Professional Documents

Culture Documents

Tamesis Manuals Safe Slinging and Signalling

Uploaded by

Seng HeangCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tamesis Manuals Safe Slinging and Signalling

Uploaded by

Seng HeangCopyright:

Available Formats

Guide to

Safe Slinging

and Signalling

2 3

Personal Message Contents

Introduction

Laing ORourke holds Health and Safety as a core business value and is

committed to achieving our vision; Lets all get home safely. Every day.

Our aspiration is that we will strive to create a health and safety

culture where:

Clients choose to work with us because of our relentless

commitment to health and safety

All our sites have a consistent look and feel and are of the

highest possible health and safety standard

Our stakeholders feel proud, empowered and recognised

for their contribution to health and safety

We feel happy for family and friends to work with us

or visit our sites to see how we mitigate risk to ensure

no one gets hurt and we all get home safely every day

We are recognised as having a world class approach

to health and safety.

Ray ORourke

Introduction 2

Who Does What? 6

Planning the Lift 8

Types of Equipment 11

Choice of Sling 14

Safe Use of Slings 15

Schedule of Common Lifts 22

Common Loads 23

The Lift 28

Positioning of Mobile Cranes 31

Outrigger, Crawler and Axle Loads 31

Lifting with Excavators 32

Lorry Loaders 32

Lifting with Forklifts and Telescopic Handlers 33

Care of Lifting Accessories 34

Signalling 35

Load vs Sling Angles 38

Angle Guides 39

4 5

Introduction Introduction

The procedures and methods outlined in this booklet are mandatory on all

Laing ORourke sites and must be followed by all Laing ORourke businesses

and their subcontractors. Additional procedures may apply when working with

different Principal Contractors.

Their authorisation must be recorded by the appointed person responsible for

lifting on the site. Slingers/signallers must know who their crane supervisor is, and

supervisors must ensure that slinger/signallers are working to agreed methods.

The appointed person must ensure that everyone in the crane team has studied

this booklet.

The purpose of the booklet is to give guidance on the correct, efcient and safe

way to lift, move and place everyday items on construction sites. Where the

circumstances of the lift are not covered by this booklet, additional procedures

must be developed by the appointed person (lifting) and the crane team must

be properly briefed in those procedures.

For simplicity, this booklet will refer to all lifting equipment as cranes, but this will

cover all lifting equipment where the load is suspended including:

Tower cranes

Mobile and crawler cranes

Lorry loaders

Runway beam hoists

Fork lift trucks tted with a hook

Excavators tted with a lifting hook/eye

Scaffold cranes.

The Laing ORourke A4 booklet The Safe Operation of Cranes (below) contains

the arrangements for the overall management of lifting operations.

Those arrangements are mandatory for all Laing ORourke crane operations and

a copy of the booklet is held by the appointed person.

The Safe

Operation

of Cranes

Only authorised persons holding a valid CPCS slinger / signaller

card are allowed to attach or detach slings and give signals to the

crane operator.

6 7

Who Does What? Who Does What?

Crane Co-ordinator

The Crane Co-ordinator will plan the sequence

of operations of cranes where there is more

than one crane to ensure components and

cranes will not collide.

Crane Driver/Operator

(CPCS Card)

This is the person who will operate the crane

to position loads or to rig the crane.

Slinger/Signaller

(CPCS Card)

The person responsible for:

Attaching and detaching the load to

and from the crane

The use of correct lifting accessories

Initiating and directing the safe movement

of the crane and load.

Appointed Person

(CPCS Card)

The competent person appointed to have

overall control of all lifting operations on site.

Their responsibilities will include:

The overall planning of lifting operations

The production of method statements

The completion of the Lifting Operations

Assessment Form

Authorisation of slingers/signallers

Maintaining records of tests and inspections

of lifting accessories and equipment.

Crane Supervisor

(CPCS Card)

The crane supervisor will direct and

supervise lifting operations on a day

to day basis to ensure compliance

with the agreed and planned methods

and correct practice.

8 9

Planning the Lift Planning the Lift

Planning all Lifts

Lifting operations must be planned to ensure that lifts are carried out safely and

efciently. The following points must always be considered:

Where loads are to be picked up

Where loads are to be placed

What areas are to be passed over

Proximity of the public

Any obstructions in the way

How the load is to be slung

How slings are to be removed and access to them

How the crane driver will be directed

The weight of the load

The radius of the lift

Any loads from a crane or outriggers and the capacity

of the ground or slab to support them

Weather conditions and light.

For all cranes the Laing ORourke Lifting Operations Assessment Form (LOAF)

must be completed.

