Professional Documents

Culture Documents

Cantilever Retaining Wall - Rameswaram

Uploaded by

D.V.Srinivasa RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cantilever Retaining Wall - Rameswaram

Uploaded by

D.V.Srinivasa RaoCopyright:

Available Formats

A)Data:-

Height of Retaining wall = 4.50m

Height of wall above G.L= 4.50m

Height of wall below G.L= 0.00m

Dry density of back fill material = 1600Kg/Cum

Water content = 0.23m

Density of back fill soil&material ( Submerged unit weight) = 1968Kg/Cum

Grade of concrete = M25

Grade of steel = Fe415

Ground water Table level (Below G.L) = 1.20m

Angle of shearing resistance of back fill material&material at toe portion() (As per report) = 32

Angle of face of wall supporting earth with horizontal()(In degrees) 87.5

(in anti clock wise direction)

Slope of back fill() = 0

Angle of wall friction () = 16

Surcharge over the back fill in terms of height of back fill = 1.20m

Undrained Cohesion ( c) = 0Kg/sqm

Characteristic compressive strength = 25N/sqmm

Tensile strength of steel = 415N/sqmm

Unit weight of concrete = 2500Kg/Cum

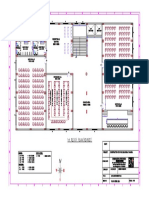

B)Dimensions of the Cantilever wall(Assumed for preliminary design):-

Thickness of stem at bottom = 0.40m

Thickness of stem at top = 0.20m

Thickness of base slab = 0.40m

Breadth of beam = 0.45m

Depth of beam = 0.60m

Dia of Bored Cast-in situ straight pile assumed = 0.50m

Depth of pile = 5.00m

C/c spacing of piles in transverse direction = 1.50m

C/c spacing of piles in longitudinal direction = 2.00m

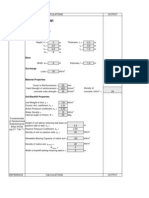

C)Design:-

i)Earth pressure calculations:-

Coefficient of active earth pressure by Coulomb's theory

2

K

a

= Sin(+)

sin sin(-) sin(+)sin(-)

sin(+)

From the above expression,

K

a

= 0.3

Hence,maximum pressure at the base of the wall Pa = 2656.80Kg/sqm

The pressure distribution along the height of the wall is as given below:-

Pressure due to

Surcharge load = 708.48

708.48

DESIGN OF CANTILEVER RETAINING WALL

4.50m

2656.80

Total Active earth pressure force = 9165.96

Height from the bottom of the wall = 1.76m

The active earth pressure acts on the wall as shown below:-

Horizontal component of the earth pressure P

h

= 8692.77Kg/m

Vertical component of the earth pressure P

v

= 2906.98Kg/m

ii)Intial proportioning of the structure :-

500

1000

4

0

0

6

0

0

200

4

5

0

0

5

0

0

0

1

8

.

5

5

CROSS SECTION DETAILS

1

7

6

0

9

2

.

5

4

2300

In view of the very poor bearing capacity of the soil,either gravity or cantilever retaining walls are

not economical.It is proposed to support the wall on base slab supported by longitudinal beams,which are

supported on piles.

As per the clause 5.6.2 of IS 2911(1)-1,the minimum spacing between friction piles should not be less than

3 times the diametre of the shaft,hence transverse spacing of 1.35m is adopted.

Hence,total width of the pile cap = 2.30m

Two rows of 450mm dia Bored cast-in-situ straight piles are proposed at spacing of 2.00m in longitudinal

direction

Computation of total vertical load on the pile :-

i)Self weight of pile = 2453.13kg

ii)Self weight of wall(2.00m length on two piles) = 3375.00kg

iii)Self weight of pile cap = 2300.00kg

iv)Self weight of beam = 500.00kg

v)Weight of earth on heel side = 8413.20kg

vi)Weight of earth on toe side = 1003.68kg

18045.01kg

The total lateral load due to earth pressure on the wall = 17385.55Kg

Deduct lateral force to be resisted by the pile cap-cum-beam system = -2361.60Kg

15023.95Kg

Hence,the pile needs to be designed for safe vertical load carrying capacity of 18.05t

Similarly,it needs to be designed for lateral load carrying capacity of 7.51t

ii)Design of pile :-

a)Safe vertical load carrying capacity:-

To estimate the safe bearing capacity of pile, the ultimate bearing capacity of pile is calculated. Static

formulae are used in estimating ultimate bearing capacity of pile.

