Professional Documents

Culture Documents

CH2

Uploaded by

Sue MengCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH2

Uploaded by

Sue MengCopyright:

Available Formats

FORUM

Council House 2 (CH2) in review

Matthew Hoogland, M.AIRAH, Exergy Australia; and Dr Paul Bannister, M.AIRAH, Exergy Australia

ABSTRACT

Council House 2 (CH2) is the City of Melbournes agship building for sustainability. The building showcases a number of innovative technologies and has attracted recognition with numerous environmental awards. But how does the building actually perform and what lessons does it have for the broader industry? The City of Melbourne was asking these questions when they invited Exergy to conduct a review of the buildings energy efciency performance in July 2012. Exergys review focused on the operation of the buildings various systems, including passive chilled beam, tri-generation, thermal storage phase-change material, shower towers and more. Key issues identied mainly pertained to the HVAC commissioning and control strategies applied to these systems not only in isoaltion, but in the complex web in which they come together. The City of Melbourne is now in the process of implementating the rst stage of measures with calculated potential to reduce energy consumption by 25%. Crucial to the success of this project will be a staged process of implementation and measurement to determine how best the buildings systems can complement each other in various modes of operation.

INTRODUCTION

Ofcially opened in August 2006, CH2 was Australias rst 6 star Green Star Design building, and showcases a number of sustainable building features. The building was designed to set new standards for low energy and high occupant comfort, bringing together a range of innovative technologies not only for the benet of those to work in it, but also to serve as a sounding board for the broader industry. But how does the building actually perform? With doubt that the building was achieving its ambitious targets, the City of Melbourne invited Exergy to undertake a review of the buildings energy efciency performance in July 2012, providing an opportunity to review the performance of the innovative and experimental design features of the building. The aims of the project were to: Quantify the existing performance of the building against NABERS 1 Energy benchmarks Identify issues impeding energy efciency performance Detail measures to improve the NABERS Energy rating Identify lessons that can be learnt from CH2. The review was based on the ndings of a whole building level 2 energy audit conducted by Dr Paul Bannister, M.AIRAH; Matthew Hoogland, M.AIRAH; and Ben Carmichael of Exergy Australia as per the requirements of AS/NZS 3598:2000. Note that the scope of the review was predominantly targeted at identifying energy efciency measures to improve the NABERS Energy performance of the building. We acknowledge that there are numerous features of interest within the building. However, in general, our investigation only went as far as that required to improve the efciency of the core systems that the energy audit revealed to be making a signicant impact on the buildings consumption. As such, detailed investigation of the peripheral features of the building such as renewable power sources and automated shading systems were not covered. We also note that water efciency and indoor environment quality were not included in the scope of the review.

44

E CO L I B R I U M M A R C H 2 0 1 4

BUILDING FEATURES

The features of CH2 that were intended to contribute to high-level energy performance are listed below. Note that we have divided the features according to the signicance with which we observed them having to the buildings current performance: Core features: Passive chilled beam cooling Tri-generation Hydronic radiant heating Extensive heat transfer and recovery between water loops Phase-change material tanks for thermal storage. Peripheral features: Building integrated wind power Solar PV and domestic hot water Shower towers Electronically actuated windows and shading Daylight harvesting.

At the time of CH2s construction most of these technologies were far from common within Australias commercial building industry. And while chilled beam technology and tri-generation systems have since become more widespread, features such as the shower towers and phase-change storage tanks are still relatively uncommon among Australias commercial building stock. Of the buildings array of technologies, arguably most technically signicant is the extensive potential for heat transfer between the seven distinct water loops. A water schematic of the sites servicing is presented in Figure 2. Among others, heat exchangers can be observed between the domestic hot water system and the primary heating water system, the primary heating water system and the primary condenser water system, the primary condenser water system and the supplementary condenser water system, and the supplementary condenser water system and the primary heating water system. Although none of these processes in isolation are particularly unusual, their summation equates to a system of unusual potential and complexity.

FORUM

Unit

HEX-1

Description

HEX to transfer coolth from the primary CHW to secondary CHW HEX for transfer between the cooling towers and the supplementary CDW system HEX for heat recovery from the primary CDW return to airside heating HEX for heat injection into the supplementary CDW system (for reversecycle PACs) HEX for transfer of coolth from the shower towers to the chilled beam network HEX for transfer of coolth to pre-cool the secondary CHW return after its path through HEX-7 and/or HEX-8 HEX for transfer of coolth from the secondary CHW system to either of the chilled beam network directly or via the PCM tanks (parallel to HEX-8) HEX for transfer of coolth from the secondary CHW system to either of the chilled beam network directly or via the PCM tanks (parallel to HEX-7)

HEX-2

HEX-3

HEX-4

HEX-5

HEX-6

HEX-7

Figure 1: CH2 west facing facade (from Swanston St).