The Project Health and Safety Plan will record the overall project specic

arrangements for the control of lifting operations.

The Project Lifting Plan will detail the specic arrangements for lifting.

The Schedule of Common Lifts will dene and describe the common lifts on

the project. Depending on the nature and complexity of the lift these could be

categorised as:

Basic

Standard

Complex.

Basic lifts involve:

Loads of established weight where there are no hazards or obstructions

within the area of operation. Typical examples are pallets of bricks or blocks,

bundles of rebar, scaffold tubes.

Standard lifts involve:

The lifting of general, frequently handled items of established weight, with no

special lifting accessories being required. This booklet describes the slinging

of this type of load and the methods shown are to be used, unless stated

otherwise by the appointed person.

Complex lifts may include:

Large pre-cast units, plant such as air handling units, generators etc.

Complex lifts may require:

Special lifting accessories such as spreader beams to ensure that the load is

lifted safely and without damage

Special connectors to connect to special built in lifting points.

Complex lifts may also involve:

Turning loads over or standing them upright

Using more than one crane to lift a load (tandem lifts).

Therefore, complex lift operations will require:

Consultation with the manufacturer, supplier or designer regarding

the correct way of slinging complex loads

Careful planning

The production of a specic method statement.

Note: Where businesses within Laing ORourke (i.e. Expanded, Select, Malling)

are contractors working for Principal Contractors other than Laing ORourke,

other procedures may apply. These will identify which lifting operations will

require specic method statements.

10 11

Always

Ensure that only authorised

slingers / signallers attach

or detach loads or signal

the crane operator.

Discuss operations with the

crane operator.

Ensure capacity of crane

is sufcient to land load

before lifting.

Include the weight of the

slings etc in the load on the

lifting hook.

Seek expert advice when

using eyebolts, plate

clamps, bull dog grips,

chain blocks etc.

Obtain conrmation that

pre-fabricated rebar

assemblies such as pad

foundations and beams

have been fabricated

to allow safe lifting.

Ensure that scaffold towers

you are asked to move are

designed to be lifted safely.

Never

Wrap hand/tag lines around

hand or body.

Use tie wires or banding to

lift loads.

Leave a suspended load

unattended.

Pass loads over the public.

Use lifting accessories for

towing or pulling.

Ride or climb on machines

or suspended loads.

Lift near power lines.

Stand or walk beneath

a load.

Connect two or more

independently slung loads

at different levels on the

same lift (sometimes known

as chandelier lifts).

Planning the Lift Types of Equipment

Chain Slings

Chains are generally the most versatile

type of sling, as well as being the most

robust. General purpose slings usually

have one, two, three or four legs.

Note that the allowable load is reduced when not using all legs.

For further information refer to pages 16 to 19.

Shortening clutches

Shortening clutches enable a multi

legged chain sling to have different

length legs to adjust to the balance

or required lifting angle of the load.

Clutches must be correctly tted

to avoid failure or shortening of the

chain life.

Chain Sling

Shortening Clutch

12 13

Types of Equipment

Wire Rope Slings

Wire rope slings are normally used for specic items

as they are cheaper than chain slings and can be made

to exact lengths for loads requiring odd leg lengths.

They cannot be bent round sharp corners however

and should be used primarily where shackles are

used to attach the sling to the load.

Wire Rope Sling

Webbing Sling Round Sling

Round and Webbing Slings

Round slings and Webbing slings are used for easily

damaged loads, and for their lightness and ease of

handling when long lengths are required.

However, they are susceptible to damage and must

be protected from sharp edges and from sliding

along the load if used at an angle.

Refer to manufacturers literature

for colour coding and further

information.

Slings must be visually checked

before use and immediately

removed and put beyond use

if damaged.

Types of Equipment

End Fittings

The end ttings on chain slings (and occasionally rope slings) will generally be

either sling hooks tted with safety catches or C hooks.

These hooks are designed to minimise the risk of the load slipping out of the

hook. In addition, the C hook is designed not to catch on obstructions and is

more robust as it does not have an easily damaged safety catch.

Special purpose ttings are available for lifting drums, pipes, packing cases etc.

RIGHT

Sling Hook with

Safety Catch

RIGHT

C Hook

WRONG Do not use

No Safety Catch

Note: Primary hooks and single leg chains must be tted

with safety catches.

14 15

Choice of Sling

Select Plant Lifting Accessory

Tagging System

Every Laing ORourke lifting accessory has its examination status and next

inspection date indicated on a yellow tag.

Thorough Examination

Six monthly thorough examinations by a competent person are required for

lifting accessories such as slings, rings, links, hooks, shackles, swivels, eye

bolts and spreader beams.

