Professional Documents

Culture Documents

Radio Controlled Aircraft

Uploaded by

C.E. Ishmeet SinghOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Radio Controlled Aircraft

Uploaded by

C.E. Ishmeet SinghCopyright:

Available Formats

[2009]

SupervisedBy:

MSSehrishMehmood

DepartofElectricalEngineering,

HITECUniversityTaxilaCantt.

[Feb25,2009]

ThunderBolt

HITECUniversityTaxilaCantt.

TeamMembers

NisarAhmed

HarisJadoon

JabranGhani

SheikhM.Arshad

GhazalArshad

SaniaAli

DesignBuildandFly

Competition2009

FinalDesignReport

DEDICATION

Dedicated to our beloved parents and respectful

Madam Samina.

2

TableofContents

1 Executive Summary 5

1.1 Design Variables 6

2 Management Summary 7

2.1 Architecture of the Design Team 7

2.2 Technical Groups 7

2.3 Scheduling, Configuration and Document Control 9

3 Conceptual Design 10

3.1 Mission Requirements 10

3.2 Alternative Configurations 12

3.2.1 Aircraft Type 12

3.2.2 Final Configuration Selection 13

3.2.3 Geometry and Performance Charts 14

4 Preliminary Design 17

4.1 Design Parameters 17

4.2 Mission Profile Optimization Analysis 18

4.3 Performance Parameters 19

4.4 Performance Code 19

4.5 Aerodynamic Model 19

4.6 Aerofoil Selection 19

4.7 Preliminary Design Result Table 21

4.8 Performance 22

4.9 Conclusion 22

5 Detailed Design 23

5.1 Structural Stability 23

5.2 Wheels 23

5.3 External Payload Release System 23

5.4 Avionics System 24

5.4.1 Servo Selection and Placement 24

5.4.2 Electronic Speed Control and Radios 24

5.4.3 Landing Gear Systems 24

5.5 Disassembly Method 25

5.6 Drawing Package 25

5.6.1 Three Views Drawing with Dimensions 26

5.6.2 System Layout and Payload Accommodation 28

5.6.3 Structural Arrangement 28

3

6 Manufacturing Plan and Processes 29

6.1 Fuselage 29

6.2 Wings 29

6.3 Wheels 29

6.4 Rated Aircraft Cost 29

7 Testing Plan 30

8 References 31

4

1 Executive Summary

This report describes the process used to

design Thunder Bolt, HITEC University entry

2008-2009 DBFC (Design Build and Fly

Competition). The goal of the design was to

maximize the competition score, which is a

combination of the report score, the total

flight score and the rated aircraft cost (RAC).

The process of designing our aircraft and

taking it to the point of flight test consists of

the sequence of steps, as illustrated in

Figure 1.1.

The conceptual design analysis focused on

selecting the configuration that would

maximize the competition score. The

competition rules were analyzed to

determine design requirements, and to

identify the most important elements of the

RAC. It was found that for all designs, there

are three major missions. Therefore, the

airplane was optimized to perform these

three missions.

Figure 1.1

The empty weight of the airplane was seen to be the most significant contributor to the RAC; so

minimizing the empty weight was a major objective throughout the design process. The ability to

disassemble the airplane was also a factor since the airplane needed to be place in a 4 ft x 2 ft x

1 ft box at the end of each mission. A chart was used to investigate some of the possible airplane

configurations. These were narrowed down through qualitative arguments to some configurations

that were analyzed using a figure of merit (FOM) analysis. The analysis included the RAC,

predicted mission performance, qualitative scores for ground handling, internal payload storage,

external payload storage, stability and control, and manufacturability for each configuration.

Based on the FOM analysis, a flying wing configuration with vertical stabilizers was determined to

provide the highest competition score. We were faced with the following complications in the

other design configurations:

5

1). Complications are to be faced with respect to the available manufacturing processes.

2). In case of flying wing models, handling of center of gravity is very difficult.

3). In case of Pusher vs. tractor aircraft, more power is required to accomplish the mission.

Also tedious calculations are involved in this

design.

During the preliminary design analyses, the

critical design variables were determined, an

optimum design was developed, and the

design was refined with known

aerodynamic, stability and control analyses.

We decided to achieve our goal by the

following sequence.

1.1 Design variables:

The considered design parameters, which

affect the aircraft performance the most are

listed below. A baseline model was

developed using these variables.

Figure 1.2

We have got the standard values, based on the experiments and analysis, and use these values

to get the optimum design to accomplish the mission.

1). Required Geometry of the plane

2). Aspect Ratio

3). Wing Loading

4). Cubic Loading

5). Stall Speed

6). Engine Performance

7). Desired Lift

8). Drag

9). The Take off speed

10). Horizontal tail location on vertical tail

11). Wing root thickness to cord ratio

12). Wing tip thickness to chord ration

13). Type of landing gear

14). Horizontal tail root thickness to Chord

ratio

15). Number of blades

The results of the optimization led to an airplane with a wing area of 700 in, an aspect ratio of

5.5, a fuselage length of 46in and a 13x8 propeller. The detailed aerodynamic analysis led to the

selection of the NACA-6412 airfoil for the wing and the conventional tail surfaces.

In the detailed design analyses the payload system design was finalized, the final components for

the airplane were selected, and the manufacturing drawings of the airplane were generated.

6

2 Management Summary

2.1 Architecture of the Design Team

The Design Build and Fly team at HITEC University consisted of undergraduate students from

Electrical Engineering Department. There were 6 members. The team was split into a number of

technical groups with a designated leader for each. At a higher level the team was under the

supervision of four experienced members; the team leader (TL), chief design engineer (CDE),

assistant chief manufacturing engineer (ACME) and chief manufacturing engineer (CME). The

team leader was responsible for running meetings, fund-raising, procurement and other

administrative tasks. The chief design engineer kept the airplane design progressing and

delegated tasks to the other technical groups. The assistant and chief manufacturing engineers

were responsible for construction and flight-testing of the airplane. Each member of the design

team belonged to at least one technical group.

Table 2.1 shows personnel assignments and each individuals level of participation.

2.2 Technical Groups

Each technical group was assigned a leader who was responsible for getting the group to meet

the deadlines set forth by the CDE and the rest of the team. The aerodynamic group was

responsible for evaluating the lift and drag and other important characteristics for flight of the

airplane. They were also tasked with selecting the airfoils for the wing and conventional tail and

setting the wing twist. The CAD Modeling group modeled the external shape, structure and

systems of the airplane using a CAD tool AutoCAD. The configuration selection group consisted

of all the team members who were present at the first few meetings. The goal of this group was to

select the best airplane configuration to complete the specified missions.

