Professional Documents

Culture Documents

Comparison of The Solubilization Effect of Micronized Poloxamers

Uploaded by

saeedazadi13520 ratings0% found this document useful (0 votes)

76 views1 pageSolubilization Effect of Micronized Poloxamers

Original Title

Comparison of the Solubilization Effect of Micronized Poloxamers

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSolubilization Effect of Micronized Poloxamers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

76 views1 pageComparison of The Solubilization Effect of Micronized Poloxamers

Uploaded by

saeedazadi1352Solubilization Effect of Micronized Poloxamers

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Comparison of the Solubilization Effect of Micronized Poloxamers,

on a poorly water-soluble model drug in capsule formulation by dry Granulation

Charles Onyiuke

BASF Corporation, Pharma Ingredients and Services, 500 White Plains Road, NY 10591

Abstract

Dry blend formulations have been the fastest and most economical methods of solid oral dosage

manufacture in the pharmaceutical industry. This study investigated the effect of micronized poloxamers

on the solubility of poorly-water soluble drugs in capsule formulation using dry blended powder.

Introduction

The ideal method of solid dosage formulation and manufacture has always been dry granulation where

the active ingredient(s) and the excipients are blended to achieve homogeneity of the mixed particles. This

is a simple, fast and economical process; but it is the most challenging method in terms of achieving a

robust formulation. The diffculty to achieve good content uniformity, inter-particle interactions, and good

choice of excipients that have similar particle sizes as that of the API (active pharmaceutical ingredients)

make this method unachievable for many formulators in the pharmaceutical industries 2,3. One of the

critical parameters in this process is the mixing time of the dry particles which need to be long enough to

enhance the blend homogeneity 5,6. This is necessary to achieve adequate drug release and stability.

Materials

Carbamazepine was obtained from BASF Corporation.

Micronized Poloxamer 188 (Lutrol F68 Micro), Poloxamer 237 (Lutrol F87 Prill), Poloxamer 338

(Lutrol F108 Prill) and Micronized Poloxamer 407 (Lutrol F127 Micro), the non-ionic surfactants of

polyoxyethylene (POE) and polyoxypropylene (POP), were obtained from BASF Corporation.

Crospovidone (Kollidon CL) was obtained from BASF Corporation.

Calcium Carbonate was obtained from Particle Dynamics.

Pro-Solv, (Silicifed Microcrystalline Cellulose (S-MCC)) was obtained from JRS Pharma LP.

Size 0 Empty Capsule Shells were obtained from Capsugel.

Poloxamers are block-copolymers consisting of

Polyoxyethylene-(POE-) and Polyoxypropylene-(POP-) units.

[POE] Unit [POP] Unit [POE] Unit

Poloxamer 188a a = ca. 79 b = ca. 28 Lutrol F 68

Poloxamer 407a a = ca. 98 b = ca. 57 Lutrol F 127

Pharmacopeia name trade name

Methods

Poloxamer 237 (Lutrol F87 Prill), and Poloxamer 338 (Lutrol F108 Prill) were micronized in-house using

Freezer/Mill 6870, SpexSample Prep. method to achieve particle size uniformity. These micronized grades

of Poloxamer 188, 237, 338, and 407 (Lutrol F68, F87, F108 and F127 respectively) with particle sizes

of 50 microns approximately; were mixed with Carbamazepine, as the model drug. Carbamazepine

was combined with each Poloxamer at 9 wt%(1:10) and 17 wt% (1:5), and blended for 20 minutes with

Calcium Carbonate 90A as fller, Kollidon CL as the super disintegrant and Silicifed Microcrystalline

Cellulose as glidant. The fnal dry granulation was flled into hard gelatin capsules, each weighing 400 mg.

The dissolution of Carbamazepine was done using Type II Dissolution Apparatus (dissolution medium:

1.0% SLS in DI water, 100 rpm, 37C). The release profle of the carbamazepine capsules was measured

using UV Detection Apparatus.

