Professional Documents

Culture Documents

DT Gate-Support Structure

Uploaded by

A M Nagabhushan Ajwal0 ratings0% found this document useful (0 votes)

126 views11 pagesHOSPET FOR THANGARABALU SMALL BANGALORE H.E. PROJECT(2X12.375MW) REV. 1 DRAFT TUBE GATE DESIGN OF SUPPORTING STRUCTURE FOR MONO RAIL HOIST / CHAIN PULLEY BLOCK 1 DESIGN DATA sl DESCRIPTION VALUES no. 1 Type of Gate Fixed wheeltypevertical gate 2 Size of vent 4350mmx3550mm 3 no. Of

Original Description:

Original Title

Dt Gate-support Structure

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHOSPET FOR THANGARABALU SMALL BANGALORE H.E. PROJECT(2X12.375MW) REV. 1 DRAFT TUBE GATE DESIGN OF SUPPORTING STRUCTURE FOR MONO RAIL HOIST / CHAIN PULLEY BLOCK 1 DESIGN DATA sl DESCRIPTION VALUES no. 1 Type of Gate Fixed wheeltypevertical gate 2 Size of vent 4350mmx3550mm 3 no. Of

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

126 views11 pagesDT Gate-Support Structure

Uploaded by

A M Nagabhushan AjwalHOSPET FOR THANGARABALU SMALL BANGALORE H.E. PROJECT(2X12.375MW) REV. 1 DRAFT TUBE GATE DESIGN OF SUPPORTING STRUCTURE FOR MONO RAIL HOIST / CHAIN PULLEY BLOCK 1 DESIGN DATA sl DESCRIPTION VALUES no. 1 Type of Gate Fixed wheeltypevertical gate 2 Size of vent 4350mmx3550mm 3 no. Of

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-1

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

DRAFT TUBE GATE

DESIGN OF SUPPORTING STRUCTURE FOR MONO RAIL HOIST /CHAIN PULLEY BLOCK

1 DESIGN DATA

sl DESCRIPTION VALUES

no.

1 Type of Gate Fixed wheeltypevertical gate

2 Size of vent 4350mmx3550mm

3 NO.vents 4

4 Clear width of opening 4.35 M

5 Clear height of opening 3.55 M

6 No. of gates 4 SET

7 Sill level RL 386.412 M

8 Top of pier level RL 410.00 M

9 Thickness of Abutment Top side/middle 1.5/0.85 M

10 Thickness of pier[inter] 1.30 M

2 PERMISSIBLE STRESSES

sl Type of stress Factor Stresses in kg/cm

no.

1.0 Sturctural Steel Thk : 0 20 mm

Structural Steel - IS : 2062 2006 Yp : 2550 kg/cm2

Grade E250 -A Factor UTS 4180 kg/cm2

a Direct compression &

compression in bending 0.66 YP 1683

b Direct tension and tension

in bending 0.66 YP 1683

c Shear stress 0.45YP 1148

d direct stress in compression 0.60YP 1530

e Bearing stress 0.75 YP 1912

Stresses in kg/cm

5 Bearing stress in concrete M25 50

6 Shear stress in concrete M25 8

7 Allowable deflection = span/750 <50mt cap.

span/500 manual operation

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-2

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

3 Height of column

Top of pier level RL 410.00 M

Sill level RL 386.412 M

LIFT = 23.588 M

height of Lifting point in gate = 3.9 M

Hoist Hook to Rail girder flange= 2 M

clearance above pier level= 0.3 M

Height of mono-rail beam = 0.6 M

Height of column = 6.8 M

Proposed 7.0 M Height columns

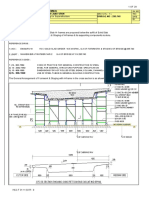

4 Load on column while operating

Max. lifting capacity of Monorail = 17.5 MT

Load on column with impact factor of 10%= 19.25 MT

weight of monorail plus Girder 1.5 MT

TOTAL = 20.75 MT

Total Load on columns= say 21 MT

The arrangement of column & girder is shown below

NIY SA NIY SA

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-3

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

5 Design of main mono rail beam on vent

Stop log gate elements are to be lifted one by one in each unit induidially

Hence load on succussive girder / column is not considered for design.

