Professional Documents

Culture Documents

Kalzip Structural

Uploaded by

ZoranCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kalzip Structural

Uploaded by

ZoranCopyright:

Available Formats

Kalzip

The ultimate in

creative freedom

with outstanding

performance

Contents

Total Capability

Kalzip Structural Deck & Cassette

Kalzip Structural Deck Material & Finishes

Kalzip Strucural Deck Section Properties

Deck Curving & Penetrations

Deck Side laps & end laps

Deck Fixings

Deck System details

Kalzip Structural Cassette

Kalzip Structural Cassette Section Properties

Cassette System Details & Dimension

Acoustics Decking & Cassette

Perforated Decking Section Properties

Perforated Cassette Section Properties

Load Span Tables

Example of using Load Span Table

Kalzip

Structural

5

6

7

8

11

12

13

14

15

16

18

20

22

25

28

38

Project: National Conference Centre, Hanoi Vietnam

Architect: GMP - Von Gerkan, Marg and Partner

Kalzip

Structural

04

Project: Jalan Besar Stadium, Singapore

Architect: SAA Partnership

Kalzip

Structural

05

Total capability

Kalzip. The ultimate in creative freedom underpinned by

sound system engineering, quality of manufacture and

installation to guarantee outstanding performance

throughout the lifetime of the building.

The high performance capability of Kalzip

is due to the fact that, as a multi-

component system, it can be configured

to meet the most demanding of

specifications. Over the years a wide range

of products have been specially developed

and tested for performance and system

compatibility giving Kalzip supreme

flexibility and versatility.

In addition, the accumulated experience

and expertise of the technical team

provides the specifier with informed

guidance when dealing with demanding

applications and a specially developed

software programme is employed to

achieve project specific calculations.

Kalzip system - a unique proposition

Kalzip, now provides one source of design,

manufacture, supply and controlled

installation for the external building

envelope. By working as a dedicated

partner with the design and project team

to test buildability, provide design solutions

and technical support and to guarantee

the quality of materials and workmanship

at every stage, we are offering an

unbeatable proposition.

In addition to Kalzip standing seam roofing,

the brand now embraces:

Integrated facades

Louvres and solar shading

Smoke ventilation products

Bespoke fabrications - flashings,

rainwater goods, infill panels, etc

To find out more, contact:

+65 6768 9081

The Kalzip aluminium standing seam

roofing system is established as a world

leader with more than 60 million square

metres installed over the past 30 years -

an unbeatable track record of performance.

With thousands of Kalzip roofs now

entering their fourth decade, the

outstanding durability of the system has

been proven in all kinds of conditions -

from typhoons in Asia Pacific through to

heavy snow loading in northern Europe

and the most corrosive urban, industrial

and marine environments in the UK, France

and Germany.

Kalzip

Structural

06

Kalzip structural deck and cassette

For enhanced acoustic absorption, decking

sheets and casettes can both be perforated

and each system can support mass, such

as increased insulation or board, which

may be introduced for more rigorous

acoustic specifications. See page 21 for

more detail on acoustic performance.

Decking sheets can be smooth, crimp or

arch curved. Both decking and cassette

can be supplied polyester coated in any

BS/RAL colour. For buildings with extreme

temperature variations, a very effective

anti-condensation coating can also be

applied.

This brochure presents the options

available for the inner skin of the Kalzip

system covering:

Kalzip steel/aluminium structural

deck

Kalzip steel/aluminium structural

cassette

With a choice of steel or aluminium, a

selection of profiles, gauges and sheet

lengths this range of products has been

developed to extend the versatility of

Kalzip, making it suitable for a wide range

of applications.

As a general rule, steel is cost effective

and provides the optimum in loading and

spanning capability; whereas aluminium

offers exceptional durability in buildings

with high humidity levels such as swimming

pools and wet industrial process plants,

e.g. paper mills.

Where structural deck and cassette are

installed there is a reduced requirement

for secondary steelwork the sheets span

between main steel rafters with the Kalzip

outer sheet being fixed either directly to

the decking or onto top hat sub-purlins

rivetted to the decking.

For any requirements not covered by the

specifications detailed in this brochure,

please contact our technical department.

Kalzip structural deck provides an

economical solution for long span

installations. Structural cassette, whilst

also suitable for long spans, have the

additional benefit of providing a clean,

flat interior surface with no visible fixings.

Where required, for exceptionally long

spans, both decking and cassette can be

extended by the introduction of special

sections within the profiles.

0.71, 0.96, 1.21 & 1.46

0.75, 1.00, 1.25 & 1.50

Approx. 12000

85, 135 & 150

EC3 BS EN 1993-1-3

Hot-dip zinc coating (Z275) to BS EN 10346:2009

Paint finish

RAL 9002

Kalzip structural deck materials and finishes

Kalzip structural decking sheets are

manufactured from high grade steel to

BS EN 10346:2009 or aluminium alloy.

Standard finishes for decking sheets,

available on a short lead time are:

Hot-dip galvanised, natural finish. Ideal

for situations where the deck is not

visible or where visual appearance is

not critical.

White polyester coated on hot-dip

galvanised substrate. This finish is

highly durable, resists scratching and

has good formability, suitable for

exterior soffits.

A wide range of special colours can be

supplied subject to order quantity and

extended delivery. Alternative coatings

such as PVdF or double-side polyurethane

are available to suit particular

specifications, e.g., swimming pools and

wet industrial processes.

Materials

Dimensions (mm)

Steel Aluminium

Base metal thickness, BMT

Nominal thickness, NT

Profile length, L (mm)

Profile height, H (mm)

Load bearing capacity

Surface finishes

Metallic coating

Non-metallic coating

Colours

1.00, 1.25 & 1.50

Approx. 12000

85, 135 & 150

EC9 BS EN 1999-1-4

-

Paint finish

07

Kalzip

Structural

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic Coating

Supreme Court, Singapore

Kalzip

Structural

08

Kalzip structural deck section properties

Kalzip SD 85/280

119.5 160.5

280

1120

40

8

4

.