Additional information is provided in the Select publication The Safe Operation

of Cranes, App. 7 Lifting Accessories Procedures.

Choice of sling

The construction, length and end ttings will depend on:

The load being lifted

The weight of the load

The size of the load, as larger loads will require longer slings

Longer slender loads would generally be slung at the 1/3rd points of the load

with appropriate leg lengths.

The shape and orientation of the load

Whether or not sling attachment points have been provided

Whether the load could be easily damaged

Whether the load is a single item or a bundle of loose items

Whether the load is palletised

Double wrapping of loose loads will use a long length of sling.

Sling Selection for Basic or Standard lifts - slinger/signallers should choose

the appropriate type of sling or chain according to this booklet and the project

specic Schedule of Common Lifts.

Sling Selection for Complex / Special lifts the slinger/signaller will use the

equipment specied in the method statement.

Safe Use of Slings

Shackles must always be used on lifting hooks if more than one sling is to be

connected to it and if the hook would be overcrowded. The angle between sling

legs on a hook must never exceed 90.

Protecting the Load or Sling

You may need to protect the sling and/or load

from damage.

If the sling passes round any sharp corners,

then suitable packing should be used to protect

the sling and/or the corners of the load.

Note the use of timber packing near the

corners of the load and slip tubes over the

beam anges in the illustration.

RIGHT

Maximum

angle 120

RIGHT

If angle less

than 90

WRONG

Angle too high

(must be less

than 90)

WRONG

Overcrowded

16 17

Safe Use of Slings

A two-legged sling will be marked with its SWL at 90, which will apply

for all angles from 0 to 90.

Note also that it could possibly be marked with its SWL at 120, in which

case the SWL will apply for angles between 90 and 120.

It is generally good practice to keep the angle to between 60 and 90. With the

slings at smaller angles the load is more likely to tip up, and may slide out of the

slings where basket or choke hitch are used.

Do not use any two-legged sling not marked with the SWL for the angle

being used, or for angles greater than 120.

Note that the SWL quoted for a two-legged sling assumes both legs are

equally loaded, and that each leg is straight.

Two Legged Slings

Used as Single Length Slings

Beware that if used as a single-legged sling, the SWL will be half of the SWL

marked on the sling.

For further SWL factors, see page 19.

Note: Hook back unused leg to the link or shackle at the top of the sling.

Two-Legged Slings

For two-legged slings, the angle

between the legs of the sling will

determine its safe working load (SWL).

Safe Use of Slings

A three-legged sling will be marked with its SWL at 45, which will apply

for all angles from 0 to 45.

Note that the SWL for a three-legged sling assumes that all legs are

equally loaded, and that each leg is at the same angle.

Do not use any three-legged sling not marked with the SWL for the

angle being used, or for angles greater than 45.

It is generally good practice to keep the angle to between 30 and 45. With the

slings at smaller angles the load is more likely to tip up.

If used with fewer than three legs, then multiply the SWL

by the factor shown in the table below. For example,

using two legs, take the SWL as being 2/3 of the SWL

marked on the sling.

For further SWL factors see page 19.

Note: Hook back unused leg to the link or shackle at the top of the sling.

Three-Legged Slings

For three-legged slings, the maximum

angle between the legs of the sling and

the vertical will determine its safe working

load (SWL).

Legs SWL x

2 2/3

1 1/3

18 19

Safe Use of Slings

A four-legged sling will be marked with its SWL at 90, which will apply

for all angles from 0 to 90.

(Note also that it could possibly be marked with its SWL at 120,

in which case the SWL will apply for angles between 90 and 120).

Do not use any four-legged sling not marked with the SWL for the angle

being used, or for angles greater than 120.

It is generally good practice to keep the angle to between 60 and 90. With the

slings at smaller angles the load is more likely to tip up.

Note that the SWL for a four-legged sling assumes that all legs are

equally loaded, and that each leg is straight.

If used with fewer than four legs, then multiply the SWL by the factor shown in

the table. For example, using three legs, take the SWL as

being 3/4 of the SWL marked on the sling.

For further SWL factors, see page 19.

Note: Hook back unused legs to the link or shackle

at the top of the sling.

Four-Legged Slings

For four-legged slings, the maximum

angle between opposite legs of the

sling will determine its safe working

load (SWL).

Legs SWL x

3 3/4

2 1/2

1 1/4

Safe Use of Slings

Methods of Slinging

SWL factors also apply according to

the type of sling and how it is used.

Examples for various types of

single-legged slings are shown here.