7

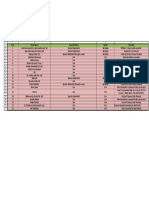

Table 2.1 Personal assignment and level of contribution.

Member Name

T

e

c

h

n

i

c

a

l

G

r

o

u

p

A

e

r

o

d

y

n

a

m

i

c

s

C

A

D

M

o

d

e

l

i

n

g

C

o

n

f

i

g

u

r

a

t

i

o

n

S

e

l

e

c

t

i

o

n

F

l

i

g

h

t

T

e

s

t

i

n

g

F

u

n

d

R

i

s

i

n

g

M

a

n

u

f

a

c

t

u

r

i

n

g

P

r

o

p

u

l

s

i

o

n

S

e

l

e

c

t

i

o

n

R

e

p

o

r

t

W

r

i

t

i

n

g

S

t

a

b

i

l

i

t

y

a

n

d

C

o

n

t

r

o

l

P

a

y

l

o

a

d

D

e

s

i

g

n

S

t

r

u

c

t

u

r

a

l

A

n

a

l

y

s

i

s

&

T

e

s

t

i

n

g

S

y

s

t

e

m

S

e

l

e

c

t

i

o

n

a

n

d

T

e

s

t

i

n

g

T

e

l

e

m

e

t

r

y

S

y

s

t

e

m

Ghazal Arshad 2 3 2 3 3 3 3 2 3 1 3 3 1

Jibran Ghani 2 1 3 3 3 2 2 3 1 3 3 2 3

Nisar Ahmed 2 2 1 1 2 2 2 1 2 2 2 2 2

Sheikh M. Arshad 3 3 2 2 2 1 2 2 3 3 1 2 3

Haris Jadoon 2 3 3 2 1 2 1 3 2 3 2 1 3

S a n i a A l i 1 3 3 3 3 3 3 3 3 2 3 3 2

The flight-testing group was in charge of all testing of the system test bed airplane and the

competition airplane. A very successful fund-raising drive was run by the fundraising group,

securing approximately 40,000 Rupees for use on the project from various sources, within the

university and outside. The manufacturing group was given the task for construction of the

airplane and other test articles. The payload design group worked to optimize the payload fairing

design and performed a CFD analysis. The performance and optimization group analyzed the

performance of the airplane and optimized the design to obtain the highest contest score. The

propulsion selection group was responsible for identifying and modeling candidate propulsion

systems to be applied to the airplane and analyzed by the performance and optimization group.

The report-writing group was responsible for documenting the design and writing the report. The

stability and control group was in charge of analyzing the static and dynamic stability

characteristics of the airplane and sizing the control surfaces. Structural design, analysis, and

testing of the airplane were carried out by the structural analysis and testing group. The systems

selection and testing group selected all of the sub-systems included on the airplane, including the

servos, radio, landing gear and brakes. The telemetry group was in charge of developing a real-

time telemetry and inertial navigation system to aid in flight-testing of the airplane.

8

2.3 Scheduling, Configuration and Document Control

The first task for the team was to set an aggressive, yet achievable schedule. In order to meet the

aggressive schedule, two team meetings were held each week from December through April. In

addition, each technical group met at least once a week when it had an approaching deadline.

Figure 2.1 shows the milestone chart for the design, construction and testing of Thunder Bolt.

Figure 2.1 Milestone Chart

To facilitate easy communication and document control, an email newsgroup was set up for the

design team members. In addition, the minutes of each meeting were typed up and sent to

members of the team for a record of what was discussed. Storage space was also set-aside on

the Yahoo Groups for storing team computer programs, documents, and drawings.

9

3 Conceptual Design

Due to the knowledge, gained till now, it has decided by our team that the design should be as

simple and basic as possible due to our limited experience in the field of aerodynamics and

aircraft modeling. Other factors for this consideration are cost effect, complexity of the design,

resources available and the described constraints including the climatic factor.

During the conceptual design phase, the team aimed at choosing an aircraft configuration to

optimize for performing each mission through an explicit Figure of Merit (FOM) screening

process. Multiple tail, gear, and payload configurations were narrowed using the same process.

3.1 Mission Requirements

The purpose of this contest was to design and construct an aircraft that would complete all

missions in an efficient manner. The External Payload Mission (EPL) requires an aircraft capable

of containing and dropping a payload of up to 3lb of air tube, while the Internal Payload Mission

(IPL) requires the same aircraft to fly the same mission profile with the same tube in its fuselage.

The final aircraft design will complete each mission efficiently while having an optimal rated

aircraft cost.

Mission and Design Requirements

Teams must complete the flight missions as outlined in the rules and regulations. Teams will have

a maximum of three flight attempts. A flight attempt is defined as advancing the throttle stick for

take-off or going past the two min preparation time. The best single flight score from each of two

different mission types will be summed for the team total flight score.

Payload Requirement

The aircraft must be configured to support both wing tip external payload carriage and fuselage

internal payload carriage. Each payload is a 12-inch long 3-inch PVC tube. The total payload will

be of 3 lbs weight. External payload must be carried on a point located within 3 inches of the wing

tip of the largest span wing. One payload point will be located at each wing tip.

External Payload Mission

Aircraft will begin the mission with external sensor payload packages. Aircraft will take-off and fly

one lap. Aircraft will take-off and fly one lap. After landing the aircraft will taxi to a specified

location and remotely deploy the PVC tube. After the ground crew would have done his job

aircraft will take off again and fly one lap. On landing, the aircraft must cross the take off start line

and come to a complete stop.

10

Re-Supply during Mission

Aircraft will begin the mission with two internal sensor payload packages. In this mission aircraft

has to fly. On landing the aircraft must cross the take off start line and come to a complete stop

and the grounds crew will have to reinstall the payload.

Structural Requirement

The airplane maximum weight may not exceed 55lb. During technical inspection, the airplane

must undergo upright and inverted wing tip tests at the maximum payload capacity without failure.

Airplane Dimensional Requirements

At the end of each mission the airplane must be disassembled and placed within a 1ft x 2ft x 4ft

box. The disassembly time is counted in the mission times, which dont end until the box is closed

and latched.

Take off Requirement

The maximum takeoff distance for each mission is 150 feet. The wheels must be off the runway

within this distance.