HEX-8

The complexity of CH2s design, coupled with the industrys general lack of familiarity with its features has proven to be one of the key challenges for the buildings operation.

Table 1: Heat exchanger (HEX) legend corresponding to Figure 2.

Microturbine heat recovery

H C C

Absorption chiller

C

Screw chillers

C

Cooling towers Boilers

H H C C C

HEX 1 HEX 2

C H

AHUs L1-9 heating convectors L1-9 chilled beams

C C C H

HEX 3

DHW HEX Primary CHW loop Secondary CHW loop HHW loop Shower tower loop Primary CDW loop

Shower towers

C C

HEX 4

H

L1-9 CDW

H

HEX 5

HEX 6

C

PCM tanks

C

Retail PACs

Chilled beam loop Tenant CDW loop Heat ow Cool ow

HEX 7 HEX 8

C

Figure 2: Simplified water schematic of HVAC services for CH2, demonstrating the diverse array of water loops and the heat transfer potential between them. Note that each line represents a flow and return path. See HEX legend in Table 1.

M A R C H 2 0 1 4 E CO L I B R I U M

45

FORUM

CURRENT ENERGY PERFORMANCE

The actual energy performance of CH2 does not currently meet the high standard of its design. Our analysis revealed the whole building NABERS Energy performance of the building to be 4.08 stars. With the aid of data obtained from the oorby-oor sub-metering system we were able to drill down to investigate the weighting of the base building and tenancy on the whole building performance. Our analysis found the base building to be performing at 3.24 stars NABERS. With several major property owners in Australia now reporting average portfolio ratings of 4.5 stars or higher, this is well below the current industry standard for good performance2 . At 3.24 stars, the emissions attributable to CH2s base building services are 68% greater than what they would be if the base building was performing at 4.5 stars. Whole building NABERS rating Date range Electricity (kWh) Gas (MJ) Diesel (Litres) Hours of occupancy No. of computers NABERS rating (decimal) NABERS star rating 1/7/11 to 30/6/12 971,270 5,133,122 0 49.2 n/a Estimated base building NABERS rating 1/7/11 to 30/6/12 571,292 5,133,122 0 49.2 n/a Estimated tenancy NABERS rating 1/7/11 to 30/6/12 399,978

250

200

150 kW 100

50

0

Mon Tue Wed Thu Fri Sat Sun

250

200

150

0 0 49.2 454

kW 100

50

4.08

3.24

5.43

Shoulder Weekday Summer Weekday

Winter Weekday Shoulder Weekend

Summer Weekend Winter Weekend

4.0 stars

3.0 stars

5.0 stars

Figure 3: Average daily (above) and seasonal (below) electrical load profiles, highlighting daily and seasonal variation in the base load.

Table 2: NABERS Energy performance parameters for July 2011 to June 2012.

also produced to help illustrate the diversity of energy sources and complementary systems within the building. It is noted that the sub-metering system could not signicantly inform the breakdown of base building services due to inadequate coverage and poor data quality from some meters.

ENERGY CONSUMPTION ANALYSIS

Interval data was obtained for the ofce buildings sole electrical utility meter. The analysis revealed unusual variation in the base load over weekdays and seasons, as presented in Figure 3. With minimal occupation of the building outside of business hours, these observations were tell-tale signs that there may have been frequent HVAC operation occuring outside of the operational hours of the building. Site inspections were conducted over a course of several months and at various times of the day and night to observe the building in its different modes of operation. The end-use breakdown is presented in Figure 4 as constructed according to the ndings of the site inspections. A Sankey ow diagram (Figure 5) was

46

E CO L I B R I U M M A R C H 2 0 1 4

KEY ISSUES

The key issues preventing CH2 from realising its potential were found to be in the strategies and commissioning of its HVAC controls. Widespread opportunities for optimising control were observed and could broadly be categorised into three groups: Priority of cooling modes. One way in which CH2 is unlike most buildings is that it has several different ways of generating cooling to provide to the oors. The source of cooling can either be via absoprtion chiller heat recovery

FORUM

350

Pumps 15% Fans 13%

300

250

Chillers 16%

200 kW 150

Oce lighting 12%

Coolin g

towers

4%

100

B as e b u il d in g

PAC units 8% Lifts 3% Car park lighting 1%

Oce equipment 25%

50

:00

:00

:00 18

Chillers

288000 MJ 33300 MJ

0:0

3:0

6:0

9:0

12

15

Miscellaneous 0%

Base building lighting Oce lighting Oce equipment Car park lighting

Lifts PAC units Miscellaneous Cooling towers

Figure 4: Electricity end-use breakdown for a 12-month period (above) and an average business day in summer (right).

