Professional Documents

Culture Documents

Laboratory EPN

Uploaded by

Mulugeta AshangoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laboratory EPN

Uploaded by

Mulugeta AshangoCopyright:

Available Formats

Electro-Pneumatics Laboratory 203

ELECTRO-PNEUMATICS

ELECTRO-PNEUMATICS

LABORATORY EXPERIMENTS

LABORATORY EXPERIMENTS

Electro-Pneumatics Laboratory 204

Electro-Pneumatics Laboratory 205

GENERAL INSTRUCTIONS

AND SAFETY PRECAUTIONS

The arrangement of the equipment on

the workstation should be as shown in

the evaluated electro-pneumatic circuit

diagram sketch.

The working pressure of pe=5 bar shall

be at the pressure regulator of the air

service unit.

The pneumatic components are to be

firmly connected with plastic tubes and

accessories according to the circuit

diagram.

Also observe the proper removal of the

connections of the hoses and other

accessories from the components.

The working voltage for the electrical

wiring diagrams shall be provided 2!

"# power supply unit and an electric

manifold unit.

The electrical components are to be

firmly connected with $umper wires and

accessories according to the circuit

diagram

%andle the components with care and

caution.

Arrange the components and other

equipment after use.

&e guided accordingly with your sub$ect

instructor.

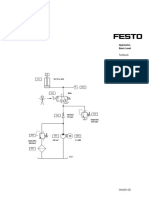

DRIVE

ELEMENT

ACTUATI

NG

ELEMENT

#ylinder

"irectional

#ontrol !alve

Air

#ompressor

'lectr

ic (otor

Y1

SIGNALI

NG

ELEMENT

)ush-

button

*elay

#ontact

*elay #oil

+olenoid

CONTR

OL

ELEMENT

24V

0V

L1

N

S1

K1

Y1 K1

Electro-Pneumatics Laboratory 206

ELECTRO-PNEUMATIC

CONTROL CHAIN

ENERGY GROUP

)neumatic and electrical energies are

required in electro-pneumatic controls.

+ignal elements, control elements and

actuating elements are supplied with

electrical energy.

Actuating elements and drive elements are

supplied with pneumatic energy.

SIGNAL ELEMENTS

The signaling elements convert manual

commands and mechanical motions into

electrical signals.

CONTROL ELEMENTS

The control elements connect the

approaching signals and direct these to the

components of the actuating element group.

ACTUATING ELEMENTS

The actuating elements take over the

function of connecting or converting

electrical energy and pneumatic energy

DRIVE ELEMENTS

The drive elements convert the pneumatic

energy into mechanical energy and motions.

REPRESENTATION OF

PNEUMATIC CIRCUIT

DIAGRAMS

Pneumatic Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 207

EXPERIMENT 1

COMMAND-VARIABLE CONTROL OF

CYLINDERS WITH SINGLE -SOLENOID

VALVES

Objective

This e-periment provides basic know-how

and skills on the proper design, set-up and

operation of electro-pneumatic controls using

the direct and indirect control of a single-acting

cylinder as an e-ample.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

. +ingle-acting cylinder

. "ouble-acting cylinder

. 122 directional control valve, electrically

operated, spring return, closed neutral

position

. 522 directional control valve, electrically

operated, spring return, closed neutral

position

. *elay units, changeover contacts

)neumatic and 'lectrical Accessories

Problem Definition 1

.. 4pon pressing a normally-open key-

operated pushbutton switch, the solenoid

coil of a directional valve shall be

directly energi5ed by this electrical

switch causing the cylinder rod of a

single-acting cylinder to move outward

to its ma-imum e-tended position.

2. The piston rod of the single-acting

cylinder should remain e-tended as long

as the button is pressed.

1. 4pon releasing the said electrical switch,

solenoid coil of that directional valve

will cause the piston rod of the single-

acting cylinder to retract and return to its

rear-end position.

Problem Definition 2

. 4pon pressing a normally-open key-

operated pushbutton switch, the coil of

an electro-mechanical relay shall be

energi5ed by this electrical switch

causing the electrical contact of this

relay to indirectly energi5e the solenoid

coil of a directional valve which then

causes the cylinder rod of a double-

acting cylinder to move outward to its

ma-imum e-tended position.

5. The piston rod of the double -acting

cylinder should remain e-tended as long

as the button is pressed.

3. 4pon releasing the said electrical switch,

the coil of the electro-mechanical relay

shall relieved of its electrical signal,

which then causes the electrically-

controlled directional valve to be

relieved of its pilot energy which then

causes the cylinder rod of a double-

acting cylinder to retract and return to its

rear-end position

Electro-Pneumatics Laboratory 208

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 209

EXPERIMENT 1

DATA SHEET

COMMAND-VARIABLE CONTROL OF

CYLINDERS WITH SINGLE -SOLENOID

VALVES

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 210

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Observation and Conclusion

EXPERIMENT &

HOLDING-ELEMENT CONTROL OF A

DOUBLE-ACTING CYLINDER WITH AN

Electro-Pneumatics Laboratory 211

IMPULSE VALVE' DIRECTLY

CONTROLLED

Objective

This e-periment demonstrates the control of

a double-acting cylinder with an electrically

controlled 522 directional control impulse valve

without the use of a relay.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

. "ouble-acting cylinder

. 522 directional control valve, electrically

operated both ways

)neumatic and 'lectrical Accessories

Problem Definition

.. 4pon momentarily pressing a normally-

open key-operated pushbutton switch,

the solenoid coil of a directional valve

shall be directly energi5ed by this

electrical switch causing the cylinder rod

of a double-acting cylinder to move

outward to its ma-imum e-tended

position.

