Professional Documents

Culture Documents

Eficiencia Energética en Iluminación

Uploaded by

Mario GonzálezCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eficiencia Energética en Iluminación

Uploaded by

Mario GonzálezCopyright:

Available Formats

E

n

e

r

g

y

E

f

f

i

c

i

e

n

c

y

Power Quality and Utilisation Guide

Energy Efficiency

Lighting

Rob van Heur

Laborelec

June 2007

250

200

150

100

50

0

G

L

S

H

A

L

S

L

/

P

L

S

D

W

/

T

Today 1985 1975

C

D

M

M

H

N

Lamp type

T

L

H

P

I

M

H

D

H

P

L

S

O

N

S

O

X

Q

L

L

E

D

E

f

f

i

c

i

e

n

c

y

(

l

m

/

W

)

2

http://www.leonardo-energy.org

Energy Efficiency

1. Introduction

Energy consumption via lighting systems is signifcant. There are nevertheless many ways to save energy in every

sector. The global electricity consumption for lighting in 2005 is estimated at 2651TWh (terawatthours), i.e. 19%

of total global electricity consumption.

Today the global light production (in lumen) can be divided as follows on the diferent sectors:

- 44 % for lighting of commercial and public building,

- 29 % for industrial lighting,

- 15 % for residential lighting,

- 12 % outdoor lighting (streets, security, road signs and car parks).

Lighting Other

47%

25%

60%

40%

43%

37%

40%

45%

100%

10%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Ofces

Stores

Schools

Hotels and homes

Restaurants and pubs

Hospitals

Warehouses

Other buildings

Public lighting

Industry

Figure 1 Energy consumption in diferent sectors

It is estimated that over the last decade global demand for artifcial light grew at an average rate of 2.4% a year.

The average lighting system had an ef cacy of more or less 18 lumens per watt (lm/W) in the early sixties, in 2005

it reached 50 lm/W.

In of ce buildings lighting is often the biggest consumer of electric energy. Studies have shown that in the service

sector the share of the lighting (for the greater part fuorescent lighting) is, on average, 37% to 45% of the entire

electricity consumption. Estimations for the energy consumption due to lighting in the diferent sectors are given

in fgure 1. We see that the share of lighting in the industry is estimated at 10%. According to estimations 35% of the

share of lighting can actually be saved by means of relighting or ef cient use of lighting in the industry.

2. Technical aspects of lighting

2.1 Defnitions in lighting

When talking about lighting, the following terms are used:

Luminous fux (lumen, lm): Total amount of visible light power emitted by a light source. This value is reported on

the package of a light bulb.

3

http://www.leonardo-energy.org

Lighting

Luminous intensity (candela, cd = lm/sr): is a measure of the luminous fux emitted by a light source in a particular

direction, measured in lumens per steradian.

Illuminance (Lux, lx): the amount of light arriving on a surface. (1lux = 1lm/m

2

) This value is used in light calculations

and design plans.

Luminance (cd/m2): measure of the density of luminous intensity in a given direction. It describes the amount of light

that passes through or is emitted from a particular area, and falls within a given solid angle. Luminance is often used

to characterize emission or refection from fat, dufuse surfaces. The luminance indicates how much luminous power

will be perceived by an eye looking at the surface from a particular angle of view. Luminance is thus an indicator of how

bright the surface will appear. In this case, the solid angle of interest is the solid angle subtended by the eyes pupil.

Colour rendering (-): The colour rendering of a light source is an indicator for its ability of realistically reproducing the

colour of an object. Colour rendering is given as an index between 0 and 100, where lower values indicate poor colour

rendering and higher ones good colour rendering.

Colour temperature (K): The colour temperature is an expression used to indicate the colour of a light source.

According to international standards, the lamp colour is compared with the colour of a black body radiator at a certain

temperature. Its expressed in degrees Kelvin (K). Below 3300K, the source is considered as warm light. Above 5300K,

the source is considered as cold light.

2.2 Levels of lighting

When designing a lighting system, the minimum amount of lighting should be considered. Specifc work requires

a specifc amount of light, which is necessary to do the task ef ciently. The minimum required levels of light for

diferent applications are given in Table 1.

