Professional Documents

Culture Documents

Bottom Hole Assemblys

Uploaded by

Z Babar KhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bottom Hole Assemblys

Uploaded by

Z Babar KhanCopyright:

Available Formats

Shallow Horizontal Wells In the Gulf of Mexico Consolidated by Tony Pershall with Input from Scott Levad, Gary

Wygul, James Tunnell, & Tim French. Devon s West Cameron 587 project we drilled seven wells, 1500 to 3000 feet TVD & as far out as 6000 feet in Section. The objective was to drill horizontally through these shallow thin gas bearing sands (8 to 20 feet thick) drilling 600of pay. Utilizing the GST, and adapting our drilling practises we were able accomplish all objectives & did so 30% under AFE. All seven wells are producing more that expected, averaging 12 MCF each, 70% more than vertical wells drilled through these sands. In this report I have included Lessons Learned & Best practices from the Directional Drillers responsible for making what we wanted to do on paper work on the rig. (Thanks guys) I ve also included PvS, BHA s, & Slide sheets from one well & some Bragging Graphs that sums up what we were able to accomplish as a Team. Drilling Sidetracking is the most prevalent hazard while drilling. Always exercise extreme caution regarding sidetrack during all drilling operations. Intentional open hole sidetracks can be accomplished with one 20stroke of the BHA at a low side orientation. Never circulate off bottom unless back reaming or moving the pipe with a high side orientation to avoid hole wash out and sidetrack. Never short trip, the risk of sidetrack is too high. Back-ream every connection to improve the condition of the hole and improve hole cleaning. Back-ream connections instead of short tripping. Back ream up and orient to high side to run back to bottom. If you continually carry a high side-chalk mark on the drill pipe, you will save time and avoid hole wash out by not having to wait for MWD T/F sync. Never trip back into open pilot hole with a drilling BHA to avoid sidetrack. If it is necessary to trip into open pilot hole consider opening the hole with a hole opener first. Avoid tripping double-bend GST motors back into any hole size to avoid the chance of sidetrack. Never pump while tripping a drilling BHA into any open hole. If the BHA will not go into the open hole, pull back out and pick up a hole opener BHA. Open the hole to bottom and then pick up the drilling BHA and re-commence drilling. Drill 9 7/8pilot hole for both 17 and 12 . This will yield better directional control and hole cleaning while drilling and less chance of sidetrack while opening the hole. Mud weight must be carefully planned and maintained. The risk of the hole collapsing is just as high as it is of losing circulation. North-seeking electronic gyro tools should only be used to orient and survey when drilling out of the 20conductor. Conventional photomechanical gyro tools that are tied into north by eyeball measurements to a tugboat-compass rig-bow-heading are far too inaccurate. The MWD tool should be run with the gyro-BHA and as soon as it yields an expectable magnetic azimuth and GTF, pull the gyro out of the string.

Plan the drill string so that the HWDP never exceeds 60 degrees of inclination. Do not plan to trip out of the hole to move the HWDP. It may be necessary to pick up the HWDP before planned to get to bottom when tripping through the 9 5/8casing to drill the 8 hole due to the higher coefficient of friction in new casing. In addition when drilling at 1500 to 2000TVD the HWDP should be run so that it is at the top when starting to drill the horizontal section. And if necessary it should be stood back and used to drill when sliding becomes difficult due to lack of available string weight. To achieve DLS, keep weight on the bit at all times by drilling up to 1000 feet per hour. Do not lower the pump rate below 250 gpm in any hole size. Do not stop drilling when changing from sliding to rotating. Spend as little time possible pumping and orienting the BHA before sliding. Record GST at bit inclination measurements every 10 . The DLS achieved on wells so far has been 3/100to 15.5/100 . The 1.83-degree bend standard 6 motor generated 10 /100DLS in the 9 7/8 pilot hole below the 20drive pipe. The 2.12-degree bend standard 6 motor generated 12 /100DLS in the 9 7/8 pilot hole below the 20drive pipe. The 1.50-degree bend standard 6 motor generated 8 /100DLS in the 12 pilot hole below the 20drive pipe. The 1.83-degree bend standard 6 motor generated 8+ /100DLS in the 12 pilot hole below the 20drive pipe. The 1.25-degree bend 6 GST motor generated 9+ /100DLS throughout the 9 7/8pilot hole below the 13 3/8casing. The 1.50-degree bend 6 GST motor generated 12 +/100DLS throughout the 9 7/8pilot hole below the 13 3/8casing. The 1.5-degree fixed plus 0.78-degree adjustable double-bend 6 3/4 GST motor generated 15.5/100' DLS throughout the 9 7/8pilot hole below the 13 3/8casing. The 1.5-degree bend 6 GST motor generated 8+ /100DLS throughout the 8 1/2 production hole below the 9 5/8casing. Hole Opening There should never be any jets in the hole opener below the cutters. All bull-nose jets must be blanked off, regardless of the vendorsrecommendations. Any jet in the bullnose renders the bull-nose ineffective by immediately washing out the extremely soft formations. A jet in the bull-nose end or side will cause a sidetrack. A jet in the side of the bull-nose on well A-15 caused and incidental sidetrack and 100+ feet of new hole was drilled unknowingly in very soft sand. Make all connections on bottom when a hole opener BHA is in the hole. Never pull the bull-nose out of the pilot hole. Drill down to the slip setting depth, stop drilling, don t pick up, set the slips, make the connection, pull up only enough to get the slips out and recommence drilling.