21000 kg

A B RA=RB= 10500kg

435+65+65=565cm

Max. B.M = 10500X565/2=2966250kgcm

a Proposed ISMB 500X180with ad.flange of 200x14 at bottom and ISMC250X80 at top

SL SECTIONS AREA

NO. W T

1 Flange[1] 25.0 0.71 17.75

2 Flange[2] 18 1.72 30.96

3 web 46.56 1.27 59.1312

4 Flange[3] 18 1.72 30.96

5 Flange[4] 20 1.4 28

166.80

A = 166.8 cm

Y1 = 27.3 cm

Y2 = 26.6 cm

Y3 = 24.8 cm

Ixx = 76255.2

Z1 = 2790.6

Z2 = 2865.0

Z3 = 3076.8

Iyy = 1369.8+2bd^3/12= (1369.8+(1*1.4*20^3/12)+3828.4)

6131.5

2966250

Max. bending stress = = 1063 kg/cm

2790.6 <1380kg/sqcm hence safe

5 xwl 5x21000 x 540

Max. deflection in girder = =

384 x EI 384x20.70 x 10^5 x 76255.2

= 0.27 cm

L 540

Allowable Deflection= = = 0.72 cms

750 750

Sear stress=fs= 21000/2/46.56/1.02= 221 kg/sqcm

DIMENSIONS

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-4

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

b Calculating the Max. Permissble bending stress as IS800-1984 Cl 6.2.3

fbc= 0.66 fcbxfy

[(fcb)^n +(fy)^n]1/n

fy=y.p=2550kg/sqcm

n=1.4

ryy= SQ,RT.of [Iyy/A]=SQ RT of [6131.5/166.8]=6.06

fcb= k1[X+k2Y]c2/c1

l/ry=565/6.06=93 X=464 k1=1 c2/c1=1

[Table-6.5] [Table 6.4&6.3]

D/T= 52.11/3.12=16.7 Y=327 k2=0.5

fcb= 1*(464+0.5*327)*1

= 627.5

As per table 6.2 for fcb =627 the allowable permissible stress

is=

fbc= 1380 kg/sqcm [table 6.2]

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-5

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

c Check for local bending of flange due to monorail long travel hoist wheel load

The stress resulting from local bending is given an empherical formula[xyplane]

x= KaxxP/t^2(root)

where kax=2

Flange thickness=t=1.72+1.4=3.12 for value of

c/a =62.5/85=0.735

p= Hoist load xImpact factor+self wt.

4 [nos. of wheel]