2. The piston rod of the double -acting

cylinder should remain e-tended even

after the pushbutton is released.

1. 4pon momentarily pressing another

normally-open key-operated pushbutton

switch, the opposite solenoid coil of the

directional valve shall be directly

energi5ed by this second electrical

switch causing the cylinder rod of a

double-acting cylinder to retract and

return to its rear-end position.

. The piston rod of the double -acting

cylinder should remain retracted even

after the latter pushbutton is released.

5. %ence, each pushbutton switch has its

own unique function of either e-tending

or retracting the cylinder only.

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

Electro-Pneumatics Laboratory 212

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 213

EXPERIMENT &

DATA SHEET

HOLDING-ELEMENT CONTROL OF A

DOUBLE-ACTING CYLINDER WITH AN

IMPULSE VALVE' DIRECTLY

CONTROLLED

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 214

Observation and Conclusion

EXPERIMENT (

STOPPING CONTROL OF A DOUBLE-

ACTING CYLINDER WITH A )*(

DIRECTIONAL CONTROL VALVE WITH

Electro-Pneumatics Laboratory 215

A CLOSED MID-POSITION'

INDIRECTLY CONTROLLED

Objective

The aim of this e-periment is to demonstrate

the most often applied solution for stop control

in electro-pneumatics. A 521 directional control

valve with a closed mid-position is used as an

actuator.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

2 ;ne-way <low #ontrol !alve

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

. "ouble-acting cylinder

. 521 directional control valve, electrically

operated, closed mid position, spring

centered

2 *elay units

changeover contacts

)neumatic and 'lectrical Accessories

Problem Definition

.. 4pon pressing a normally-open key-

operated pushbutton switch, the coil of

an electro-mechanical relay shall be

energi5ed by this electrical switch

causing the electrical contact of this

relay to indirectly energi5e the solenoid

coil of a directional valve which then

causes the cylinder rod of a double-

acting cylinder to slowly move outward

to its ma-imum e-tended position such

that the length of its forward stroke is

dependent upon the duration of the

pressing of the pushbutton.

2. 4pon pressing another normally-open

key-operated pushbutton switch, the coil

of another electro-mechanical relay shall

be energi5ed by this second electrical

switch causing the electrical contact of

this relay to indirectly energi5e the

opposite control-solenoid coil of the

same directional valve which then

causes the cylinder rod to slowly move

inward to its ma-imum retracted

position such that the length of its

backward stroke is also dependent upon

the duration of the pressing of that

pushbutton.

1. The piston rod of the double -acting

cylinder should remain in whatever

position it has reached when either of the

two pushbuttons is released or not being

pressed.

. %ence, each pushbutton switch has its

own unique function of either e-tending

or retracting the cylinder to a certain

length of stroke only.

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

Electro-Pneumatics Laboratory 216

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 217

EXPERIMENT (

DATA SHEET

STOPPING CONTROL OF A DOUBLE-

ACTING CYLINDER WITH A )*(

DIRECTIONAL CONTROL VALVE WITH

A CLOSED MID-POSITION'

INDIRECTLY CONTROLLED

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 218

Observation and Conclusion

EXPERIMENT +

LOGICAL CONTROL OF A DOUBLE-

ACTING CYLINDER WITH A SINGLE--

Electro-Pneumatics Laboratory 219

SOLENOID VALVE AND A DOUBLE-

SOLENOID VALVES'

Objective

The aim of this e-periment is to convey the

understanding for the logical =A>"? and =;*?

functions in relay technology.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

2 "ouble-acting cylinder

. 522 directional control valve, electrically

operated, spring return,

. 522 directional control valve, electrically

operated both ways

2 *elay units, changeover contacts

)neumatic and 'lectrical Accessories

Problem Definition 1

.. 4pon pressing neither of two key-

operated pushbutton switches, the spring

of a single-solenoid spring return valve

shall cause the cylinder rod of a double-

acting cylinder to assume a retracted

position.

2. 4pon pressing either of the two

normally-open key-operated pushbutton

switches alone, the coil of its

corresponding electro-mechanical relay

shall be energi5ed by the actuated

electrical switch causing the electrical

contact of that relay to indirectly

energi5e the solenoid coil of a single-

solenoid valve which then causes the

cylinder rod of the double-acting

cylinder to move outward to its

ma-imum e-tended position. 4pon

releasing the chosen pushbutton, the

cylinder rod will retract and return to its

rear-end position.

1. 4pon pressing both pushbutton switches

/not necessarily being at the same time0,

the cylinder rod shall also assume a

retracted position.

Problem Definition 2

. 4pon pressing neither of two key-

operated pushbutton switches, the

double-solenoid valve shall cause the

cylinder rod of a double-acting cylinder

to assume a retracted position. %ence,

the opposite solenoid should be initially

energi5ed by the proper relay contact

arrangement.

5. 4pon pressing either of the two

normally-open key-operated pushbutton

switches alone, the coil of its

corresponding electro-mechanical relay

shall be energi5ed by the actuated

electrical switch causing the electrical

contact of that relay to indirectly

energi5e the solenoid coil of a double-

solenoid valve which then causes the

cylinder rod of the double-acting

cylinder to move outward to its

ma-imum e-tended position. >ote that

when the solenoid is energi5ed, the

initially energi5ed opposite solenoid

Electro-Pneumatics Laboratory 220

should be de-energi5ed at the same time.

4pon releasing the chosen pushbutton,

the cylinder rod will retract and return to

its rear-end position.