5

t

R

5

Product specifications

Spans generally up to 4m

Cover width 1,120mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Material Section Properties - SD 85/280

Narrow flange under compression (mid span)

Bending moment

M

c, Rd

(kNm/m)

5.58

7.85

10.17

12.38

Effective moment

of inertia, I

eff

(cm

4

/m)

79.71

118.02

159.15

196.00

Reaction capacity at intermediate,

R

w, Rd

(kN/m)

Minimum support width of 40mm

12.05

22.27

35.33

51.16

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression (mid span)

Bending moment

M

c, Rd

(kNm/m)

4.58

7.07

9.67

11.89

Effective moment

of inertia, I

eff

(cm

4

/m)

79.19

117.58

156.83

191.47

Reaction capacity at intermediate,

R

w, Rd

(kN/m)

Minimum support width of 40mm

9.42

16.95

26.79

39.15

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Non-standard item

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

(kg/m

2

)

7.88

10.51

13.14

15.77

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

09

Kalzip

Structural

145 165

310

930

43

1

3

7

t

Kalzip SD 135/310

Product specifications

Spans generally up to 6m

Cover width 930mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Material Section Properties - SD 135/310

Narrow flange under compression (mid span)

Bending moment

M

c, Rd

(kNm/m)

9.32

13.34

17.14

21.00

Effective moment

of inertia, I

eff

(cm

4

/m)

199.07

300.83

397.97

500.25

Reaction capacity at intermediate,

R

w, Rd

(kN/m)

Minimum support width of 40mm

11.00

21.97

34.62

49.93

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression (mid span)

Bending moment

M

c, Rd

(kNm/m)

7.31

11.24

15.41

19.26

Effective moment

of inertia, I

eff

(cm

4

/m)

211.88

313.23

418.86

517.22

Reaction capacity at intermediate,

R

w, Rd

(kN/m)

Minimum support width of 40mm

9.00

16.14

25.43

37.01

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Non-standard item

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

(kg/m

2

)

9.50

12.66

15.83

18.99

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Kalzip

Structural

10

110 170

280

840

40

1

5

5

t

R

6

Kalzip SD 150/280

Product specifications

Spans generally up to 8m

Cover width 840mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Material Section Properties - SD 150/280

Narrow flange under compression (mid span)

Bending moment

M

c, Rd

(kNm/m)

10.85

16.27

21.56

26.51

Effective moment

of inertia, I

eff

(cm

4

/m)

273.36

395.60

519.11

656.86

Reaction capacity at intermediate,

R

w, Rd

(kN/m)

Minimum support width of 40mm

11.14

21.78

35.58

52.46

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression (mid span)

Bending moment

M

c, Rd

(kNm/m)

10.68

16.28

21.74

26.83

Effective moment

of inertia, I

eff

(cm

4

/m)

318.80

467.13

612.19

749.12

Reaction capacity at intermediate,

R

w, Rd

(kN/m)

Minimum support width of 40mm

10.82

20.05

32.81

49.90

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Non-standard item

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

(kg/m

2

)

10.52

14.02

17.52

21.03

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Curving

Decking profile can be naturally curved

longitudinally to the radii shown in the

table. It can also be curved in transverse

direction as per the picture shown above.

Please contact our technical department

for information.

Minimum natural longtitude curving radii (m) of decking profiles

Profile

Radii

SD85/280

130

SD135/310

200

SD150/280

220

Penetrations

Small openings

Section A-A

Large openings

Section B-B

Penetrations less than 400 x 400mm

Steel channel both sides of opening

Penetrations greater than 400 x 400mm

Steel channel both sides of opening and

transverse steel channels between rafters

11

Kalzip

Structural

Kalzip

Structural

12

Side laps

Profile

SD85/280

SD135/310

SD150/280

Standard side lap arrangement

1120

930

840

Effective cover width

Effective cover width

Effective cover width

Kalzip Standard lap

SD85/280

End laps

In order to optimise the spanning capability

of the decking profiles it is sometimes

necessary to introduce non-standard

end-lap arrangements.

Standard end-lap arrangement Extended end-lap arrangement

Supported end-lap arrangement Gerber method - used to simulate multi-

span conditions

Where decks are required for diaphragm or stressed skinned functions we recommend

that you contact our technical department in order to clarify the fixing frequency and

boxing in of the end and side lap details. Note there are limitations when using perforated

steel decks, or any aluminium deck for stressed skin.

13

Kalzip

Structural

Fixings

Kalzip fastener for steel decking

Detail Application Frequency Fastener type Max. clamping

length, mm

SFS

fastener code

Base Thickness,

mm

Structural steel

decking sheet to

mild steel rafters/

purlins

As per design

requirements

5.5mm dia. Self drilling t = 1.5 - 5.0

t = 4.0 - 14.0

t = 2 - unlimited

12

14

15

SD5-H15-5.5x25

SD14-H15-5.5x30

TDB-S-S16-6-6.3x25 6.3mm dia. Self-tapping

Structural steel

decking sheet

side-lap stitching

As per design

requirements

4.8mm dia. Self drilling t = < 2 2 SL2-4.8x20

Structural steel

decking sheet

end-lap stitching

As per design

requirements

4.8mm dia. Self drilling t = < 2 2 SL2-4.8x20

Mild steel sub-

purlin to structural

decking

As per design

requirements

6.0mm dia. Self drilling t = 0.6 - 3.8mm 2 - 4 SL3/2-5-S-SV16-6.0x27

Kalzip Advanced

E-clip/ST-clip with

5mm thk. thermal

pad to structural

steel decking

As per design

requirements

5.8mm dia. Self drilling

6.0mm dia. Self drilling

t = 1.2 - 2.0mm

t = 0.7 - 1.2mm

t = 1.3 - 3.2mm

18

6 - 18

6 - 13

SX2/18-A16-5.8x35

SDK2-S-377-6.0x35

SDK3-S377-6.0x30

Kalzip Advanced

E-clip/ST-clip with

5mm thk. thermal

pad to sub-purlin

As per design

requirements

5.8mm dia. Self drilling

6.0mm dia. Self drilling

t = 1.2 - 2.0mm

t = 1.3 - 3.2mm

18

6 - 13

SX2/18-A16-5.8x35

SDK3-S377-6.0x30

Kalzip fastener for aluminium decking

Detail Application Frequency Fastener type Max. clamping

length, mm

SFS

fastener code

Base Thickness,

mm

Structural alu

decking sheet to

mild steel

rafters/purlins

As per design

requirements

5.5mm dia. Self drilling t = 1.5 - 5.0

t = 4.0 - 14.0

t = 2 - unlimited

8

12

15

SX5/8-S16-5.5x33

SX14/12-S16-5.5x40

TDB-S-S16-6-6.3x25 6.3mm dia. Self-tapping

Structural alu

decking sheet

side-lap stitching

As per design

requirements

4.8mm dia. Self drilling 2 SL2-S-S14-4.8x22

Structural alu

decking sheet

end-lap stitching

As per design

requirements

4.8mm dia. Self drilling 2 SL2-S-S14-4.8x22

Alu sub-purlin to

structural alu

decking

As per design

requirements

6.0mm dia. Self drilling 2 - 4 SL3/2-5-S-SV16-6.0x27 t = 0.6 - 4.8

Kalzip Advanced

E-clip/ST-clip with

5mm thk. thermal

pad to structural

alu decking

As per design

requirements

6.0mm dia. Self drilling 6 - 18 SDK2-S-377-6.0x35 t = 0.9 - 2.5

Kalzip Advanced

E-clip/ST-clip with

5mm thk. thermal

pad to alu sub-

purlin

As per design

requirements

6.0mm dia. Self drilling 6 - 18

6 - 13

SDK2-S-377-6.0x35

SDK3-S-377-6.0x30

t = 0.9 - 2.5

t = 2.0 - 3.2

Notes:

1. Above information is only for reference. Any structural design of fasteners should contact APAC technical team.

2. Tool accessory - DS-K265 socket is required for SDK type fastening

Kalzip

Structural

14

Deck system details

Kalzip Standing seam on Kalzip

structural decking with solid

board

Kalzip standing seam sheet

Insulation

Advanced E clip/ ST clip

Vapour control layer

Solid board

Kalzip structural decking

1

2

3

4

5

6

1

2

3

4

5

6

Kalzip Standing seam on Kalzip

structural decking

Kalzip standing seam sheet

Insulation

Advanced E clip/ ST clip

Vapour control layer

Kalzip structural decking

1

2

3

4

5

1

2

3

4

5

Kalzip Standing seam on Kalzip

structural decking with top hat &

solid board

Kalzip standing seam sheet

Insulation

Advanced E clip/ ST clip

Vapour control layer

Top hat

Solid board

Kalzip structural decking

1

2

3

4

5

6

7

1

2

3

4

5

6

7

15

Kalzip

Structural

Suitable for both roof and wall applications,

Kalzip structural cassette are available in

both aluminium and steel and are available

as a tested and proven alternative lining

element for the Kalzip standing seam

system. With good strength and stability,

Kalzip structural cassettes are suitable for

long span applications and there is also a

reduced requirement for structural

steelwork.

Once in position the interior face of

the cassette provides a clean and pleasing

appearance with no visible fixings.

For increased spanability a special

section can be inserted into the side lap

of the cassette.

Structural cassette materials and

finishes

Kalzip structural cassette are manufactured

from high grade steel to BS EN 10346 or

from aluminium alloy.

Perforated versions are available where

acoustic absorption is required. The sheets

also have the strength to support the

introduction of additional mass such as

particle board or plaster board where there

is a requirement for good sound reduction.

For further details, please refer to the

acoustic section, or contact our technical

department.

Standard finishes for cassette, available

on a short lead time are:

Hot-dip galvanised, natural finish. Ideal

for situations where the cassette is not

visible or where visual appearance is

not critical.

White polyester coated on hot-dip

galvanised substrate. This finish is highly

durable, resists scratching and has

good formability, suitable for

exterior soffits.

Alternative perforation patterns and sizes

are available to suit specific requirements.

Perforated cassette will improve the

acoustic conditions within a building by

helping to optimise reverberation times.

Furthermore, the cassette can contribute

to noise reduction and noise containment

within the building by the inclusion of mass

above the cassette such as particle board

or plaster board and the inclusion of air

spaces within the system. If the application

requires, the system can be configured

for both acoustic absorption and noise

reduction. To obtain the correct

specification for precise acoustic

requirements, please contact our

technical department.

Product advantages

Capable of spanning up to 6m

between trusses

Eliminates the need for purlins

Concealed fixing

Provides smooth internal finish

eliminating the need for a seperate

ceiling

Kalzip structural cassette

Materials

Dimensions (mm)

Steel Aluminium

Base metal thickness, BMT

Nominal thickness, NT

Profile length, L (mm)

Profile height, H (mm)

Load bearing capacity

Surface finishes

Metallic coating

Non-metallic coating

Colours

0.71, 0.96, 1.21 & 1.46

0.75, 1.00, 1.25 & 1.50

Approx. 12000

100 & 145

EC3 BS EN 1993-1-3

Hot-dip zince coating (Z275) to BS EN 10346:2009

PVdF & Polyester

RAL standard colours in accordance with the Kalzip colour chart, special colours available

on request

1.00, 1.25 & 1.50

Approx. 12000

100 & 145

EC9 BS EN 1999-1-4

-

PVdF, Polyester & Stucco embossed

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Kalzip

Structural

16

Kalzip structural cassette section properties

30

600

9

9

B

A

33

1

0

0

Kalzip SC 100/600

Product specifications

Spans generally up to 4m

Cover width 600mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Material Section Properties - SC 100/600

Narrow flange under compression (mid span)

Bending

moment, M

c, Rd

(kNm/m)

1.97

3.77

6.21

8.17

Moment

of inertia,

I (cm

4

/m)

126.64

177.14

224.33

271.88

Reaction capacity at

intermediate, R

w, Rd

(kN/m)

5.46

9.59

14.79

21.00

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression (mid span)

Bending

moment, M

c, Rd

(kNm/m)

2.13

3.39

4.86

6.53

Moment of inertia,

I (cm

4

/m)

77.97

110.56

145.22

181.20

Reaction capacity at

intermediate, R

w, Rd

(kN/m)

5.46

9.59

14.79

21.00

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Non-standard item

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

(kg/m

2

)

8.69

11.58

14.47

17.37

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

17

Kalzip SC 145/600

30

600

1

4

4

B

A

33

1

4

5

Product specifications

Spans generally up to 6m

Cover width 600mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Kalzip

Structural

Material Section Properties - SC 145/600

Narrow flange under compression (mid span)

Bending

moment, M

c, Rd

(kNm/m)

3.72

6.79

9.55

12.52

Moment

of inertia,

I (cm

4

/m)

283.89

395.38

501.92

609.89

Reaction capacity at

intermediate, R

w, Rd

(kN/m)

5.48

9.64

14.78

21.00

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression (mid span)

Bending

moment, M

c, Rd

(kNm/m)

3.38

5.28

7.61

10.27

Moment of inertia,

I (cm

4

/m)

181.73

256.87

337.63

421.40

Reaction capacity at

intermediate, R

w, Rd

(kN/m)

5.48

9.64

14.78

21.00

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Non-standard item

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

(kg/m

2

)

9.64

12.85

16.06

19.27

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Kalzip

Structural

18

Cassette system details

Kalzip Standing seam on Kalzip

structural cassette with top hat

(Diagonally)

Kalzip standing seam sheet

Insulation

Advanced E clip/ ST clip

Top hat

Vapour control layer

Kalzip structural cassette

1

2

3

4

5

6

1

2

3

4

5

6

Kalzip Standing seam on Kalzip

structural cassette with top hat

(perpendicular to cassette)