Open the hole at a minimum of 300 feet per hour. Always try to keep a little weight on the bit even if you must drill at 1000 feet per hour. Pump at least 650 gpm. Rotate at 120 RPM. Never rotate if sitting still. Back ream the hole opener out of the hole. Run a full gauge near bit stabilizer immediately behind all hole openers. The full gauge stabilizer will help prevent sidetrack. Also, a full gauge stabilizer will help to fully open the hole at the excessive rates of penetrations require for hole opening operations on these type wells. Spiral-bladed near bit stabilizers will better support the hole opener, do less damage to the well bore wall and have less ability to induce sidetrack in these soft formations than will straight-bladed stabilizers. Casing All casing strings should always be set on bottom prior to cementing. This is to avoid hole troubles seen during well A-18 caused by sloughing and caving cement from the 59' of rat hole left below the 13 3/8" casing. The cement fell down hole and caused two incidental sidetracks and a premature hole opener run. Orienting the deviated drive pipe should only be done with a north-seeking electronic gyro. Conventional photomechanical gyro tools that are tied into north by eyeball measurements to a tugboat-compass rig-bow-heading are far too inaccurate. The deviated drive pipe may walk right or left in azimuth by as much as 45 degrees while being driven. The planned direction of the drive pipe should always take this into consideration for anti-collision. The pipe orientation can not be controlled while it is being driven, except while the pipe is still driving at less than 50 hit per foot, a pad eye can be welded on and tension held with a air tugger which as the pipe is driven can turn the pipe in the desired direction. The four stabilizer bars welded to the bottom 10of the drive pipe shoe must be absolutely straight to help prevent the pipe from walking right or left while it is being driven. The pipe orientation can not be controlled while it is being driven except as mentioned above. The painted scribe lines on the deviated drive pipe must be absolutely straight to avoid mis-orientation before the pipe is driven. All scribe lines should be inspected for straightness with a level-center-finder on the rig prior to picking up the pipe. The 20" drive pipe had a deviated shoe with a 0.4-0.6 degree bend 8 feet behind the shoe. The deviated drive pipe build rates on six wells were: A-18 was 3.12/100 DLS. A-15 was 4.44/100 DLS. A-16 (Q-Slot) was 4.25/100 DLS. A-17 was 4.03/100 DLS. A-8 was 9.47/100DLS (drive pipe kicked off platform structural member) A-9 was 3.19/100DLS