3. 4pon pressing both pushbutton switches

/not necessarily being at the same time0,

the cylinder rod shall also assume a

retracted position.

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 221

EXPERIMENT +

DATA SHEET

LOGICAL CONTROL OF A DOUBLE-

ACTING CYLINDER WITH A SINGLE--

SOLENOID VALVE AND A DOUBLE-

SOLENOID VALVES'

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 222

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Observation and Conclusion

EXPERIMENT )

PRIORITY CONTROL OF A DOUBLE-

ACTING CYLINDER WITH A SINGLE--

SOLENOID VALVE' SPRING RETURN'

Electro-Pneumatics Laboratory 223

Objective

@n this e-periment, the most common priority

control methods for actuating circuit systems are

demonstrated as well as the various possible

circuits with latching /storage circuits0 using

relay.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

2 #ontrol switch-2 pushbutton unit

2 "ouble-acting cylinder

2 522 directional control valve, electrically

operated, spring return,

1 *elay units, changeover contacts

)neumatic and 'lectrical Accessories

Problem Definition

.. @nitially, upon momentarily pressing a

key-operated pushbutton switch, the coil

of an electro-mechanical relay shall be

energi5ed by this electrical switch

causing the electrical contact of this

relay to indirectly energi5e the solenoid

coil of a directional valve causing the

cylinder rod of a double-acting cylinder

to move outward to its ma-imum

e-tended position and stay e-tended.

2. 4pon momentarily pressing another key-

operated pushbutton switch, the coil of

another electro-mechanical relay shall be

energi5ed by this electrical switch

causing the electrical contact of this

relay to indirectly energi5e the solenoid

coil of another directional valve causing

the cylinder rod of another double-acting

cylinder to move outward to its

ma-imum e-tended position and stay

e-tended. >ote that the first cylinder will

now move to its ma-imum retracted

position and stay retracted the same time

the second cylinder will e-tend.

1. 4pon momentarily pressing the first

pushbutton switch again, the coil of the

first electro-mechanical relay shall be

energi5ed again by this electrical switch

causing the electrical contact of this

relay to indirectly energi5e the solenoid

coil of the first directional valve causing

the cylinder rod of the first double-acting

cylinder to move outward to its

ma-imum e-tended position and stay

e-tended. >ote that the second cylinder

will now move to its ma-imum retracted

position and stay retracted the same time

the first cylinder will e-tend.

. %ence, whichever pushbutton switch is

actuated at any time shall cause its own

controlled cylinder to e-tend and stay

e-tended the same time making the other

cylinder to retract and stay retracted.

5. %owever, upon momentarily pressing a

third key-operated pushbutton switch,

the cylinder rod of any of the two

cylinders that is e-tended at any time

shall be retracted and stay retracted.

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

Electro-Pneumatics Laboratory 224

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 225

EXPERIMENT )

DATA SHEET

PRIORITY CONTROL OF A DOUBLE-

ACTING CYLINDER WITH A SINGLE--

SOLENOID VALVE' SPRING RETURN'

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 226

Observation and Conclusion

EXPERIMENT ,

TIMER CONTROL OF A DOUBLE-

ACTING CYLINDER WITH A DOUBLE--

SOLENOID VALVE

Electro-Pneumatics Laboratory 227

Objective

This e-periment shows the use of an electric,

switch-on timer relay element in a hold element

control.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

. "ouble-acting cylinder

2 522 directional control valve, electrically

operated both ways

2 *elay unit, changeover contacts

2 Timer *elay units

)neumatic and 'lectrical Accessories

Problem Definition

.. 4pon momentarily pressing a key-

operated pushbutton switch, a pre-

determined time shall elapse after which

will energi5e a double-solenoid valve

shall cause an initially retracted cylinder

rod of a double-acting cylinder to move

outward to its ma-imum e-tended

position and stay e-tended. />ote that

being a double-solenoid valve, the

opposite solenoid should be initially

energi5ed to ensure that the cylinder rod

is also initially retracted0.

2. &y the same time that the cylinder had

e-tended, another pre-determined time

should elapsed after which will cause the

cylinder rod to automatically retract and

return to its rear-end position and stay

retracted.

1. >ote that only electro-mechanical relays

and their corresponding contacts are to

be used for the circuit and that roller

limit switches and cylinder switches are

not allowed for this problem.

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

Electro-Pneumatics Laboratory 228

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 229

EXPERIMENT ,

DATA SHEET

TIMER CONTROL OF A DOUBLE-

ACTING CYLINDER WITH A DOUBLE--

SOLENOID VALVE

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 230

Observation and Conclusion

EXPERIMENT -

POSITION -DEPENDENT

SEQUENTIAL CONTROL OF A DOUBLE-

Electro-Pneumatics Laboratory 231

ACTING CYLINDER USING A DOUBLE--

SOLENOID VALVE

Objective

This e-periment intends to facilitate the

understanding of reciprocation controls of a lone

cylinder and provides practical knowledge of

setting up a simple reciprocating control system.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

. "ouble-acting cylinder

. 522 directional control valve, electrically

operated both ways

*elay unit, changeover contacts

2 *oller limit switch or cylinder switch

)neumatic and 'lectrical Accessories

Problem Definition

.. 4pon momentarily pressing a key-

operated pushbutton switch, a double-

solenoid valve shall cause the cylinder

rod of a double-acting cylinder to

immediately to move outward to its

ma-imum e-tended position. />ote that

being a double-solenoid valve, the

opposite solenoid should be initially

energi5ed to ensure that the cylinder rod

is also initially retracted0. 4pon reaching

its ma-imum outward stroke, the

cylinder rod will automatically retract

and return to its rear-end position.