Flight Course

The orientation (direction) of the flight course will be adjusted based on the prevailing winds as

determined by the Flight Line J udge. The flight course will be positioned to maintain the greatest

possible safety to personnel and facilities. The nominal flight course is shown in the Figure below.

11

3.2 Alternative Configuration

Alternative configurations were formulated for the aircraft type, empennage, payload systems,

landing gear, and propulsion system. Configuration possibilities and FOMs were analyzed for

each section.

3.2.1 Aircraft Type

When comparing multiple alternatives several assumptions were made: the aircraft could operate

with one motor, each alternative would have similar wing lifting efficiency and fuselage length, the

maximum allowable payload could be carried, and each alternative would perform at the same

design wind speed. More detailed analysis would be necessary if one configuration would not

have appeared superior based on the FOMs.

Conventional Monoplane

A conventional configuration was used as a baseline for comparing the configurations. The

performance characteristics would be easily predicted with ample historical data available. The

design was adopted due to the simplicity and the handling of the aircraft to accomplish the

mission.

Flying Wing

A pure tailless flying wing offered lower cost due to its lack of a tail and a small fuselage. In

addition, a flying wing would offer limited structural weight and drag. However, it had poor

handling qualities and would require sophisticated augmentation to perform the optimum mission

profile.

Blended-Wing-Body

The blended-wing-body would have the same handling qualities as a conventional configuration,

but less drag due to blended intersections and a more streamlined shape. It could also have a

higher RAC due to more fuselage volume.

Canard

A canard design would allow for the horizontal control surface to not detract from the overall lift of

the aircraft. This configuration would have good stall characteristics, but be limited during takeoff.

Flexible motor setups would easily be implemented.

Bi-plane

A bi-plane configuration would be able to produce a large amount of lift with smaller wings;

however, cost is very high for multiple wings. A bi-plane would be very similar to a conventional

design with respect to flight characteristics.

The FOMs used to screen the different configurations are listed below and then used in Table 3.1

to rank each configuration.

12

Figure of

Merit

Weighting

Factor

Conventional Flying

Wing

Blended

Wing

Canard Bi-Plane

RAC

0.33 2 3 1 2 1

Takeoff

Distance

0.27 2 2 2 1 3

Handling

Qualities

0.25 3 1 3 2 2

Drag

Efficiencies

0.15 2 3 3 2 1

Total

1 2.25 2.23 2.07 1.73 1.79

Table 3.1: Overall Configuration Weighted Decision Matrix

3.2.2 Final Configuration Selection

We have the following weather/field considerations while designing different parts of the aircraft.

Factor Assumed Value

Altitude 0 ft

Pressure 14.7 psi

Temperature 15C

Air Speed 3.5 m/s

Mach Number. 1.672*(10

-2

)

Air Density 1.225 kg/m

Air Viscosity 1.785*(10

-3

) kg/m.sec

13

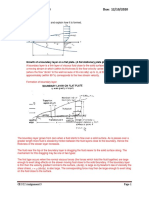

3.2.3 Geometry and Performance Charts

Fuselage:

Length 45.9 in

Width 6 in

Height 5 in

Cockpit Shape Rounded

Re Number 2.857*(10

5

)

Drag 2.42*(10

2

) N

C

D

6.218*(10

3

)

Wings:

Wing area is crucial for take-off with a short runway. Data found during conceptual design

showed the conceptual configuration lifting off at 150 feet with the smallest possible wing area.

This trend increases the scoring potential but causes major concerns during take-off. High wing

loading allows for faster cruise velocities but longer take-off distances. Wingspan also has a

major effect on wing efficiency.

Span 62 in

Root Chord 12 in

Tip Chord 10.5 in

CL 1.236

Re Number 71685.5

Profile Wing drag 5.712*(10^-2) N

CD 7.799*(10^-3)

Wing Induced Drag 0.1268 N

CD 9.619*(10^-3)

14

Horizontal Tail:

Tail Span 10 in

Tail Root chord 6 in

Tail tip chord 4 in

Re Number 32237.3

Tail Profile drag 1.793*(10^-2)N

Tail Profile Cd 9.489*(10

-3

)

Vertical Tail:

Height 8 inch

Bottom Chord 7 Inch

Top chord 5 inch

Vertical tail Re Number 38529.2

Vertical Tail drag 1.65*(10

-2

)N

Cd 9.081*(10

-3

)

Wheels:

Wheel diameter 3 inch

Wheel thickness 0.75 inch

Number. of wheel 3

Wheel Re Number 10769.2

Total wheel drag 1.433*(10^-2)

Wheel Cd 0.4040

From the above calculation we got the following set of results,

Required Thrust 0.1405N

Required Power 0.5122 Watt

Total drag 0.1301N

Cd total 0.4462

15

Fig. 3.1 Relative Importance of Various Factors in the RAC

Fig. 3.2 Final Concept Design

16

4 Preliminary Design

The chosen configuration from the conceptual design phase was separated into three groups:

aerodynamic, structural, and propulsion groups. Critical design parameters were selected and

studied within each group. FOMs were used to find appropriate sizes for many of the design

parameters. The mission model program from the conceptual design phase was modeled more

accurately and a propulsion performance program was created. These programs optimized the

most important design parameters, while the remainder of the design parameters where

subsequently analyzed and sized.

4.1 Design Parameters

Critical design parameters were selected within each design group. The aerodynamic group

investigated wing area, airfoil, wingspan, and fuselage and empennage size, while the structures

group investigated payload amount and boom length. The propulsion group investigated motor

selection, battery selection and number of cells, propeller pitch and size, and takeoff and cruise

power.

Wing Area: Wing area is crucial for take-off with a short runway. High wing loading

allows for faster cruise velocities but longer take-off distances.

Wingspan: Wingspan has a major effect on wing efficiency and RAC. RAC is minimized

for given wing areas as the aspect ratio is lowered, but high aspect ratio wings become

more efficient. Also, RAC is minimized with a rectangular wing making elliptical and

tapered wings highly penalized. Therefore a RAC/efficiency tradeoff must be made.

Construction, fit-in-box, and the ability to pass the wing tip loading test were other

considerations.

Airfoil: Airfoil selection is important because of its direct affect on take-off and cruise.

Three low speed airfoils were chosen based on historical data for further analysis: a high

lift airfoil, a low drag airfoil, and a more balanced airfoil. The high lift airfoil will be best

during takeoff due to its high lift coefficient, but its drag possibilities during cruise will be a

great concern. While the low drag airfoil will perform well during cruise due to its low drag

coefficients, but its low lift coefficients will be a concern during takeoff. The balanced

airfoil performed well in both cruise and takeoff situations.