= 21000x2

= 10500 kg

4

10500

x= = 1079 kg/sqcm

3.12^2

The stress resulting from load bending y-z plane

y= KazxP/t^2 where kaz=0.6

for value of

c/a =62.5/85=0.735

y= 5250X0.6 /3.12^2 = 324 kg/sqcm

combined stress at inside of the flange

c=

x + y + x x y

=

= 2107 kg/sqcm <0.85x2550=2167kg/sqcm

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-6

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

7 Design of columns [END/INTERM-PIER]

Max. reaction of girder on column = 21000 kg

Height of column= 800 cms

Proposed 2- ISMC300X90 BACK TO BACK

A=45.74x2= 91.48 cm^2

Ixx=2xIyy+2xAx[D/2]^2

Ixx=2x311.5+2x45.74x20^2 = 37215 cm^4

Iyy=2xIxx+2xwx[D/2-t of web]^2/12

Iyy=2x6384.2+2x9x[40/2-7.6]^2/12 = 13281 cm^4

Zxx= 37215/[D/2+FLW/2]= = 2482 cm^3

Zyy== 13281/[D/2] = 885.4 cm^3

rxx= SQ,RT.of [Ixx/A]=SQ RT of [37215/91.48]=20.2 cm

ryy= SQ,RT.of [Iyy/A]=SQ RT of [13281/91.48]=12.05 cm

Effective Ht. of column

Lxx=1.5*700= 1050 cm

Lyy=0.5*700= 350 cm

LXX/rxx= 1050/20.25= 51.9 <200

Lyy/ryy= 350/15.6= 22 <200

permissible compressive stress for l/r =52 is 1164 kg/sqcm

actual compressive stress in column= 21000/91.48= 230 kg/sqcm

max.load on colomn= 21000 kg

self wt.of column+beam= 1000 kg

total load 22000

Max. compressive stress in column= 22000/91.48= 240 kg/sqcm

BASE PLATE

FLOW

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-7

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

WIND LOADS

A]Wind in the direction of flow

wind pressure= 160 kg/m^2

width of column= 0.3 m

form factor 1.6

wind load per mtr ht of column=

0.3x160x1.6= 77 kg

B]Wind from main girder

wind pressure= 160 kg/m^2

width of column= 0.62 m

form factor 1.6

effective length of girder on each colomn=

7.8/2= 3.9 m

wind load on column=

0.55*3.15x160x1.6= 619 kg

C]Wind form mono-rail hoist

wind pressure= 160 kg/m^2

width of hoist= 0.6 m

ht of hoist 1

form factor 1.6

effective load on each colomn= 50%

wind load from hoist on column= 0.6*1.5x160x1.6x1/2=

77 kg

total wind load on top of column= 619+77 696 kg

A

B

WIND LOAD

A WIND LOAD

WIND LOAD

WIND LOAD

MA

AXIAL

LOAD-P

A

B B

A

AXIAL

LOAD-P

AXIAL

LOAD-P

FLOW

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-8

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

Moment at -A

a]due to wind load on wind ward column

MA1= 77x[700/100]x700

2

188650 kgcm

a]due to concentrated load at B

MA2= 696*700

487200 kgcm

Total moment at A

MA= MA1+MA2= 675850 kgcm

For Int/end column

Stress in column at A due to moments

fa= MA/Zxx= 763 kg/sqcm

<1683 kg/sqcm

check for unity formula (240/1164+763/1683) 0.7 <1

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-9

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

8 BATTENS

Battens are proposed for columns

Heght of column= 700cm

r min. Of column= 12.05cm

L/r min. = 58.1

spacing of battens shall be minimum of following

1] L/r min. < 40

2] 0.6XL/rmin. = 0.6x58.1= 35 <40

l= 35x12.05 = 422 cm

Proposed battens at 1000mm c/c =d

Depth of intermediate batten =300mm

Thickness of batten =10mm

Adopt battens of size 300x10 mm at 1000mm c/c.