Carbamazepine Formulations with Different

Lutrol

Micro Grades in 1:5 ratios

Materials

Drug: Poloxamer Ratio ( w/w % )

(1:0) Control (1:5) (1:5) (1:5) (1:5)

Carbamazepine 5.0 5.0 5.0 5.0 5.0

Lutrol F68 Micro 0.0 25.0 0.0 0.0 0.0

Lutrol F127 Micro 0.0 0.0 25.0 0.0 0.0

Lutrol F87 Micro Prill 0.0 0.0 0.0 25.0 0.0

Lutrol F108 Micro Prill 0.0 0.0 0.0 0.0 25.0

Kollidon CL 12.5 10.5 10.5 10.5 10.5

Calcium Carbonate 69.5 59.0 59.0 59.0 59.0

Pro-Solv ( S-MCC ) 13.0 0.5 0.5 0.5 0.5

T O T A L 100.0 100.0 100.0 100.0 100.0

Table I

Carbamazepine Formulations with Different

Lutrol

Micro Grades in 1:10 ratios

Materials

Drug: Poloxamer Ratio ( w/w % )

(1:0) Control (1:10) (1:10) (1:10) (1:10)

Carbamazepine 5.0 5.0 5.0 5.0 5.0

Lutrol F68 Micro 0.0 50.0 0.0 0.0 0.0

Lutrol F127 Micro 0.0 0.0 50.0 0.0 0.0

Lutrol F87 Micro Prill 0.0 0.0 0.0 50.0 0.0

Lutrol F108 Micro Prill 0.0 0.0 0.0 0.0 50.0

Kollidon CL 12.5 5.0 5.0 5.0 5.0

Calcium Carbonate 69.5 39.0 39.0 39.0 39.0

Pro-Solv ( S-MCC ) 13.0 0.5 0.5 0.5 0.5

T O T A L 100.0 100.0 100.0 100.0 100.0

Table II

Results

0

10

20

30

40

50

60

70

80

90

100

0 15 30 45 60 120

C

a

rb

a

m

a

z

e

p

in

e

(%

R

e

le

a

s

e

d

)

Release Prole of Carbamazepine Capsule in Dry Blend

Formulation with Lutrol Micro as Solubilizer

Time (min.)

Control

F68 (1:5)

F87 (1:5)

F108 (1:5)

F127 (1:5)

Figure1. Control: Carbamazepine:Poloxamer Ratio (1:5)

0

10

20

30

40

50

60

70

80

90

100

0 15 30 45 60 120

C

a

rb

a

m

a

z

e

p

in

e

(%

R

e

le

a

s

e

d

)

Release Prole of Carbamazepine Capsule in Dry Blend

Formulation with Lutrol Micro as Solubilizer

Time (min.)

Control

F68 (1:10)

F87 (1:10)

F108 (1:10)

F127 (1:10)

Figure II. Control: Carbamazepine:Poloxamer Ratio (1:10)

Discussion

Physical mixtures of Carbamazepine and different Lutrol F micro grades in capsule formulations

increased Carbamazepine solubility relatively. The capsules from the 1:5 ratio formulations have less

solubility enhancement than those from the 1:10 ratio. In two hours, the capsules of Lutrol F68 micro

(1:10 ratio) showed a 97% drug release as compared to 92% from the Lutrol F68 micro (1:5 ratio),

formulations. This is relatively due to the 50% increase in the amount of Lutrol F68 in fgure II formulation.

In both formulations, Lutrol F127 showed a very small solubilization effect due to its known gelling

property associated with its high molecular weight. However, at 1:10 ratio, Lutrol F127 showed 75%

drug released after two hours. Lutrol F87 at 1:5 ratio, showed 75% drug release as opposed to 1:10

ratio with only about 70% drug release. Lutrol F108 showed a better drug release at 1:5 ratio, (62%) as

opposed to below 50% in the 1:10 ratio. It is desirable to increase the mixing time of the ingredients to

assure good content uniformity and most importantly enhance complexation of the drug particles with

the poloxamer molecules 3,4. The comparative study of the behavior of these Lutrol grades in a tablet

formulation is desirable 1,5.