As per Appendix A of IS 2911(1)-1

Ultimate bearing capacity of a pile is given by

,

Q

u

= Q

s

+ Q

p

Where Q

s

= Skin frictional resistance,

Q

p

= End bearing resistance

In the present case,the pile passes through the fine sand for a depth of 8.40m(As per soil testing report)

Q

s

= f

s

x A

s

f

s

= K P

di

tan

Where,

K = coefficient of earth pressure;

P

di

= average effective overburden pressure in kgf/cm

= angle of wall friction between pile and soil in degrees(To be taken equal to )

A

s

= surface area of pile

Effective overburden preesure at top of the pile = 960.00Kg/sqm

Effective overburden preesure at the level of pile tip = 5598.40Kg/sqm

(Upto Water Table + After water table)

Average effective overburden pressure along pile shaft P

di

= 3279.20Kg/m

Hence Q

s

= 4822.52kg

Q

p

= q

p

x A

p

q

p

= P

di

(N

q

-1)

Where,

P

di

= Effective overburden pressure at tip of the pile in kgf/cm

N

q

= Bearing capacity factor as per Fig.1 of IS 2911(1)-1

A

p

= End bearing area of pile

N

q

= 40

P

di

= 5598.4Kg/sqm

A

p

= 0.20sqm

Hence,Q

p

= 43667.52kg

Ultimate bearing capacity of pile = 48490.04kg

Applying a factor of safety of 2, allowable safe bearing capacity = 24.25t

b)Lateral load carrying capacity:-

Case1:- Pile considered as short fixed head pile embedded in cohesion less soil

The pile considered as short restrained(Fixed head) pile embedded in cohesionless soil.As per Broom's

theory,failure takes place when the load applied to the pile is equal to the ultimate lateral resistance of the soil

P

u

= 1.5 L

2

d K

p

Where,

L = Length of embeddment

d = Diametre of pile

K

p

= Coefficient of passive earth pressure

Hence P

u

= 100000.00kg

Safe lateral load carrying capacity = 33.33t

(Applying a factor of safety of 3)

Case2:- Pile considered as short fixed head pile embedded in normally consolidated clay

The lateral load capacity of the pile is estimated as per the layer of soil situated at the ground level, as it

will have the major contribution in the lateral load capacity of pile.

As the top most soil layer is normally consolidated clay,

T =

5

(EI/

h

)

E = 5000f

ck

= 25000000

I = 0.00307 m

4

For medium sand

h

= 5260.00KN/cum

T = 1.71

From Figure 2 of IS: 2911 (Part 1)-19793, depth of fixity L

f

= 2.500m

As the pile is short pile,the length of fixity is greater than the actual length,hence actual length is to be

considered for design.

Hence,lateral load capacity of fixed head pile is calculated as,

Q = 12EIY/L

3

where, Y = limiting lateral deflection of pile head = 5 mm for bridge substructures

Hence Q = 294.72KN 29.47t

Load carrying capacity is taken as average of the above two values 31.40t

c)Structural design of pile:-

Now,the fixed end moment of the equivalent cantilever is given by

Mu = Q(Lf)/2 = 9.39t-m =93.90KNm

Applying a reduction factor of 0.82 as per IS 2911(PartI)-I,the moment = 77.00KNm

The pile is to be designed for axial load Pu = 270.75KN

and moment of Mu = 115.50KNm

Assuming percentage of steel p = 0.75

p/fck = 0.03

P

u

/fckD2 = 0.043

Mu/fckD3 = 0.037

d'/D = 0.15

Area of steel required = 1471.88sqmm

Using 16mm dia HYSD bars,No.of bars required for each pile = 7.324243631

Hence provide 8 Nos of 16mm dia bars for each pile

Provide 8mm ties at 200mm c/c

Hence,the safe lateral load carrying capacity of pile is 31.40t

The passive earth pressure on grade beam = K

p

h = 3936.00Kg/sqm

Passive earth pressure force for 2.0m length = 2361.60Kg 2.36t

Hence,the total lateral load carrying capacity of the structure is 65.16t

The total lateral load due to active earth pressure = 17385.55Kg 17.39t < 65.16t

Hence safe.