The 20" drive pipe had a deviated shoe with a 0.4-0.6 degree bend 8 feet behind the shoe. The deviated shoe on the 20drive pipe could have a more aggressive bend, 0.8 to 1.2 degrees to yield a greater DLS on future wells. The maximum DLS that 13 3/8casing can be run in without sidetrack is 10/100 . The 13 3/8" casing should have a deviated shoe joint with a 1.0-1.5 degree bend 10 feet behind the shoe to assist getting it bottom in the soft formations when the DLS is greater than 10/100 . Displace the open 12 hole prior to running 9 5/8casing with fresh mud (9% low gravity solids), 2% lubricant and 6#/bbl polymer beads to reduce the coefficient of friction significantly. Torque and drag calculations for 9 7/8casing runs experienced on nonlubricated wells yield a coefficient of friction 0.40. The A-17 well 12 open hole displace yielded a coefficient of friction of 0.285. The lack of solids and the lubrication reduced the friction factor for A-17 by 29%. The cost of the new mud pill was $10,000. Directional Future well-bore planning should include a graduated build rate immediately beneath the drive pipe. The formation at the drive pipe shoe is extremely soft and will not allow the hole-opener or 13-3/8casing to follow an aggressive bend. Always plan the wells with enough cushion to allow one incidental sidetrack. Every incidental sidetrack will cause the loss of at least 3 degrees of inclination and or azimuth turn and the loss of at least 10of TVD. Survey intervals should be no more than 30to insure TVD accuracy. Once the well is horizontal in the target sand, angle can be maintained by weight on bit, flow or ROP. An ROP of 150ft/hr or less will cause a drop in angle, an ROP of 300ft/hr or more will build angle. Except for azimuth or a change in geologic interpolation sliding can be held to a minimum. The drive pipe shoe will rarely end up being at the exact planned bottom hole location. Small inaccuracies in setting-depth, inclination and direction will dramatically effect the forward directional plan to achieve the directional targets. It is absolutely necessary to redesign the well path even when small errors occur with the Drive pipe shoe location. It is necessary to have strong well planning skills on the rig with PowerPlan s Well Design program. A new directional plan should be prepared from every new projected bit location to drill the straightest path to the target (PBHL). This will minimize torque and drag experienced while running the casing and production strings. Always try to optimize the sail angle in the tangent section foremost when redesigning directional plans. Try to conserve TVD footage first to allow the lowest possible sail angle. This will maximize the ability to run casing and production strings. Make azimuth corrections to the new well plans only after inclination, TVD and sail angles have been optimized.

PennzEnergy Exploration & Production, L.L.C.

WELL

OCS-G-02021 Well A-17

FIELD

OG West Cameron Block 587

STRUCTURE

PennzEnergy A-Platform Rowan Paris

Magnetic Parameters Model: BGGM 1999 Dip: 58.259 Mag Dec: 3.386 Date: May 31, 2000 FS: 48107.6 nT

Surface Location Lat: N28 9 40.028 Lon: W93 20 56.194 North: -178153.25 ftUS East: 1350253.06 ftUS Grid Conv: -1.0078 Scale Fact:1.0004

Miscellaneous Slot: P (A-17): A-17 Rev10 tp+jbj 4000' VS Elev Ref: RKB(119.00ft above MSL) Date Drawn: 11:47:45AM 28-Sep-2000

800

1600

2400

3200

4000

4800

PLAN VIEW

Surface Location: North:-178153.25 ftUS, East:1350253.06 ftUS Grid Coord N(+)/S(-) E(+)/W(-) ftUS ftUS -177161.82 1353454.45 -176960.87 1354072.91 MD 349.00 544.34 544.35 855.01 855.02 1381.66 4036.83 4246.20 4251.59 4901.59 INCL 0.00 5.86 5.86 29.02 29.02 81.41 81.41 89.78 90.00 90.00 AZIM 120.0 120.0 120.0 79.2 79.2 72.0 72.0 72.0 72.0 72.0 NAD27 Louisiana State Planes, Southern Zone, US Feet Local Cooord VSEC N(+)/S(-) E(+)/W(-) Shape ft ft ft 3349.62 991.00 3200.00 Point 3999.62 1191.86 3818.19 Point VSEC N(+)/S(-) E(+)/W(-) 0.00 0.00 0.00 6.68 -4.99 8.64 6.68 -4.99 8.64 93.41 1.28 97.80 93.42 1.28 97.81 510.28 113.67 499.60 3135.66 924.89 2996.52 3344.23 989.33 3194.87 3349.62 991.00 3200.00 3999.62 1191.86 3818.19

Scale (1 in = 800 feet)

1600

Major Axis

Target Name AL Sand Heel AL Sand Toe Critical Points Mud Line, Begin 3 20" Casing Point KOP Begin 8.00/1 13 3/8" Casing Po Begin 10.00/100' Begin 81.41 Late Begin 4.00/100' 9 5/8" Casing Poi AL Sand Heel PBHL/TD

TVD ft 1542.00 1574.00 TVD 349.00 544.00 544.01 839.00 839.01 1129.33 1525.93 1541.99 1542.00 1542.00

AL Sand Toe PBHL/TD

DLS 0.00 3.00 3.00 8.00 8.00 10.00 0.00 4.00 4.00 0.00

800

9 5/8'' Casing Point

.00 th 72 zimu A ld Ho

20'' Casing Point

Vertical Section View

0

Mud Line, Begin 3.00/100' Deviated Drive Pipe

Build and Turn 8.00/100 ft

13 3/8'' Casing Point

500

True Vertical Depth (1 in = 500 feet) Elev Ref: RKB(119.00ft above MSL)