Conclusion

Micronized grades of Lutrol

F68 and F127 improved the solubility of

carbamazepine when compared to control capsule formulation.

Carbamazepine was more soluble in micronized Lutrol

F68 than in Lutrol

F127

micro, F87 and F108 micro prill.

The small particle size of the micronized Lutrol

grades ensured optimum

ingredient miscibility and blend homogeneity.

The gelling property of Lutrol

F127 micro can be utilized in Dry Blend

formulations to provide sustained or delayed drug release

6

.

Dry blend granulation where micronized Lutrol

F68 and F127 are used to

solubilize poorly water-soluble drugs, such as Carbamazepine, is a robust and

economical method of solid dosage manufacture.

The solubilization effect of Poloxamers studied decreased from

F68 > F127 > F87 >108.

References

1. The infuence of three poly(oxyethylene)poly(oxypropylene) surface active block co-polymers on the

solubility behavior of Indomethacin. Pharma Acta Helv. 60 No. 12 (1985) 339-344

2. Kinetic studies on the stability of Indomethacin in alkaline aqueous solution containing

poly(oxyethylene)poly(oxypropylene) surface active block copolymers. Pharma Acta Helv. 60 No. 12

(1985) 345-350

3. Pluronic surfactants affecting Diazepan solubility, compatibility and adsorption from i.v. admixture

solutions. J. Parent. Sci & Tech Vol. 41 No. 3, May-June (1987) 83-87

4. Comparative study of Prill and Micronized Poloxamers Using Different Conventional Granulation

Techniques, AAPS Poster presentation 2005

5. Effect of Micronized Poloxamers on Poorly Water Soluble Drugs, AAPS 2003

6. Solubilization of selected poorly soluble Drugs in directly compressible formulations Using micronized

Poloxamers, AAPS Poster presentation 2007

You might also like

- Measurement of SubstructureDocument24 pagesMeasurement of SubstructureAamaniVeeranam80% (10)

- Paracetamol PDFDocument23 pagesParacetamol PDFJinav GhataliaNo ratings yet

- Quantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFDocument11 pagesQuantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFThinh DangNo ratings yet

- Flexible Packaging IntroDocument17 pagesFlexible Packaging Introascii02No ratings yet

- Research BulletsDocument18 pagesResearch BulletsVong Albios DogomeoNo ratings yet

- Abstract (Lab 2) Ionization ConstantDocument12 pagesAbstract (Lab 2) Ionization Constantmirdza94No ratings yet

- Science8 Q2 Module3 (Week6)Document30 pagesScience8 Q2 Module3 (Week6)Mary Grace Lemon100% (1)

- Pluronic PeDocument16 pagesPluronic PeTrev GlasbeyNo ratings yet

- Review of Poloxamer 407 Dumortier 2006Document20 pagesReview of Poloxamer 407 Dumortier 2006Edgard PaivaNo ratings yet

- Synthesis and Antibacterial Activity of 1-MonolaurinDocument5 pagesSynthesis and Antibacterial Activity of 1-Monolaurini love chubzNo ratings yet

- Industrial Training PRESENTATION (Benazir)Document6 pagesIndustrial Training PRESENTATION (Benazir)Benazir ShuguftaNo ratings yet

- HPLC UspDocument2 pagesHPLC Uspchem6310No ratings yet

- REGULATORY SCIENCE OF LIPOSOME DRUGDocument6 pagesREGULATORY SCIENCE OF LIPOSOME DRUGrandatagNo ratings yet