Centre to centre spacing between two rows of 500mm dia piles = 1.50m

Hence,the over all width of the base slab = 2.30m

Design of wall or stem:-

Factored bending moment Mu = 22960.26Kgm

Effective depth required d = M

u

/0.138f

ck

b = 257.98mm

Over all depth provided = 400.00mm

Effective depth provided(Assuming 40mm cover) d = 352.00mm

M

u

/bd

2

= 1.853

From table 2 of SP 16,percentage of steel required = 0.566

Area of steel required = 1992.32sqmm

Hence provide 16mm dia HYSD bars@ 100mm c/c spacing

Hence A

st

provided = 2009.60sqmm

Curtail 1/3rd of the reinforcement from half of the height

Check for shear:-

Percentage of tension steel = 0.57

Maximum shear force on the member = 86.93KN

Factored Design shear force = 130.39KN

Nominal shear stress t

v

=V

u

/bd = 0.37 N/sqmm <2.8 N/sqmm

(As per Table 20 of 1S 456)

Hence section is safe from shear strength point of view

The design shear strength of concrete for the above steel percentage from

Table 19 of IS 456 is

0.51 N/sqmm > 0.37

Hence,no shear reinforcement is required.

Provide temperature re inforcement @ 0.12%

Area required = 360.00sqmm

Provide 1/3rd of above reinforcement on earthen side = 120.00sqmm

Provide 8mm dia @ 300mm c/c on earthen side

Provide 2/3rd of above reinforcement on other side = 240.00sqmm

Provide 8mm dia @ 200mm c/c on other side

Provide 10mm bars at 300mm c/c vertically on the outer face to support horizontal rods

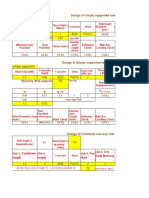

Design of base slab:-

Thickness of base slab assumed = 0.40m

The loading on the base slab can be approximated as shown below:-

Wt.of wall = 3375.00Kg/m 33.75

Earth pressure = 8692.77Kg/m

Self weight = 1000.00kg/m/m

Wt.of earth = 8856kg/m/m 1.76m

R

A

R

B

0.4 0.69 0.81 0.4

0.85

Analysis is carried out assuming fixed supports to arrive at max.hogging moment,further supports

are assumed to be hinged to arrive at max.sagging moments.

After analysis,

R

A

= 12.540kN

R

B

= 141.170kN

The bending moment diagram is as shown below:-

100.12Knm

100.12Knm

Moment at A = 8.64Knm

Moment at B = 36.24Knm

Factored bending moment Mu = 150.18Knm

Effective depth required d = M

u

/0.138f

ck

b = 208.64mm

Over all depth provided = 400.00mm

Effective depth provided(Assuming 40mm cover) d = 355.00mm

M

u

/bd

2

= 1.192

From table 2 of SP 16,percentage of steel required = 0.353

Area of steel required = 1253.15sqmm

Hence provide 16mm dia HYSD bars@ 150mm c/c spacing

Hence A

st

provided = 1339.73sqmm

Check for shear:-

Percentage of tension steel = 0.38

Maximum shear force on the member = 141.17KN

Factored Design shear force = 211.76KN

Nominal shear stress t

v

=V

u

/bd = 0.60 N/sqmm <2.8 N/sqmm

(As per Table 20 of 1S 456)

Hence section is safe from shear strength point of view

The design shear strength of concrete for the above steel percentage from

Table 19 of IS 456 is

0.43 N/sqmm > 0.17

Hence,no shear reinforcement is required.