Fuselage length & Empennage Size: It was desired for the entire plane length to be

less than 4 feet long so that it could fit in the box. A one-piece fuselage and empennage

would benefit the structural integrity and weight of the plane. The empennage size must

be sufficient to stabilize the aircraft. As overall aircraft length increases the RAC

17

increases. Drag decreases as the fuselage length increases and empennage size

decreases. A compromise must be made to minimize both RAC and drag.

Battery Selection and Number of Cells: Battery weight has the most effect on RAC.

The capacity of the batteries had to be sufficient to perform the mission profile while

minimizing the amount of unspent energy. A lower capacity battery would require more

cells, thus increasing voltage and RPM. A high capacity battery would complete the

mission using fewer cells, thus decreasing voltage and RPM. Minimizing the number of

batteries would lower the weight of the system, thus decreasing the RAC.

Propeller Pitch and Size: Propeller pitch and size impacts the amount of thrust

produced. A propeller with a high pitch to diameter ratio would be more efficient at higher

airspeeds than a low pitch to diameter ratio propeller. The propeller selection had to be

based on a trade-off between takeoff and flight performance.

Takeoff & Cruise Power: Takeoff and cruise power must be optimized to increase the

scoring potential of the aircraft. The power generated at takeoff would account for the

majority of the available energy from the propulsion system. The remaining amount of

energy would be consumed during cruise. The thrust at take-off must not create a current

over 40 amps or use too much energy from the batteries causing an insufficient amount

of power for cruise. Gear ratios and propeller sizes may be changes to better suit take-off

situations or cruise situations.

4.2 Mission Profile Optimization Analysis

To optimize the airplane, the first step was to select the variables that would be used to describe

a given design. The goal was to minimize the number of design variables necessary to describe

the airplane and to determine its propulsion, aerodynamic, weight, performance and cost

characteristics. The selected configuration, contest rules and intuition guided the selection of the

design variables.

Aspect Ratio 5.5

Wing span 62 inch

Wing area 700 in2

Wing tip chord 10.5 inch

Wing root chord 12 inch

Motor +Battery Weight 15 N

Propeller 13 x 8

Fuselage length 45.9 inch

Width 6 inch

Height 5 inch

Cockpit shape Rounded

Horizontal tail span 10 inch

Horizontal tail root chord 6 inch

Horizontal tail tip chord 4 inch

18

Vertical tail height 8 inch

Vertical tail bottom chord 7 inch

Vertical tail top chord 5 inch

Wheel diameter 3 inch

Wheel thickness 0.75 inch

No. of wheels 3

4.3 Performance Parameters

Lift 25 N

CL 1.23

CL max 2.24

CD 0.4462

Maximum L/D 8.2

4.4 Performance Code

The performance of the aircraft is judged by different software named; Design Foil II, Drag

Estimator version 1.5.

4.5 Aerodynamic Model

The role of the aerodynamic model was to generate a drag polar to be used in the performance

code. The drag coefficient for the airplane was calculated as a function of Reynolds number and

lift coefficient by using a method that included a build up of wing profile drag, wing induced drag,

fuselage drag and wheels drag etc. The total drag was calculated using the software, named as

Drag Estimator version 1.5.

The performance parameters along with their values are given in the above table.

4.6 Aerofoil Selection

Aerofoil plays an important role in the functioning of the aircraft. Several different airfoils types

where considered: high lift airfoil, low drag airfoil and a balanced airfoil. High lift airfoils where

eliminated due to high drag possibilities, while low drag airfoils where eliminated due to takeoff

concerns. An airfoil that was a compromise between low drag and high lift was chosen. So

NACA-6412 aerofoil was chosen. This aerofoil has the following configuration along with the data

points, generated by the FoilSim II.

19

Upper Surface

X Y P V

-0.508 0.055 101.264 39

-0.495 0.074 101.233 47

-0.469 0.092 101.226 48

-0.432 0.109 101.226 48

0.385 - 0.122 101.228 48

-0.329 0.132 101.232 47

-0.265 0.136 101.236 46

-0.194 0.136 101.241 45

-0.119 0.131 101.247 44

-0.041 0.12 101.254 42

0.037 0.104 101.261 40

0.117 0.085 101.268 38

0.194 0.063 101.275 36

0.266 0.039 101.282 34

0.333 0.016 101.288 32

0.392 -0.0050 101.294 30

0.44 -0.023 101.299 28

0.475 -0.035 101.304 27

0.494 -0.042 101.308 25

Lower Surface

X Y P V

-0.508 0.055 101.264 39

-0.509 0.037 101.326 16

-0.497 0.021 101.336 7

-0.472 0.0070 101.322 19

-0.433 -0.0020 101.313 23

-0.381 -0.0090 101.309 25

-0.317 -0.012 101.308 25

-0.242 -0.011 101.309 25

-0.156 -0.0080 101.31 24

-0.063 -0.0050 101.312 23

0.034 -0.0020 101.313 23

0.132 -0.0020 101.315 22

0.227 -0.0050 101.315 22

0.313 -0.011 101.316 22

0.386 -0.02 101.315 22

0.442 -0.03 101.314 22

0.479 -0.038 101.313 23

0.496 -0.043 101.311 24

0.494 -0.042 101.308 25

20

4.7 Preliminary Design Results Tables

Aspect ratio 5.5

Wing span 62 inch

Wing area 700 in2

Wing tip chord 10.5 inch

Wing root chord 12 inch

Motor +Battery Weight 15 N

Propeller 13 x 8

Fuselage length 45.9 inch

Width 6 inch

Height 5 inch

Cockpit shape Rounded

Horizontal Tail Span 10 inch

Horizontal tail root chord 6 inch

Horizontal tail tip chord 4 inch

Vertical tail height 8 inch

Vertical tail bottom chord 7 inch

Vertical tail top chord 5 inch

Wheel diameter 3 inch

Wheel thickness 0.75 inch

No. of wheels 3

21

4.8 Performance

Lift 25 N

CL 1.63

CL max 2.24

Cd 0.4462

Maximum L/D 8.15

4.9 Conclusions

The results predicted from the preliminary design program showed some differences from optimal

velocities and aircraft sizes predicted during the conceptual design phase. This was due to the

introduction of improved estimates for power plant efficiencies, current limits, and more accurate

algorithms for predicting drag and thrust. Some trends found in conceptual design were verified,

such as the increase in score with aspect ratio and load factor. Unlike results predicted during

conceptual design, the preliminary design program predicted that adding cells to the battery pack

would increase the total score, up to battery weights beyond the 5-lb limit.