Application Minimum illuminance in lux

Of ces

General of ce work (intermittent reading and writing) 300

Continuous reading and writing 500

Drawing 500

Drawing with special visual requirements 700

Archives, corridors, halls, staircases, dressing rooms, toilets, dining-rooms 100

Sales rooms

Sales rooms 500

Passage ways 200

Storage, packing, loading points, reception of goods 100

Schools

Class rooms 300

Drawing rooms 500

Industry

Passage ways, staircases, storage of raw material, storehouse for cars 50

Treatment of large products, machine rooms, elevators, storage, packing, loading

points, reception of goods

100

Simple assembly, mechanical treatments, cutting and packing of meat, woodwork,

coachwork

200

Simple machine work, control, repair 300

Accurate machine work and assembly, textile work, precise soldering and welding 500

Tasks with special visual requirements like treatment of coloured cotton, wool, silk and

artifcial fbres

700

Tasks with extreme visual requirements like treatment of jewels, clockworks, precision-

instruments, sorting out tobacco, dosing and mixing colours, fnal control of textile

1000

Table 1 Minimum levels of lighting

4

http://www.leonardo-energy.org

Energy Efficiency

The levels in table 1 are the minimum levels that a lighting system should have at the end of its life-cycle. When

designing a lighting system the values in this table still have to be multiplied by a planning factor that takes into

account a decrease in the light production of lamps and armatures over the life span because of deterioration of light

intensity. This factor is also called maintenance or design factor.

Considering for example a design factor of 1.25, the required minimum intensity is 400lx. The system should now

be designed at 1.25 x 400 = 500lx. This will ensure that the minimum intensity is guaranteed during the life span.

2.3 Life span

The most frequently used term is average or median life span: this is the number of operational hours under

standardized ageing conditions in the laboratory, after which 50% of the lamps is defective (a lamp is defective when

it does no longer burn, when it is fickering or when the stream of light has decreased to 70% of the nominal stream

of light.). Usually, this is where the confusion starts, because in America the defnition for average or median life span

is restricted to the life span where 50% of the lamps have fallen out (or, in other words, no longer produce light).

Because of this diference in defnition, the life span in a catalogue of an American manufacturer will be much higher

than the life span of the same type of lamps from European manufacturers.

The economic or useful life span is the life span for usage in real circumstances when x% has fallen out. This percentage

is determined by local requirements or commitments and the cost price of single light relamping compared to group

relamping. In general, it is assumed that the useful or economic life span of fuorescence lamps for functional inside

lighting is the one where 20% of the lamps are defective (30% for outside lighting).

2.4 Critical elements in lighting

The following four elements should be taken into account to assure an appropriate visual perception:

1. Level of lighting

As explained in paragraph 2.2, the minimum illuminance necessary for its designed purpose depends

on the application. Table 1 gives a good overview of common applications. Proper lighting makes work less

tiresome. The (statistical) percentage of tired workers will decrease with increasing lux.

2. Luminance in the feld of vision

Appropriate lighting reduces the (statistical) number of errors made when performing a task.

3. Absence of irritating refection (glare)

The luminance limitation should always be considered. This will be further discussed in paragraph 3.2.

The type of armature will play an important role concerning this topic. The measure that is used to determine

how much light is coming out of a lighting fxture in a particular direction is luminous intensity.

4. Color rendering

This element indicates the ability of the light source to realistically produce the colour of an object.

The diferences of the various types of lamps are discussed in paragraph 3.1

Besides these technical elements, also the esthetical facet is usually taken into account.

5

http://www.leonardo-energy.org

Lighting

3. Energy savings techniques

3.1 Ef ciency of light bulbs

The last decade the light bulb has evolved. Nowadays, there are many types of light bulbs, each with their specifc

energy ef ciency. The energy ef ciency is expressed in lumen / watt.

By making the right choice concerning the type of lamp for a certain application, a lot of energy can be saved. That

is why we always have to consider the energy consumption, the light quality and the investment cost.

In the following table (table 2) diferent types of lamps are compared with regard to life span, ef ciency, light colour

and colour rendering.