The same principles also apply to

multi-legged slings.

Single leg

in-line

Single leg

basket

Single leg

back hooked

Single leg

choked

Single leg

halshed

Endless

in-line

Endless

choked

Endless

basket

METHOD OF USE

S

i

n

g

l

e

l

e

g

i

n

l

i

n

e

S

i

n

g

l

e

l

e

g

c

h

o

k

e

d

S

i

n

g

l

e

l

e

g

b

a

s

k

e

t

0

9

0

S

i

n

g

l

e

l

e

g

b

a

c

k

h

o

o

k

e

d

S

i

n

g

l

e

l

e

g

h

a

l

s

h

e

d

E

n

d

l

e

s

s

i

n

-

l

i

n

e

E

n

d

l

e

s

s

c

h

o

k

e

d

E

n

d

l

e

s

s

b

a

s

k

e

t

0

9

0

S

L

I

N

G

M

A

T

E

R

I

A

L

Chain 1 0.8 1.4 1 1.5 N/A 1 N/A

Wire Rope 1 1 1.4 1 2 1 1 1.4

Webbing 1 0.8 1.4 N/A N/A 1 0.8 1.4

Fibre Rope 1 0.8 1.4 1 N/A 1 0.8 1.4

Round N/A N/A N/A N/A N/A 1 0.8 1.4

N/A = not applicable do not use

single wrapped

double wrapped

Safe Working Load (SWL) Factors

20 21

Safe Use of Slings

Sling Hooks

When slinging, hooks must always

face outwards from the crane hook.

Al

Choke Hitch

Do not batter down slings to increase

the grip, allow the angle to form naturally.

Maximum permitted angle is 120.

Choke angle

Safe Use of Slings

Webbing Slings

Wide webbing slings cannot be used

at any sideways angle where the sling

would not be equally loaded across its

width. This will usually apply where the

sides of the load are at. When lifting

round pipes, for example, there would

not be this problem.

Hand/Tag Lines

In certain circumstances, hand/tag

lines should be attached to the load.

These will be used to prevent the load

swinging or spinning and to help to

position it.

Arrange the tag line length and

position to avoid the line snagging

when moving the load.

Wrong

Wide webbing sling loaded

on edge only

Using a hand/tag line

Vacuum Lifting Attachments

Vacuum attachments are frequently used by specialist contractors

Vacuum lifting attachments must be approved and certicated

Dual circuit vacuum lifters are highly recommended with each circuit

capable of carrying the full rated load

Secondary Safety Device (SSDs) such as straps are essential with single

circuit lifters but are also strongly advised on other lifts

Operators must be competent and formally trained in their use.

22 23

Common Loads

Scaffold Tubes

When lifting bundles of tubes, bars or

other loose materials, whether banded or

not, slings should be double wrapped.

The illustration shows slings in double

wrap choke hitch. The SWL factor is 0.8

for chain slings used in this way.

Palletised Loads

An example of a frequently lifted load that

requires special equipment is a pallet of bricks or

blocks requiring crane forks with safety netting.

Note that the mesh size should be smaller than

the smallest item to be lifted.

Concrete and Muck Skips

Concrete and muck skips should not be lifted directly by

the crane hook. A single-leg sling (commonly known as

a drop or skip chain) should be used, as moving a heavy

crane hook precisely into place can be difcult.

Schedule of Common Lifts

Each project should have a Schedule of Common Lifts document.

This schedule will detail the types and weights of the various loads it is

anticipated will be encountered on the project, describe the lifting accessories

that will be required and detail any particular limitations or controls on the lift.

The appointed person (lifting) will prepare this schedule before work

commences and will regularly review and maintain it.

The schedule will also be used to brief the crane team on the correct practices

and techniques for most of the common lifts that will be undertaken.

See example of typical schedule below

11b. Wall Cage

Method:

x ton 2 leg chains onto ym long spreader beam with

drop chains at 1m cc attached to T40 ? lifting bar.

Lifting beams must be provided with feet to avoid

stressing the drop eyes when stored on the ground.

Precautions:

Approval for lift must be in place before lifting

reinforcement.

Refer to Project Task Sheet for fxing and lifting

requirements.

24 25

Common Loads Common Loads

Steel Sections Rubbish Skips

Typical arrangement of special sling, with steel

box sections under skip and steel tube spreaders

to keep sling legs vertical.

Keyhole plates on skip lugs are for location

purposes, not for lifting.

Skips with specially adapted lifting points are

acceptable, providing there has been a thorough

examination every 6 months.

Beware of rusted oors; they can fall out when

the skip is lifted.

Stillages

Wrap slings round corner posts.