Provide same reinforcement at bottom also.Provide 10mm dia bars @150mm c/c at top&bottom

as distribution reinforcement .

Design of beam:-

Breadth of the beam assumed = 0.45m

Depth of the beam assumed = 0.60m

UDL on beam :-

Due to self weight of slab = 1150.00Kg/m

Due to weight of retained earth = 8413.20Kg/m

9563Kg/m

Twisting moment on beam :-

Due to earth pressure(Distributed to both beams) = 7653.42Kgm

2.00m

After analysis,the bending moment diagram is

31.90Knm

15.90Knm

Factored bending moment Mu = 47.85Knm

Torsional Moment 'T' in KN-m 114.80Knm

Equivalent bending moment M

t

in KN-m 157.57Knm

Design Moment M

e1

in KN-m 205.42Knm

Effective depth required d = M

u

/0.138f

ck

b = 363.75mm

Over all depth provided = 600.00mm

Effective depth provided(Assuming 40mm cover) d = 552.00mm

M

u

/bd

2

= 1.498

From table 2 of SP 16,percentage of steel required = 0.449

Area of steel required = 1115.32sqmm

Hence provide 4 Nos of 20mm dia HYSD bars both at top&bottom

Provide 2-12mm dia on each face as side face reinforcement

Hence A

st

provided = 1256.00sqmm

Percentage of tension steel = 0.51

Maximum shear force on the member = 46.40KN

Factored shear force = 69.60KN

Design shear force including equivalent shear due to torsion = 477.78KN

Nominal shear stress t

v

=V

u

/bd = 1.92 N/sqmm <2.8 N/sqmm

(As per Table 20 of 1S 456)

Hence section is safe from shear strength point of view

The design shear strength of concrete for the above steel percentage from

Table 19 of IS 456 is

0.49 N/sqmm Hence V

uc

= 121.72KN

V

us

= V

u

-V

uc

= 356.06KN

V

us

/d = 6.45 KN/cm

Using 10mm dia two legged vertical stirrups,from table 62 of SP 16,the spacing required is 85mm

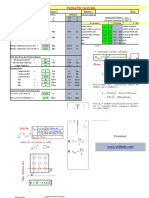

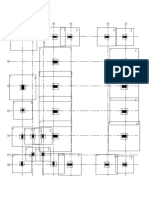

However,from safety point of view,provide 10mm dia 2 legged stirrups @ 80mm c/c

15306.84

0.00

8mm bars@300mm c/c

10mm bars@300mm c/c

12mm bars@175mm c/c

8mm bars@200mm c/c

0.00m

0.15 0.30 0.15

1.80m

Beam size 0.375x0.50m

At bottom 10mm mat

Main steel:- 150mm c/c

4-16mm both at top

and bottom

Shear steel:-

8mm stirrups@110mm At top 10mm mat

c/c 150mm c/c

375mm DUR piles

DETAILS OF REINFORCEMENT

5 Nos--12mm dia main

6mm dia stirrups

at 300mm c/c

10mm bars@300mm c/c

8mm bars@200mm c/c

0.30m

1.75m

1.15m

DETAILS OF REINFORCEMENT

0.85m

You might also like

- The Letter and The Cosmos How The Alphabet Has Shaped The Western View of The WorldDocument285 pagesThe Letter and The Cosmos How The Alphabet Has Shaped The Western View of The Worldmarnekib100% (3)

- Admin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Document3 pagesAdmin Block: Pile Cap (3pile Group) Design by Bending Theory To Bs 8110 Part 1Saifulazreen Mahyan100% (1)

- Design Report of Intz Type Water Tank-Bia-01.07.2015 PDFDocument56 pagesDesign Report of Intz Type Water Tank-Bia-01.07.2015 PDFGR Kanna100% (1)

- Retaining WallDocument25 pagesRetaining WalldhaifanNo ratings yet

- DESIGN OF GRAVITY RETAINING WALLDocument10 pagesDESIGN OF GRAVITY RETAINING WALLD.V.Srinivasa RaoNo ratings yet