Transverse shear=S = 2.5%Xof axial load

Transverse shear=S = 2.5%X22000 = 550 kg

Longitudinal shear =Sd/na s= transeverse shear

Moment=Sd/2n d=c/c distance of battens longitudinally

n=no of parallel planes of battens

a=min. distanace across welds

(450-2*15)=420mm

Moment=Sd/2n = 550x100/(2x2) = 9625 kgcm

Longitudinal shear =Sd/na= 550X100/(2X42) = 458 kg

distance between centroids of member=400mm =c

min. effective depth reqdd=75% of c = 300mm provide 300mm

Longitudinal shear stress = 458/[30x1] = 54kg/sqcm

Bending stress = 22000/2

= 212 kg/sqcm

1/6 x1x30 < 1530 kg/sqcm

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-10

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

9 Design of Column base plate

Proposed base plate= 600x400x20mm

moment on each column base = MA= 676850 kgcm

Total load on column= 22 mt

a]The thickness of base plate requiored as per cl.6.4.3 of IS800 is

t= 3w[a^2-b^2/4]fb

t= thickness of base plate

w=the pressure of loading

under base plate=22000/[60x40]= 9.2 kg/sqcm

a= the greater projection of plate beyond column= 10cm

b= the lesser projection of plate beyond column= 10cm

fb=1530 kg/sqcm

t= 1.3 cm Providded 20mm thickness of plate

b]checking the unit width of cantilever portion

bending moment = 9.2x10x10/2= 460 kgcm

0.666

bending stress= 460/0.66= 697 kg/sqcm

<1530kg/sqcm

BASE PLATE

FLOW

DESIGN CALUCULATIONS OF

KARE POWER M/S NARAYAN SUPPORT STRUCTURE FOR PAGE-11

RESOURCES PRIVATE ENGINEERS DRAFT TUBE GATE HOIST

LTD. HOSPET FOR THANGARABALU SMALL

BANGALORE H.E. PROJECT(2X12.375MW) REV. 1

10 Design of Foundation Bolts

Proposed 6nos. of Bolts/column

Distance between holes c/c= 50cm

No. of effective bolt= 3

Max. B.M. in column= 676850 kgcm

Tensile load on each Bolt/ column = 50cm

676850 =

Proposed 20 mm bolts

50x3 5355 kg

A in Tensile = 9.425cm^2

A in Shear = 8.01cm^2

Tensile stress in Bolt= 5355/9.425=568kg/sqcm <945kg/sqcm

Shear stress = 22000*10%/(2x8.04)=131kg/sqcm

Length of bolt =l= 5093 = 90cm

px2x9 [M-250 Shear stress=9kg/sqcm]

Adopted 1200 mm long bolt with 50 mm thread length..

10a Check for compressive stresses in concrete

MA= = 676850 kgcm

Ecentricity=e= mc/pc= 676850/2200= 30.76 cm

size of column base= b=40cm h=60cm

e/h= 11.75/60= 0.512667

Area of tensile steel = 9.425 [2xpie/4xd^2]

AREA OF COM. STEEL = 0

EFFECTIVE DEPTH=h-d1=60-5=55cm

[b*h^2/6]+[2(ac-1)Asc/h] x[0.5h-d1]^2

modulus section =J= (40*55^2/6)+((2*13-1)*16.08)/55*(0.5*55-5)^2

= 22335.488

Atr=b*d+(m-1)Asc= 40*55+(13-1)*16.08 m=13

= 2313.1

Max comp stress= PC*1000/Atr+Mc/j

(22000/2313.1)+(803200/222335.5)

13 kg/sqcm <50kg/sqcm

Min comp stress= PC*1000/Atr-Mc/j

(22000/2313.1)-(803200/222335.5)

6 kg/sqcm <50kg/sqcm

11 CONNECTION DETAILS BETWEEN MONO RAIL GIRDER &COLUMN GIRDER.

Max. load occurs when pulley block is at cross girder

MAX. designed load = 22000 kg

Proposed 6 nos. of M20 Bolts

A in Tensile = 2.45 cm^2

A in Shear = 3.14 cm^2

Shear stress in bolt= 22000/(6x3.14X2)= 583 kg/sqcm

[double shear] <865 kg/sqcm

ooooooo oooooooo ooooooo

V

You might also like

- Gid 091 CV Cal 3070C PDFDocument9 pagesGid 091 CV Cal 3070C PDFmadhu100% (1)

- Gantry CraneDocument18 pagesGantry Craneamirthraj7494% (16)

- Design of 26m Precast Piles for Bangladesh Power PlantDocument6 pagesDesign of 26m Precast Piles for Bangladesh Power PlantcivixxNo ratings yet

- Shutter DesignDocument28 pagesShutter DesignRajendra Prasad GubbalaNo ratings yet

- Gantry CraneDocument31 pagesGantry CraneWaheed Ahmad100% (1)

- Gantry CraneDocument31 pagesGantry CraneWaheed AhmadNo ratings yet

- Structural Design of Raft Foundation Based On Geotechnical AnalysisDocument6 pagesStructural Design of Raft Foundation Based On Geotechnical AnalysisNaresh KumarNo ratings yet