- HPMC Pittcon 2008Document1 pageHPMC Pittcon 2008Sonet SahaNo ratings yet

- ICH Q3C Residual SolventsDocument40 pagesICH Q3C Residual SolventsRiccardo TorelliNo ratings yet

- Cell GrowthDocument48 pagesCell GrowthAlfin MartaNo ratings yet

- Is Iso 1066 1975Document9 pagesIs Iso 1066 1975Clausius ClapeyronNo ratings yet

- FDA Draft Guidance on Dexamethasone; Tobramycin Ophthalmic Suspension StudiesDocument5 pagesFDA Draft Guidance on Dexamethasone; Tobramycin Ophthalmic Suspension Studiesjaiminrshah1990No ratings yet

- Single PotDocument7 pagesSingle Potsky.blueNo ratings yet

- Webinar CEP 2.0 May 2023Document51 pagesWebinar CEP 2.0 May 2023Julia ShulgaNo ratings yet

- Acid Ascorbic StabilityDocument29 pagesAcid Ascorbic StabilityJaime PerezNo ratings yet

- Biotech PDFDocument24 pagesBiotech PDFandigyNo ratings yet

- Polymers 07 00777 PDFDocument27 pagesPolymers 07 00777 PDFalthea badayos100% (1)

- Determine ash contentDocument1 pageDetermine ash contentMasood SabirNo ratings yet

- Petition Response Letter From FDA CDER To Insys Therapeutics, IncDocument12 pagesPetition Response Letter From FDA CDER To Insys Therapeutics, IncKyleJaegerNo ratings yet

- Geo MatrixDocument3 pagesGeo MatrixXuan NhiNo ratings yet

- Comprehensive Quality by Design for Pharmaceutical Product Development and ManufactureFrom EverandComprehensive Quality by Design for Pharmaceutical Product Development and ManufactureGintaras V. ReklaitisNo ratings yet

- ASTM D4984 CO2 en Gas NaturalDocument3 pagesASTM D4984 CO2 en Gas Naturalfamturbo0% (1)

- User Com 1Document12 pagesUser Com 1Clint FosterNo ratings yet

- Phenols in FuelDocument12 pagesPhenols in Fuelvzimak2355No ratings yet

- High-Performance Liquid ChromatographyDocument5 pagesHigh-Performance Liquid ChromatographyYulia PrimasariNo ratings yet

- USP Chapters For Pharm - PackagingDocument20 pagesUSP Chapters For Pharm - PackagingMd Tayfuzzaman100% (1)

- SOP For Bubble Point Test - Pharmaceutical GuidelinesDocument1 pageSOP For Bubble Point Test - Pharmaceutical Guidelinespiyusharora1964No ratings yet

- Butyl lithium titration methodsDocument2 pagesButyl lithium titration methodsRodary DymarcuzNo ratings yet

- USP Glycerin Monograph Modernization - Background - 2013 PDFDocument36 pagesUSP Glycerin Monograph Modernization - Background - 2013 PDFMuhamad Gaddafi SamsudinNo ratings yet

- Macrogols BPDocument4 pagesMacrogols BPASHOK KUMAR LENKANo ratings yet

- Plant LectinsDocument25 pagesPlant Lectinsshady182100% (1)

- HPMC Viscosity GradesDocument10 pagesHPMC Viscosity GradesKhoa Duy100% (1)

- Chlorination of Alcohol Using PPh3Document3 pagesChlorination of Alcohol Using PPh3Theresa Raquel De FreitasNo ratings yet

- 02 Downstream ProcessDocument29 pages02 Downstream Processnishit1990No ratings yet

- Encapsulation and Controlled ReleaseDocument29 pagesEncapsulation and Controlled ReleaseKasan BasanNo ratings yet

- DeDocument3 pagesDesindromfall100% (1)

- Production of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Filamentation-Suppressed Recombinant Escherichia ColiDocument5 pagesProduction of Poly (3-Hydroxybutyrate) by Fed-Batch Culture of Filamentation-Suppressed Recombinant Escherichia Coliapi-3743140No ratings yet