Do not attempt to lift double stacked

stillages. Beware of overloading

scaffold boards if landing loaded

stillages on a scaffold.

Columns

Use purpose designed lifting point

or bracket.

Pin

Rubber

Belt

Opertaing

Ropes

Remote release

shackle used

during column

erection.

Pipes

For short pipes, pass sling through pipe. Use a 1.4 SWL

factor for webbing slings used in this way.

For long pipes, use two slings in choke hitch, double

wrapping if slings are likely to slide together. Provided

that no angle exceeds 90, then use the SWL for one

sling for the SWL of this arrangement. Note that a

shackle is required to connect the slings at the top.

Where a pipe is being placed into an adjacent trench,

a single webbing sling can be used, which will make it

easier to engage the spigot into the socket of the next

pipe by allowing the pipe to be suitably angled.

SWL factor for these webbing slings is 0.8.

Beams

Use double wrapped slings when

sling legs could slide together.

The SWL factor is 0.8 for chain

slings used in this way.

26 27

Common Loads Common Loads

ISO Containers and

Portable Ofces

Special lifting gear must be used to lift

containers unless otherwise assessed

and agreed. This gear will be tted

with ISO Twistlocks which are designed

to t the sockets in the corners of the

container.

Never use any type of hook, shackle

or other device tted directly into

these sockets.

Always refer to the portable ofce

manufacturers literature for maximum

weight (ofce and contents) and for

minimum sling leg length.

Before lifting:

Empty or assess weight of contents

Secure loose items that may slide

during lifting

Secure jack legs to eliminate

risk of fall

Check the condition of oor

of containers

Access to attach and detach slings.

Prefabricated Rebar Assemblies

These assemblies rely on tying wire to hold them together.

Attachment points MUST be formally agreed with your appointed person

and temporary works co-ordinator and noted in the method statement

or Schedule of Common Lifts document.

Mesh

Pass each hook of a four-legged chain

through the mesh and return to form

a choke hitch. Lifting points must be

positioned evenly to prevent undue

bending on the mesh bundle. Tighten

bite as necessary.

Mesh and Rebar

Container

Ofce

28 29

The Lift The Lift

Before Lifting

Only authorised slingers/signallers are to sling loads.

After slinging, but before lifting, the following must be considered:

Is there an exclusion zone required under the lift radius?

Are the slings undamaged and properly attached to the load?

Is the crane hoist rope vertical?

Is the load free to be lifted i.e. not xed to anything else?

Are the legs of a multi legged sling equally loaded?

Are the slings free of knots, tangles, etc?

Are spare sling legs hooked up to the master link on the lifting hook?

Is the safety catch on the lifting hook closed?

Are there any obstructions above the load preventing a straight lift?

Is the master link on the lifting hook free and in the centre of the bowl

of the hook?

Are all personnel clear of the load?

Is there a slinger/signaller in position to receive the load?

Is the landing site prepared to take the load?

Are the weather conditions acceptable?

If required, are hand/tag lines attached to the load?

Are there sufcient slingers/signallers in position to keep an eye on the load

at all times during the lift and to direct the crane operator?

If the above are addressed, then, and only then, may the load be lifted.

Taking the Weight

As the load comes onto the crane, the jib may deect (especially telescopic

jibs). The crane operator will correct this so the hoist rope remains vertical.

The slinger/signaller should also be aware that the load may swing.

Lifting the Load

Now slowly lift the load a short distance above the ground.

Then check that:

The load is balanced and stable

The legs of the sling are at the correct angles

Any packing pieces are in place and sound

The load itself is not over stressed, especially when lifting packing cases,

timber, large pre-cast or pre-stressed concrete units etc, which could fail

under the loads applied due to lifting.

Be aware that relatively large, light loads can be blown about

by the wind.

Warning! For a 6m

2

shutter, with the wind blowing at a speed of 31mph

(14 m/s), the sideways force on the ply is equal to the weight of an

11 stone (73 kg) man! An 8 x 4 sheet of ply would still be half this.

30 31

The Lift The Lift

During the Lift

The load can now be lifted and moved to its landing area.

While in the air, avoid:

Where possible, passing over personnel working on the site

Lifting over or near members of the public

Power lines

Projecting scaffolding

Air space violation.

Landing the Load

The load should be landed gently to ensure it is not damaged and that the

crane does not receive any shock loading.

Before landing the load, check that:

The landing area will take the weight of the load

There is sufcient space for the load

There are strips of timber or similar on which to land the load such that the

slings can be easily removed by hand.