22

5 Detailed Design

The goals of the detail design process were to select and size all of the internal components and

to integrate all aspects of the design. This included selection of all the avionics equipment, a

detailed weight breakdown, design of the payload system, structural sizing, and 3D solid

modeling of the airplane.

5.1 Structural Stability

The fuselage of the aircraft was decided to be build of BALSA wood. The reason for this is its

high strength to weight ratio. Along with this, we have our wings; made of Thermo pole material

and they are strengthened by the coating of Fiber Glass on them. Also, the spars present in the

wings to control the ailerons may provide strength to the wings.

5.2 Wheels

The wheels are to be placed under the fuselage, near to the propeller end to support the load of

the body and to reduce the frictional effect of the ground during the take-off and landing

phenomenon.

5.3 External payload Release System

Since the loading of the payloads onto the wing hard-points is timed during the Senor Reposition

Mission, the payload reloading mechanism had to be quick. Mounting the payloads on the bottom

of the wings made the most sense since the payloads would need to be dropped at specific

locations on the runway. The part of the payload mount attachment housed in the wing needed to

be light to keep the airplane weight down. The part of the payload mount attachment fixed on the

payload could be as heavy as need be as long as the total payload weight did not exceed three

pounds. The entire mechanism needed to be reliable enough to be used many times without

failing, and strong enough that the payloads would not break off the airplane or drop during flight

or ground handling. The clamps for the payloads are located within 4 inches distance from the

wings root chord. These are basically designed, following the concept of gates. A separate

channel is dedicated for the operation of releasing the payloads.

23

5.4 Avionics System

The avionics system for the aircraft needed to be as reliable as possible while having little

negative effect on the performance of the aircraft. This meant that the components needed to be

light and be small so that they could fit inside aircraft and not produce any unnecessary drag.

5.4.1 Servo Selection and Placement

The lightest servos that provided the required torque were chosen for each respective

component. Futaba 3015 motor was selected for the propulsion system. This motor has light

weight and can produce required thrust. It has 1000 revolution per minute per volt. CS-12 MG

servo were selected for ailerons, rudder, and nose wheel steering mechanism, a Futaba S3102

servo for the brake actuator, and Futaba S3102 servos for the payload release mechanisms. The

servos for the ailerons and rudder were placed with the wings and tails respectively, and used a

Rotary Drive System (RDS) to actuate the control surface. Since the RDS is built into the wing or

tail during the construction process, the entire structure is stronger and provides for more reliable

control surface actuation. The servos to actuate the ailerons and rudder were placed at the span-

wise center of the control surfaces directly behind the spar.

5.4.2 Electronic Speed Control and Radios

The electronic speed control (ESC) and radio receiver needed to be as light as possible while

providing the required performance. Since the aircraft is powered by a brushless motor that draws

approximately 40 amps out of 4 cells, the ESC needed to handle a steady 40 amp draw and

bursts of up to 50 amps at the supplied voltage. The lightest ESC that fit these requirements was

the Tower Pro 40.

The receiver radio chosen was made by Futaba with a 7-inch long micro receiver antenna. It is a

4-channel FM receiver that has a programmable failsafe mode, as required by the contest. During

testing it showed no loss of range till 2km. It was chosen because one made by W-Fly show

noticeable loss of range over 500m. In addition, the 7-inch long antenna fits completely inside the

fuselage and does not produce drag like a traditional receiver antenna by trailing behind aircraft.

5.4.3 Landing Gear Systems

As mentioned in the conceptual design section of the report, a tricycle landing gear configuration

with brakes was selected for its good ground handling characteristics. Most of the available

commercial brake systems would have been able to provide enough performance, but were too

heavy since they were made for scale jets. The three lightest systems were a magnetic system

made by Kavan, a pneumatic system made by BVM, and a hydraulic system made by Bob

Fiorenze. A differential braking system would have required two master cylinders, two high torque

24

servos, and extremely precise calibration in order for the airplane to be able to track straight while

braking. In addition, the high torque servos would weigh considerably more than the standard

servos used throughout the rest of the aircraft. The nose wheel gear selected was a dual strut

system made by Fults out of 5/32 music wire that weighed 2.3oz. Adding a wheel and a standard

servo for steering brought the total nose wheel steering system weight to 4.0 oz.

5.5 Disassembly Method

It is quite clear from the rules that the airplanes are not to fit in the box in the assembled form. So

for this, an appropriate mechanism was to be designed for the assembly of the entire system. We

have two separate wings for the aircraft, which are to be assembled with the fuselage. To handle

this situation, we have the screws system attached with the wings and the body of the airplane.

5.6 Drawing Package

Drawings of the airplane were made in the AutoCAD 2006 modeling program. The following

assembly drawing package does not include the full set of manufacturing prints that was used to

build the aircraft. The assembly drawings include:

Thunder Bolt Top View page 27

Thunder Bolt Side View page 28

Thunder Bolt Front View page 28

Structural Layout and Payload Accommodation Drawing page 29

Final Structural Arrangement Drawing page 29

25

5.6.1 Three View Drawing with Dimensions

Here is the top View of Aircraft with necessary Dimensions.

26

Side View of Thunder Bolt with dimension looks like:-

Thunder Bolt from front Side:-

27

5.6.2 System Layout and Payload Accommodation

Picture of system layout and payload accommodation of Thunder Bolt with its parts name is

given there.

5.6.3 Structural Arrangement

Final 3D structural arrangement drawing of the aircraft is:-

28

6 Manufacturing Plan and Processes

The selection of the materials and processes for the manufacturing of the airplane were important

throughout the design process. It was important that the airplane be built in a reasonable time

with materials and methods that the team could afford and were familiar with. It was also

important that the airplane be kept light and strong to increase its performance. A scheduling

approach was used to develop the manufacturing plan to accomplish these goals. With all these

considerations in the mind, we decided to use the Balsa wood, Thermo pole material and

fiberglass to build the aircraft. The details of the whole idea are described below for different

components of the aircraft.

6.1 Fuselage

Fuselage has been built of Balsa wood using the truss design considerations to support the whole

structure of the body and the load of the wings on the fuselage. This involves the coating of the

Monokote on the body. The conventional process of the woodcutting was used to develop the

truss structure.