- Insoluble Drug Delivery StrategiesDocument12 pagesInsoluble Drug Delivery StrategiespsykhodelykNo ratings yet

- Ftir and Gc-Fid CharacterizationDocument8 pagesFtir and Gc-Fid CharacterizationIpeghan Otaraku100% (1)

- FurfuralDocument9 pagesFurfuralwahamanwah67% (3)

- Pharmaceutical EngineringDocument24 pagesPharmaceutical EngineringKedai Kado UnikNo ratings yet

- Effect of System Parameters On Controlled ReleaseDocument49 pagesEffect of System Parameters On Controlled ReleaseSindhur Sreedharan MNo ratings yet

- 1228 5 PDFDocument5 pages1228 5 PDFdeepanmb007No ratings yet

- Characterization of METHOCEL Cellulose Ethers by Aqueous SEC With Multiple DetectorsDocument11 pagesCharacterization of METHOCEL Cellulose Ethers by Aqueous SEC With Multiple DetectorsCastoriadisNo ratings yet

- Oxidized AlginateDocument5 pagesOxidized AlginateThinh Nguyen TienNo ratings yet

- The Clinical Use of Monolaurin As A Dietary Supplement: A Review of The LiteratureDocument6 pagesThe Clinical Use of Monolaurin As A Dietary Supplement: A Review of The Literaturerevolvevijaya123No ratings yet

- Content Uniformity of Direct Compression TabletsDocument12 pagesContent Uniformity of Direct Compression Tabletsanggi yudhatamaNo ratings yet

- Tablet EverfesentDocument12 pagesTablet EverfesentAdit Taufik100% (1)

- Wurstertechnology ProcessvariablesinvolvedandScaleupscienceDocument11 pagesWurstertechnology ProcessvariablesinvolvedandScaleupsciencemadhuNo ratings yet

- Slow and Controlled Release and Stabilized Fertilizers An Option For Enhancing Nutrient EfficiencyDocument163 pagesSlow and Controlled Release and Stabilized Fertilizers An Option For Enhancing Nutrient EfficiencyWalter EduarteNo ratings yet

- An Overview of The Recent Advantages in Spray DryingDocument14 pagesAn Overview of The Recent Advantages in Spray DryingAlfonso CubillosNo ratings yet

- Production and Active Pharmaceutical Ingredients 5EEC Group 1Document10 pagesProduction and Active Pharmaceutical Ingredients 5EEC Group 1Derrick RamosNo ratings yet

- Experiment No. 3: Preparation of SoapDocument16 pagesExperiment No. 3: Preparation of SoapTrisha TadiosaNo ratings yet

- Bacteriological Analytical Manual OnlineDocument946 pagesBacteriological Analytical Manual OnlineGianella 17No ratings yet

- ErythromycinDocument2 pagesErythromycinAHMAD SYAUQI AIMAN BIN ABU BAKARNo ratings yet

- B 03 110921e Solubility Enhance CompendiumDocument130 pagesB 03 110921e Solubility Enhance CompendiumMostofa RubalNo ratings yet

- Who Expert CommitteeDocument352 pagesWho Expert Committeesaeedazadi1352No ratings yet

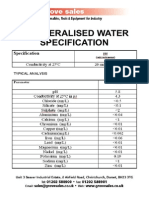

- DeIonized Water SpecDocument1 pageDeIonized Water Specsaeedazadi1352No ratings yet

- Modulation of Protein Aggregation by Polyethylene PDFDocument13 pagesModulation of Protein Aggregation by Polyethylene PDFsaeedazadi1352No ratings yet

- Poloxamers As Solubilizing Agents in Solid DispersionsDocument1 pagePoloxamers As Solubilizing Agents in Solid Dispersionssaeedazadi1352No ratings yet