- Arcelormittal Beams Calculator V3.02: D:/... /Vários/Estruturas Mistas/Madre Escada Apoio 2.PmxDocument6 pagesArcelormittal Beams Calculator V3.02: D:/... /Vários/Estruturas Mistas/Madre Escada Apoio 2.PmxSílvio GonçalvesNo ratings yet

- RCC Oht AlternateDocument50 pagesRCC Oht AlternateVarad Sonawadekar100% (1)

- Precast Pile Analysis & Design.400Document4 pagesPrecast Pile Analysis & Design.400civixxNo ratings yet

- Limit State Design of Liquid Retaining SectionDocument6 pagesLimit State Design of Liquid Retaining Sectionarif_rubinNo ratings yet

- Prestressed Concrete Box Beams Bridge DesignDocument10 pagesPrestressed Concrete Box Beams Bridge DesignPanha MenhNo ratings yet

- CSA S16 09 Example 001Document7 pagesCSA S16 09 Example 001thanzawtun1981No ratings yet

- Unrestrained-Beam (STEEL PROJEK)Document11 pagesUnrestrained-Beam (STEEL PROJEK)AsmatSalSabilaNo ratings yet

- Bridge CH 5 Example On Slab BridgeDocument16 pagesBridge CH 5 Example On Slab BridgeHabhaile Asfaw83% (6)

- Ngasi Consulting Engineers: REF CalculationDocument27 pagesNgasi Consulting Engineers: REF CalculationJohn NjorogeNo ratings yet

- Design Project1Document19 pagesDesign Project1Syed Munawar Ali100% (1)

- Portal Frame Rafter DesignDocument132 pagesPortal Frame Rafter DesignBobor Emmanuel OfovweNo ratings yet

- Scomposite-24.24Document87 pagesScomposite-24.24manish sharmaNo ratings yet

- Example1 1-StraightsupportedDocument7 pagesExample1 1-StraightsupportedOmar BayouNo ratings yet

- Design of Beam to Column ConnectionDocument13 pagesDesign of Beam to Column ConnectionGautam SharmaNo ratings yet

- South Quater at 26-05-2014Document27 pagesSouth Quater at 26-05-2014Oecoep IteemNo ratings yet

- 1017 - 19.08m 9.4.14Document90 pages1017 - 19.08m 9.4.14ravi4paperNo ratings yet

- Gantry Girder UnprotectedDocument95 pagesGantry Girder Unprotectedjignesh14283% (12)

- Main FileDocument9 pagesMain FileSyed Munawar AliNo ratings yet

- DG Consulting EngineersDocument8 pagesDG Consulting EngineersThakshayani SellavelNo ratings yet

- Ba Culvertf TestDocument16 pagesBa Culvertf TestsanjuktaacharyyaNo ratings yet

- Analysis and Design of Monorail BeamDocument93 pagesAnalysis and Design of Monorail BeamkumsbamaNo ratings yet

- RCC FDN Design-Wet SoilDocument12 pagesRCC FDN Design-Wet SoilHikmat AyerNo ratings yet

- Fin Irjmets1683986998Document9 pagesFin Irjmets1683986998Yuvraj Singh BhadoriaNo ratings yet

- Tension Anchors1.3 - Rock BoltsDocument5 pagesTension Anchors1.3 - Rock Boltsibnmessaoud10No ratings yet

- Access Scaffoding DesignDocument10 pagesAccess Scaffoding DesignSyed Munawar Ali100% (5)

- Compression Members ProblemsDocument23 pagesCompression Members ProblemsReyNo ratings yet

- Structural Steel Design Project: Calculation SheetDocument18 pagesStructural Steel Design Project: Calculation Sheetrameshbabu_1979No ratings yet

- Precast Driven Pile 450x450-350x350Document55 pagesPrecast Driven Pile 450x450-350x350civixxNo ratings yet

- Plate StandDocument6 pagesPlate Standmoseslugtu6324No ratings yet

- Abutment 45+705 110110Document106 pagesAbutment 45+705 110110AmbrishNo ratings yet

- Structural design and analysis of a low-rise buildingDocument42 pagesStructural design and analysis of a low-rise buildingMohammed SumerNo ratings yet