2. 4pon reaching its initial position, the

cylinder rod will again automatically

e-tend and retract repeatedly until

another key-operated pushbutton switch

is momentarily pressed at any time to

bring it to a complete stop but finishing

the last sequence and returning the

cylinder rod in its initial position.

1. %ence, .$se/-.$$# se01e%e $2 A3 A-

using roller limit switches or cylinder

switches.

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

Electro-Pneumatics Laboratory 232

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 233

EXPERIMENT -

DATA SHEET

POSITION-DEPENDENT SEQUENTIAL

CONTROL OF A DOUBLE-ACTING

CYLINDER USING A DOUBLE--

SOLENOID VALVE

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 234

Observation and Conclusion

EXPERIMENT 4

POSITION-DEPENDENT SEQUENTIAL

CONTROL OF TWO DOUBLE-ACTING

Electro-Pneumatics Laboratory 235

CYLINDER USING DOUBLE--SOLENOID

VALVES

Objective

This e-periment intends to facilitate the

understanding of sequential controls of two

cylinders and provides practical knowledge of

setting up a control system with two pneumatic

drives. The actual design and practice in

developing sequential diagram and pneumatic

and electrical circuit diagram shall also be

e-ercised.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

2 "ouble-acting cylinder

2 522 directional control valve, electrically

operated both ways

3 *elay unit, changeover contacts

*oller limit switch or cylinder switch

. 'lectronic sensor unit

)neumatic and 'lectrical Accessories

Problem Definition

.. 4pon detecting an ob$ect, an electronic

sensor shall energi5e a double-solenoid

valve which will cause the cylinder rod

of a double-acting cylinder /cylinder A0

to immediately move outward to its

ma-imum e-tended position. />ote that

being double-solenoid valves, the

opposite solenoids should be initially

energi5ed to ensure that the two

cylinders rods are also initially

retracted0. 4pon reaching its ma-imum

outward stroke, another double-solenoid

valve shall cause the cylinder rod of

another double-acting cylinder /cylinder

&0 to automatically move outward to its

ma-imum e-tended position.

2. 4pon reaching cylinder &As ma-imum

outward stroke, cylinder A will

automatically retract and return to its

rear-end position. >ote that during the

retraction of cylinder A, cylinder &

remains e-tended. 4pon reaching

cylinder AAs initial position, cylinder &

will automatically retract and return to

its rear-end position.

1. 4pon reaching cylinder &As initial

position, the sequence of cylinder

actions will then repeat continuously if

the electronic sensors continuously

detects the ob$ect, otherwise the

sequence will automatically stop at &-

finishing the last sequence and returning

the cylinder rods in their initial

positions.

. /;)T@;>AB0 The initiation of the

sequence can also optionally triggered

by a key-operated switch and stopped by

another key-operated switch.

5. %ence, $#e%-.$$# * .$se/-.$$#

se01e%e $2 A3 B3 A- B- using roller

limit switches cylinder switches.

Procedure

Electro-Pneumatics Laboratory 236

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 237

EXPERIMENT 4

DATA SHEET

POSITION-DEPENDENT SEQUENTIAL

CONTROL OF TWO DOUBLE-ACTING

CYLINDER USING DOUBLE--SOLENOID

VALVES

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 238

Observation and Conclusion

EXPERIMENT 5

TIME-BASED PROCESS CONTROL

FOR POSITION-DEPENDENT

SEQUENTIAL CONTROL OF TWO

Electro-Pneumatics Laboratory 239

DOUBLE-ACTING CYLINDER USING

DOUBLE--SOLENOID VALVES

Objective

This e-periment intends to facilitate the

understanding of incorporating a timer control

circuit on sequential controls based process of

two cylinders and provides practical knowledge

of setting up a control system with two

pneumatic drives.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

2 "ouble-acting cylinder

2 522 directional control valve, electrically

operated both ways

3 *elay unit, changeover contacts

*oller limit switch or cylinder switch

. Timer *elay 4nit

)neumatic and 'lectrical Accessories

Problem Definition

.. 4pon momentarily pressing a key-

operated pushbutton switch, a double-

solenoid valve shall be energi5ed which

will cause the cylinder rod of a double-

acting cylinder /cylinder A0 to

immediately move outward to its

ma-imum e-tended position. />ote that

being double-solenoid valves, the

opposite solenoids should be initially

energi5ed to ensure that the two

cylinders rods are also initially

retracted0. 4pon reaching its ma-imum

outward stroke, another double-solenoid

valve shall cause the cylinder rod of

another double-acting cylinder /cylinder

&0 to automatically move outward to its

ma-imum e-tended position.

2. 4pon reaching cylinder &As ma-imum

outward stroke, cylinder A will

automatically retract and return to its

rear-end position. >ote that during the

retraction of cylinder A, cylinder &

remains e-tended. 4pon reaching

cylinder AAs initial position, cylinder &

will automatically retract and return to

its rear-end position.

1. 4pon reaching cylinder &As initial

position, the sequence of cylinder

actions will then repeat continuously

until a predetermined time has elapsed

which will then automatically stop the

sequential movements of the cylinders at

&- finishing the last sequence and

returning the cylinder rods in their initial

positions.

. >ote that the sequence of cylinder

movements can also be manually

stopped at any instant without regards to

the timer-based process control element

when another key-operated pushbutton

switch is momentarily pressed.

5. %ence, t"6e-78se/ .$se/-.$$#

se01e%e $2 A3 B3 A- B- using roller

limit switches cylinder switches.

