Professional Documents

Culture Documents

Line Sizing Criteria Con

Uploaded by

anhhung80Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Line Sizing Criteria Con

Uploaded by

anhhung80Copyright:

Available Formats

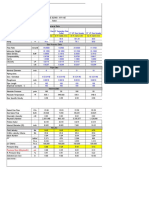

P 50 barg

P>50 barg

P 50 barg

P> 50 barg

Gravity Flow

Cooling Water

Main header

Other

Notes:

1. The velocity limit should not exceed 4.75 m/s (15 ft/s) at maximum flow rate in accordance with API 14E Chapter 2.3

2. Reference to be made to the material specialist for materials and velocity limitations. Minimum velocity shall be 2 m/s

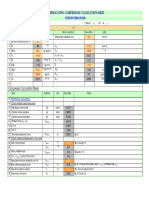

Gases, General (1)

Compressor Suction:

Reciprocating type (2) (2)

P > 80 15000

6000

20< P 50 7500

50< P 80 10000

P 20

SERVICE LINE SIZE

PRESSURE

(Barg)

MAXIMUM

VELOCITY

(m/s)

MAXIMUM

RhoV

2

Rich Amine, Sour Water

Line sizing criterial for liquid service

Line sizing criterial for vapor service

2.5 3.5

2

4.5 (1)

3

2"

3"

Side-Stream Draw-Off

0.6 0.6 0.9

0.9 0.6 0.9

0.3 0.5

3.5 9

7 9

7

1.5 to 3 (1)

1.5 to 3 (1)

7

0.8

3.5 4.5

7 9

PRESSURE DROP

(bar/km)

Normal Maximum

SERVICE LINE SIZE

12" - 18"

20"

2"

3" - 6"

MAXIMUM

VELOCITY

(m/s)

0.6 0.9

2.3 3.5 Pump suction, sub-cooled

0.9

1.2

1.5

1.8

Pump suction, bubble point

0.6

0.9

1.2

1.5

2"

3" - 10"

8" - 18"

20"

Pump Discharge (Continuos

service)

Pump Discharge (Intermittent

service)

Centrifugal type

Anti-Surge

Notes:

General:

- In addition to the above criteria, risk of excessive noise and erosion shall be considered

when setting the maximum velocity

1. The above indicated line sizing criteria are va lid for continuous operation. For this case, the pressure drop in bar/km shall

be less than 5% of the static absolute pressure for long headers and 10 % for short headers. For intermittent operation,

these limits may be increased on a case-by-case analysis. Where sufficient pressure drop is available, the pressure drop limit

of 10% for short headers may be increased to 30% and the RhoV limit of 15 000 Pa may be increased to 25 000 Pa.

2. Same criteria as for Gases, General and allowable pressure drop between 0.2 and 0.7 bar/km.

3. Same criteria as for Gases, General and allowable pressure drop between 0.5 and 1.2bar/km. The exceptional temperatures

generated by a fire shall not be considered for mechanical design temperature selection.

For two-phase flow lines, the follo wing criteria shall be applied:

- Vm shall be less than 25 m/s (m for mean velocity) or ErosionalVelocity (Ve), whichever smaller

- (RhoV)m: 5 000 to 15 000 Pa (m for mean velocity and mean density) For all two phase lines, the flow regime shall be checked for

both horizontal and vertical flow. Slug and plug flow should be avoided.

2 phase gas liquid density may be calculated using following formula:

Where:

: density at flowing conditions, kg/m

G: mass flowrate, kg/hr

mixed phase

Subscript L: liquid phase

Subscript G: gas phase

Erosional velocity shall be defined based on API RP 14E 5th Edition (reaffirmed March 2007):

Where:

m: mixed phase density at flowing conditions, kg/m

C: empirical constant. C value will be 122 for continuous services and 152 for intermittent services.

As these constants are felt to give a conservative value they will be modified using the following

Line sizing criterial for two phase flow services

50< P 80 15000

P > 80 25000

(3) (3)

20< P 50 10000

Subscript m:

factors for design with solids free fluids. For solid laden fluids, Material Engineer to be consulted

Carbon Steel = C x 1.35

13% Cr. Stainless Steel = C x 2.0

Duplex Stainless Steel & Austenitic Stainless Steels = C x 3.0

1. The velocity limit should not exceed 4.75 m/s (15 ft/s) at maximum flow rate in accordance with API 14E Chapter 2.3

2. Reference to be made to the material specialist for materials and velocity limitations. Minimum velocity shall be 2 m/s

1. The above indicated line sizing criteria are va lid for continuous operation. For this case, the pressure drop in bar/km shall

be less than 5% of the static absolute pressure for long headers and 10 % for short headers. For intermittent operation,

these limits may be increased on a case-by-case analysis. Where sufficient pressure drop is available, the pressure drop limit

of 10% for short headers may be increased to 30% and the RhoV limit of 15 000 Pa may be increased to 25 000 Pa.