6.2 Wings

Wings are decided to be made of the thermo pole material; which will be further strengthened by

the covering of fiberglass and the support of the Balsa wood strips at the lower ends of the wings.

The strength of the wings can also be increased by the insertion of aluminum spar/rod.

6.3 Wheels

Wheels were selected to be made of carbon fibers, as these are considered excellent to decrease

the friction and to carry the load of the whole body.

6.4 Rated Aircraft Cost

The cost of the rated Aircraft is shown below.

Radio Control (4-Channel) with Servos Rs. 13500/-

Motor Rs. 5000/-

Battery Pack Rs. 4500/-

Electronic Speed Control Rs. 6800/-

Balsa Wood Rs. 3000/-

Monokoat Rs. 2500/-

Propeller +Spinner Rs. 1000/-

Aluminum Rods Rs. 500/-

29

7 Testing Plan

To validate analytical data and calculations; testing becomes the most important aspect of

developing the aircrafts design. New designs can be instantaneously confirmed or invalidated.

Due to the importance of testing, we have used different software to test the aircraft.

30

References

Aerodynamics by Leslie R. Parkinson

(The Macmillan Company. New york)

Home-Built Aircraft by David B.Thurston

(The Macgraw Hill Book Company, Inc)

Aircraft layout and Detail design by Newton H.Anderson

(The Macgraw Hill Book Company, Inc)

Aerodynamics for Engineers (3rd Addition) by J ohn J .Bertin & Micahel L.Smith

(The Prentice Hall international, Inc)

Flight Dynamics Principles by M V Cook

(J ohn Wiley & Sons Inc., New York)

Airplane Performance, Stability and Control by Courtland D.Perkins & Robert E.Hage

(J ohn Wiley & Sons Inc., New York)

Airplane Flight Dynamics And Automatic Flight Controls by J an Roskam

(Design, Analysis and Research Corporation, USA)

Design of Aircraft (2

nd

Indian Reprint) by Thomas C. Corke

(Pearson Education, Inc. Singapore)

31

You might also like

- General Aviation Aircraft Design: Applied Methods and ProceduresFrom EverandGeneral Aviation Aircraft Design: Applied Methods and ProceduresRating: 4.5 out of 5 stars4.5/5 (29)

- (Lectures 1,2 and 3) : TopicsDocument11 pages(Lectures 1,2 and 3) : TopicsSanthosh SabapathyNo ratings yet

- 2018dbf Illinois Institute of Technology Design ReportDocument42 pages2018dbf Illinois Institute of Technology Design Reportapi-644476404No ratings yet

- Flight Vehicle Design - III YearDocument51 pagesFlight Vehicle Design - III Yeargvsmsurya100% (1)

- Conceptual Design of A Primary Trainer Airplane-PTADocument11 pagesConceptual Design of A Primary Trainer Airplane-PTATarik Hassan ElsonniNo ratings yet

- SAE Aero Design Challenge 2017 Final Design ReportDocument27 pagesSAE Aero Design Challenge 2017 Final Design ReportYusufNo ratings yet

- Winning Reports Feb 2018 PDFDocument234 pagesWinning Reports Feb 2018 PDFMehmood AhmadNo ratings yet

- Aircraft Design PDFDocument570 pagesAircraft Design PDFrobson2015No ratings yet

- Dokumen - Tips - Aircraft Design Project 1 568e8c1761270 PDFDocument74 pagesDokumen - Tips - Aircraft Design Project 1 568e8c1761270 PDFZheer Safeen SuleimanNo ratings yet

- Aircraft DesignDocument574 pagesAircraft DesignSammy-papa Maropeng ShikaNo ratings yet

- DBF-Proposal Final FinalDocument5 pagesDBF-Proposal Final FinalSaif RezaNo ratings yet

- (Lectures 1,2 and 3) : TopicsDocument12 pages(Lectures 1,2 and 3) : Topicsamiry1373No ratings yet

- Design, Fabrication & Performance Analysis of An Unmanned Aerial VehicleDocument8 pagesDesign, Fabrication & Performance Analysis of An Unmanned Aerial VehicleGanesan BNo ratings yet

- Multi-Objective Optimisation of Aircraft Range and Fuel ConsumptionDocument10 pagesMulti-Objective Optimisation of Aircraft Range and Fuel Consumptionkannar737No ratings yet

- Research Paper Design and Development of Aircraft Droop Nose Ribs by Using OptistructDocument4 pagesResearch Paper Design and Development of Aircraft Droop Nose Ribs by Using OptistructDeepika PandeyNo ratings yet

- Chris AdpDocument62 pagesChris AdpChristan LNo ratings yet

- Ahs ProjectDocument59 pagesAhs Projectdhinesh dinsNo ratings yet

- C C C C C C C CDocument206 pagesC C C C C C C CRita FiorentinoNo ratings yet

- Development of The MDO Framework For The Helicopter Conceptual DesignDocument9 pagesDevelopment of The MDO Framework For The Helicopter Conceptual DesignNhật VũNo ratings yet

- Aircraft DesignDocument22 pagesAircraft DesignShivam100% (1)

- Aircraft Crash AnalysisDocument100 pagesAircraft Crash AnalysisSrinivas RallabandiNo ratings yet

- Aerodynamic Design Analysis and Testing of Propellers For Small Unmanned Aerial VehiclesDocument13 pagesAerodynamic Design Analysis and Testing of Propellers For Small Unmanned Aerial VehiclesHaydar YahyaNo ratings yet

- Chapter 1Document170 pagesChapter 1Uday RaoNo ratings yet

- Design, Modeling and Analysis of Landing Gear of An AircraftDocument26 pagesDesign, Modeling and Analysis of Landing Gear of An AircraftJoel MathewNo ratings yet

- 1st Univmichigan FTR Dbvf-2021Document22 pages1st Univmichigan FTR Dbvf-2021sohaibumer2001No ratings yet

- Codr Aiaa CompliantDocument39 pagesCodr Aiaa Compliantapi-644476404No ratings yet

- Aircraft Landing Gear Design ProjectDocument20 pagesAircraft Landing Gear Design Projectchristo.t.josephNo ratings yet

- Aircraft Design Project 1Document74 pagesAircraft Design Project 1sangeetha_baskaran96100% (1)

- Aircraft Design Report: 2007/2008 AIAA Cessna/Raytheon Design/Build/Fly CompetitionDocument60 pagesAircraft Design Report: 2007/2008 AIAA Cessna/Raytheon Design/Build/Fly Competitionthundergod88No ratings yet