Electro-Pneumatics Laboratory 240

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 241

EXPERIMENT 5

DATA SHEET

TIME-BASED PROCESS CONTROL

FOR POSITION-DEPENDENT

SEQUENTIAL CONTROL OF TWO

DOUBLE-ACTING CYLINDER USING

DOUBLE--SOLENOID VALVES

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 242

Observation and Conclusion

EXPERIMENT 19

COUNTER-BASED PROCESS

CONTROL FOR POSITION-DEPENDENT

SEQUENTIAL CONTROL OF TWO

Electro-Pneumatics Laboratory 243

DOUBLE-ACTING CYLINDER USING

DOUBLE--SOLENOID VALVES

Objective

This e-periment intends to facilitate the

understanding of incorporating a counter control

circuit on sequential controls based process of

two cylinders and provides practical knowledge

of setting up a control system with two

pneumatic drives.

List of Components and Equipment

Qty. Des!"#t"$%

. )neumatic power supply

. Air service unit /filter with water

separator, pressure regulator and

pressure gauge0 with 122 directional

control ball valve

. )neumatic "istributor, 3-fold

. 2!"# power supply unit

. 'lectric (anifold unit

. #ontrol switch-2 pushbutton unit

2 "ouble-acting cylinder

2 522 directional control valve, electrically

operated both ways

3 *elay unit, changeover contacts

*oller limit switch or cylinder switch

. #ounter 4nit

)neumatic and 'lectrical Accessories

Problem Definition

.. 4pon momentarily pressing a key-

operated pushbutton switch, a double-

solenoid valve shall be energi5ed which

will cause the cylinder rod of a double-

acting cylinder /cylinder A0 to

immediately move outward to its

ma-imum e-tended position. />ote that

being double-solenoid valves, the

opposite solenoids should be initially

energi5ed to ensure that the two

cylinders rods are also initially

retracted0. 4pon reaching its ma-imum

outward stroke, another double-solenoid

valve shall cause the cylinder rod of

another double-acting cylinder /cylinder

&0 to automatically move outward to its

ma-imum e-tended position.

2. 4pon reaching cylinder &As ma-imum

outward stroke, cylinder A will

automatically retract and return to its

rear-end position. >ote that during the

retraction of cylinder A, cylinder &

remains e-tended. 4pon reaching

cylinder AAs initial position, cylinder &

will automatically retract and return to

its rear-end position.

1. 4pon reaching cylinder &As initial

position, the sequence of cylinder

actions will then repeat continuously

until a number of sequential movements

has been completed based on a

predetermined number of desired counts

which will then automatically stop the

sequential movements of the cylinders at

&- finishing the last sequence and

returning the cylinder rods in their initial

positions.

. >ote that the sequence of cylinder

movements can also be manually

stopped at any instant without regards to

the counter-based process control

element when another key-operated

pushbutton switch is momentarily

pressed.

Electro-Pneumatics Laboratory 244

5. %ence, $1%te!-78se/ .$se/-.$$#

se01e%e $2 A3 B3 A- B- using roller

limit switches cylinder switches.

Procedure

.. +ketch the pneumatic circuit diagram

based on the stated problem definition.

2. +ketch the electrical circuit diagram

based on the stated problem definition.

1. %ave your instructor check your circuit

diagram for proper evaluation.

. 6ather the required components and

arranged them properly on the

workstation and in accordance with the

verified electro-pneumatic circuit

diagram.

5. #onnect the pneumatic components with

plastic tubes and accessories according

to the circuit diagram.

3. #onnect the electrical components with

$umper wires and accessories according

to the circuit diagram.

7. (ake sure that the air service unit switch

is in the off position and double check

the connections of the hoses and other

accessories if they are firmly coupled to

the components for safe operation.

8. Turn on the pneumatic power supply

/compressor0 compressed-air distributor.

9. Turn on the switch the air service unit

and set the working pressure of pe=5 bar

at the pressure regulator.

.:. Turn on the 2"#! power supply

distributor.

... The e-periment is started and the proper

function is verified.

.2. *eturn and arrange the components and

other equipment properly upon

completion of the e-periment.

.1. "raw the pneumatic circuit diagram on

the data sheet. +tate your observations

and conclusion.

Electro-Pneumatics Laboratory 245

EXPERIMENT 19

DATA SHEET

COUNTER-BASED PROCESS

CONTROL FOR POSITION-DEPENDENT

SEQUENTIAL CONTROL OF TWO

DOUBLE-ACTING CYLINDER USING

DOUBLE--SOLENOID VALVES

Pneumatic Circuit Diagram

Electrical Wiring Diagram

Electro-Pneumatics Laboratory 246

Observation and Conclusion

You might also like

- Pneumatic Systems: Module 2: Direct and Indirect Control in Electro-PneumaticsDocument19 pagesPneumatic Systems: Module 2: Direct and Indirect Control in Electro-PneumaticsĐiệp NgọcNo ratings yet

- SKEM 3742 Electro Hydraulic LabsheetDocument6 pagesSKEM 3742 Electro Hydraulic Labsheetcikgu_relaNo ratings yet

- Exercise 13: Conveyor Belt: 1: Problem DescriptionDocument10 pagesExercise 13: Conveyor Belt: 1: Problem DescriptionyashveerluvNo ratings yet

- Electro Pneumatics m2 StudentDocument21 pagesElectro Pneumatics m2 StudentArt NidayNo ratings yet

- Electro-Pneumatic Control Systems GuideDocument8 pagesElectro-Pneumatic Control Systems GuideIvy Totanes TaborNo ratings yet