- Design of Pier Footing for Canal Trough StructureDocument15 pagesDesign of Pier Footing for Canal Trough StructureSandip UpNo ratings yet

- Solid Slab - 10m.Document8 pagesSolid Slab - 10m.Aditya JoshiNo ratings yet

- Design Concrete Box CulvertsDocument9 pagesDesign Concrete Box CulvertsSUPERINTENDING ENGINEER100% (1)

- Impact of K-Pop Music On The Academic PDocument29 pagesImpact of K-Pop Music On The Academic Pdave tayron paggao100% (1)

- JCL RefresherDocument50 pagesJCL RefresherCosta48100% (1)

- Balive Bridge EstimateDocument77 pagesBalive Bridge EstimateD.V.Srinivasa Rao100% (1)

- Masonry Compound WallDocument4 pagesMasonry Compound Wallasingh4000% (1)

- RCC RETAINING WALL Cantilever R1Document2 pagesRCC RETAINING WALL Cantilever R1Usama ChauguleNo ratings yet

- Open Well Staircase Design 01Document7 pagesOpen Well Staircase Design 01Roshan KejariwalNo ratings yet

- ANSI B4.1-1967 Preferred Limits and Fits For Cylindrical PartsDocument25 pagesANSI B4.1-1967 Preferred Limits and Fits For Cylindrical Partsgiaphongn100% (5)

- PDF Wind Load Calculations As Per Is 875 Part 3xls CompressDocument85 pagesPDF Wind Load Calculations As Per Is 875 Part 3xls CompressNews Side Effects.No ratings yet

- Drain Cum Retaining WallDocument12 pagesDrain Cum Retaining WallvivekNo ratings yet

- Water TankDocument22 pagesWater TankSamik SenNo ratings yet

- L Shaped Reatining WAll With HORZONTAL Bach FillDocument29 pagesL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- Return Wall 10mDocument23 pagesReturn Wall 10mAkhil Singhal100% (2)

- Counter Fort Reatining WAll With HORZONTAL Bach FillDocument52 pagesCounter Fort Reatining WAll With HORZONTAL Bach FillRajib Chowdhury100% (1)

- Pier Cap DesignDocument2 pagesPier Cap DesignAnand SoniNo ratings yet

- Well Foundation DesignDocument4 pagesWell Foundation DesignArpan SahaNo ratings yet

- Section A: General Input: and Per Meter Strip LengthDocument10 pagesSection A: General Input: and Per Meter Strip LengthlaxNo ratings yet

- Design of Combined Footing (CFDocument12 pagesDesign of Combined Footing (CFp_ignatiusNo ratings yet

- Report and DesignDocument53 pagesReport and Designkiran raghukiranNo ratings yet

- Pipe CulvertDocument14 pagesPipe CulvertPraveen M balaramNo ratings yet

- RCC BOX BRIDGE DESIGNDocument53 pagesRCC BOX BRIDGE DESIGNSreeraja SreevilasanNo ratings yet

- Retaining Wall Design CalculationsDocument6 pagesRetaining Wall Design Calculationsdocument123456789100% (1)

- Pile Design Cal - Rev-1Document9 pagesPile Design Cal - Rev-1Nitin SakpalNo ratings yet

- Design of Simply Supported One Way SlabDocument15 pagesDesign of Simply Supported One Way SlabNikhil100% (2)

- Design of Retaining WallDocument5 pagesDesign of Retaining WallRektorUnitelNo ratings yet

- RCC Abutment - 67.738 MDocument11 pagesRCC Abutment - 67.738 MSn SatyanarayanaNo ratings yet

- ANALYSIS & DESIGNDocument7 pagesANALYSIS & DESIGND.V.Srinivasa RaoNo ratings yet

- VJA Meeting Hall Detailed EstimateDocument56 pagesVJA Meeting Hall Detailed EstimateD.V.Srinivasa Rao100% (1)

- Confinement DesignDocument405 pagesConfinement DesignJAcc COncepcionNo ratings yet