Kalzip standing seam sheet

Insulation

Advanced E clip/ ST clip

Top hat

Vapour control layer

Kalzip structural cassette

1

2

3

4

5

1

2

3

4

5

Kalzip Standing seam on Kalzip

structural cassette with solid

board

Kalzip standing seam sheet

Insulation

Advanced E clip/ ST clip

Vapour control layer

Solid board

Kalzip structural cassette

1

2

3

4

5

6

1

2

3

4

5

6

6

6

19

Kalzip

Structural

Fixings

Kalzip fastener for steel cassette

Detail Application Frequency Fastener type Max. clamping

length, mm

SFS

fastener code

Base Thickness,

mm

Structural steel

cassette sheet to

mild steel

rafters/purlins

As per design

requirements

5.5mm dia. Self drilling t = 1.5 - 5.0

t = 4.0 - 14.0

t = 2 - unlimited

12

14

15

SD5-H15-5.5x25

SD14-H15-5.5x30

TDB-S-S16-6-6.3x25 6.3mm dia. Self-tapping

Structural steel

cassette sheet

side-lap stitching

As per design

requirements

4.8mm dia. Self drilling t = < 2 2 SL2-4.8x20

Structural steel

cassette sheet

end-lap stitching

As per design

requirements

4.8mm dia. Self drilling t = < 2 2 SL2-4.8x20

Mild steel sub-

purlin to structural

cassette

As per design

requirements

6.0mm dia. Self drilling

4.8mm dia. Alu bulb-tite

rivet with EPDM washer

7.1mm dia. Alu bulb-tite

rivet with EPDM washer

t = 0.6 - 3.8mm 2 - 4

1.5 - 6.3

1.2 - 9.5

SL3/2-5-S-SV16-6.0x27

RV6604-6-4W

RV6603-9-6W

Kalzip Advanced

E-clip/ST-clip with

5mm thk. thermal

pad to structural

steel cassette

As per design

requirements

6.3mm dia. Self drilling

6.0mm dia. Self drilling

t = 1.2 - 2.0mm

t = 0.7 - 1.2mm

t = 1.3 - 3.2mm

18

6 - 18

6 - 13

SX2/18-A16-6.3x35

SDK2-S-377-6.0x35

SDK3-S377-6.0x30

Kalzip Advanced

E-clip/ST-clip with

5mm thk. thermal

pad to sub-purlin

As per design

requirements

6.3mm dia. Self drilling

6.0mm dia. Self drilling

t = 1.2 - 2.0mm

t = 1.3 - 3.2mm

18

6 - 13

SX2/18-A16-6.3x35

SDK3-S377-6.0x30

Notes:

1. Above information is only for reference. Any structural design of fasteners should contact APAC technical team.

2. Tool accessories - Power Bird Rivetting is required for rivet type fastening & DS-K265 socket is required for SDK type fastening

Kalzip fastener for aluminium cassette

Detail Application Frequency Fastener type Max. clamping

length, mm

SFS

fastener code

Base Thickness,

mm

Structural alu

cassette sheet to

mild steel

rafters/purlins

As per design

requirements

5.5mm dia. Self drilling t = 1.5 - 5.0

t = 4.0 - 14.0

t = 2 - unlimited

12

14

15

SX5/8-S16-5.5x33

SX14/12-S16-5.5x40

TDB-S-S16-6-6.3x25 6.3mm dia. Self-tapping

Structural alu

cassette sheet

side-lap stitching

As per design

requirements

4.8mm dia. Self drilling 2 SL2-S-S14-4.8x22

Structural alu

cassette sheet

end-lap stitching

As per design

requirements

4.8mm dia. Self drilling 2 SL2-S-S14-4.8x22

Alu sub-purlin to

structural cassette

As per design

requirements

6.0mm dia. Self drilling

4.8mm dia. Alu bulb-tite

rivet with EPDM washer

7.1mm dia. Alu bulb-tite

rivet with EPDM washer

t = 0.6 - 3.8mm 2 - 4

1.5 - 6.3

1.2 - 9.5

SL3/2-5-S-SV16-6.0x27

RV6604-6-4W

RV6603-9-6W

Kalzip Advanced

E-clip/ST-clip with

5mm thk. thermal

pad to structural

alu cassette

As per design

requirements

6.0mm dia. Self drilling t = 0.9 - 2.5mm 6 - 18 SDK2-S-377-6.0x35

Kalzip Advanced

E-clip/ST-clip with

5mm thk. thermal

pad to alu sub-

purlin

As per design

requirements

6.0mm dia. Self drilling t = 0.9 - 2.5mm

t = 2.0 - 3.2mm

6 - 18

6 - 13

SDK2-S-377-6.0x35

SDK3-S-377-6.0x30

Kalzip

Structural

20

Acoustics - decking & cassette

Kalzip structural decking sheets are available

perforated to provide sound absorption

performance. Alternative perforation patterns and

sizez are available to suit specific requirements.

Perforated decking & cassette will improve

the acoustic conditions within a building

by helping to optimise reverberation times.

Furthermore, the decking & cassette sheets

can contribute to noise reduction and noise

containment within the building by the

inclusion of mass above the decking or

cassette sheet such as particle board or

plasterboard and the inclusion of air spaces

within the system. If the application

requires, the system can be configured

for both acoustic absorption and noise

reduction. To obtain the correct

soecification for precise acoustic

requirements, please contact our

technical department.

Kalzip

decking sheet

85/280

135/310

150/280

100/600

145/600

60

60

60

200

200

35

35

35

35

35

11

9

9

12

11

Perforated

band width

Perforated

area %

Total void

area %

Approx. reduction in

load bearing capacity %

15

12

10

40

30

5mm dia.

8

8

21

Kalzip

Structural

Acoustics - Decking

Kalzip Standing seam on Kalzip

perforated structural decking

Kalzip standing seam sheet

Insulation

Kalzip clip

Top hat

Vapour control layer

30 mm thk solid board (100 kg/m3)

SD 150/280, 1 mm thk Alu web perforated

1

2

3

4

5

6

7

1

2

3

4

5

6

7

Acoustic absorption coefficient of Kalzip Structural Deck Roof

Spans generally up to 3m

Cover width 1120mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Perforation 5D x 8P, 35%

119.5 160.5

280

1120

40

8

4

.