3. Same criteria as for Gases, General and allowable pressure drop between 0.5 and 1.2bar/km. The exceptional temperatures

- (RhoV)m: 5 000 to 15 000 Pa (m for mean velocity and mean density) For all two phase lines, the flow regime shall be checked for

empirical constant. C value will be 122 for continuous services and 152 for intermittent services.

As these constants are felt to give a conservative value they will be modified using the following

factors for design with solids free fluids. For solid laden fluids, Material Engineer to be consulted

You might also like

- Chevron Line Sizing GuidelinesDocument6 pagesChevron Line Sizing GuidelinesWayne Monnery0% (1)

- Gas Line Size-1Document12 pagesGas Line Size-1svnaik14No ratings yet

- Breather Valves DatasheetDocument4 pagesBreather Valves Datasheetmilton1987No ratings yet

- Design Guide for Sizing PipesDocument27 pagesDesign Guide for Sizing PipesKaliya PerumalNo ratings yet

- Liquid Line SizingDocument6 pagesLiquid Line SizingManoj KumarNo ratings yet

- Gas Line SizingDocument11 pagesGas Line SizingEbby OnyekweNo ratings yet

- Depressurization Calculation..Document12 pagesDepressurization Calculation..Faber TrujilloNo ratings yet

- Tank Pressure During Pump OutDocument1 pageTank Pressure During Pump OutRexx MexxNo ratings yet

- Relief and Blowdown Report: Page 1 of 21Document21 pagesRelief and Blowdown Report: Page 1 of 21TarekNo ratings yet

- Line Sizing Design Guide, Rev 1Document24 pagesLine Sizing Design Guide, Rev 1mohsen ranjbarNo ratings yet

- PSV Sizing Psv-402 Update PsetDocument7 pagesPSV Sizing Psv-402 Update PsetBui Khoi NguyenNo ratings yet

- Gas Line Sizing - Api 14E Input Description Unit: General DataDocument13 pagesGas Line Sizing - Api 14E Input Description Unit: General DataSamuel OnyewuenyiNo ratings yet

- Blowdown Orifice Sizing CalculationDocument2 pagesBlowdown Orifice Sizing CalculationOmprakaash MokideNo ratings yet

- PSV Sizing Calculations for LOX Cryogenic VesselDocument3 pagesPSV Sizing Calculations for LOX Cryogenic VesselpavanNo ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- Line Sizing (SI) Gas PhaseDocument10 pagesLine Sizing (SI) Gas PhaseRian Intan SaputraNo ratings yet

- E3 Field Development Production Separator DesignDocument5 pagesE3 Field Development Production Separator DesignhaiderNo ratings yet

- PSV Thermal SizingDocument16 pagesPSV Thermal Sizingahmad santoso0% (1)

- Vessel Sizing SpreadsheetDocument28 pagesVessel Sizing SpreadsheetEmamokeNo ratings yet

- EQUIPMENT DATA SHEET FOR DUAL POLARITY DESALTERS 1P21-DE-0471 AND 1P21-DE-0472Document11 pagesEQUIPMENT DATA SHEET FOR DUAL POLARITY DESALTERS 1P21-DE-0471 AND 1P21-DE-0472Chakravarthy Bharath0% (1)

- Air Consumption Rev 1Document1 pageAir Consumption Rev 1Cahyadi YadiNo ratings yet

- 3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Document1 page3.2.G.2.3.D Two Phase Sep Sizing API 521 SI Units1Mike DukasNo ratings yet

- Line Sizing GuidelinesDocument31 pagesLine Sizing Guidelinesc_nghia100% (3)

- Separator Sizing SpreadsheetDocument22 pagesSeparator Sizing SpreadsheetSatria 'igin' Girindra Nugraha100% (1)

- Knock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet NozzleDocument11 pagesKnock Out Drum Sizing Parameters Value Unit Remark: Gas Outlet Nozzlejazeel alaviNo ratings yet

- FGCP Line Sizing CalculationsDocument86 pagesFGCP Line Sizing CalculationsToyinNo ratings yet

- Line Sizing Design Basis - General Specification PDFDocument11 pagesLine Sizing Design Basis - General Specification PDFSaiKumarNo ratings yet