Type of lamp Average life span (hr) Ef ciency

(lm/watt)

Light colour Colour rendering

Incandescent lamp

Normal lamps 1 000 6 15 Extra warm white Very good

Halogen lamps 2 000 - 4 000 10 24 Warm white Very good

Low pressure mercury-vapour lamps

(fuorescent lamps)

Tubular lamps (TL) 12 000 -20 000 45 105 Warm white to cool white Good to very good

Compact lamps (CFL) 10 000 - 12 500 40-80 Warm white to cool white Good to very good

High pressure lamps

High pressure mercury-vapour lamps 12 000 30-60 Warm white to cool white Moderate

High pressure sodium lamps

Metal Halide

25 000

12 000-18 000

46 150

72-110

Yellow white

Warm white to cool white

Bad to good

Good to very good

Induction lamps 60 000 50 80 Warm white to neutral white good

Low pressure sodium lamps 18000 100 200 Monochromatic orange none

Table 2 characteristics of diferent types of lamps

Lamps can be divided into 4 main categories: incandescent, gas discharge, induction and solid state. Gas discharge

lamps generally contain mercury or sodium gas. This gas can be applied in high or low pressure conditions. Figure 3

shows in which category diferent types of lamps belong.

Incandescent Gasdischarge

GLS Halogen

High pressure Low pressure

Mercury Sodium Mercury Sodium

HPL-N

HPI (T)

MHD

MHN

CDM

SON (T)

SON-C

SDW-T

TL

TL-HF

SL

PL

PLC

SOX

SOX-E

Low voltage

High voltage

QL

Induction

LED

Solid

state

Figure 3 Categories of light sources

6

http://www.leonardo-energy.org

Energy Efficiency

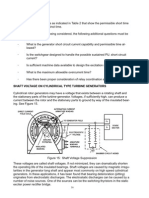

There are many diferences in ef ciency. Over the years the light produce of the diferent lamps has evolved. This

is shown in fgure 4.

250

200

150

100

50

0

G

L

S

H

A

L

S

L

/

P

L

S

D

W

/

T

Today 1985 1975

C

D

M

M

H

N

Lamp type

T

L

H

P

I

M

H

D

H

P

L

S

O

N

S

O

X

Q

L

L

E

D

E

f

f

i

c

i

e

n

c

y

(

l

m

/

W

)

Figure 4 Lamp ef ciency evolution

With regard to the lamp ef ciency, colour rendering and light colour of the various types of lamps, there are big

diferences.

Incandescent lamps have the lowest ef ciency: 95% of the power taken up is lost as heat, only 5% is converted into

light. On the other hand, incandescent lamps have an excellent colour rendering, which implies that in the radiated

light all frequencies and also all colours are represented. Moreover, their purchase price is low.

Incandescent lamps can be used in applications with less burning hours or applications which demand high colour

rendering.

High pressure mercury gas discharge lamps produce almost white light and are used in applications where a high

power lamp is needed with good ef ciency (30-60 lm/W) and good colour rendering (80). High power versions are

used at sports felds and sports halls where the lamp is mounted at great height. Mercury vapour lighting is the oldest

HID technology and can be considered obsolete.

High pressure sodium gas discharge lamps produce yellow-white light and are often used in street lighting

applications in populated areas such as cities or villages. The ef ciency is about 100-150 lm/W. Colour rendering

is low at about 25.

Metal halide lamps are among the most energy ef cient sources of white light available today (up to 100lm/W). Like

fuorescent and high-pressure sodium lamps, metal halide lamps produce light by passing an electric arc through

a mixture of gases. In a metal halide lamp, a compact arc tube contains a high-pressure mixture of argon, mercury,

and a variety of metal halides. Colour rendering is very good, up to 96.

Low pressure mercury gas discharge lamps produce white light. Fluorescent lamps (TL, PL etc.) are the most common

gas discharge lamps.

Fluorescent lamps are used in applications where good colour rendering (80-90) and good ef ciency (up to 105 lm/W)

are essential. They are used in of ces, shops, schools, factories, etc.

In 1995 the TL5 was introduced. The TL5 is characterised by a diameter of only 16mm. Also the TL5 is a little

bit shorter than its predecessors. This allows the armatures to be smaller, which has economical and esthetical

advantages.

Another example of fuorescent lamps is the compact lamp (SL). Power ef ciency is good (50lm/W) with good

colour rendering (80-90). Compact fuorescent lamps have the same size and ftting as normal incandescent lamps.

This means that for example a 75W incandescent lamp can easily be replaced by an 18W SL lamp. The life span is

about 8 times longer than the incandescent lamp. Compact fuorescent lamps are most commonly used in domestic

applications.