- Ss Aniara Csv1evalcshbmvschrxDocument9 pagesSs Aniara Csv1evalcshbmvschrxsaeedazadi1352No ratings yet

- Kolliphor® P 188 Solid, Suitable For Cell Culture, Suitable For Insect Cell Culture, Suitable For Plant Cell Culture - Sigma-AldrichDocument2 pagesKolliphor® P 188 Solid, Suitable For Cell Culture, Suitable For Insect Cell Culture, Suitable For Plant Cell Culture - Sigma-Aldrichsaeedazadi1352No ratings yet

- Effects of Tween 20 and Tween 80 On The StabilityDocument14 pagesEffects of Tween 20 and Tween 80 On The Stabilitysaeedazadi1352No ratings yet

- Types of WaterDocument5 pagesTypes of WaterknarasimhacharyuluNo ratings yet

- Human FibrinogenDocument2 pagesHuman Fibrinogensaeedazadi1352No ratings yet

- Detection and Prevention of Protein Aggregation Before, DuringDocument9 pagesDetection and Prevention of Protein Aggregation Before, Duringsaeedazadi1352No ratings yet

- Genentech PatentDocument25 pagesGenentech Patentsaeedazadi1352No ratings yet

- Nutropin PM EDocument65 pagesNutropin PM Esaeedazadi1352No ratings yet

- CE 7100 Specs ENDocument2 pagesCE 7100 Specs ENsaeedazadi1352No ratings yet

- Development of A Sustained-Release Recombinant Human GrowthDocument6 pagesDevelopment of A Sustained-Release Recombinant Human Growthsaeedazadi1352No ratings yet

- Pierce Manual Protein AssayDocument40 pagesPierce Manual Protein Assayjavier redruelloNo ratings yet

- Review Prevalence of Unwanted Pregnancy in Iran: A Systematic Review and Meta-AnalysisDocument14 pagesReview Prevalence of Unwanted Pregnancy in Iran: A Systematic Review and Meta-Analysissaeedazadi1352No ratings yet

- Knowledge Translation: Introduction To Models, Strategies, and MeasuresDocument44 pagesKnowledge Translation: Introduction To Models, Strategies, and Measuressaeedazadi1352No ratings yet

- Endotoxin Detection and Removal FormDocument1 pageEndotoxin Detection and Removal Formsaeedazadi1352No ratings yet

- Knowledge Translation: Introduction To Models, Strategies, and MeasuresDocument44 pagesKnowledge Translation: Introduction To Models, Strategies, and Measuressaeedazadi1352No ratings yet

- Biological Activity Analysis of Native and Recombinant StreptokinaseDocument16 pagesBiological Activity Analysis of Native and Recombinant Streptokinasesaeedazadi1352100% (1)

- Full TeFermentation Strategies For Recombinant Protein Expression in The Methylotrophic Yeast Pichia PastorisxtDocument14 pagesFull TeFermentation Strategies For Recombinant Protein Expression in The Methylotrophic Yeast Pichia Pastorisxtsaeedazadi1352No ratings yet

- 8gCCMZn ewAC PDFDocument166 pages8gCCMZn ewAC PDFsaeedazadi1352No ratings yet

- Research Journal of Pharmaceutical, Biological and Chemical SciencesDocument10 pagesResearch Journal of Pharmaceutical, Biological and Chemical Sciencessaeedazadi1352No ratings yet

- CEPrimer5Document129 pagesCEPrimer5saeedazadi1352No ratings yet

- Knowledge Translation: Introduction To Models, Strategies, and MeasuresDocument44 pagesKnowledge Translation: Introduction To Models, Strategies, and Measuressaeedazadi1352No ratings yet

- Tosoh CatalogDocument116 pagesTosoh Catalogsaeedazadi1352No ratings yet

- Knowledge Translation: Introduction To Models, Strategies, and MeasuresDocument44 pagesKnowledge Translation: Introduction To Models, Strategies, and Measuressaeedazadi1352No ratings yet