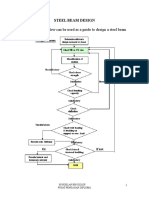

- The Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberDocument27 pagesThe Flow Chart Below Can Be Used As A Guide To Design A Steel Beam MemberIrfan SyafriNo ratings yet

- BOX Culvert Load DetailsDocument7 pagesBOX Culvert Load Detailsragalwar100% (1)

- StaggingDocument12 pagesStaggingBilal Ahmed BarbhuiyaNo ratings yet

- Neintitulat 1Document20 pagesNeintitulat 1Epure GabrielNo ratings yet

- Advanced Design of Steel Structure Composite Beam DesignDocument6 pagesAdvanced Design of Steel Structure Composite Beam DesignNaim YaqeenNo ratings yet

- One Way Slab DesignDocument16 pagesOne Way Slab DesignAssad Mohammed AliNo ratings yet

- Owner:-North Eastern Owner: - North Eastern: Electric Power Corporation Ltd. Electric Power Corporation LTDDocument13 pagesOwner:-North Eastern Owner: - North Eastern: Electric Power Corporation Ltd. Electric Power Corporation LTDIrshad KhanNo ratings yet

- Steel Beam DesignDocument27 pagesSteel Beam DesignSyazwi Akram Ab RazakNo ratings yet

- FORMWORK DESIGNDocument28 pagesFORMWORK DESIGNsubhananya50% (4)

- Difference Beetween Is 800-2007 & Is 800-1984Document96 pagesDifference Beetween Is 800-2007 & Is 800-1984ayazmadNo ratings yet

- Neutral Axis N 72.9712Document9 pagesNeutral Axis N 72.9712Anil PanjwaniNo ratings yet

- RCC footing design calculationsDocument19 pagesRCC footing design calculationsimtiyaz_baadilNo ratings yet

- Design of Box CulvertDocument21 pagesDesign of Box CulvertAnirbanBhattacharjeeNo ratings yet

- 3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesFrom Everand3D Modeling of Nonlinear Wave Phenomena on Shallow Water SurfacesNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Bulk Head - 180515Document90 pagesBulk Head - 180515A M Nagabhushan AjwalNo ratings yet

- Div. Gate Assembly r1 ModelDocument1 pageDiv. Gate Assembly r1 ModelA M Nagabhushan AjwalNo ratings yet

- Kare Gate Roller Assembly 11-02-14 Model - PDF DDocument1 pageKare Gate Roller Assembly 11-02-14 Model - PDF DA M Nagabhushan AjwalNo ratings yet

- Fabrication and Erection of Intake, Draft Tube and GatesDocument3 pagesFabrication and Erection of Intake, Draft Tube and GatesA M Nagabhushan AjwalNo ratings yet

- Operation Manual1 1Document19 pagesOperation Manual1 1A M Nagabhushan AjwalNo ratings yet

- Kasturi Furnace & CCM Shed DrawingDocument1 pageKasturi Furnace & CCM Shed DrawingA M Nagabhushan AjwalNo ratings yet

- Guidelines For Steel Girder Bridge Analysis'Document154 pagesGuidelines For Steel Girder Bridge Analysis'm4004No ratings yet

- InternshipDocument19 pagesInternshipshubha shreeNo ratings yet

- Boring Log Sample ComputationDocument18 pagesBoring Log Sample ComputationMARK VINCENT NAVARRO80% (5)

- Code of Practice for Underground Winding SystemsDocument58 pagesCode of Practice for Underground Winding SystemsSteve PennNo ratings yet

- PEB Structural Components GuideDocument312 pagesPEB Structural Components GuidejjjhassanNo ratings yet

- M04 Rebar WorksDocument66 pagesM04 Rebar WorksReynaldo LugtuNo ratings yet

- Earthworks Construction SpecificationsDocument71 pagesEarthworks Construction SpecificationsFatima EberoNo ratings yet