- Afm PPT 2.1Document33 pagesAfm PPT 2.1Avi malavNo ratings yet

- Design of Typical Community HallDocument52 pagesDesign of Typical Community HallD.V.Srinivasa Rao0% (1)

- Design of Typical Community HallDocument52 pagesDesign of Typical Community HallD.V.Srinivasa Rao0% (1)

- JSW Severfield Structure Ltd. composite column design EC4Document3 pagesJSW Severfield Structure Ltd. composite column design EC4RonakShahNo ratings yet

- Boundary Wall Design Calculations With PileDocument32 pagesBoundary Wall Design Calculations With PileWahid wrbel100% (1)

- Pier Cap Plan: Project:-Client: - ConsultantsDocument1 pagePier Cap Plan: Project:-Client: - ConsultantsShaileshRastogiNo ratings yet

- Manage Faisalabad WasteDocument2 pagesManage Faisalabad WasteUsama SanaullahNo ratings yet

- Box Culvert 20mDocument68 pagesBox Culvert 20mV P GUPTANo ratings yet

- Design of RCC Wing WallDocument6 pagesDesign of RCC Wing WallAnkit Singla100% (1)

- Design of RCC Retaining WallDocument9 pagesDesign of RCC Retaining Wallbhagvat daveNo ratings yet

- 1634858239Document360 pages1634858239iki292100% (1)

- Electric Submersible Pumps For The Petroleum IndustryDocument20 pagesElectric Submersible Pumps For The Petroleum Industrysouthli100% (1)

- 29+635 - (32 Deg Skew)Document27 pages29+635 - (32 Deg Skew)Praveen CyssanNo ratings yet

- Design of Pile Cap and Abutment WallDocument20 pagesDesign of Pile Cap and Abutment Wallshashibhushan singh100% (1)

- Retaining Wall DesignDocument126 pagesRetaining Wall DesignSeph RjyNo ratings yet

- Design of Pile CapDocument5 pagesDesign of Pile CapJohn STCNo ratings yet

- Cantilever Retaining WallDocument4 pagesCantilever Retaining Wallsharath mathewNo ratings yet

- Design of Bored Piles Is 2911-Part 1sec2Document5 pagesDesign of Bored Piles Is 2911-Part 1sec2Armaan GuptaNo ratings yet

- Retaining Wall Based On ACI 318-02Document6 pagesRetaining Wall Based On ACI 318-02ابو عمر الأسمريNo ratings yet

- Intze Tank-75kL Design 16M STAGING - SBC 8TON PER SMTDocument25 pagesIntze Tank-75kL Design 16M STAGING - SBC 8TON PER SMTMUKESH RAJENDRANo ratings yet

- Bucket DesignDocument6 pagesBucket Designוויסאם חטארNo ratings yet

- Water TankDocument32 pagesWater TankSujay Santra50% (2)

- Design of ReservoirDocument40 pagesDesign of ReservoirrajarshiboseNo ratings yet

- Cantilever Retaining WallDocument5 pagesCantilever Retaining WallAmit SinghNo ratings yet

- Design of Cantilever Retaining WallDocument23 pagesDesign of Cantilever Retaining WallD.V.Srinivasa RaoNo ratings yet

- 325KL ESR Tank Seismic AnalysisDocument14 pages325KL ESR Tank Seismic Analysissanju middya100% (1)

- Pile Cap Design Calculations With CSI SAFEDocument6 pagesPile Cap Design Calculations With CSI SAFEroshanNo ratings yet

- Compound Wall DesignDocument31 pagesCompound Wall Designnikki naidu50% (2)

- Design of Claritube SettlerDocument19 pagesDesign of Claritube SettlerGomatesh PatilNo ratings yet

- Analysis of Well FoundationDocument5 pagesAnalysis of Well FoundationSumit Jadhav0% (1)

- Rigid Pavement Design As Per IRC 58 2011 BUC and TDC AnalysisDocument3 pagesRigid Pavement Design As Per IRC 58 2011 BUC and TDC Analysisarvind sharmaNo ratings yet