7

http://www.leonardo-energy.org

Lighting

Low pressure sodium gas discharge lamps produce monochromatic yellow light. The ef ciency is very good (200 lm/W)

but they have very poor colour rendering. Because of the poor colour rendering these lamps are only used in applications

where colour rendering is less important. Most commonly these lamps are used for security lighting and street lighting

in non populated areas.

Induction lamps produce white light. They were introduced in the early 90s and have good ef ciency (80lm/W) and

colour rendering (80-90). However, the most important advantage is the life span of over 60.000 hours. Therefore

induction lamps can be used in applications where a long life span is required.

Solid state lighting (SSL): The next revolution in lighting technologies has begun with the developments of the Solid-

state lighting in the form of light-emitting diodes (LEDs) and recently organic light-emitting diodes (OLEDs). LEDs are

made of semiconductor material and emit light when a current passes through them. Power ef ciency is fairly good

(45lm/W) and is expected to become even better in the near future. LEDs are available in a wide variety of color and

power.

3.2 Ballasts

A ballast has to be used together with a fuorescent lamp to operate it. In relation to energy ef ciency the power

consumption of the ballast should be considered. A considerable diference in ef ciency exists between the various

ballasts found in the industry. Very inef cient ballasts can use up to 20% of the total energy consumption. Remark

that, with an energy-ef cient ballast, not only the ballasts will consume less, but also the lamps will consume less.

The total energy saving can run up to 40% of total consumption.

There are 2 main categories of ballasts, electronic and conventional electromagnetic ballasts. Also the starters, which

are used in combination with the ballasts, can be conventional or electronic. Several aspects have to be taken into

account when choosing a ballast and starter. The characteristics do not only depend on the type of system, but also

on the manufacturer. Important aspects are:

! Investment cost

! Energy ef ciency of the total lighting system

! Lifetime of the ballast

! Lifetime of the lamp (which is infuenced by the ballast)

! Possibility of fickering and/or stroboscopic efect when starting the lamp

! Heat development of the ballast and lamp

! Possibility of dimming

! Infuence on the power quality of the power supply line

! Possibility of stroboscopic efect

! Size and weight of starter and ballast

! Durability against environmental infuences, mainly the ambient temperature

! Infuence on light production during life span

3.3 Armatures

Light bulbs are mounted in an armature. The type of armature has a great efect on the energy ef ciency. Not all light

that is produced by the lamp leaves the armature. This is, among other things, because of the shape and the material

of the mirror and the shield at the bottom of the armature.

The main function of the armature is to refect the light towards its designated area. A light bulb produces light at 360

degrees. The armature will guide and refect the light to make it a useful beam.

The ef ciency of an armature is the ratio between the amount of light produced by the light bulb and the amount

of light, which leaves the armature.

8

http://www.leonardo-energy.org

Energy Efficiency

In the following table 3 the armature ef ciency for some types of armature is given.

Type of lighting device Armature ef ciency Luminance limitation

Opal difusers 30 to 40% Hardly any

Mirror refectors and shielding at 50 50 to 65% Excellent

Mirror refectors and shielding at 60 60 to 75% Very good

Industrial armatures and linear assembly 70 tot 90% Little to good

Table 3 Armature ef ciency for a few types of armatures

The luminance limitation should always be considered. For example, in an of ce building with a lot of computer

screens, an armature with less luminance limitation will cause a lot of refections in the computer screens.

The ef ciency of the lighting will be good, but the lighting will not be functional.

In general, the more attention is paid to shielding the stream of light from the lighting device to avoid blinding,

the lower the ef ciency of the device becomes.

3.4 Lighting control

Energy consumption of lighting systems is directly linked to the number of burning hours. It is obvious that reducing

the number of burning hours will reduce the amount of energy that is used.

Another way to save energy is to dim the artifcial light when there is enough daylight present.

In this chapter a number of techniques are explained.

3.4.1 Presence of people

In many buildings it is common that the lights are still switched on, without anyone being present. Not everybody

switches the light of when he or she leaves the room. There are many ways to address this problem.

! Central time-switch: This is a quite simple solution. At pre-programmed times (for example after working hours)

all or some of the lights are switched of. This can be done by a short interruption pulse in the power supply.

After the pulse the light can be switched on as usual. It is important to separate power supplies from other

power supplies because of the short power interruptions. The switch of pulse can also be generated when for

example a burglary alarm system is set active. This will ensure nobody is present when the lights are switched

of.