20'' Casing Point5.86 544 MD KOP Begin 8.00/100' Build & Turn

13 3/8'' Casing Point 29.02 855 MD Begin 10.00/100' Build & Turn

Proposal Survey

1000

Begin 81.41 Lateral81.41 1382 MD

Quality Control Date Drawn:28-Sep-2000 Drawn by:Tony Pershall Checked by: ______________ Client OK: ______________

1500

9 5/8'' Casing Point89.78 4246 MD PBHL/TD 90.00 4902 MD AL Sand Heel AL Sand Toe

500

1000

1500

2000

2500

3000

3500

4000

4500

Vertical Section Departure at 72.00 deg from (0.0, 0.0). (1 in = 500 feet)

Bottom Hole Assembly #1

Client DEVON Energy Well lease OCS-G-02021 Well A-17 OH Location West Cameron Block 587

Description Bit Bit GT-1; TFA= .79 Cross Over Sub Bit # 1 Vendor HTC Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill ROWAN ROWAN Serial # P05YC MBS-80295 675-01152 XOS-60115 672-MC XOS-70199 MDC-925 DY-243 MSS-60003 NMF-60054 NMF-60058 9HWDP DP OD/ID 12 1/4 4 x 16 6 3/4x7 23/4 1/4 6 3/4 Tool 6 1/2 3 1/2 6 3/4 2 7/8 6 3/4 2 3/4 6 3/4 Tool 7 3 1/4 6 1/2 3 6 3/4x5 2 7/8 6 3/4x5 2 7/8 5 3 5 4.276 Connections 6 5/8 REG 6 5/8 REG 4 1/2 REG 4 1/2 REG 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 5 1/2 FH 5 1/2 FH 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF PIN BOX PIN BOX BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX

Job Number IN Depth Date Rig F.N.

40004739

OUT

349 853 5/13/00 5/13/00 ROWAN Paris

Blade Length 1.00 1.05 12 1/8 19.99 1.68 9.38 2.69 27.31 3.12 2.62 Cumulated 1.00 2.05 22.04 23.72 33.10 35.79 63.10 66.22 68.84 99.81 130.72 401.73 401.73

.30 14.84

A675M Power Pak w/ 1.83 Bend 7/8 R/S; Nozzle= Float Sub None Non-Mag Pony Collar Cross Over Sub MWD Tool Filter Sub UBHO Sub NM Flex Collar NM Flex Collar 9 Jnts HWDP (5 ) G DP 5to Surface

3.30 3.30

30.97 30.91 271.01

WOB GPM RPM Torque BH Temp PSI Off/On

MIN 2 300 30 30 500

MAX 15 300 60 80 700

Drilling Parameters

BHA Type Formation Stab. Spacing Directional Driller Drill / Circ Hrs Inc In/Out Azimuth In/Out Build/Walk Rate Clearance In/Out Bit Wear Grade Steerable Gumbo & Sand Scott Levad Mike Felder Mud Type Mud Wt./ Visc. PV / YP % Solid / Sand Chlorides Spud Mud 9.4 42 6 25 7 Tr 1000 HookLoad 98 Pick Up Wt. 100 Slack Off Wt. 96 Wt. Below Jars -376,781 Wt. Above Jars Total Air Wt. -436,091 7/8 1.83 No

Sliding Rotating Footage 245 88 % 73.57% 26.43% Hours 0:00:00 ROP ? ? IADC 111 Max DLS 7.4

Performance

4.50 4.50 22.03 107.10 Rotor Jet Bit to Bend PDM Fail? Trip Reason Hrs Lost PDM 1-1-WT-A-E-1/8-NO-TD None 5.8 No TD None Pwr Sect/RS Reg Bends / ABH 1.83 Brg Lube/Dump Mud DP Size 5 DP Conn 4 1/2 IF DP Grade G-105

Purpose: Directional drill 12 1/4pilot hole to csg pnt. Comments: Bit to MWD survey: 52 Bit to Gyro : 79.

Good run. BHA yielded 8/100DLS sliding.