- Validation Report On The 2 Phase Line Sizing 3 PDFDocument18 pagesValidation Report On The 2 Phase Line Sizing 3 PDFJoseph MedinaNo ratings yet

- Cvsize (Control Valve Sizing)Document8 pagesCvsize (Control Valve Sizing)EslamSheblNo ratings yet

- Ge312-1121 Columns - DrumDocument20 pagesGe312-1121 Columns - DrumDiarista Thoma SaputraNo ratings yet

- Process Datasheet For DeaeratorDocument3 pagesProcess Datasheet For DeaeratorAnonymous 7IKdlmNo ratings yet

- Pipeline Sizing Calculation For Nitrogen Line: 1.0 G EneralDocument4 pagesPipeline Sizing Calculation For Nitrogen Line: 1.0 G EneralLai HuynhNo ratings yet

- Vessel Sizing For Hysys SimulationDocument1 pageVessel Sizing For Hysys SimulationSaravanan Ilango100% (1)

- Line Sizing GuidelinesDocument32 pagesLine Sizing Guidelinesyunjun12100% (2)

- Spreadsheet Calculates Nitrogen Purging Requirements for Storage TankDocument7 pagesSpreadsheet Calculates Nitrogen Purging Requirements for Storage TankWickyNo ratings yet

- Preliminary Line Sizing CalculationsDocument7 pagesPreliminary Line Sizing CalculationsKips AksNo ratings yet

- CPF-010 Utility Line Sizing Attachment - 0Document31 pagesCPF-010 Utility Line Sizing Attachment - 0goodspeed_phNo ratings yet

- Heat Loss Insulated PipeDocument3 pagesHeat Loss Insulated PipeKatie BensonNo ratings yet

- Centrifugal Pumps: Process Calculation / Data SheetDocument3 pagesCentrifugal Pumps: Process Calculation / Data SheetMurali MuthuNo ratings yet

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- Sizing Calculation Spreadsheet PSVDocument1 pageSizing Calculation Spreadsheet PSVkenoly123No ratings yet

- Weymouth Gas Flow CalculationsDocument44 pagesWeymouth Gas Flow CalculationsPierre GermaineNo ratings yet

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- SEL-TBD-O-CA-001 R0 Process Simulation Report SignedDocument12 pagesSEL-TBD-O-CA-001 R0 Process Simulation Report Signedahmad santosoNo ratings yet

- Liquid Pipe Sizing: Group Technology SolutionsDocument1 pageLiquid Pipe Sizing: Group Technology SolutionsAhmad SiddiqNo ratings yet

- 3phase Separator Size 2010 VerADocument24 pages3phase Separator Size 2010 VerACristina BarbulescuNo ratings yet

- Instrument Air Design CalculationsDocument1 pageInstrument Air Design CalculationsBesan LaduNo ratings yet

- Section 7 - Separation EquipmentDocument9 pagesSection 7 - Separation Equipmentlulis171No ratings yet

- Flare Ko Drum SizingDocument5 pagesFlare Ko Drum SizingSujith Sekar100% (2)

- GPSA - Methanol Inhibition Rate RevisedDocument11 pagesGPSA - Methanol Inhibition Rate RevisedrmaganNo ratings yet

- 9 - Horizontal Flare Knock Out Drum Sizing1Document2 pages9 - Horizontal Flare Knock Out Drum Sizing1Anonymous APc7I7100% (1)

- PSV Sizing SheetDocument5 pagesPSV Sizing SheetDhanraj Vasanth100% (1)

- GM479-R0731-000-PR-RP-0003 - 2-Esd PhilosophyDocument19 pagesGM479-R0731-000-PR-RP-0003 - 2-Esd PhilosophySuper 7No ratings yet

- PSV Sizing Report (Fire Case)Document7 pagesPSV Sizing Report (Fire Case)Elias EliasNo ratings yet

- Specification For Air Compressors and Air Dryer PackagesDocument21 pagesSpecification For Air Compressors and Air Dryer PackagesSudjono BroNo ratings yet

- Data Sheet 3Document3 pagesData Sheet 3Fitroh MalikNo ratings yet

- Spreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2Document26 pagesSpreadsheet - Gas Blanketed Tanks - Inbreathing Process Calculations & Control Valve Sizing - Rev2venkatesh801No ratings yet

- Separator Sizing SpreadsheetDocument40 pagesSeparator Sizing SpreadsheetWalid Ben Husein100% (2)

- 193749259 Velocity in Pipeline for Natural GasDocument8 pages193749259 Velocity in Pipeline for Natural GasМихаил ПолковниковNo ratings yet