! Presence detection: Can be used for rooms that are used rarely or intermittently. For example toilets, storage

rooms, etc. The lights are switched on / of by sensors which detect the presence of persons in the room.

It is important to use specifc sensors for this purpose. Sensors based on infrared as well as ultrasonic techniques

are capable to detect persons, even when they do not move. This will avoid that lights are switched of when

someone is still present.

! Advanced control systems: In buildings which have a pattern of usage that is known in advance programmable

controls can be used. For example, in schools lighting can be switched on /of according to the timetable.

3.4.2 Presence of day light

Energy in lighting systems can also be saved when daylight is used. Often lights remain switched on, although there

is enough daylight present. Energy can be saved when the amount of artifcial light is reduced, according to the

amount of natural light (daylight). This can be done by on/of switching, automatic switching, central dimming

systems or decentral dimming systems.

! Switching manually: Switching of the lighting system is done manually for each room, part of a room or even

separate lights. When there is enough daylight present the area near the windows will have enough light,

even when the lights are switched of. The lighting system should be designed in a way that the light can

be switched in rows, parallel to the windows. The function of the switches should be obvious to the users.

This type of switching is easy to install, but is dependent on its usage.

9

http://www.leonardo-energy.org

Lighting

! Automatic switching: Lights or a group of lights are switched on/of according to a central light sensor that

is located in a reference room. An important remark concerning this system is that the light is not switched

on/of frequently during the day: it is preferred to set a delay for switching. Also the user should have the

opportunity to switch the light back on manually.

! Central dimming systems: these systems use a light sensor that is located in a reference room. All the

other rooms are controlled by this sensor. This system can be used for a number of rooms at the same side

of a building. Depending on the amount of daylight present in the reference room the lights will be dimmed

or even switched of. The main advantage of this system is that the intensity of light will be constant during

the day. The transition from daylight to artifcial light will be gradual.

! Decentral dimming systems: In the last years decentral dimming systems are becoming more popular. Big

advantage is that the intensity of light in each room is no longer dependent on the amount of daylight in the

reference room. Each armature has its own sensor to detect the amount of daylight. The quality of the light

sensor (LDR) is important. Every armature should be calibrated so all the lights are dimmed the same amount.

The amount of energy savings is dependent on the amount of daylight in the of ce. The amount of daylight depends on the

size of the windows, building design, size and colour of the room. In standard of ces about 30% of energy can be saved.

In fgure 6 a decision making table is given for lighting control systems.

Daylight available?

Yes No

Pattern of usage

One or two users:

Variable occupation:

*** Local Switching

** Presence detection

* Time switching

* Daylight dependent

switching

Continuous full occupation

*** Local Switching

** Daylight dependent

switching

* Time switching

Very low level of occupation:

No continuous use

*** Presence detection

** Local Switching

* Time switching

* Daylight dependent

switching

All types of usage:

*** Presence detection

*** Time switching and

local switching

Pattern of usage

Multiple users:

Variable occupation:

*** Time switching

** Local Switching

* Daylight dependent

switching

* Presence detection

Usage according to fxed

time table

(not continuous)

*** Time switching

* Local Switching

* Daylight dependent

switching

* Presence detection

Continuous full occupation

*** Time switching

** Daylight dependent

switching

** Local Switching

LEGEND

*** Recommended, will save energy

** Is expected to save energy, pay back time should be considered.

* Can be considered, detailed study is necessary.

Figure 6 Decision making in lighting control.

10

http://www.leonardo-energy.org

Energy Efficiency

4. Human aspect

In all lighting designs the human aspect should be considered. Lighting has a big efect on the physical well being

and productivity.

One of the aspects is visual comfort. The working environment in an of ce has a large efect on the human mood

and productivity. In theory a very energy ef cient lighting system would be a system which only brings light on the

surface where its needed, in general the working surface. In that case the walls and ceilings would remain unlit.

In practice, the room will appear very unlit and uncomfortable. It will not be pleasant to work in such an environment.

Savings in energy (if not done properly) can cause costs in productivity.

Colour rendering and colour temperature is also an aspect which has infuence on the human mood. When the

lighting system in a room has low colour rendering, not all colours will appear as they are. Incandescent lamps have

very good colour rendering, but are energy inef cient. The colour rendering of fuorescent lamps varies from 30 to 90.

In generally, colours will appear better when colour rendering is higher. For example an industrial white light (colour

rendering 33) produces a lot of green and less red. Objects that are lit by this type of lamp will appear greenish.