The slinger / signaller must ensure they are in a place of safety when receiving

the load, ensuring they cannot be crushed between the load and a xed object

or pushed over an open edge.

A safe means of access should be used to reach the slings on tall items.

After the Lift

Only trained and authorised slingers / signallers are permitted to detach slings

from the load.

Take care with bundles of tubes and similar items as they can collapse when

landed. Pipes can roll, so make sure suitable chocks are used to prevent this

from happening.

The legs of the sling should now be hooked back onto the master link, shackle

etc on the crane hook, or removed and stored properly.

Positioning of mobile cranes

The siting and positioning of mobile cranes must be carefully considered

to identify risk from poor ground, local services, proximity of other hazards

and access

In some circumstances, special permits or consents may be required.

Outrigger, crawler and axle loads

The temporary works co-ordinator must be consulted on the bearing

capacity of the ground or oor slabs on which cranes may be positioned

The temporary works co-ordinator must be consulted on or check the design

of spreader beams or mats required under outriggers, axles or crane tracks.

32 33

The Lift

Lifting with excavators

Excavators lifting any suspended loads are cranes, so relevant crane

assessments and documentation are required, including Lifting Operations

Assessment Forms (LOAFs)

Loads may only be suspended from approved lifting points, not the bucket

Excavators are restricted to very basic lifting at or near ground level and

should not travel with a load, except over very short distances

Only CPCS carded slinger signallers can attach or detach suspended loads

unless the Health Safety & Environmental Director has previously approved

in writing an alternative qualication for special circumstances.

Lorry loaders

Lorry loader operators must hold a CPCS or ALLMI card

Suppliers deliveries do not require a LOAF where ground conditions

are good and there are no special hazards

General site lifting duties using lorry loaders are subject to the same

procedures as for conventional crane lifts and include planning, testing,

supervising and executing the lift

CPCS certicated slinger signallers must attach or detach loads (where

this is not carried out by the trained delivery driver).

Lifting with forklifts & telescopic handlers

Forklifts lifting suspended loads are dened as cranes so relevant crane

assessments and documentation are required, including LOAFs

Forklift operators require a CPCS Operators card and use CPCS Slinger

Signallers to attach/detach loads

Special certicated lifting adaptors must be used to centre the load

Forklifts and telehandlers should avoid travelling with suspended loads

due to the high risk of dynamic instability. The use of a crane is usually

a better option.

The Lift

34 35

Signalling

Generally, signals will be given to the crane operator either by radio

or by hand signals. This will be decided by the appointed person and

detailed in the project lifting plan.

Radio Signals

If radios are chosen, then the following method of use must be followed:

All instructions must be repeated continuously, for example LOWER,

LOWER, LOWER. until the movement is complete

If instructions stop getting through, the crane operator must immediately

bring the load to a HALT to guard against failure of the radio system.

If there is more than one crane on site and more than one slinger / signaller /

crane operator team using radios, then the appointed person must devise a

safe system of work to ensure that there are no problems such as one crane

operator following the instructions being given to another.

Hand Signals

If hand signals are chosen, ensure that:

There is always a line of sight between signaller and crane operator

If the line of sight is broken, there are intermediate signallers allocated

There is no confusion as to which slinger / signaller is controlling the crane

there may be more than one signaller in the vicinity of the lift

The signaller faces the crane operator whenever signalling

Visiting crane operators understand the standard hand signals overleaf,

taken from BS7121: part 1.

Crane operators must be instructed to respond only to authorised slingers/

signallers wearing items of high visibility clothing which will uniquely identify

them to the crane operator. This clothing, which will generally be orange high

visibility helmets and jackets or vests, will be approved by the appointed person.

The hand signals from BS 7121: Part 1 illustrated on next page are to be used

as the standard hand signals to direct the crane operator.

Care of Lifting Accesories

Lifting accessories include slings, shackles, eye bolts, spreader beams etc.

All types of lifting accessories are highly stressed in service and their condition

must be monitored to ensure that they will not fail when loaded.

Thorough examinations of all lifting accessories must be undertaken by a

competent person every six months and a record issued. This will be arranged

by the appointed person or crane supervisor.

Visual inspections must be carried out by the slinger/signaller at least daily.

If any damage is seen, the item must not be used until examined by a

competent person.

Webbing slings, or any sling made from synthetic bres, should be examined

before and after every lift as they are extremely vulnerable to being cut by sharp

edges. If there is any sign of a cut or fraying in the fabric, they should be taken

out of use and examined by a competent person.

Slings should be stored in dry conditions, preferably hanging on a rack where

they will not get tangled, wet or contaminated by dirt, grease, cement, concrete

etc. They must not be left hanging on the lifting hook where they could pose a

hazard if blown about by the wind.