5

t

A

B

R

5

Kalzip

Structural

22

Perforated decking section properties

Kalzip SD 85/280P

Product specifications

Material & section properties - SD 85/280P 5.0D x 8.0P, 35%

Narrow flange under compression

Bending moment,

Mc,Rd (kNm/m)

4.66

6.50

8.34

10.10

Effective moment

of inertia, Ieff

(cm

4

/m)

67.26

103.62

137.38

167.88

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

12.05

22.27

35.33

51.16

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression

Bending moment,

Mc,Rd (kNm/m)

3.36

5.38

7.56

9.32

Effective moment

of inertia, Ieff

(cm

4

/m)

63.10

96.01

130.59

159.80

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

9.42

16.95

26.79

39.15

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

Non-

perforated

(kg/m

2

)

7.88

10.51

13.14

15.77

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Spans generally up to 5m

Cover width 930mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Perforation 5D x 8P, 35%

145 165

310

930

43

1

3

7

t

A

B

23

Kalzip SD 135/310P

Product specifications

Kalzip

Structural

Material & section properties - SD 135/310P 5.0D x 8.0P, 35%

Narrow flange under compression

Bending moment,

Mc,Rd (kNm/m)

8.18

11.57

14.84

18.18

Effective moment

of inertia, Ieff

(cm

4

/m)

178.40

271.37

359.70

452.97

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

11.00

21.97

34.62

49.93

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression

Bending moment,

Mc,Rd (kNm/m)

5.85

9.24

12.67

15.74

Effective moment

of inertia, Ieff

(cm

4

/m)

178.70

270.13

360.2

443.15

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

9.00

16.14

25.43

37.01

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

Non-

perforated

(kg/m

2

)

9.50

12.66

15.83

18.99

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

110 170

280

840

40

1

5

5

t

A

B

R

6

Kalzip

Structural

24

Kalzip SD 150/280P

Product specifications

Spans generally up to 7m

Cover width 840mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Perforation 5D x 8P, 35%

Material & section properties - SD 150/280P 5.0D x 8.0P, 35%

Narrow flange under compression

Bending moment,

Mc,Rd (kNm/m)

9.76

14.77

18.92

23.25

Effective moment

of inertia, Ieff

(cm

4

/m)

243.37

355.33

467.12

592.08

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

11.14

21.78

35.58

52.46

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression

Bending moment,

Mc,Rd (kNm/m)

8.40

13.49

18.33

22.7

Effective moment

of inertia, Ieff

(cm

4

/m)

265.97

402.58

534.57

655.52

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

10.82

20.05

32.81

49.90

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

Non-

perforated

(kg/m

2

)

10.52

14.02

17.52

21.03

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

25

Kalzip

Structural

Perforated cassette section properties

30

600

9

9

B

A

33

1

0

0

86 184 60 184 86

Spans generally up to 3m

Cover width 600mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Perforation 5D x 8P, 35%

Kalzip SC 100/600P

Product specifications

Material & section properties - SC 100/600P 5.0D x 8.0P, 35%

Narrow flange under compression

Bending moment,

Mc,Rd (kNm/m)

1.54

2.21

3.02

4.13

Effective moment

of inertia, Ieff

(cm

4

/m)

108.90

152.62

193.99

238.91

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

5.46

9.59

14.79

21.00

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression

Bending moment,

Mc,Rd (kNm/m)

1.59

2.40

3.30

4.29

Effective moment

of inertia, Ieff

(cm

4

/m)

65.43

91.68

118.33

146.91

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

5.46

9.59

14.79

21.00

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

Non-

perforated

(kg/m

2

)

8.69

11.58

14.47

17.37

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Kalzip

Structural

26

30

600

1

4

4

B

A

33

1

4

5

86 184 60 184 86

Spans generally up to 5m

Cover width 600mm

Max. length 12.0m

Nominal thickness 0.75mm to 1.50mm

Perforation 5D x 8P, 35%

Kalzip SC 145/600P

Product specifications

Material & section properties - SC 145/600P 5.0D x 8.0P, 35%

Narrow flange under compression

Bending moment,

Mc,Rd (kNm/m)

3.02

4.31

5.82

7.79

Effective moment

of inertia, Ieff

(cm

4

/m)

248.60

348.23

444.31

540.53

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

5.48

9.64

14.78

21.00

Note:

1. Material & section properties for aluminium are calculated on project basic.

2. Reaction capacity at end support is R

w, Rd

/2.

3. Section properties are calculated to EC3 BS EN 1993-1-3:2006.

Wide flange under compression

Bending moment,

Mc,Rd (kNm/m)

2.55

3.82

5.31

7.00

Effective moment

of inertia, Ieff

(cm

4

/m)

152.73

212.04

276.93

343.32

Reaction capacity at intermediate,

Rw,Rd (kN/m)

Minimum support width of 40mm

5.48

9.64

14.78

21.00

* Base metal thickness is the thickness of the metal substrate only. It does not include the surface finishes.

* Nominal thickness = BMT + Metallic coating

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Yield

strength

F

y

(N/mm

2

)

320

320

320

320

Base

metal

thickness,

BMT (mm)

0.71

0.96

1.21

1.46

Weight, w

Non-

perforated

(kg/m

2

)

9.64

12.85

16.06

19.27

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

Nominal

thickness,

NT (mm)

0.75

1.00

1.25

1.50

27

Kalzip

Structural

Supreme Court, Singapore

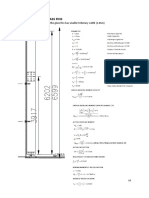

Kalzip structural deck

SD 85/280

119.5 160.5

280

1120

40

8

4

.

5

t

A

B

R

5

Minimum support width is 40mm

(1)

Ultimate limit state - Imposed load where position A under compression at midspan

Single span support

Double span support

Multiple span support

Ultimate limit state - Wind suction where position B under compression at midspan

Single span support

Double span support

Multiple span support

Service limit state - Imposed load where position A under compression at midspan

Single span support

Double & multiple span support

Service limit state - Wind suction where position B under compression at midspan

Single span support

Double & multiple span support

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

28

29

Kalzip

Structural

145 165

310

930

43

1

3

7

t

A

B

SD 135/310

Kalzip structural deck

Minimum support width is 40mm

(1)

Ultimate limit state - Imposed load where position A under compression at midspan

Single span support

Double span support

Multiple span support

Ultimate limit state - Wind suction where position B under compression at midspan

Single span support

Double span support

Multiple span support

Service limit state - Imposed load where position A under compression at midspan

Single span support

Double & multiple span support

Service limit state - Wind suction where position B under compression at midspan

Single span support

Double & multiple span support

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

30

110 170

280

840

40

1

5

5

t

A

B

R

6

SD 150/280

Kalzip structural deck

Minimum support width is 40mm

(1)

Ultimate limit state - Imposed load where position A under compression at midspan

Single span support

Double span support

Multiple span support

Ultimate limit state - Wind suction where position B under compression at midspan

Single span support

Double span support

Multiple span support

Service limit state - Imposed load where position A under compression at midspan

Single span support

Double & multiple span support

Service limit state - Wind suction where position B under compression at midspan

Single span support

Double & multiple span support

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

31

SD 85/280 P

119.5 160.5

280

1120

40

8

4

.