Pumps Fans Average summer prole

3500 MJ

Solar PV Utility gas supply 5,133,000 MJ

2607000 MJ 2525000 MJ

Utility electricity supply

3513700 MJ

Miscellaneous 154800 MJ

Total electricity supply 4,165,200 MJ

25200 MJ 648000 MJ 2322000 MJ

Microturbine

Boilers Standing losses Combustion losses

1004400 MJ 658800 MJ

Flue losses

861000 MJ

1098000 MJ

Oce equipment Lighting

HVAC electrical Heat recovery

327600MJ 152000 MJ 115000 MJ 831000 MJ

1500500 MJ

505000 MJ

173000 MJ

Oce lighting Base building lighting Car park lighting Heat rejection

478800 MJ

Fans

122400 MJ

547200 MJ

327600 MJ

Reticulation losses

58500 MJ

Chillers PAC units Field heating

Pumps

637200 MJ

Solar hot water

57600 MJ

162000 MJ

Domestic hot water Shower towers electricity [MJ] gas [MJ] hot water energy [MJ] heat (losses) [MJ] Field cooling Condenser water [MJ] PCM/reticulation losses Chilled water [MJ] Rejected heat [MJ]

Cooling towers

Figure 5: Sankey flow diagram. This diagram demonstrates the flow of energy into the building and throughout its sub-systems. The diversity of energy sources and uses within the building is evident, as well as the degree of energy transfer and heat recovery between the range of sub-systems. Note that thermal energy flows in the CHW and CDW networks are not quantified.

21

:00

t in g ligh 3%

M A R C H 2 0 1 4 E CO L I B R I U M

47

FORUM

from the micro-turbine, the screw chillers, the cooling towers or the shower towers. Production of cooling can either be after-hours and stored within phase-change material (PCM) tanks or delivered directly during occupied hours. Observations of the building through a range of conditions revealed that the system often failed to prioritise the most efcient cooling mode available. This regularly resulted in signicant energy wastage overnight for charging of PCM tanks, which proved to be the issue responsible for the overnight operation (Figure 3). More importantly though, poor consideration of cooling modes meant the building was largely operating without an economy cycle, thus leading to excessive use of the electric chillers. Optimisation of HVAC parameters. A number of the temperature, ow and pressure set-points that the buildings air and water systems were operating to were xed in spite of variable demand conditions. Examples included constantpressure control for chilled water and heating hot water pumps, constant-ow control for air-handler fans, and constant water temperature control for chiller plant condenser water. Tuning of HVAC operation. A range of smaller operational issues were identied that summed up to a reasonable quantity of lost energy for the site. Such issues included general exhaust fans running when not required, car park ventilation fans running irrespective of CO set points, pumps running when there was no heating/cooling within the uid they were circulating, heat exchangers (HEX) opening the primary valve without the secondary valve, and so on. A comprehensive revision of the strategies and commissioning of the HVAC controls was recommended to address these issues, including improved economy cycle operation, vairable set-points for key water and air systems, and a general tightening up of HVAC control to avoid wasteful operation. However, the physical components of a system must be operating reliably for controls measures to achieve their full potential. Observations of CH2s plant suggested the system was generally in good working condition, but there was evidence of a modest range of less visible issues that may have been preventing optimum performance. The majority of these issues were consistent with the usual failure modes of commercial HVAC systems, including air within the water networks, instances of dubious sensor accuracy, valves failing to seal, compromised HEX efciency and poor performance of PCM tanks. A tune-up process was recommended to help mitigate the risk they posed to the performance of the building.

Figure 6: Cooling system operating when free cooling is available from ambient conditions.

corresponding to a wet bulb temperature of approximately 10C. In these cool conditions, the cooling towers are capable of providing sufcient cooling to the building, with no need for the chilled water plant. This opportunity exists for most of winter but was overlooked by the systems control strategy. As noted in the green circles labelled B, there were a number of pumps operating at this time apparently for no purpose. The absorption chiller had faulted out of operation, preventing the cooling system from providing any cooling. However, the failure was not communicated to the pumps, and thus they were each running to circulate roomtemperature water throughout the building.