- Aircraft Design ProjectDocument75 pagesAircraft Design ProjectPrabowo Galih Mahanendra100% (1)

- Project On UAV Design For Flight Competition in SAE Aero Design West-2013Document12 pagesProject On UAV Design For Flight Competition in SAE Aero Design West-2013Arenas Lopez ShermanNo ratings yet

- Design and Fabrication of Unmanned Arial Vehicle For Multi-Mission TasksDocument10 pagesDesign and Fabrication of Unmanned Arial Vehicle For Multi-Mission TasksTJPRC PublicationsNo ratings yet

- Department of Mechanical EngineeringDocument58 pagesDepartment of Mechanical EngineeringStanPuneetNo ratings yet

- AD Final NotesDocument68 pagesAD Final NotesthandialNo ratings yet

- Wind Tunnel Testing and Validation of Helicopter RDocument13 pagesWind Tunnel Testing and Validation of Helicopter RAlexandre PerezboldeNo ratings yet

- Seminar Report 2Document80 pagesSeminar Report 2ashsadsadNo ratings yet

- Aircraft Design Project - 1Document80 pagesAircraft Design Project - 1Abhishekhari50% (2)

- Lecture-1 Introduction To Aircraft Design - 1Document13 pagesLecture-1 Introduction To Aircraft Design - 1tempNo ratings yet

- AerohelixDocument14 pagesAerohelixHemank SoniNo ratings yet

- Computational Aerodynamic Performance Study of A Modern Blended Wing Body Airplane ConfigurationDocument10 pagesComputational Aerodynamic Performance Study of A Modern Blended Wing Body Airplane ConfigurationTJPRC PublicationsNo ratings yet

- ADA Multidisciplinary Design OptDocument10 pagesADA Multidisciplinary Design OptDhiren DarjiNo ratings yet

- Jjmie: Design Analysis and Modeling of A General Aviation AircraftDocument9 pagesJjmie: Design Analysis and Modeling of A General Aviation AircraftDario ForestiereNo ratings yet

- APSC 258 – L2D: Preliminary Report on Hovercraft Design for Fertilizer DeliveryDocument36 pagesAPSC 258 – L2D: Preliminary Report on Hovercraft Design for Fertilizer DeliveryAiman RidwanNo ratings yet

- The Aircraft Design Process: OutlineDocument32 pagesThe Aircraft Design Process: Outlinesmugge juniorNo ratings yet

- Aerodynamic Analysis of Rear Wings and Rear SpoilerDocument9 pagesAerodynamic Analysis of Rear Wings and Rear SpoilerBảo Toàn LêNo ratings yet

- Design Project I of Business JetDocument47 pagesDesign Project I of Business Jetkrishna1922422No ratings yet

- Aircraft Design ProcessDocument66 pagesAircraft Design ProcessHarsha HarNo ratings yet

- Syllabus Ae452 2022Document6 pagesSyllabus Ae452 2022öznur uluNo ratings yet

- Adp 1: Multi-Role Combat AircraftDocument68 pagesAdp 1: Multi-Role Combat AircraftTechnology Informer100% (2)

- Design and Development of Fully Composite Mini Unmanned AerialDocument43 pagesDesign and Development of Fully Composite Mini Unmanned Aerialrajkiran_rajNo ratings yet

- Flight Vehicle Design Aircraft DesignDocument18 pagesFlight Vehicle Design Aircraft DesignKarthikeya ReddyNo ratings yet

- Missile System Design Integrated With System Engineering MethodologyDocument13 pagesMissile System Design Integrated With System Engineering MethodologyPrasanna NaikNo ratings yet

- 2008-MarginOfDoom Cal Poly PomonaDocument53 pages2008-MarginOfDoom Cal Poly PomonageggioNo ratings yet

- Ijert Ijert: CEASIOM: An Open Source Multi Module Conceptual Aircraft Design ToolDocument7 pagesIjert Ijert: CEASIOM: An Open Source Multi Module Conceptual Aircraft Design Toolarafath1985No ratings yet

- Systematic Design Method For Bonded Repair Based oDocument8 pagesSystematic Design Method For Bonded Repair Based oMike PenceNo ratings yet

- ExconDocument14 pagesExconmed turkiNo ratings yet

- Ac DesignDocument0 pagesAc DesignOliver JanevNo ratings yet

- GAMAFORCE (Gadjah Mada Flying Object Research Center)Document25 pagesGAMAFORCE (Gadjah Mada Flying Object Research Center)sanane bananeNo ratings yet

- Small Unmanned Fixed-wing Aircraft Design: A Practical ApproachFrom EverandSmall Unmanned Fixed-wing Aircraft Design: A Practical ApproachNo ratings yet

- FwfqwffweqfDocument1 pageFwfqwffweqfC.E. Ishmeet SinghNo ratings yet

- Client StatusDocument1 pageClient StatusC.E. Ishmeet SinghNo ratings yet

- Database For ContainerizationDocument37 pagesDatabase For ContainerizationC.E. Ishmeet SinghNo ratings yet

- Book 1Document1 pageBook 1C.E. Ishmeet SinghNo ratings yet

- Vacancy Detail - WSP CareersDocument2 pagesVacancy Detail - WSP CareersC.E. Ishmeet SinghNo ratings yet

- Referral Letter TemplateDocument1 pageReferral Letter TemplateC.E. Ishmeet SinghNo ratings yet

- IMM Group2Document17 pagesIMM Group2C.E. Ishmeet SinghNo ratings yet

- The Institution of Engineers (India) : Royal CharterDocument5 pagesThe Institution of Engineers (India) : Royal CharterC.E. Ishmeet SinghNo ratings yet

- Sr. No. Rollno Stname MARKS - OUT - OF - 20Document1 pageSr. No. Rollno Stname MARKS - OUT - OF - 20C.E. Ishmeet SinghNo ratings yet

- British Council IELTS Online ApplicationDocument3 pagesBritish Council IELTS Online ApplicationC.E. Ishmeet SinghNo ratings yet

- British Council IELTS Online ApplicationDocument3 pagesBritish Council IELTS Online ApplicationC.E. Ishmeet SinghNo ratings yet

- Piping Syllabus IshmeetDocument2 pagesPiping Syllabus IshmeetC.E. Ishmeet SinghNo ratings yet

- PMI Training CentersDocument4 pagesPMI Training CentersC.E. Ishmeet SinghNo ratings yet