The human skin will appear a bit pale.

For of ce buildings a colour rendering of 80 is appropriate.

When working with computer screens or other refecting surfaces glare or blinding should be avoided because it will

have a negative efect on the productivity.

5. Conclusions

In lighting design energy can be saved. There are numerous types of lights and armatures. Every application has

its own demands regarding the type of lighting that is used. The human factor should also be considered when

designing a lighting system.

The approach in lighting design demands following action plan in order to improve overall energy ef ciency:

! Determine the type of light bulb that is required for the application.

! Determine the right type of armature.

! Choose an energy ef cient ballast.

! Check for opportunities in lighting control.

! Check for opportunities to use daylight.

! Take in mind the human aspect of lighting.

6. References

[1] Lighting calculation software: www.dial.de

[2] General information: www.energy.gov.on.ca, http://lighting.copperwire.org

[3] Course information HVK1 (Dutch NSVV, www.nsvv.nl )

[4] Horst Lange, Handbuch fr Beleuchtung, Ecomed Verlagsgesellschaft AG & Co. KG, Landsberg am Lech, 1992,

ISBN 3-609-75390-0

You might also like

- 3Ch8 - 8. LIGHTING SYSTEM PDFDocument11 pages3Ch8 - 8. LIGHTING SYSTEM PDFstarykltNo ratings yet

- Zumbotel Lighting HandbookDocument298 pagesZumbotel Lighting HandbookPrecious DeDeNo ratings yet

- Licht Hand BuchDocument298 pagesLicht Hand BuchsumanthdixitNo ratings yet

- Hotel DistributionDocument162 pagesHotel DistributionIbrahimSamirNo ratings yet

- 15 Technical PDFDocument26 pages15 Technical PDFAhmad Hamouda100% (1)

- Lighting SystemsDocument8 pagesLighting SystemsRathnayaka LNo ratings yet

- Lightingdesignstudentsguide Lec EUDocument133 pagesLightingdesignstudentsguide Lec EUCassandra PeredaNo ratings yet

- Lighting Handbook PhilipsDocument223 pagesLighting Handbook PhilipsfmtzvargasNo ratings yet

- Light Illumination PDFDocument18 pagesLight Illumination PDFKirti gargNo ratings yet

- IlluminanceDocument6 pagesIlluminanceFirman Pahrizal100% (1)

- Guide To Lux LevelDocument17 pagesGuide To Lux LevelHarshini Muthukani100% (1)

- Lighting Fundamentals: U.S. EPA Green Lights ProgramDocument19 pagesLighting Fundamentals: U.S. EPA Green Lights Programforevertay2000No ratings yet

- Energy Efficient Artificial LightingDocument17 pagesEnergy Efficient Artificial LightingPathum SudasingheNo ratings yet

- Lighting Handbook 08Document324 pagesLighting Handbook 08Albert TuazonNo ratings yet

- The Fundamentals of Lighting PDFDocument20 pagesThe Fundamentals of Lighting PDFVasilis Karageorgiou100% (1)

- Eacm R16 - Unit-2-2Document36 pagesEacm R16 - Unit-2-2GVRS EEENo ratings yet

- Licht Hand BuchDocument370 pagesLicht Hand BuchMochammad SholichudinNo ratings yet

- Lighting: Electrical Energy Equipment: LightingDocument40 pagesLighting: Electrical Energy Equipment: LightingSurajit BondhopadhayaNo ratings yet

- CVS 467chapter 4 Electrical Lighting Design - 231018 - 094335Document47 pagesCVS 467chapter 4 Electrical Lighting Design - 231018 - 094335Benon NyabutoNo ratings yet

- Lighting FundamentalsDocument31 pagesLighting FundamentalsAnil NairNo ratings yet

- Dimming Fluorescent Lighting GuideDocument9 pagesDimming Fluorescent Lighting GuideshounakroyNo ratings yet

- FAGERHULT Belysningsplanering UKDocument9 pagesFAGERHULT Belysningsplanering UKTommyc1024No ratings yet

- Lighting Part2 LPQIDocument8 pagesLighting Part2 LPQIJorge MazorraNo ratings yet

- Low Energy Artificial LightingDocument25 pagesLow Energy Artificial LightingTewodrosNo ratings yet

- PEC and Principles of IlluminationDocument59 pagesPEC and Principles of IlluminationA.M BravoNo ratings yet