5

t

A

B

R

5

Single span support

Double span support

Multiple span support

Single span support

Double span support

Multiple span support

Single span support

Double & multiple span support

Single span support

Double & multiple span support

Kalzip structural deck

Minimum support width is 40mm

(1)

Perforation pattern 5D x 8P, 35%

Ultimate limit state - Imposed load where position A under compression at midspan

Ultimate limit state - Wind suction where position B under compression at midspan

Service limit state - Imposed load where position A under compression at midspan

Service limit state - Wind suction where position B under compression at midspan

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

32

145 165

310

930

43

1

3

7

t

A

B

SD 135/310 P

Single span support

Double span support

Multiple span support

Single span support

Double span support

Multiple span support

Single span support

Double & multiple span support

Single span support

Double & multiple span support

Kalzip structural deck

Minimum support width is 40mm

(1)

Perforation pattern 5D x 8P, 35%

Ultimate limit state - Imposed load where position A under compression at midspan

Ultimate limit state - Wind suction where position B under compression at midspan

Service limit state - Imposed load where position A under compression at midspan

Service limit state - Wind suction where position B under compression at midspan

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

33

110 170

280

840

40

1

5

5

t

A

B

R

6

SD 150/280 P

Single span support

Double span support

Multiple span support

Single span support

Double span support

Multiple span support

Single span support

Double & multiple span support

Single span support

Double & multiple span support

Kalzip structural deck

Minimum support width is 40mm

(1)

Perforation pattern 5D x 8P, 35%

Ultimate limit state - Imposed load where position A under compression at midspan

Ultimate limit state - Wind suction where position B under compression at midspan

Service limit state - Imposed load where position A under compression at midspan

Service limit state - Wind suction where position B under compression at midspan

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

34

SC 100/600

Kalzip structural cassette

Minimum support width is 40mm

(1)

Single span support

Double span support

Multiple span support

Single span support

Double span support

Multiple span support

Single span support

Double & multiple span support

Single span support

Double & multiple span support

30

600

9

9

B

A

33

1

0

0

Ultimate limit state - Imposed load where position A under compression at midspan

Ultimate limit state - Wind suction where position B under compression at midspan

Service limit state - Imposed load where position A under compression at midspan

Service limit state - Wind suction where position B under compression at midspan

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

35

SC 145/600

Kalzip structural cassette

Minimum support width is 40mm

(1)

Single span support

Double span support

Multiple span support

Single span support

Double span support

Multiple span support

Single span support

Double & multiple span support

Single span support

Double & multiple span support

30

600

1

4

4

B

A

33

1

4

5

Ultimate limit state - Imposed load where position A under compression at midspan

Ultimate limit state - Wind suction where position B under compression at midspan

Service limit state - Imposed load where position A under compression at midspan

Service limit state - Wind suction where position B under compression at midspan

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

36

SC 100/600 P

Single span support

Double span support

Multiple span support

Single span support

Double span support

Multiple span support

Single span support

Double & multiple span support

Single span support

Double & multiple span support

Kalzip structural cassette

Minimum support width is 40mm

(1)

Perforation pattern 5D x 8P, 35%

30

600

9

9

B

A

33

1

0

0

86 184 60 184 86

Ultimate limit state - Imposed load where position A under compression at midspan

Ultimate limit state - Wind suction where position B under compression at midspan

Service limit state - Imposed load where position A under compression at midspan

Service limit state - Wind suction where position B under compression at midspan

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

37

SC 145/600 P

Kalzip structural cassette

Single span support

Double span support

Multiple span support

Single span support

Double span support

Multiple span support

Single span support

Double & multiple span support

Single span support

Double & multiple span support

Minimum support width is 40mm

(1)

Perforation pattern 5D x 8P, 35%

30

600

1

4

4

B

A

33

1

4

5

86 184 60 184 86

Ultimate limit state - Imposed load where position A under compression at midspan

Ultimate limit state - Wind suction where position B under compression at midspan

Service limit state - Imposed load where position A under compression at midspan

Service limit state - Wind suction where position B under compression at midspan

Notes:

1. Above load span tables are designed to EC3 BS EN 1993-1-3:2006 by considered stiff bearing length is 10mm.

The definition of stiff bearing length is defined in Section 6.3, BS 1993-1-5:2006.

2. Above calculation is only indicating the member capacity.

3. Minimum yield strength = 320N/mm

2

.

4. BMT - thickness of the metal substrate only

5. The deflection limit of service calculations is L/200 or 30mm whichever is lower.

6. For further detail of design calculation, for example fastening design, stiff bearing greater than

10mm and others, please contact Kalzip Technical Team.

Kalzip

Structural

38

Example of using load span table

Design Data:

SD profile

Profile base metal thickness

Span condition

= SD 150/280

= 1.46mm

= Single span

Loadings:

Total dead load (included SD selfweight), DL

Live load, LL

Wind pressure, WLp

Wind suction, WLs

= 0.5 kN/m

2

= 0.75 kN/m

2

= 1 kN/m

2

= -2 kN/m

2

Ultimate limit state

Load combination to BS 5950

1.4DL + 1.6LL

1.4DL + 1.4WLp

DL + 1.4WLs

The critical downward load

The critical upward load

= 1.90 kN/m

2

= 2.10 kN/m

2

= -2.30 kN/m

2

= 2.10 kN/m

2

= -2.30 kN/m

2

Service limit state

Load combination to BS 5950

DL + LL

DL + WLs

= 1.25 kN/m

2

= -1.50 kN/m

2

Refering to ultimate limit state - single span table at 4th row:

The maximum allowable span of downward load 2.10 kN/m

2

is 9m

The maximum allowable span of upward load -2.30 kN/m

2

is 9m

Refering to service limit state - single span table at 4th row:

The maximum allowable span of downward load 1.25 kN/m

2

is 7.2m

The maximum allowable span of upward load -1.50 kN/m

2

is 6.8m

As summarized, the maximum allowable span of above loadings is 6.8m which the deflection

is the limit criteria for this design

Note:

1. The deflection limit L/200 or 30mm whichever is lower used to check the downward case

2. The deflection limit L/200 is used to check the upward case

3. The load span tables are only for preliminary dimensioning and do not replace the required

static proof.

Kalzip around the world

39

Kalzip

Structural

Kalzip international

Changes within the construction industry

have led Kalzip to develop a dedicated

international team with the commercial

and technical experience to support and

service customer requirements on a

global scale.