- Velocity in Pipeline For Natural GasDocument8 pagesVelocity in Pipeline For Natural GasNakkolopNo ratings yet

- Luyen Dich VA Qua Mau Cau Thong Dung-tech24.VnDocument190 pagesLuyen Dich VA Qua Mau Cau Thong Dung-tech24.VnvanthuannguyenNo ratings yet

- Thu Phan NanDocument1 pageThu Phan Nananhhung80No ratings yet

- Đề thi học kì 2 môn Tiếng Anh lớp 6 trường THCS Tảo Dương VănDocument21 pagesĐề thi học kì 2 môn Tiếng Anh lớp 6 trường THCS Tảo Dương Vănanhhung80No ratings yet

- Tower Rescue Plan SummaryDocument4 pagesTower Rescue Plan Summaryanhhung80No ratings yet

- Giac Mo Chapi Tab by Tran Tien - Songsterr Tabs With RhythmDocument1 pageGiac Mo Chapi Tab by Tran Tien - Songsterr Tabs With Rhythmanhhung80No ratings yet

- Essential boiler system functions and safety questionsDocument4 pagesEssential boiler system functions and safety questionsanhhung8080% (5)

- Steam Tracing Excel 2007Document74 pagesSteam Tracing Excel 2007mani170487No ratings yet

- PL Pm1atest PDFDocument6 pagesPL Pm1atest PDFcutiegal1980No ratings yet

- PL Pm1atest PDFDocument6 pagesPL Pm1atest PDFcutiegal1980No ratings yet

- Giac Mo Chapi Tab by Tran Tien - Songsterr Tabs With RhythmDocument1 pageGiac Mo Chapi Tab by Tran Tien - Songsterr Tabs With Rhythmanhhung80No ratings yet

- Dew CalculationDocument6 pagesDew CalculationHaykal Yuqdha0% (1)

- How To Do A System Restore Tieng NhatDocument10 pagesHow To Do A System Restore Tieng Nhatanhhung80No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Protect Centrifugal Pumps From Low Flows PDFDocument12 pagesProtect Centrifugal Pumps From Low Flows PDFicingrockNo ratings yet

- Thu Phan NanDocument1 pageThu Phan Nananhhung80No ratings yet

- Thu Phan NanDocument1 pageThu Phan Nananhhung80No ratings yet

- Presentations Oil Refinery ProcessesDocument36 pagesPresentations Oil Refinery ProcessesGururaj SreepatharaoNo ratings yet

- BQMN C5 MnenDocument55 pagesBQMN C5 Mnenanhhung80No ratings yet

- Presentations Oil Refinery ProcessesDocument36 pagesPresentations Oil Refinery ProcessesGururaj SreepatharaoNo ratings yet

- Wind Diesel Systems by Krishna Raghavan, Arrakis AssociateDocument7 pagesWind Diesel Systems by Krishna Raghavan, Arrakis Associateanhhung80No ratings yet

- Giac Mo Chapi Tab by Tran Tien - Songsterr Tabs With RhythmDocument1 pageGiac Mo Chapi Tab by Tran Tien - Songsterr Tabs With Rhythmanhhung80No ratings yet

- Calculate Z follow Peng Robinson Equation: P (kpa) T (K) Pc (kpa) Tc (K) R A B a b W f (Z) Z MW ρ kg/m3 V=ZRT/PDocument1 pageCalculate Z follow Peng Robinson Equation: P (kpa) T (K) Pc (kpa) Tc (K) R A B a b W f (Z) Z MW ρ kg/m3 V=ZRT/Panhhung80No ratings yet

- Fuel PropertiesDocument20 pagesFuel Propertiesanhhung80No ratings yet

- Hyundai Pump SUBMERGED C PUMP PDFDocument0 pagesHyundai Pump SUBMERGED C PUMP PDFanhhung80No ratings yet

- Manuals Plate and Shell Heat Exchanger Brochure PDFDocument2 pagesManuals Plate and Shell Heat Exchanger Brochure PDFanhhung80No ratings yet

- INTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESDocument89 pagesINTERNAL PRESSURE CALCULATIONS FOR PIPING & PIPELINESCastro Quinteros WinstonNo ratings yet

- Gas Turbine Inlet Air Cooling System: Bob OmidvarDocument41 pagesGas Turbine Inlet Air Cooling System: Bob OmidvarKangjin ChoNo ratings yet

- Các dấu trong Tiếng AnhDocument2 pagesCác dấu trong Tiếng Anhanhhung80No ratings yet