- Parenteral Quality ControlDocument388 pagesParenteral Quality Controlsaeedazadi1352No ratings yet

- AminesDocument31 pagesAminesJoseph YayenNo ratings yet

- Knight Boiler ManualDocument80 pagesKnight Boiler ManualAnonymous 7xHNgoKE6eNo ratings yet

- Chapter 2Document2 pagesChapter 2LolmasterNo ratings yet

- Gas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 ADocument33 pagesGas-Insulated Switchgear: Type 8DN8 Up To 170 KV, 63 Ka, 4000 APélagie DAH SERETENONNo ratings yet

- Activity No. 5 Capacitive Circuit ObjectivesDocument4 pagesActivity No. 5 Capacitive Circuit ObjectivesJohn Paul BaquiranNo ratings yet

- NCERT: Why Is Steel More Elastic Than Rubber?Document7 pagesNCERT: Why Is Steel More Elastic Than Rubber?Satyam RaiNo ratings yet

- Remote Sensing: Comparison of The Selected State-Of-The-Art 3D Indoor Scanning and Point Cloud Generation MethodsDocument26 pagesRemote Sensing: Comparison of The Selected State-Of-The-Art 3D Indoor Scanning and Point Cloud Generation MethodsVICTOR PEREZNo ratings yet

- Ford Eectch98Document79 pagesFord Eectch98jockerNo ratings yet

- Programming structures if, for and while loopsDocument16 pagesProgramming structures if, for and while loopsFrancisco AristizabalNo ratings yet

- Active Heating and CoolingDocument16 pagesActive Heating and Coolinga_j_sanyal2590% (1)

- Essay For Villa Savoye AbstractDocument1 pageEssay For Villa Savoye AbstractFrancis PohNo ratings yet

- Applications and Interpretation Standard SpecimensDocument56 pagesApplications and Interpretation Standard SpecimensNahir ClaraNo ratings yet

- Cork Properties Capabilities and ApplicationsDocument22 pagesCork Properties Capabilities and ApplicationsVijay AnandNo ratings yet

- Connective TissueDocument6 pagesConnective TissuecrtgyhujikNo ratings yet

- A Framework For Transforming Artifacts From Data Flow Diagrams ToDocument7 pagesA Framework For Transforming Artifacts From Data Flow Diagrams Tow_mahmudNo ratings yet

- Jm-10 Operation Manual Rev02 UnlockedDocument121 pagesJm-10 Operation Manual Rev02 UnlockedAlan Jimenez GonzalezNo ratings yet

- Timer Counter ArduinoDocument8 pagesTimer Counter ArduinoKietDangNo ratings yet

- 11 Risks and Rates of Return KEYDocument12 pages11 Risks and Rates of Return KEYkNo ratings yet

- Week 10 TelecommunicationsDocument7 pagesWeek 10 TelecommunicationsGuido MartinezNo ratings yet

- FT 539G Eng 01Document4 pagesFT 539G Eng 01lmw_arunNo ratings yet

- AC axial compact fan technical specificationsDocument5 pagesAC axial compact fan technical specificationsdhanasekhar27No ratings yet

- ME4111 Engineering and Mechanical PrinciplesDocument5 pagesME4111 Engineering and Mechanical PrinciplesEdvard StarcevNo ratings yet

- 4MA0 4HR Que 20140115Document24 pages4MA0 4HR Que 20140115Lalith77No ratings yet

- 384 TungaloyDocument32 pages384 Tungaloyp.designNo ratings yet

- Tut 5. Two-Column Hammerhead Pier PDFDocument35 pagesTut 5. Two-Column Hammerhead Pier PDFOscar Varon BarbosaNo ratings yet

- Hospital Managemen T System: Oose LAB FileDocument62 pagesHospital Managemen T System: Oose LAB FileAASHNo ratings yet