- Ejercicios y Soluicones de Neumatica 16Document44 pagesEjercicios y Soluicones de Neumatica 16Alexander PenadoNo ratings yet

- Pneumatics ElectropneumaticsDocument44 pagesPneumatics ElectropneumaticswanNo ratings yet

- Electron Pneumatic CircuitDocument59 pagesElectron Pneumatic CircuitArun SìvaNo ratings yet

- Extract From R927001115 - Practice Electro Pneumatics Student enDocument8 pagesExtract From R927001115 - Practice Electro Pneumatics Student enKristine Cullen100% (1)

- Hydraulic Furnace Door Control CircuitDocument4 pagesHydraulic Furnace Door Control CircuitAbdul Aziz Abdul Rahim100% (1)

- Ejercicios y Soluciones de Electroneumatica 15Document33 pagesEjercicios y Soluciones de Electroneumatica 15Alexander PenadoNo ratings yet

- TRAINING MANUAL PNEUMATICS PROJECT EXERCISESDocument17 pagesTRAINING MANUAL PNEUMATICS PROJECT EXERCISESSriram SastryNo ratings yet

- Pneumatic TechnologyDocument29 pagesPneumatic TechnologyVictor Al100% (1)

- Lab Manual PneumaticsDocument19 pagesLab Manual PneumaticsGautam Anikirala0% (1)

- Electropneumatics Basic Level: Workbook TP 201Document54 pagesElectropneumatics Basic Level: Workbook TP 201Saúl Ríos0% (2)

- Electropneumatic and Hydraulic DNT241: Experiment No. 4Document7 pagesElectropneumatic and Hydraulic DNT241: Experiment No. 4Izz Hanzalah AhmadNo ratings yet

- FESTO Electro-Hydraulics - Basic LevelDocument203 pagesFESTO Electro-Hydraulics - Basic LevelAnonymous nOqqYoDvz100% (2)

- Electropneumatics Basic LevelDocument48 pagesElectropneumatics Basic LevelHamsini712No ratings yet

- Worksheets Electropneumatics Basic LevelDocument128 pagesWorksheets Electropneumatics Basic LevelNur SyimahNo ratings yet

- JKM Pneumatic CIRCUIT SystemDocument50 pagesJKM Pneumatic CIRCUIT SystembeselamuNo ratings yet

- Workbook Pneumatics Basic LevelDocument152 pagesWorkbook Pneumatics Basic LevelTRAN TAN73% (15)

- FESTO - EP211 - Introduction To Electropneumatics SolutionDocument33 pagesFESTO - EP211 - Introduction To Electropneumatics SolutionFrancisco Olguín RodríguezNo ratings yet

- Electro PneumaticDocument40 pagesElectro PneumaticMasrur Afifin100% (2)

- Safety in Pneumatic Systems: Workbook TP 250Document25 pagesSafety in Pneumatic Systems: Workbook TP 250Ganabpaty ThiagarajanNo ratings yet

- Fluid Power Ebook Fluid Power BasicsDocument233 pagesFluid Power Ebook Fluid Power Basicspatil_raaj7234No ratings yet

- LAB Pneumatic FinalDocument25 pagesLAB Pneumatic FinalshamizNo ratings yet

- Chapter 8: Fluid Basic Electrical and Logic Control SystemDocument34 pagesChapter 8: Fluid Basic Electrical and Logic Control SystemSiraj BusseNo ratings yet

- Festo-PLC (Text Book Basic Level1)Document238 pagesFesto-PLC (Text Book Basic Level1)aneshsum100% (6)

- Problems of Pneumatic Circuit DesignDocument13 pagesProblems of Pneumatic Circuit Designvijay100% (3)

- Welding rail cylinder circuit with pressure sequence and time delayDocument99 pagesWelding rail cylinder circuit with pressure sequence and time delaymanikandan_murugaiahNo ratings yet

- DanielGwapo PDFDocument144 pagesDanielGwapo PDFalexisNo ratings yet

- 01 TP 101pneumatics Work Book Basic LevelDocument200 pages01 TP 101pneumatics Work Book Basic LevelGF MANo ratings yet

- Worksheets Pneumatics Basic LevelDocument144 pagesWorksheets Pneumatics Basic Levelvrjr0% (1)

- FESTO - Process Control System - WorkbookDocument211 pagesFESTO - Process Control System - WorkbookFrancisco Olguín Rodríguez100% (1)

- Hydraulics Basic Level PDFDocument276 pagesHydraulics Basic Level PDFIwan Sb100% (1)

- Mechatronics Lab ManualDocument54 pagesMechatronics Lab ManualAjay Chacko100% (1)

- Pneumatic Systems Guide to Components, Circuits and ApplicationsDocument30 pagesPneumatic Systems Guide to Components, Circuits and ApplicationsMuizzuddin RosliNo ratings yet

- MPS-PA Compact-Workstation Workbook SolutionsDocument2,220 pagesMPS-PA Compact-Workstation Workbook SolutionsLiz Barbosa100% (5)

- Electro Pneumatics StudentDocument24 pagesElectro Pneumatics StudentbooNo ratings yet

- Electro PneumaticsDocument136 pagesElectro PneumaticsJaphet GabatanNo ratings yet

- FESTO Electropneumatics WorkbookDocument144 pagesFESTO Electropneumatics WorkbookAbdallah SalahNo ratings yet

- MODULE 5 Pneumatic Control Circuits PDFDocument108 pagesMODULE 5 Pneumatic Control Circuits PDFchandrashekar m100% (1)