- Summary of IS 3370 Detailing RequirementsDocument2 pagesSummary of IS 3370 Detailing RequirementsKanaiyalal N. ShethNo ratings yet

- Combined Footing For TwoDocument15 pagesCombined Footing For Twoer.praveenraj30No ratings yet

- Steel Transverse Seismic ArrestorDocument3 pagesSteel Transverse Seismic ArrestorNAUTILUS87100% (1)

- DESIGN OF SLAB-CantileverDocument10 pagesDESIGN OF SLAB-CantilevermeenuNo ratings yet

- Design of Isolated Footing (Rf1 - 14&20) : Input DataDocument1 pageDesign of Isolated Footing (Rf1 - 14&20) : Input DataD.V.Srinivasa RaoNo ratings yet

- Community K Parva-GF PlanDocument1 pageCommunity K Parva-GF PlanD.V.Srinivasa RaoNo ratings yet

- Community K Parva-FF PlanDocument1 pageCommunity K Parva-FF PlanD.V.Srinivasa RaoNo ratings yet

- Old Designs ApprovedDocument14 pagesOld Designs ApprovedD.V.Srinivasa RaoNo ratings yet

- Community Pathanaguluru PLANDocument1 pageCommunity Pathanaguluru PLAND.V.Srinivasa RaoNo ratings yet

- STP Gollapudi SectionsDocument1 pageSTP Gollapudi SectionsD.V.Srinivasa RaoNo ratings yet

- RCC Drain DesignDocument1 pageRCC Drain DesignD.V.Srinivasa RaoNo ratings yet

- Women's Hostel Building Grid Line PlanDocument1 pageWomen's Hostel Building Grid Line PlanD.V.Srinivasa Rao100% (1)

- Agriculture Building PlanDocument1 pageAgriculture Building PlanD.V.Srinivasa RaoNo ratings yet

- Working Women's HostelDocument21 pagesWorking Women's HostelD.V.Srinivasa RaoNo ratings yet

- You Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterDocument1 pageYou Created This PDF From An Application That Is Not Licensed To Print To Novapdf PrinterD.V.Srinivasa RaoNo ratings yet

- DPRC 1st Floor Plan RevisedDocument1 pageDPRC 1st Floor Plan RevisedD.V.Srinivasa RaoNo ratings yet

- DPRC Kanuru GF PDFDocument1 pageDPRC Kanuru GF PDFD.V.Srinivasa RaoNo ratings yet

- 21 Column ProformaDocument2 pages21 Column ProformaD.V.Srinivasa RaoNo ratings yet

- DPRC at Kanuru FF Plan - RevisedDocument1 pageDPRC at Kanuru FF Plan - RevisedD.V.Srinivasa RaoNo ratings yet

- Proposals For Improvements To Rubbish Roads: S.No Mandal Grampanchayat Name of The Road LengthDocument4 pagesProposals For Improvements To Rubbish Roads: S.No Mandal Grampanchayat Name of The Road LengthD.V.Srinivasa RaoNo ratings yet

- Design of Two Way and One Way Slabs for MMS BuildingDocument4 pagesDesign of Two Way and One Way Slabs for MMS BuildingD.V.Srinivasa RaoNo ratings yet

- Muslim's Shadikhana Community Hall Plan & Soil ReportDocument8 pagesMuslim's Shadikhana Community Hall Plan & Soil ReportD.V.Srinivasa RaoNo ratings yet

- Kankipadu Mandal AMC RecordingDocument23 pagesKankipadu Mandal AMC RecordingD.V.Srinivasa RaoNo ratings yet

- Government of Andhrapradesh Panchayat Raj Engineering DepartmentDocument2 pagesGovernment of Andhrapradesh Panchayat Raj Engineering DepartmentD.V.Srinivasa RaoNo ratings yet

- VRO Bldg. FinalDocument84 pagesVRO Bldg. FinalD.V.Srinivasa RaoNo ratings yet

- Footing Lay-Out 20tDocument1 pageFooting Lay-Out 20tD.V.Srinivasa RaoNo ratings yet