- A Tutorial On Gassmann Fluid Substitution: Formulation, Algorithm and Matlab CodeDocument9 pagesA Tutorial On Gassmann Fluid Substitution: Formulation, Algorithm and Matlab CodemaitrierwinNo ratings yet

- Client StatusDocument1 pageClient StatusC.E. Ishmeet SinghNo ratings yet

- BG BG BG BG BRRRRRRRRDocument2 pagesBG BG BG BG BRRRRRRRRC.E. Ishmeet SinghNo ratings yet

- Dcanckanc AsDocument1 pageDcanckanc AsC.E. Ishmeet SinghNo ratings yet

- SghshghaahhDocument1 pageSghshghaahhC.E. Ishmeet SinghNo ratings yet

- DNFDNFD KSNC NFPHN PFIDocument2 pagesDNFDNFD KSNC NFPHN PFIC.E. Ishmeet SinghNo ratings yet

- Piping Master NotesDocument5 pagesPiping Master NotesCarlos Del ToroNo ratings yet

- Vacancy Detail - WSP CareersDocument2 pagesVacancy Detail - WSP CareersC.E. Ishmeet SinghNo ratings yet

- VVSVSVSRFRDocument2 pagesVVSVSVSRFRC.E. Ishmeet SinghNo ratings yet

- FD:JFF"FDSF G RGDocument2 pagesFD:JFF"FDSF G RGC.E. Ishmeet SinghNo ratings yet

- GgkgigigDocument2 pagesGgkgigigC.E. Ishmeet SinghNo ratings yet

- GDK NBZKDocument1 pageGDK NBZKC.E. Ishmeet SinghNo ratings yet

- Admin#IshmeetDocument1 pageAdmin#IshmeetC.E. Ishmeet SinghNo ratings yet

- NLKNSLNLSNBDocument1 pageNLKNSLNLSNBC.E. Ishmeet SinghNo ratings yet

- B31.1 Vs B31.3Document18 pagesB31.1 Vs B31.3Muhammed Ali Noureddeen100% (2)

- Admin TRNGDocument1 pageAdmin TRNGC.E. Ishmeet SinghNo ratings yet

- Pdms Admin SyllabusDocument5 pagesPdms Admin SyllabusC.E. Ishmeet SinghNo ratings yet

- Subsonic Wind Tunnel AF100 PDFDocument4 pagesSubsonic Wind Tunnel AF100 PDFGabriel VazquezNo ratings yet

- Aerodynamic and Flow Characteristics of Tall Buildings With Various Unconventional ConfigurationsDocument16 pagesAerodynamic and Flow Characteristics of Tall Buildings With Various Unconventional ConfigurationsVinay GoyalNo ratings yet

- Aileron ReversalDocument8 pagesAileron ReversalMohamed Omar IbrahimNo ratings yet

- Full-Scale Flight Test From Sea Level of An Abort-Escape System For A Project Mercury CapsuleDocument45 pagesFull-Scale Flight Test From Sea Level of An Abort-Escape System For A Project Mercury CapsuleBob Andrepont100% (1)

- +++ Fundamental and Advanced Topics in Wind PowerDocument434 pages+++ Fundamental and Advanced Topics in Wind PowerMurat Ateş100% (1)

- Effect of Side Gust On The Performance of A Supersonic Inlet With Bleed SystemDocument24 pagesEffect of Side Gust On The Performance of A Supersonic Inlet With Bleed SystemAzeem KhanNo ratings yet

- COB-2019-1386 Winglet Design Optimization Using A Multi-Objective Genetic AlgorithmDocument4 pagesCOB-2019-1386 Winglet Design Optimization Using A Multi-Objective Genetic AlgorithmLucas GewehrNo ratings yet

- Assignment 3-Solutions PDFDocument6 pagesAssignment 3-Solutions PDFNickson KomsNo ratings yet

- 13th International Conference on TechnologyDocument79 pages13th International Conference on TechnologyDiego Fernando AVENDA¥O RODRIGUEZNo ratings yet

- CalSpan Upset Recovery TrainingDocument2 pagesCalSpan Upset Recovery TrainingHighspeed FlyboyNo ratings yet

- Esdu CatalogueDocument105 pagesEsdu CatalogueUl50% (4)

- Winglet Design and Analysis For Low-Altitude Solar Powered UAV PDFDocument24 pagesWinglet Design and Analysis For Low-Altitude Solar Powered UAV PDFAdit 0110No ratings yet

- Hampdon Wind Tunnel H 6910 12 CDLDocument41 pagesHampdon Wind Tunnel H 6910 12 CDLardiantio887No ratings yet

- Canard (Aeronautics)Document10 pagesCanard (Aeronautics)p6a4nduNo ratings yet

- Model Rocket Stability: in This IssueDocument5 pagesModel Rocket Stability: in This IssueKALASH PARIPURNAMNo ratings yet

- Literature StudyDocument281 pagesLiterature StudybramiozoNo ratings yet

- Week-10 Wind Energy (Part 2) - 2020-2021 - 2TDocument54 pagesWeek-10 Wind Energy (Part 2) - 2020-2021 - 2TSka dooshNo ratings yet

- 71 PutilovaDocument8 pages71 Putilova1xlaleNo ratings yet

- Solution of Kme 064Document25 pagesSolution of Kme 064Atul JainNo ratings yet

- Helicopter Rotor System and DesignDocument27 pagesHelicopter Rotor System and DesignSumeet Ghodke75% (8)

- Answer A Answer B: Banked Turn While Maintaining Altitude?Document3 pagesAnswer A Answer B: Banked Turn While Maintaining Altitude?ash krisNo ratings yet

- Report 0Document22 pagesReport 0MONISHA.K 1CK19EC038No ratings yet

- Calibration of Wind Tunnel PDFDocument289 pagesCalibration of Wind Tunnel PDFRaamaChandiranNo ratings yet

- Sheet 3Document33 pagesSheet 3Ahmed AdelNo ratings yet

- CH 9 Flow Over Immersed BodiesDocument165 pagesCH 9 Flow Over Immersed BodiesMujtaba Rizvi67% (3)

- Airplane Performance and Propulsion 1Document14 pagesAirplane Performance and Propulsion 1Ruvarashe KambilaNo ratings yet

- Aeroelastic Tailoring of The Composite WingDocument11 pagesAeroelastic Tailoring of The Composite Wingjunjie yiNo ratings yet

- Module 5pt1Document27 pagesModule 5pt1shamoon1985No ratings yet

- Airfoil NomenclatureDocument25 pagesAirfoil Nomenclatureqasim zaheer100% (1)