A changing industry

An increase in global relationships has

taken design and construction to a new

level where architects, installation

contractors and construction sites can be

based in three completely separate

countries. Where this occurs the Kalzip

international team work closely with their

regional colleagues and each of the project

specialists to offer their service and support

through all stages of design, tender

and construction.

Benefitting design teams worldwide

Bringing together a wealth of experience

over a range of disciplines, the Kalzip

international team ensures that all the key

stages in designing, tendering, securing

and delivering the project are addressed.

Tailoring specifi cations precisely to the

customers requirements, Kalzip provides

assistance and guidance with calculations,

local building standards, climate

considerations, logistics, and installation.

All these are complex yet fundamental

requirements, and ones that form the basis

of the international team in supporting the

project from concept to completion. With

each project there is a clear direction with

established levels of responsibility and

focus. Lines of communication are

improved and every project is monitored

and progressed on all fronts with regional

differences and language considerations

taken into account.

For further information email:

international@kalzip.com

Kalzip

Structural

40

An impressive list of international projects

stand testament to Kalzips ability to perform

in a wide array of applications and conditions

Project: Student Halls of Residence, Osijek, Croatia

Architect: Arvum Teh

41

Kalzip

Structural

1. Agora Theatre

Lelystad, The Netherlands

2. Science Museum

Valencia, Spain

3. Spencer Street Station

Melbourne, Australia

4. University Federal Credit Union

Texas, USA

5. DELL Call Centre

Montpellier, France

6. Motorway Inn

Quinto, Switzerland

7. BMW

Leipzig, Germany

8. Barajas Airport

Madrid, Spain

9. Fashion Centre

Almere, The Netherlands

10.Taipei Arena

Taipei, Taiwan

1. 2.

3. 4. 5.

6.

7. 8.

9. 10.

11.Millennium Grandstand

Nad Al Sheba Dubai

12.Leon van Gelder College

Groningen, The Netherlands

13.Wrth Offices

Den Bosch, The Netherlands

14.Mumbai T1B Domestic Airport

Mumbai, India

15.Foshan Lingnan Pearl Stadium

Foshan, China

16.Nanjing Olympic Centre

Nanjing, China

17.Mapo Waste Incinerator

Seoul, South Korea

18.Exhibition Hall 3

Frankfurt, Germany

19.AsiaWorld Expo

Hong Kong

20.National Grand Theatre

Beijing, China

11. 13.

14. 15.

16.

17. 18.

19. 20.

Kalzip

Structural

42

12.

43

The Kalzip Business Unit forms part of the

Distribution and Building Systems Division. With

independent sites in Germany, Belgium, France,

United Kingdom, Singapore, China, Portugal and

Spain, as well as, 20 sales and representative offices

the world over, the Business Unit produces roof and

wall cladding systems under the trademark Kalzip.

Kalzip was first launched onto the market in 1968.

Since then over 70 million square metres of Kalzip

standing seam profiled sheets have been fitted to

roofs and facades. The low weight, malleability and

durability of the aluminium have made it a leading

product that also lends itself to the creation of

unusual architectural forms. In this way, Kalzip

continues to open up new technical and

aesthetic horizons.

Please ask for further information without obligation.

Take advantage of our

wealth of experience and the

comprehensive range of

Kalzip

services available

Kalzip

Structural

www.kalzip.com

While care has been taken to ensure that the

information contained in this brochure

is accurate, neither Tata Steel Europe Limited

nor its subsidiaries accept responsibility or

liability for errors or information which is found

to be misleading.

Copyright 2010

Kalzip Asia Pte Ltd

English

Australia

Kalzip Australia

Unit 1, 66-74 Micro Circuit

Dandenong South, Victoria 3175

Australia

T: +61 3 8762 5506

F: +61 3 8762 5549

sales.au@kalzip.com

China

Kalzip (Guangzhou) Limited

Suite 2310, North Tower The Hub

1068 Xin Gang East Road

Haizhu District

Guangzhou, China 510335

T: +86 20 8904 7408

F: +86 20 8923 1863

sales.cn@kalzip.com

Singapore

Kalzip Asia Pte Ltd

25 Pioneer Crescent

Singapore 628554

T: +65 6768 9081

F: +65 6898 9374

sales.sg@kalzip.com

Hong Kong

Kalzip Asia Pte Ltd

Unit 17-18, 7/F., Delta House

3 On Yiu Street, Siu Lek Yuen

Shatin, N.T.

Hong Kong

T: +852 2887 5277

F: +852 2234 6739

sales.hk@kalzip.com

India

Corus India Pvt. Ltd

310, 3rd Floor, Vipul Agora,

M.G. Road, Gurgaon

Haryana - 122002

India

T: +91 124 4848 800

F : +91 124 4848 801

sales.in@kalzip.com

Taiwan

Kalzip Asia Pte Ltd

5F., No.1-10, Lane 174

Huaide St., Banqiao City

Taipei County 220

Taiwan (R.O.C.)

T: +886 2 2257 1418

F: +886 2 2257 9458

sales.tw@kalzip.com

You might also like

- Rib DeckDocument38 pagesRib DeckUntuksign UpsajaNo ratings yet

- Keystone Steel Lintel BrochureDocument42 pagesKeystone Steel Lintel BrochureconriordanNo ratings yet

- Kalzip Systems Brochure MEDocument72 pagesKalzip Systems Brochure MEjmcc2No ratings yet

- Kalzip Facade SystemsDocument24 pagesKalzip Facade SystemsAndon Setyo WibowoNo ratings yet

- UK TechnBroschDocument52 pagesUK TechnBroschMarcos AmorimNo ratings yet

- Manual of Purlin and Girt DesignDocument64 pagesManual of Purlin and Girt DesigntitlesaengNo ratings yet

- 106000Document36 pages106000ThaisailerNo ratings yet

- UK-Kalzip-Systems Products and ApplicationsDocument72 pagesUK-Kalzip-Systems Products and ApplicationsaddindxNo ratings yet

- HCW 14-Us HalfenDocument36 pagesHCW 14-Us HalfenALBERT100% (1)

- Facades and InterfacesDocument43 pagesFacades and Interfacesissamoune100% (2)

- SAS Curtain Wall BrochureDocument28 pagesSAS Curtain Wall BrochureAngga RamadhanNo ratings yet

- Curtain WallDocument3 pagesCurtain WalljitenderaNo ratings yet

- Advanced Structural Systems: Curtain WallsDocument13 pagesAdvanced Structural Systems: Curtain WallsSajid QuaziNo ratings yet

- Indianapolis Airport StructuralDocument3 pagesIndianapolis Airport Structuralrorobinhoodiee100% (1)

- 1207-2016+Curtain+Walls CompressedDocument114 pages1207-2016+Curtain+Walls CompressedJose Luis Soto Petralanda100% (1)