- 13 Pneumatic CircuitsDocument9 pages13 Pneumatic CircuitsUday Bagade100% (1)

- Festo ElectroPneumatics Workbook Advanced Level TP202 44 2005Document44 pagesFesto ElectroPneumatics Workbook Advanced Level TP202 44 2005Avtomatika Kole Nehtenin80% (10)

- Chapter 7 - Hydraulic Operation Circuit and ApplicationDocument19 pagesChapter 7 - Hydraulic Operation Circuit and ApplicationMuhammad AbdullahNo ratings yet

- V2 EXP2 Logic Valve and Sequence Control For Multiple Cylinder OperationDocument12 pagesV2 EXP2 Logic Valve and Sequence Control For Multiple Cylinder OperationJane Ruby GonzalesNo ratings yet

- Pneumatic Circuit Design GuideDocument120 pagesPneumatic Circuit Design GuideKubheran SelvathuraiNo ratings yet

- Basic Pneumatic Examen PDFDocument34 pagesBasic Pneumatic Examen PDFRosalino Leonides Martinez Marquez100% (1)

- Lab PracticeDocument14 pagesLab Practicesaliana binti sanusi50% (2)

- Neutral Position in DCVDocument6 pagesNeutral Position in DCVAimee SpearsNo ratings yet

- Understanding Pneumatics in AutomationDocument116 pagesUnderstanding Pneumatics in AutomationMady Deka Apriliya100% (4)

- Bul 36115 Servo Valve OperationDocument12 pagesBul 36115 Servo Valve Operationrikkitech100% (1)

- 02 Textbook TP501 enDocument236 pages02 Textbook TP501 enAlexander PenadoNo ratings yet

- Practice 3 Workshop Report NewDocument12 pagesPractice 3 Workshop Report NewMuhd Nur HaziqNo ratings yet

- LAB 2 PnuematicDocument16 pagesLAB 2 Pnuematicanuar bin ahmadNo ratings yet

- 11BDocument5 pages11BAjith KumarNo ratings yet

- Electro-Hydraulic and Electro-Pneumatic Laboratory GuideDocument18 pagesElectro-Hydraulic and Electro-Pneumatic Laboratory GuideJovan MitrevskiNo ratings yet

- Electrical Control of Hydraulic SystemsDocument46 pagesElectrical Control of Hydraulic SystemsJagan FaithNo ratings yet

- Maroti Kalganche 1904061Document5 pagesMaroti Kalganche 1904061069-Arjun KharatNo ratings yet

- Direct and Indirect ControlDocument31 pagesDirect and Indirect Controladaptive4u45270% (1)

- HRM User ManualDocument61 pagesHRM User ManualMulugeta AshangoNo ratings yet

- MI 400 Questions IB GuideDocument6 pagesMI 400 Questions IB GuideMulugeta AshangoNo ratings yet

- Overtime Pre-Approval Form: Overtime Provision: Employees Are Not Permitted To Work Overtime Without TheDocument1 pageOvertime Pre-Approval Form: Overtime Provision: Employees Are Not Permitted To Work Overtime Without TheMulugeta AshangoNo ratings yet

- The Center of Dynamic Learning: How Many Stars Are There in The Picture?Document1 pageThe Center of Dynamic Learning: How Many Stars Are There in The Picture?Mulugeta AshangoNo ratings yet

- IntroductionDocument1 pageIntroductionMulugeta AshangoNo ratings yet

- WCDMA Radio Network Optimization GuideDocument79 pagesWCDMA Radio Network Optimization GuideAsh Shiddiqi100% (4)

- GSM Drive Testing Guide for Network PerformanceDocument8 pagesGSM Drive Testing Guide for Network PerformanceUjlfoDibnvbiNo ratings yet

- EEL 7 SpeakingDocument20 pagesEEL 7 SpeakingSathish KumarNo ratings yet

- Overview of GSMDocument1 pageOverview of GSMMulugeta AshangoNo ratings yet

- Electronic Communications Committee (ECC) Within The European Conference of Postal and Telecommunications Administrations (CEPT)Document16 pagesElectronic Communications Committee (ECC) Within The European Conference of Postal and Telecommunications Administrations (CEPT)Mulugeta AshangoNo ratings yet

- John Doe: Qualifications OverviewDocument2 pagesJohn Doe: Qualifications OverviewPatel PritNo ratings yet

- GSM Drive Testing Guide for Network PerformanceDocument8 pagesGSM Drive Testing Guide for Network PerformanceUjlfoDibnvbiNo ratings yet

- GSM Drive Testing Guide for Network PerformanceDocument8 pagesGSM Drive Testing Guide for Network PerformanceUjlfoDibnvbiNo ratings yet

- Drive Testing Training Prepared by ZenebeDocument4 pagesDrive Testing Training Prepared by ZenebeMulugeta AshangoNo ratings yet

- Drive TestDocument24 pagesDrive TestSalman Zahid100% (5)

- Source Code For CounterDocument2 pagesSource Code For CounterMulugeta AshangoNo ratings yet

- Laboratory EPNDocument44 pagesLaboratory EPNMulugeta AshangoNo ratings yet

- Drive Testing Training Prepared by ZenebeDocument4 pagesDrive Testing Training Prepared by ZenebeMulugeta AshangoNo ratings yet

- 291 LabmanualDocument354 pages291 LabmanualMulugeta AshangoNo ratings yet

- Developing Cold Fusion Applications Tutorial: Lesson 1 - Web Development Process of Static PagesDocument28 pagesDeveloping Cold Fusion Applications Tutorial: Lesson 1 - Web Development Process of Static PagesMulugeta AshangoNo ratings yet