Never allow any item of lifting accessories to be used for towing

or pulling.

36 37

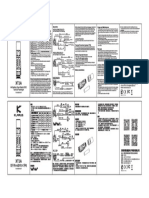

Signalling Signalling

Operations Start Stop Emergency Stop

Clench and unclench

ngers to signal

inch the load

Hoist Lower Slowly Lower

Slew in Direction Indicated

Jib Up Jib Down

Signal with one hand, other hand on head

Derricking or Lufng Jib

Extend Jib

or Trolly Out

Retract Jib

or Trolly In

Travel in Direction Indicated

Signal with one hand, other hand on head

Telescopic Jib or Horizontal Jib

Signal with both hands

Travel to me Travel from me

Operations Cease

38 39

Load vs Sling Angles Angle Guides

9

0

4

5

3

0

1

2

0

6

0

10t

5t 5t

1

0

t

1

0

t

10 t

120

7

.

1

t

7

.

1

t

10 t

90

5

.

8

t

5

.

8

t

60

10 t

5

.2

t 5

.2

t

10 t

30

Use these angles as a

guide to sling angles.

Illustration showing how the load in

each leg of a sling increases as

the angle increases.

Laing ORourke Plc

Bridge Place, Anchor Boulevard, Admirals Park,

Crossways, Dartford, Kent DA2 6SN

tel: +44 (0)1322 296200 fax: +44 (0)1322 296262

web: www.laingorourke.com

2008 Laing ORourke Plc Revised October 2008

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A-Z Fruits PDFDocument20 pagesA-Z Fruits PDFSeng HeangNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Efficient Editing With VimDocument5 pagesEfficient Editing With VimSeng HeangNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Calculation Curvature HDDDocument1 pageCalculation Curvature HDDSeng HeangNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Rainflow Lecture PDFDocument6 pagesRainflow Lecture PDFSeng HeangNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Resultcomparison Deeplines TheoryDocument1 pageResultcomparison Deeplines TheorySeng HeangNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Technical Air Pro Material DataDocument1 pageTechnical Air Pro Material DataSeng HeangNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Integration Formulas: 1. Common IntegralsDocument5 pagesIntegration Formulas: 1. Common IntegralssiegherrNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 2000m Length FloodDocument1 page2000m Length FloodSeng HeangNo ratings yet

- CJC TermoparDocument13 pagesCJC TermopareilenclnNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Submerged Weight of Wire Cable Vs Empty PipeDocument1 pageSubmerged Weight of Wire Cable Vs Empty PipeSeng HeangNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- GeoTechnical FormulasDocument34 pagesGeoTechnical FormulasTptaylor100% (3)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Submerged Weight of Wire Cable Vs Empty PipeDocument1 pageSubmerged Weight of Wire Cable Vs Empty PipeSeng HeangNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Undrained and Drained Shear StrengthDocument23 pagesUndrained and Drained Shear Strengthetecham100% (63)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Welding InformationDocument13 pagesWelding InformationStavangerEngNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Norman S. Nise Control Systems Engineering,: 5 EditionDocument18 pagesNorman S. Nise Control Systems Engineering,: 5 EditionJseophNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- DOT Pipeline RepairsDocument18 pagesDOT Pipeline RepairsSeng HeangNo ratings yet

- GeoTechnical FormulasDocument34 pagesGeoTechnical FormulasTptaylor100% (3)

- Weld SymbolsDocument1 pageWeld SymbolsSeng HeangNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Os j301 - 2011 04Document12 pagesOs j301 - 2011 04Iyyappan PonnusasthaNo ratings yet

- Created By: Sling Selection GuideDocument3 pagesCreated By: Sling Selection GuideSeng HeangNo ratings yet

- Created By: Sling Selection GuideDocument3 pagesCreated By: Sling Selection GuideSeng HeangNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Hydrostatics No.3Document13 pagesHydrostatics No.3Seng HeangNo ratings yet

- Integration FormulasDocument1 pageIntegration FormulasSeng HeangNo ratings yet

- Shape 3 4Document9 pagesShape 3 4Seng HeangNo ratings yet

- Anti Corrosion Field Joint DefinitionDocument1 pageAnti Corrosion Field Joint DefinitionSeng HeangNo ratings yet

- Fem For Thermomechanical ProcessDocument23 pagesFem For Thermomechanical ProcessSeng HeangNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Introduction To Finite Element Method: Tai Hun KwonDocument7 pagesIntroduction To Finite Element Method: Tai Hun KwonLANKAPALLISURINo ratings yet