- SDM Example 3 Steel SMF PDFDocument30 pagesSDM Example 3 Steel SMF PDFRicardoMallmaNo ratings yet

- Piled Raft A New Foundation Design PhiloDocument10 pagesPiled Raft A New Foundation Design Philodhan singhNo ratings yet

- 15 Church Street - BC IssueDocument67 pages15 Church Street - BC Issuemarlonmasudog.jrNo ratings yet

- Monitoring Steel Girder Stability PDFDocument12 pagesMonitoring Steel Girder Stability PDFYaselaNo ratings yet

- The Shard PDFDocument13 pagesThe Shard PDFRuxandra Maria Popescu100% (1)

- Concrete Grade EquivalentDocument3 pagesConcrete Grade EquivalentHoang Duc LocNo ratings yet

- MIT - Precast Floor System 1962Document159 pagesMIT - Precast Floor System 1962Nelson ChinNo ratings yet

- Project Title: Exercise 1Document2 pagesProject Title: Exercise 1tfvnjyNo ratings yet

- RAILPLAN CONSULTANT SDN. BHD. 4-12-2008, Thursday, 15:35:20Document1 pageRAILPLAN CONSULTANT SDN. BHD. 4-12-2008, Thursday, 15:35:20Ahmad ZubirNo ratings yet

- SAP2000 Presentation 200410 Shell, Plate & MembraneDocument6 pagesSAP2000 Presentation 200410 Shell, Plate & MembraneCSEC Uganda Ltd.No ratings yet

- VCB 2023 Concrete Technology: AdmixtureDocument16 pagesVCB 2023 Concrete Technology: AdmixtureYazuraPoyoNo ratings yet

- Advanced Retrofitting Techniques For Reinforced Concrete Structures: A State of An Art Technical ReviewDocument24 pagesAdvanced Retrofitting Techniques For Reinforced Concrete Structures: A State of An Art Technical ReviewHARSHALNo ratings yet

- Progress-Report Toril 01.30.2020Document1 pageProgress-Report Toril 01.30.2020Fedilino P. FornollesNo ratings yet

- Souq House-GF PlanDocument1 pageSouq House-GF PlanØwięs MØhãmmedNo ratings yet

- Deflection of Simply Supported and Cantilever BeamsDocument7 pagesDeflection of Simply Supported and Cantilever BeamsZol Has100% (1)

- CIEM6000S - Lecture7 - 2023Document75 pagesCIEM6000S - Lecture7 - 2023K. Y. S LAUNo ratings yet

- 435R-95 Control of Deflection in Concrete StructuresDocument89 pages435R-95 Control of Deflection in Concrete StructuresIbrahim MNo ratings yet

- RCC Lab ReportDocument18 pagesRCC Lab ReportShuvanjan Dahal50% (4)

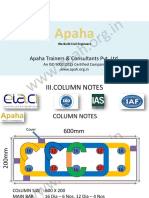

- RCC-Column-Notes - Apaha-Trainers-and-Consultants-Punjisksjd JSJDJSJJSJD Isisjjdd JSJSJDJD JsjsjeDocument17 pagesRCC-Column-Notes - Apaha-Trainers-and-Consultants-Punjisksjd JSJDJSJJSJD Isisjjdd JSJSJDJD Jsjsjepranjal soniNo ratings yet

- HARGA SUBKON Hotel IndonesiaDocument79 pagesHARGA SUBKON Hotel IndonesiaRajinda BintangNo ratings yet

- Investigation of Linear Dynamic Analysis and Duc-Tile Design of High Rise Structure As Per Revised Indian CodeDocument12 pagesInvestigation of Linear Dynamic Analysis and Duc-Tile Design of High Rise Structure As Per Revised Indian CodeIJRASETPublicationsNo ratings yet

- Material ScheduleDocument12 pagesMaterial ScheduleAneeq MustafaNo ratings yet

- Swann Direct Catalogue Wall Ties and Restraint FixingsDocument34 pagesSwann Direct Catalogue Wall Ties and Restraint FixingsHASEEBNo ratings yet