumeEzekiel Jake Del MundoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Rencana Pembelajaran Semester Sistem Navigasi ElektronikDocument16 pagesRencana Pembelajaran Semester Sistem Navigasi ElektronikLastri AniNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Abb Drives: User'S Manual Flashdrop Mfdt-01Document62 pagesAbb Drives: User'S Manual Flashdrop Mfdt-01Сергей СалтыковNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- BRD TemplateDocument4 pagesBRD TemplateTrang Nguyen0% (1)

- Emperger's pioneering composite columnsDocument11 pagesEmperger's pioneering composite columnsDishant PrajapatiNo ratings yet

- Beams On Elastic Foundations TheoryDocument15 pagesBeams On Elastic Foundations TheoryCharl de Reuck100% (1)

- Individual Differences: Mental Ability, Personality and DemographicsDocument22 pagesIndividual Differences: Mental Ability, Personality and DemographicsAlera Kim100% (2)

- (SIRI Assessor Training) AM Guide Book - v2Document19 pages(SIRI Assessor Training) AM Guide Book - v2hadeelNo ratings yet

- Ata 36 PDFDocument149 pagesAta 36 PDFAyan Acharya100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Short Term Training Curriculum Handbook: General Duty AssistantDocument49 pagesShort Term Training Curriculum Handbook: General Duty AssistantASHISH BARAWALNo ratings yet

- Area Access Manager (Browser-Based Client) User GuideDocument22 pagesArea Access Manager (Browser-Based Client) User GuideKatherineNo ratings yet

- Learning HotMetal Pro 6 - 132Document332 pagesLearning HotMetal Pro 6 - 132Viên Tâm LangNo ratings yet

- 13-07-01 Declaration in Support of Skyhook Motion To CompelDocument217 pages13-07-01 Declaration in Support of Skyhook Motion To CompelFlorian MuellerNo ratings yet

- ECON Value of The FirmDocument4 pagesECON Value of The FirmDomsNo ratings yet

- Ebook The Managers Guide To Effective Feedback by ImpraiseDocument30 pagesEbook The Managers Guide To Effective Feedback by ImpraiseDebarkaChakrabortyNo ratings yet

- Palmetto Bay's Ordinance On Bird RefugeDocument4 pagesPalmetto Bay's Ordinance On Bird RefugeAndreaTorresNo ratings yet

- Proposal Semister ProjectDocument7 pagesProposal Semister ProjectMuket AgmasNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Dissolved Oxygen Primary Prod Activity1Document7 pagesDissolved Oxygen Primary Prod Activity1api-235617848No ratings yet

- Pyrometallurgical Refining of Copper in An Anode Furnace: January 2005Document13 pagesPyrometallurgical Refining of Copper in An Anode Furnace: January 2005maxi roaNo ratings yet

- MsgSpec v344 PDFDocument119 pagesMsgSpec v344 PDFqweceNo ratings yet

- Credentials List with Multiple Usernames, Passwords and Expiration DatesDocument1 pageCredentials List with Multiple Usernames, Passwords and Expiration DatesJOHN VEGANo ratings yet

- Civil Aeronautics BoardDocument2 pagesCivil Aeronautics BoardJayson AlvaNo ratings yet

- 4Q Labor Case DigestsDocument53 pages4Q Labor Case DigestsKaren Pascal100% (2)

- Ayushman BharatDocument20 pagesAyushman BharatPRAGATI RAINo ratings yet

- Conversion of Units of Temperature - Wikipedia, The Free Encyclopedia PDFDocument7 pagesConversion of Units of Temperature - Wikipedia, The Free Encyclopedia PDFrizal123No ratings yet

- MSDS Summary: Discover HerbicideDocument6 pagesMSDS Summary: Discover HerbicideMishra KewalNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)