- Lighting FundamentalsDocument43 pagesLighting Fundamentalszeeshanahmad111No ratings yet

- Improving Dairy Farm Lighting EfficiencyDocument18 pagesImproving Dairy Farm Lighting Efficiencyroco13426ygNo ratings yet

- Illum Lec1Document148 pagesIllum Lec1Minerva AbantoNo ratings yet

- Chapter 4 Illumination1Document37 pagesChapter 4 Illumination1GurusumiNo ratings yet

- Lighting and acoustic testing of a lecture hallDocument30 pagesLighting and acoustic testing of a lecture hallMuhammad Zakwan HamiziNo ratings yet

- Lighting Illumination LevelsDocument13 pagesLighting Illumination LevelsAhmed Hanae Kassem100% (2)

- Setting Illumination LevelsDocument31 pagesSetting Illumination LevelsForam PatelNo ratings yet

- Light Level MeasurementDocument10 pagesLight Level Measurementpatel1029poojaNo ratings yet

- Notes On Ligthing TeachersDocument45 pagesNotes On Ligthing TeachersNKWENTI FLAVIOUS TANUENo ratings yet

- Report DesignDocument81 pagesReport DesignMUHAMMAD MUNIR ASYRAF BIN AB RAZAK STUDENTNo ratings yet

- UK, Carbon Trust, Energy Efficiency in LightingDocument32 pagesUK, Carbon Trust, Energy Efficiency in LightingDetlef LoyNo ratings yet

- Lighting SystemsDocument7 pagesLighting SystemsSuhas AcharyaNo ratings yet

- Lighting Fundamentals: The Two Objectives of The Lighting Designer AreDocument58 pagesLighting Fundamentals: The Two Objectives of The Lighting Designer AresenthilkumarNo ratings yet

- Illumination Practices: For Diploma in Electrical EnginneringDocument15 pagesIllumination Practices: For Diploma in Electrical EnginneringJyotirmoy RoyNo ratings yet

- Building Services - IiDocument17 pagesBuilding Services - IiyashaswiniNo ratings yet

- ILLUMINATIONDocument50 pagesILLUMINATIONBeen Carlo De JasminNo ratings yet

- ch2 (LIGHTING)Document19 pagesch2 (LIGHTING)IbrahimSamirNo ratings yet

- Unit 5-Outdoor ApplicationDocument7 pagesUnit 5-Outdoor Applicationsayali GatkalNo ratings yet

- Architecture BLD NOTES 2Document12 pagesArchitecture BLD NOTES 2Mwaniki WilNo ratings yet

- Lighting Retrofit and Relighting: A Guide to Energy Efficient LightingFrom EverandLighting Retrofit and Relighting: A Guide to Energy Efficient LightingNo ratings yet

- Electronics 3 Checkbook: The Checkbooks SeriesFrom EverandElectronics 3 Checkbook: The Checkbooks SeriesRating: 5 out of 5 stars5/5 (1)

- Environment and Energy: Environmental Aspects of Energy Production and Use with Particular Reference to New Technologies a Report of the United Nations Economic Commission for EuropeFrom EverandEnvironment and Energy: Environmental Aspects of Energy Production and Use with Particular Reference to New Technologies a Report of the United Nations Economic Commission for EuropeNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports, Volume 1: Synthetic Methodology to Converters and Components TechnologyFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 1: Synthetic Methodology to Converters and Components TechnologyNo ratings yet

- Architecture - Comfort and EnergyFrom EverandArchitecture - Comfort and EnergyM. SalaNo ratings yet

- Handbook of Energy Data and Calculations: Including Directory of Products and ServicesFrom EverandHandbook of Energy Data and Calculations: Including Directory of Products and ServicesNo ratings yet

- Solar Electricity Basics: Powering Your Home or Office with Solar EnergyFrom EverandSolar Electricity Basics: Powering Your Home or Office with Solar EnergyRating: 5 out of 5 stars5/5 (3)

- Plumbing, Electricity, Acoustics: Sustainable Design Methods for ArchitectureFrom EverandPlumbing, Electricity, Acoustics: Sustainable Design Methods for ArchitectureNo ratings yet

- Protein Tertiary and Quaternary StructureDocument18 pagesProtein Tertiary and Quaternary Structuremaryscribd241No ratings yet