PCM charging with chilled water

EXAMPLES OF CONTROL OPPORTUNITIES

A series of screenshots from the BMS are presented below with notes against the opportunities they highlight.

Figure 7: Chilled water system operating at 04.00 to charge the PCM tanks.

Erroneous cooling system operation during business hours

Figure 6 demonstrates the buildings cooling system operating on July 27, 2012. The following opportunities for improvement were observed: As noted in the yellow circle labelled A, the outside air conditions at this time were 12.5C and 72%RH,

48

E CO L I B R I U M M A R C H 2 0 1 4

Figure 7 demonstrates the chilled water system operating at 04.00 on November 21, 2012. The chillers were found to be operating overnight to charge the PCM tanks. This operation appeared to occur regularly throughout the shoulder and summer months between the hours of 00.00 and 06.00 on business days. The design intent of the PCM charging process is to take advantage of cool overnight conditions and charge the tanks with the cooling towers to avoid having to use the electric chillers during the day. If the PCM tanks are performing ideally, charging them via the electric chillers overnight should not result in a signicant loss of energy. However, there did appear to be a high level of energy loss associated with this operation.

FORUM

25 20 15 10 5 0

Average internal tank temp PCM charging process PCM discharging process

9:00 AM 2:00 AM 6:00 AM 8:00 AM 4:00 AM 3:00 AM 5:00 AM 7:00 AM 1:00 AM 10:00 AM 12:00 AM 9:00 PM 2:00 PM 6:00 PM 8:00 PM 4:00 PM 3:00 PM 5:00 PM 7:00 PM 1:00 PM 11:00 AM 10:00 PM 12:00 PM 11:00 PM

conditions (18.4C). Heating should not be required in an ofce building with ambient conditions above 18.0C. As circled in yellow and labelled B, the system elected to operate the heat reclaim pump from the condenser water loop to serve the heating needs of the air handlers at this time. However, the temperature of the ow into the HEX, out of the HEX, into the AHUs and out of AHUs was each measured at 19.5C, indicating there was no transfer of heat occurring in the system and thus the pumps were not achieving anything. As circled in green and labelled C, the heating hot water network was engaged at this time. Inspection of the BMS heating demand indicated that the AHU system was registering a demand on the heating hot water plant despite not using the heating hot water.

Temperature (DegC)

Figure 8: PCM charging and discharging process on the 14/11/12 demonstrating the disparity between charging and discharging times.

Logs of the charging and discharging process were plotted against the average tank internal temperature in Figure 8. The following observations were made: While the charging process (signied by the decreasing tank temperature) lasted for approximately ve hours from 00.00 to 05.00, the tanks were fully discharged (signied by increasing tank temperature) after one hour upon start-up. The temperature is continuously decreasing during the charging process. The temperature of a PCM remains constant while the material is undergoing a phase change (changing from liquid to solid). That the tank temperature was continuously decreasing during the charging process implied that there was no phase change within the tank; i.e., the chilled water was merely cooling the material down in its existing phase (most likely liquid). The thermal storage capacity of the tank relies on the materials nature to absorb coolth as it changes from liquid to solid phase; thus the tanks provide minimal storage without the phase-change process.

Constant speed pumping

Figure 10: Constant speed pumping control for heating and cooling systems.

Erroneous operation of heating plant and air-handling plant

Figure 10 presents the operation of heating (in red) and cooling (in blue) reticulation in the building on October 18, 2012. We noted these pumps operating at the same speed across a range of different internal and ambient conditions. Introducing dynamic resets to the pressure set-points was recommended to help them turn down to meet demand, which would also apply more broadly to other air and water systems as well.

MEASURES FOR IMPLEMENTATION

The report was delivered in December 2012, with recommendations made for wholesale revision to the HVAC controls in addition to a suite of hardware tuning items and minor retrots. With budget awarded for FY13/14, at the time of writing the City of Melbourne and Exergy are in the planning phase for implementation of the rst stage of measures. They are presented in Table 3. Figure 11 demonstrates the measures improving the base buildings rating to 4.5 stars. However, it is important to note that the savings were conservatively calculated as what we expected to be available from an install and leave it type approach. We anticipate that an intensive process of monitoring and tuning will reveal greater potential from the buildings existing systems. Crucial to the success of this project will be a functioning sub-metering system to inform a critique of each of the buildings

M A R C H 2 0 1 4 E CO L I B R I U M

Figure 9: Air-handling plant engaging the heating system in mild conditions.