- D.V.Srinivasa Rao: Csi Bridge 2014, Bentley Leap Bridge Enterprise, Staad BeavaDocument5 pagesD.V.Srinivasa Rao: Csi Bridge 2014, Bentley Leap Bridge Enterprise, Staad BeavaD.V.Srinivasa RaoNo ratings yet

- Kavity StadiumDocument21 pagesKavity StadiumD.V.Srinivasa RaoNo ratings yet

- RCC Combined Footing DesignDocument21 pagesRCC Combined Footing DesignD.V.Srinivasa Rao67% (3)

- Textual Equivalence-CohesionDocument39 pagesTextual Equivalence-CohesionTaufikNo ratings yet

- ScifiDocument156 pagesScifiSynergymag0% (1)

- Synthesis and Characterization of Nanoparticles of Iron OxideDocument8 pagesSynthesis and Characterization of Nanoparticles of Iron OxideDipteemaya BiswalNo ratings yet

- HTTP API - SMS Help GuideDocument8 pagesHTTP API - SMS Help Guideaksh11inNo ratings yet

- Inami, Problem Other MindsDocument19 pagesInami, Problem Other MindsfortyrrNo ratings yet

- Journal of Statistical Planning and Inference: Akanksha S. KashikarDocument12 pagesJournal of Statistical Planning and Inference: Akanksha S. KashikarAkanksha KashikarNo ratings yet

- David Sosa - The Import of The Puzzle About BeliefDocument31 pagesDavid Sosa - The Import of The Puzzle About BeliefSr. DanieoNo ratings yet

- Variable frequency drives for electric submersible pumpsDocument34 pagesVariable frequency drives for electric submersible pumpshermit44535No ratings yet

- The Cultural Diversity Phenomenon in Organisations and Different Approaches For Effective Cultural Diversity Management - A Literary Review PDFDocument21 pagesThe Cultural Diversity Phenomenon in Organisations and Different Approaches For Effective Cultural Diversity Management - A Literary Review PDFeugene123No ratings yet

- U.S. Copyright Renewals, 1962 January - June by U.S. Copyright OfficeDocument471 pagesU.S. Copyright Renewals, 1962 January - June by U.S. Copyright OfficeGutenberg.orgNo ratings yet

- Lpi - 101-500Document6 pagesLpi - 101-500Jon0% (1)

- What Is "The Mean Relative To Us" in Aristotle's Ethics? - Lesley BrownDocument18 pagesWhat Is "The Mean Relative To Us" in Aristotle's Ethics? - Lesley Brownatonement19No ratings yet

- 7949 37085 3 PBDocument11 pages7949 37085 3 PBAman ChaudharyNo ratings yet

- Biologicalisation - Biological Transformation in ManufacturingDocument32 pagesBiologicalisation - Biological Transformation in ManufacturingGuillermo AvilesNo ratings yet

- Final Project SociologyDocument14 pagesFinal Project Sociologyvikas rajNo ratings yet

- DN 6720 PDFDocument12 pagesDN 6720 PDFChandan JhaNo ratings yet

- Propagating Trees and Fruit Trees: Sonny V. Matias TLE - EA - TeacherDocument20 pagesPropagating Trees and Fruit Trees: Sonny V. Matias TLE - EA - TeacherSonny MatiasNo ratings yet

- Lesson Exemplar On Contextualizing Science Lesson Across The Curriculum in Culture-Based Teaching Lubang Elementary School Science 6Document3 pagesLesson Exemplar On Contextualizing Science Lesson Across The Curriculum in Culture-Based Teaching Lubang Elementary School Science 6Leslie SolayaoNo ratings yet

- AgendaDocument72 pagesAgendaThusitha WickramasingheNo ratings yet

- Impact of Social Media in Tourism MarketingDocument16 pagesImpact of Social Media in Tourism MarketingvidhyabalajiNo ratings yet

- AufEx4 02 02Document28 pagesAufEx4 02 02BSED SCIENCE 1ANo ratings yet