- Fem For Thermomechanical ProcessDocument23 pagesFem For Thermomechanical ProcessSeng HeangNo ratings yet

- Model 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveDocument1 pageModel 3:1 Pilot Ratio, Standard Capacity Counterbalance ValveRonildo - HydraparNo ratings yet

- The Shaping MachineDocument104 pagesThe Shaping MachineJohn Smith90% (10)

- Heli-Coil Metric Inserts Aerospace Standard Interchangeability ListDocument2 pagesHeli-Coil Metric Inserts Aerospace Standard Interchangeability ListshadiNo ratings yet

- Lab 3.1.9c Straight-Through Cable ConstructionDocument3 pagesLab 3.1.9c Straight-Through Cable ConstructionDennis OonNo ratings yet

- Group 2 Main Control Valve: A. ALP165 1. StructureDocument46 pagesGroup 2 Main Control Valve: A. ALP165 1. StructureJuan GarciaNo ratings yet

- Screenshot 2023-04-05 at 2.49.56 AMDocument89 pagesScreenshot 2023-04-05 at 2.49.56 AMAshrakat Khaled BadawyNo ratings yet

- Picture Frame Miter Sled PlanDocument2 pagesPicture Frame Miter Sled PlanIndonesian Thuglife100% (1)

- Peugeot ManualDocument18 pagesPeugeot Manualjuupu100% (3)

- D4B802A2B8E Gearbox - 0D9 DSGDocument153 pagesD4B802A2B8E Gearbox - 0D9 DSGAndrei Baluse75% (4)

- Wiring Design & CalculationsDocument36 pagesWiring Design & CalculationsSerrano Ivan Jasper100% (1)

- Lecture 18 Data AcquisitionDocument58 pagesLecture 18 Data AcquisitionMohan Ruban0% (1)

- MLVS0402L Series Engineering Specification: ScopeDocument8 pagesMLVS0402L Series Engineering Specification: ScopecafosokNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Stepper MotorsDocument17 pagesStepper MotorsJadeNo ratings yet

- 576 1 80 cct-1Document110 pages576 1 80 cct-1Danny Cacuango100% (1)

- Busbar Trunking Assembly: Horizontal and Vertical ApplicationsDocument16 pagesBusbar Trunking Assembly: Horizontal and Vertical ApplicationsMd.SafwanNo ratings yet

- Leroy Somer UMV3301Document156 pagesLeroy Somer UMV3301Paulo SilvaNo ratings yet

- Class AssignmentDocument5 pagesClass Assignmentalisa naziraNo ratings yet

- Roboracebook 7236b8f147f389d21bfaDocument6 pagesRoboracebook 7236b8f147f389d21bfaRaistar BabaNo ratings yet

- Gos-6Xxg Family Dual Trace Oscilloscope: Members of The FamilyDocument36 pagesGos-6Xxg Family Dual Trace Oscilloscope: Members of The FamilyNguyen VansuNo ratings yet

- Description: Si PhotodiodeDocument4 pagesDescription: Si PhotodiodebobbbNo ratings yet

- DatasheetDocument6 pagesDatasheetHexagonal ClipNo ratings yet

- ATR72Document3 pagesATR72NebNo ratings yet

- Test Certificate For Multi-Turn Actuators: Setting and Functional TestDocument1 pageTest Certificate For Multi-Turn Actuators: Setting and Functional TestSouvik DaluiNo ratings yet

- Engine - ID4 2.2L Diesel - : Item SpecificationDocument104 pagesEngine - ID4 2.2L Diesel - : Item SpecificationRichard Andrianjaka LuckyNo ratings yet

- Epson C4-Series Robot Manual (r16)Document256 pagesEpson C4-Series Robot Manual (r16)Produccion TAMNo ratings yet

- ModulmaxDocument13 pagesModulmaxRuben Oscar100% (1)

- Specifications Usage and Maintenance Operation: AA Battery Dual-Switch EDC Tactical FlashlightDocument1 pageSpecifications Usage and Maintenance Operation: AA Battery Dual-Switch EDC Tactical FlashlightspyrosNo ratings yet

- EasyPact EZC EZC100F3080Document5 pagesEasyPact EZC EZC100F3080Rizal PrasetyoNo ratings yet

- The Ratio of Voltage and Electric Current in A Closed CircuitDocument12 pagesThe Ratio of Voltage and Electric Current in A Closed Circuitzunaira123478% (9)

- BVM Engineering College (An Autonomous Institution)Document3 pagesBVM Engineering College (An Autonomous Institution)Prabhat SinghNo ratings yet