Figure 9 demonstrates the outside air-handling plant operating on October 18, 2012. Several issues were observed with its operation: As circled in red and labelled A, the heating pump had been engaged for the air-handling plant despite the mild ambient

49

FORUM

Measure

% Energy saving

Payback (yrs)

Base building NABERS star impact 1.14

CONCLUSIONS

1. CH2 is currently performing well below its potential due to the state of the HVAC controls. It appears that the complexity associated with the buildings web of relatively unfamiliar sub-systems has led to a range of awed strategies and operational issues. 2. The building is an excellent illustation of the importance of optimising control strategies and commissioning control behaviour for sub-systems, not only individually but also in their operation as a whole system and under numerous scenarios. 3. The building is expected to achieve 4.5 stars NABERS base building performance with the measures currently intended for implementation. Further improvement is expected to be realised with intensive monitoring and tuning. 4. Upgrade of the buildings sub-metering system, combined with a staged process of implementation and measurement is necessary not only to optimise the buildings operation but also to inform the industry on the performance of its more experimental technologies. This review marks the beginning of a project from which much more will hopefully be learnt regarding the performance of its many features.

HVAC controls revision of re-commissioning Upgrade supplementary CDW system to variable ow Optimise after-hours DHW servicing Back-of-house lighting controls Sub-metering verication and monitoring Total

19.7%

5.2

1.4%

9.3

0.13

3.9%

8.1

0.06

0.3%

22

0.02

n/a 25.2%

n/a 7.2

n/a 1.36

FOOTNOTES

1.

Table 3: Short-to-medium term measures for implementation.

National Australian Built Environment Building Rating System, www.nabers.gov.au 2. See annual reports available online for CPA, GPT Group and DEXUS. Each accessed 21/01/2014: http://www.cfsgam.com.au/au/property/cpa/Investor_ Centre/Reports_and_presentations/ http://www.gpt.com.au/Sustainability/Our-Environment/ NABERS-Ratings http://dexus.com/investor/home.aspx

Monitoring and tuning

ACKNOWLEDGMENTS

2.5 3

Existing rating HVAC re-commissioning Optimise after hours DHW servicing Sub-metering and monitoring

3.5 4 4.5 5 Base Building NABERS Energy Rating

HVAC controls revision

5.5

We would like to acknowledge the keen assistance of Michele Leembruggen (Sustainability Branch), Allen McCowan (Property Services) and their colleauges within the City of Melbourne, as well as Matt Waller of Transeld Services and Peter Collins of Schneider Electric.

Upgrade CDW system to variable ow BOH lighting controls

About the authors

Matthew Hoogland, M.AIRAH, is a senior consultant with Exergy Australia based in Melbourne. Email him via matt@xgl.com.au Dr Paul Bannister, M.AIRAH, is the manging director of Exergy Australia, based in Canberra. Email him via paul@xgl.com.au

Figure 11: Base building NABERS improvement path.

features as they are plugged in and out of the control strategy. This process will serve to provide a blueprint for how the buildings complex array of sub-systems can best collaborate with each other. Furthermore, with this information the building will nally be in a position to provide feedback to the industry on the performance of the experimental technologies it features.

You might also like

- Evacuation ReportDocument2 pagesEvacuation ReportSue MengNo ratings yet

- VCCI Best Practice Guide For Tendering and Contract ManagementDocument32 pagesVCCI Best Practice Guide For Tendering and Contract ManagementJOHN MASEFIELDNo ratings yet

- Procurement ProcessDocument9 pagesProcurement ProcessSue MengNo ratings yet

- HBR Strategic HumorDocument2 pagesHBR Strategic HumorSue MengNo ratings yet

- Identified Risks For DeveloperDocument1 pageIdentified Risks For DeveloperSue MengNo ratings yet

- BERDocument14 pagesBERSue MengNo ratings yet

- 271010946Document10 pages271010946Sue MengNo ratings yet

- Pigovian TaxesDocument27 pagesPigovian TaxesSue MengNo ratings yet

- Case Based Allocation of Onsite Supervisory ManpowerDocument20 pagesCase Based Allocation of Onsite Supervisory ManpowerSue MengNo ratings yet

- Merrill PDFDocument5 pagesMerrill PDFSue MengNo ratings yet

- Merrill PDFDocument5 pagesMerrill PDFSue MengNo ratings yet

- 5 WallDocument36 pages5 WallSue MengNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Air Distribution System Vav VRVDocument3 pagesAir Distribution System Vav VRVsiva ramanNo ratings yet