- Architecture For Internet IsDocument17 pagesArchitecture For Internet IsMulugeta AshangoNo ratings yet

- Technical Report Writing NotesDocument78 pagesTechnical Report Writing NotesMulugeta AshangoNo ratings yet

- Frequency Modulation: Analog and Digital Communications Autumn 2005-2006Document16 pagesFrequency Modulation: Analog and Digital Communications Autumn 2005-2006Mulugeta AshangoNo ratings yet

- Database ModelingDocument28 pagesDatabase ModelingAlex KanbarNo ratings yet

- Measurement and Instrumentation Principles, First Edition - Alan S MorrisDocument491 pagesMeasurement and Instrumentation Principles, First Edition - Alan S MorrisAhmad QadomiNo ratings yet

- (Solutions Manual) Elements of Electromagnetics - Sadiku - 3rd PDFDocument422 pages(Solutions Manual) Elements of Electromagnetics - Sadiku - 3rd PDFPonteyoss Konjokeloss80% (64)

- Electronic ComponentDocument4 pagesElectronic Componentyee cNo ratings yet

- Pin Diagram of Ic 4033 PDFDocument6 pagesPin Diagram of Ic 4033 PDFdeepak_kr22781No ratings yet

- List of Experiments: Ge8261-Engineering Practices Laboratory - Group BDocument57 pagesList of Experiments: Ge8261-Engineering Practices Laboratory - Group BJeeva RathnamNo ratings yet

- Water Level Indicator Project PresentationDocument17 pagesWater Level Indicator Project PresentationVaishnavi SahuNo ratings yet

- Laporan 4 Simple Audio Amplifier PDFDocument9 pagesLaporan 4 Simple Audio Amplifier PDFAzman HanafiahNo ratings yet

- EEE108: Build a Digital Object Counter CircuitDocument9 pagesEEE108: Build a Digital Object Counter CircuitAnil Yvs100% (1)

- Bee Micro Project 2Document14 pagesBee Micro Project 2amitsonkar509No ratings yet

- Photonic Integrated Circuits - A Technology and Application PrimerDocument13 pagesPhotonic Integrated Circuits - A Technology and Application Primeryasir_0092No ratings yet

- BC20 32S 5 - Manual PDFDocument182 pagesBC20 32S 5 - Manual PDFHandy LeeNo ratings yet

- Evaluation OF Protective Relays: Prepared by Gopala Krishna Palepu Ade/Mrt (Protection)Document13 pagesEvaluation OF Protective Relays: Prepared by Gopala Krishna Palepu Ade/Mrt (Protection)bpchimeraNo ratings yet

- Applied Physics: By: Engr. Muhammad Adnan Malik Class of BS-CS, NCBA&E, MULTANDocument79 pagesApplied Physics: By: Engr. Muhammad Adnan Malik Class of BS-CS, NCBA&E, MULTANRoma KhalilNo ratings yet

- Design and Construction of A Heart Beat MonitorDocument29 pagesDesign and Construction of A Heart Beat MonitorEngr. CasmirNo ratings yet

- PCB Troubleshooting Techniques GuideDocument3 pagesPCB Troubleshooting Techniques GuideEdgar Dauzon0% (1)

- BXE Practical Journal (Experiment No. 1 To 8) - 1Document55 pagesBXE Practical Journal (Experiment No. 1 To 8) - 1kakashi hatakeNo ratings yet

- IEC Standard ListingDocument19 pagesIEC Standard Listingreji1usNo ratings yet

- LM386 Is A Low Voltage Audio Amplifier and Frequently Used in Battery PoweredDocument10 pagesLM386 Is A Low Voltage Audio Amplifier and Frequently Used in Battery PoweredShivraj BankarNo ratings yet

- Solve ElecDocument35 pagesSolve Eleccingoski123No ratings yet

- Automatic Night LightDocument18 pagesAutomatic Night LightSubhash Bajaj100% (3)

- Experiment No: 1 Familiarization of Electronic Components AimDocument49 pagesExperiment No: 1 Familiarization of Electronic Components Aimarun joseNo ratings yet

- Progress Chart & Achievement ChartDocument12 pagesProgress Chart & Achievement ChartBernadette Delos SantosNo ratings yet

- Melc 1 Applying Quality Standards AqsDocument29 pagesMelc 1 Applying Quality Standards AqsRicky BalceNo ratings yet

- Water Level Indicator Project SummaryDocument20 pagesWater Level Indicator Project SummaryMuhammad Yasir Qureshi100% (1)

- Chapter 1Document26 pagesChapter 1nida2505No ratings yet

- Course Curriculum Catalogue (Rev 7-19) PDFDocument38 pagesCourse Curriculum Catalogue (Rev 7-19) PDFCristina Díaz ÁlvarezNo ratings yet

- ROI in The Discrete Manufacturing IndustryDocument19 pagesROI in The Discrete Manufacturing Industrymasantos_mirNo ratings yet

- PBL Electronics PragyaDocument16 pagesPBL Electronics PragyaSahil SoniNo ratings yet

- Basic Electronic ComponentsDocument9 pagesBasic Electronic ComponentsMackRoss PerezNo ratings yet

- Experiment 1 FamiliarizationDocument7 pagesExperiment 1 FamiliarizationSeif-El-Islam BayNo ratings yet

- Beginner's Guide to LTSpiceDocument10 pagesBeginner's Guide to LTSpiceNicolás VillegasNo ratings yet

- Complect PresntionDocument13 pagesComplect PresntionKubra ĖdrisNo ratings yet