- Introduction To Glass Curtain Wall SystemsDocument7 pagesIntroduction To Glass Curtain Wall SystemsguillermoNo ratings yet

- UK SP MB Kingspan Multibeam Brochure PDFDocument144 pagesUK SP MB Kingspan Multibeam Brochure PDFhemendraengNo ratings yet

- En Downloads Brochures TexlonHSP ETFE Brochure enDocument4 pagesEn Downloads Brochures TexlonHSP ETFE Brochure ennubis_zionNo ratings yet

- Product - Library-Axilume Balustrade Technical ManualDocument60 pagesProduct - Library-Axilume Balustrade Technical ManualHSP19fNo ratings yet

- Com Flor 60 BrochureDocument28 pagesCom Flor 60 BrochureHanniel MadramootooNo ratings yet

- Dynamic Watertightness Tests For Curtain WallingDocument4 pagesDynamic Watertightness Tests For Curtain WallingHCStepNo ratings yet

- HALFEN Curtain Wall Support SystemsDocument36 pagesHALFEN Curtain Wall Support Systemsvinthf100% (2)

- Northclad AcmDocument2 pagesNorthclad Acmresearcher911No ratings yet

- Kal ZipDocument16 pagesKal ZipNgaiLamNo ratings yet

- Kingspan AccessoriesDocument9 pagesKingspan AccessoriesthedogishighNo ratings yet

- Gutmann Curtain Wall Systems f50 Plus f60 Plus enDocument1 pageGutmann Curtain Wall Systems f50 Plus f60 Plus enNacer IzriNo ratings yet

- Curtain Wall FirestopDocument3 pagesCurtain Wall FirestopendysaujanasNo ratings yet

- Curtain WallDocument49 pagesCurtain WallDaniel ReynoldsNo ratings yet

- CWDC 1 08 GasketsDocument59 pagesCWDC 1 08 GasketsJoni StulicNo ratings yet

- 1e5 Glass Structures l5 Me Glued ConnectionDocument60 pages1e5 Glass Structures l5 Me Glued ConnectionPaulNo ratings yet

- Check For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Document5 pagesCheck For Glass Fins: The Location Where We Have The Glass Fins Has Smaller Tributary Width (1.44m)Laurence SarmientoNo ratings yet

- Bollards Catalogue en A4 Metric v.2.0 WebDocument20 pagesBollards Catalogue en A4 Metric v.2.0 WebspasmNo ratings yet

- Facade-Alumimum & Glazing Works Scope-Technical SpecificationsDocument5 pagesFacade-Alumimum & Glazing Works Scope-Technical SpecificationsHasnain SafdarNo ratings yet

- Strength Design Methods For Glass StructuresDocument147 pagesStrength Design Methods For Glass Structuresامين الزريقيNo ratings yet

- Kingspan Structural KSP Multideck Technical Handbook LR 122018 en UKDocument140 pagesKingspan Structural KSP Multideck Technical Handbook LR 122018 en UKdion2110No ratings yet

- Building Design Assigment Glass FacadeDocument25 pagesBuilding Design Assigment Glass FacadeCeejay TanwangcoNo ratings yet

- Façade System: 18AR35 Atif MominDocument11 pagesFaçade System: 18AR35 Atif MominAtif MominNo ratings yet

- Planning - THERM - Timber - H-I - H-V - 2016 (RAICO)Document542 pagesPlanning - THERM - Timber - H-I - H-V - 2016 (RAICO)AnrStukNo ratings yet

- Cantilever Curtain WallDocument18 pagesCantilever Curtain WallkingdbmNo ratings yet

- Curtain WallDocument36 pagesCurtain Wallhayat49000100% (1)

- H11 Roof and Wall Systems ............................................................................ 5Document53 pagesH11 Roof and Wall Systems ............................................................................ 5Anonymous qabSVjzrANo ratings yet

- GYP547 ResGuide 2011 - 557fDocument56 pagesGYP547 ResGuide 2011 - 557fduckman2009No ratings yet

- Design Components For Structural GlazingDocument8 pagesDesign Components For Structural GlazingnonspodNo ratings yet

- UK & Ireland Coating Selector: A Guide To The Kingspan Range of CoatingsDocument32 pagesUK & Ireland Coating Selector: A Guide To The Kingspan Range of CoatingsSuresh BabuNo ratings yet

- Isopan - Isolite 0Document8 pagesIsopan - Isolite 0Anonymous Un0gh7No ratings yet

- UK-Kalzip Facade System TechnicalDocument32 pagesUK-Kalzip Facade System TechnicalMarcos AmorimNo ratings yet

- Unitised Element FacadesDocument32 pagesUnitised Element FacadesGhani SulistionoNo ratings yet

- MANUAL DE INSTALACION - Securail HorizontalDocument25 pagesMANUAL DE INSTALACION - Securail HorizontalDpto Ingenieria PROINTE100% (1)

- Curtain Wall Types: Technical Note No. 14Document1 pageCurtain Wall Types: Technical Note No. 14Eslam YahiaNo ratings yet

- Curtain Walls ReportDocument13 pagesCurtain Walls ReportAshwini Bramhane100% (3)

- Securope On Hot Deck and Zinc Roof: Installer ManualDocument22 pagesSecurope On Hot Deck and Zinc Roof: Installer ManualDpto Ingenieria PROINTENo ratings yet

- Alucobond Technical DataDocument67 pagesAlucobond Technical DatadylanhengNo ratings yet

- Curtain Wall Stick SystemDocument15 pagesCurtain Wall Stick SystemAnonymous PWdOlxY100% (2)

- 8607 Kingspan Multibeam Technical Handbook Structural Products and Systems 042018 UK en LRDocument148 pages8607 Kingspan Multibeam Technical Handbook Structural Products and Systems 042018 UK en LRmadhav sreekumarNo ratings yet

- KALZIP Roof Technical BrochureDocument52 pagesKALZIP Roof Technical Brochureiask5275100% (1)

- Technical ManualDocument36 pagesTechnical Manualneeshakothari31No ratings yet

- Cofraplus77 enDocument28 pagesCofraplus77 enKristály AnikóNo ratings yet

- Locked SeamDocument8 pagesLocked SeamTony DuignanNo ratings yet

- Design of Digester Biogas Tank Part 3: 3D Digester Biogas Tank ModelDocument6 pagesDesign of Digester Biogas Tank Part 3: 3D Digester Biogas Tank ModelZoranNo ratings yet

- Document 1Document1 pageDocument 1ZoranNo ratings yet

- Trepel Challenger 700Document2 pagesTrepel Challenger 700ZoranNo ratings yet