- How To Choose A TransformerDocument2 pagesHow To Choose A TransformerSNo ratings yet

- Construction Materials Store ManagementDocument4 pagesConstruction Materials Store ManagementBharath AswinNo ratings yet

- Car Pollution BookletDocument12 pagesCar Pollution BookletVianaNo ratings yet

- 9315 200-500kVA Installation and Initial Startup Parallel CabinetsDocument3 pages9315 200-500kVA Installation and Initial Startup Parallel CabinetsElvis Eliud HernándezNo ratings yet

- SOLAR BOOST™ 3024i: Installation and Operation ManualDocument19 pagesSOLAR BOOST™ 3024i: Installation and Operation ManualArgenis BriceñoNo ratings yet

- Wave Optics SolutionsDocument26 pagesWave Optics SolutionsAjay AgrawalNo ratings yet

- Operation Guide 3159: Getting AcquaintedDocument6 pagesOperation Guide 3159: Getting AcquaintedhenkNo ratings yet

- Steam Displacement - Kern River Field PDFDocument7 pagesSteam Displacement - Kern River Field PDFSusan Li HBNo ratings yet

- Project ProposalDocument4 pagesProject ProposalRoyNo ratings yet

- Instrumentation & Control Cable ScheduleDocument53 pagesInstrumentation & Control Cable ScheduleAhmad DagamsehNo ratings yet

- Energy Transfer Forms and MeasurementDocument4 pagesEnergy Transfer Forms and MeasurementAlberto CasiniNo ratings yet

- Aircraft DesignDocument159 pagesAircraft DesignVinod Kumar sNo ratings yet

- MCQ Astm Distillation: Abdul Majeed Ahmed Hossam IsmailDocument4 pagesMCQ Astm Distillation: Abdul Majeed Ahmed Hossam IsmailAbdul Majeed AhmedNo ratings yet

- Thyristor 3 Phase InverterDocument31 pagesThyristor 3 Phase InverterjorgeNo ratings yet

- HIGH FREQUENCY FATIGUE FAILURE IN SILENCER/PULSATION DAMPERSDocument6 pagesHIGH FREQUENCY FATIGUE FAILURE IN SILENCER/PULSATION DAMPERS4jawwy markme026100% (1)

- PCH VLT AutomationDrive Design 0 75 KW PDFDocument200 pagesPCH VLT AutomationDrive Design 0 75 KW PDFAnkitdarkoptiNo ratings yet

- Busduct PDFDocument7 pagesBusduct PDFrohith87nairNo ratings yet

- Field Bus CommunicationDocument30 pagesField Bus CommunicationArun KumarNo ratings yet

- Astor: Test TransformerDocument1 pageAstor: Test TransformermominzadahNo ratings yet

- Irfpc50, Sihfpc50: Vishay SiliconixDocument9 pagesIrfpc50, Sihfpc50: Vishay Siliconixxor_45No ratings yet

- Final Expcurves SiDocument37 pagesFinal Expcurves Siمصطفى أحمد عبد الرزاق هاديNo ratings yet

- Question Bank SMDocument10 pagesQuestion Bank SMamurugan_22No ratings yet

- EasyPact CVS - LV510804Document3 pagesEasyPact CVS - LV510804Mouath AlraoushNo ratings yet

- LR HAZID Study For LNG Fuel SupplyDocument116 pagesLR HAZID Study For LNG Fuel SupplyMatteo ConciNo ratings yet

- Chaudhry2021 Does Culture Affect Energy PovertyDocument16 pagesChaudhry2021 Does Culture Affect Energy PovertyRaul MJNo ratings yet

- Motorcycle CatalogDocument24 pagesMotorcycle CatalogCarsten JakobsenNo ratings yet

- Ibrahim Dincer, Adnan Midilli, Haydar Kucuk (Eds.) - Progress in Exergy, Energy, and The Environment-Springer International Publishing (2014) PDFDocument1,055 pagesIbrahim Dincer, Adnan Midilli, Haydar Kucuk (Eds.) - Progress in Exergy, Energy, and The Environment-Springer International Publishing (2014) PDFpheliphs100% (2)

- Zero BezzelDocument2 pagesZero BezzelkhoerulmuftiNo ratings yet

- Guidelines for permissible short time overload current and excitation system design questionsDocument2 pagesGuidelines for permissible short time overload current and excitation system design questionsJuan Fernando UbeiraNo ratings yet