- Carbon Capture and Storage: Reducing CO2 Emissions to 24 Billion TonsDocument15 pagesCarbon Capture and Storage: Reducing CO2 Emissions to 24 Billion Tonsanhhung80No ratings yet

- Advantages & Disadvantages CITWDocument5 pagesAdvantages & Disadvantages CITWSreePrakashNo ratings yet

- Procedure Installation of Lighting - LABUAN BAJO PDFDocument6 pagesProcedure Installation of Lighting - LABUAN BAJO PDFWika Djoko ONo ratings yet

- Manage Safety Changes (MOCDocument5 pagesManage Safety Changes (MOCWirawan Adi Setya RNo ratings yet

- Resume of MD Saiful HyderDocument4 pagesResume of MD Saiful Hyderimtheboss*No ratings yet

- Microcontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiDocument4 pagesMicrocontrolled Electromagnetic Engine: Atul Kumar Singh, Prabhat Ranjan TripathiTarun SinghNo ratings yet

- Operating Instructions, FormulaDocument35 pagesOperating Instructions, FormulaandymulyonoNo ratings yet

- Power Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesDocument29 pagesPower Transmission, Distribution and Utilization: Lecture# 13 &14: Underground CablesPhD EENo ratings yet

- W 7570 enDocument276 pagesW 7570 enthedoors89No ratings yet

- Interaction & Bank EffectDocument6 pagesInteraction & Bank EffectAkash KandwalNo ratings yet

- How To Install GmtsarDocument24 pagesHow To Install GmtsardedetmixNo ratings yet

- YCMOU-6th Semester Question Papers-7Document5 pagesYCMOU-6th Semester Question Papers-7phase_shekhar21No ratings yet

- Civil 3 8sem PDFDocument43 pagesCivil 3 8sem PDFG0utham100% (1)

- Operation Manual: Daikin Room Air ConditionerDocument92 pagesOperation Manual: Daikin Room Air ConditionerbenNo ratings yet

- AS1895/7 E-FLEX Sealing Solutions: Part Number AS1895/7 Reference Duct Size Seal DimensionsDocument1 pageAS1895/7 E-FLEX Sealing Solutions: Part Number AS1895/7 Reference Duct Size Seal DimensionsAlex Zambrana RodríguezNo ratings yet

- LDX2101 Spec SheetDocument2 pagesLDX2101 Spec SheetGaurav NarulaNo ratings yet

- Pull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLineDocument7 pagesPull Test Procedure - Chile Cabildo & Villa Seca 3MW-SkyLinecnuneza4No ratings yet

- Timing Chain Tensioner ResetDocument4 pagesTiming Chain Tensioner ResetHybrid RacingNo ratings yet

- Online Institute Reporting Slip of The Application Number - 200310422837 PDFDocument1 pageOnline Institute Reporting Slip of The Application Number - 200310422837 PDFRohith RohanNo ratings yet

- Modernize Customer Service with a Cloud-Based Contact CenterDocument11 pagesModernize Customer Service with a Cloud-Based Contact CenterMishNo ratings yet

- Grounding Vs BondingDocument2 pagesGrounding Vs BondingVictor HutahaeanNo ratings yet

- ESD Protection in CMOS: Characterization and Failure AnalysisDocument113 pagesESD Protection in CMOS: Characterization and Failure AnalysisElisavNirolfNo ratings yet

- Filter DesignDocument4 pagesFilter Designhassan11783No ratings yet

- CS-280E Chain Saw: Parts CatalogDocument16 pagesCS-280E Chain Saw: Parts CatalogГоран СтанишићNo ratings yet

- Engine & Transmission ToolsDocument45 pagesEngine & Transmission Toolsabduallah muhammad100% (1)

- Parts List 8198417 RevCDocument12 pagesParts List 8198417 RevCSonaina KhanNo ratings yet

- Anchors and Fall Arrest System A Guide To Good Practice: PublicationDocument22 pagesAnchors and Fall Arrest System A Guide To Good Practice: PublicationEdward C100% (1)

- 5TH Week EnergyDocument6 pages5TH Week EnergyMira VeranoNo ratings yet

- 1 s2.0 S0038080612000790 Main PDFDocument16 pages1 s2.0 S0038080612000790 Main PDFJuanSebastianGamezNo ratings yet

- InverterDocument8 pagesInverterrajinipre-1No ratings yet

- CH (1) : Introduction: 1.1: Database Management SystemsDocument5 pagesCH (1) : Introduction: 1.1: Database Management SystemsaboalfotohNo ratings yet