- Ashp 2 EuroklimatDocument3 pagesAshp 2 EuroklimatAmr SallahNo ratings yet

- QCVN 09-2013 National Technical Regulation On Energy Efficiency Buildings (Eng)Document56 pagesQCVN 09-2013 National Technical Regulation On Energy Efficiency Buildings (Eng)Law ArveyNo ratings yet

- Item Designation CoordinatesDocument3 pagesItem Designation CoordinatesKammoeNo ratings yet

- Maytag Service ManualDocument118 pagesMaytag Service ManualLyndonCharles100% (1)

- TE - Mech - RAC - Chapter 4 - VCC Cycles-1Document98 pagesTE - Mech - RAC - Chapter 4 - VCC Cycles-1Aniket MandalNo ratings yet

- Hap Carrier Learning-Part 1Document18 pagesHap Carrier Learning-Part 1alishakibniaNo ratings yet

- Ymfe (24-60) Bnjmcmo(s) - X 14 Seer Solo FrioDocument4 pagesYmfe (24-60) Bnjmcmo(s) - X 14 Seer Solo FrioAb CaamañoNo ratings yet

- Product Data: 40RUA / 40RUSDocument56 pagesProduct Data: 40RUA / 40RUSSergio SaldiviaNo ratings yet

- Heat Exchanger Performance Comparison: Single vs Multi-Pass DesignDocument4 pagesHeat Exchanger Performance Comparison: Single vs Multi-Pass DesignUzair BukhariNo ratings yet

- Mem 202104 e P Series CatalogueDocument36 pagesMem 202104 e P Series CatalogueMatteo TorresNo ratings yet

- Tekmar Thermostat 557 p9335 03Document2 pagesTekmar Thermostat 557 p9335 03api-221502147No ratings yet

- Demand Based VentilationDocument10 pagesDemand Based VentilationSadiya IqbalNo ratings yet

- Load EstimationDocument2 pagesLoad EstimationSourabh SinghNo ratings yet

- R744 Technicians Manual CETIAT GRETHDocument62 pagesR744 Technicians Manual CETIAT GRETHLuis CarlosNo ratings yet

- HVAC Updated Vendor ListDocument3 pagesHVAC Updated Vendor Listramadan rashadNo ratings yet

- Term Paper On Air ConditionerDocument7 pagesTerm Paper On Air Conditionerc5qd4nn8No ratings yet

- Cold Hard FactsDocument85 pagesCold Hard Factspsn_kylmNo ratings yet

- Ashrae - Basic Chiller Plant DesignDocument59 pagesAshrae - Basic Chiller Plant DesignAmro Metwally El Hendawy100% (3)

- Control and condition air with an air handler unitDocument10 pagesControl and condition air with an air handler unitSreekanth MadakaNo ratings yet

- Ice Skating Rink Product GuideDocument8 pagesIce Skating Rink Product GuidecashloverNo ratings yet

- AHU Eurovent ISKID Part 1Document27 pagesAHU Eurovent ISKID Part 1Joaquim MonteiroNo ratings yet

- EWAD-C - Technical Data - PDFDocument56 pagesEWAD-C - Technical Data - PDFAbooaliNo ratings yet

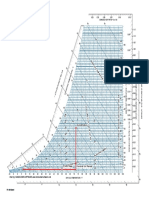

- State Point & Process Report: Psychrometric Chart Psychrometric ChartDocument1 pageState Point & Process Report: Psychrometric Chart Psychrometric ChartLee ChorneyNo ratings yet

- Ventilo-Convecteurs: Console / en AllègeDocument2 pagesVentilo-Convecteurs: Console / en AllègeMed SammarNo ratings yet

- BROAD X Absorption Chiller Model Selection Design ManualDocument46 pagesBROAD X Absorption Chiller Model Selection Design Manualpseudosil0% (1)

- TECS-W IOM ManualDocument60 pagesTECS-W IOM Manualxuyen tran100% (4)

- Aw2 14 - RF28HF 141013Document107 pagesAw2 14 - RF28HF 141013ridapebonNo ratings yet

- Samsung Rt29bvms Rt23bvdr-Bvpw Avms Rt26avpw-Avms Rt31avms-Avpw Rt34avms-Avpw SMDocument22 pagesSamsung Rt29bvms Rt23bvdr-Bvpw Avms Rt26avpw-Avms Rt31avms-Avpw Rt34avms-Avpw SMTANPAMONo ratings yet