Version 4.1

Slide Sheet for BHA #1

Client DEVON Energy Well lease OCS-G-02021 Well A-17 Location West Cameron

Date S/R From To Tool Face

Job Number

40004739

#587

Footage Slide Rotate

BHA Type Steerable Bit Description Bit GT-1; TFA= .79 PDM Description 675-01152

Survey Inc Azi WOB RPM GPM

Rig ROWAN Paris Directional Scott Levad Drillers Mike Felder

Torque PSI Off PSI On

MD

DLS

Comments Clean 20DP

5/13/2000 R S R S R S R S R S R S R S 520 530 570 591 629 638 660 686 724 734 772 774 824 834 530 570 591 629 638 660 686 724 734 772 774 824 834 853 10 30L 30L 35L 20L 5L 30L 30L 40 21 38 9 22 26 38 10 38 2 50 10 19

415.0

2.50

117.00

3.80

510.0

6.50

107.00

4.30

605.0

11.75

101.00

5.60

723.0 753.2 801.0

16.47 18.58 22.03

110.23 109.17 107.10

4.40 7.10 7.40

2 5 5 5 5 5 5 5 5 3 5 3 10 3 15

25 25 25 60 60 60 60 60

300 300 300 300 300 300 300 300 300 300 300 300 300 300 300

20 20 20 50 50 50 50 50

500 500 500 500 500 500 500 500 500 500 500 500 500 500 500

500 550 550 550 550 550 650 550 600 550 600 550 650 550 700

Avg. Slide Avg. Rotate

35.00 12.57

Total %

245 73.6%

88 26.4%

MIN MAX Comments

2 15

25 60

300 300

20 50

Drill the 12 1/4pilot hole to 13 3/8csg pnt.

Version 4.1

Page 1

Bottom Hole Assembly #2

Client DEVON Energy Well lease OCS-G-02021 Well A-17 OH Location West Cameron Block 587

Description Bull Nose 17 1/2Hole Opener 16 1/2Stabilizer NM Flex Collar NM Flex Collar 9 Jnts HWDP (5 ) Bit # Vendor Smith Smith Smith Anadrill Anadrill ROWAN Serial # N/A 46078 C 28059 NMF-60054 NMF-60058 9HWDP OD/ID 7 11/16 2 7/8 8 2 7/8 8 1/2 2 7/8 6 3/4x5 2 7/8 6 3/4x5 2 7/8 5 3 Connections 6 5/8 REG 6 5/8 REG 6 5/8 REG 6 5/8 REG 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF PIN BOX PIN BOX BOX PIN BOX PIN BOX PIN BOX

Job Number IN Depth Date Rig F.N.

40004739

OUT

349 853 5/13/00 5/13/00 ROWAN Paris

Blade Length 3.45 4.32 18.62 30.97 30.91 271.01 Cumulated 3.45 7.77 26.39 57.36 88.27 359.28

Jet=3x20 2.00 6 5/8 3.30 3.30 16 1/2

WOB GPM RPM Torque BH Temp PSI Off/On Footage % Hours ROP IADC Max DLS

MIN 1 600 130 80 700 Sliding

MAX 10 600 130 80 700 Rotating 504 100.00% ? HO

Drilling Parameters

BHA Type Formation Stab. Spacing Directional Driller Drill / Circ Hrs Inc In/Out Azimuth In/Out Build/Walk Rate Clearance In/Out Bit Wear Grade Hole opener Gumbo & Sand Scott Levad Mike Felder Mud Type Mud Wt./ Visc. PV / YP % Solid / Sand Chlorides Spud Mud 9.4 42 6 25 7 Tr 1000 HookLoad 95 Pick Up Wt. 95 Slack Off Wt. 95 Wt. Below Jars -774,677 Wt. Above Jars Total Air Wt. -899,803

Performance

Rotor Jet Bit to Bend PDM Fail? Trip Reason Hrs Lost PDM 1-1-WT-A-E-N-NO-TD Pwr Sect/RS Bends / ABH Brg Lube/Dump DP Size 5 DP Conn 4 1/2 IF DP Grade S-135

TD

Purpose: Open 12 1/4Hole to 17 1/2for 13 3/8Caseing Run. Comments: Good run.

Version 4.1

Bottom Hole Assembly #3

Client DEVON Energy Well lease OCS-G-02021 Well A-17 OH Location West Cameron Block 587

Description Bit # 9-7/8 9-7/8 Bit Bit 2 MX-C1; TFA= .79 Bit Cross Over Sub A675M - GST w/ 1.5 Bend 7/8 R/S; Nozzle= None Float Sub Cross Over Sub Receiver Sub CDR Tool MWD Tool Filter Sub NM Flex Collar NM Flex Collar 90 Jnts. G DP 5 9 Jnts HWDP (5 ) Jars (Hyd/Mech) 20Jnts HWDP (5 ) G DP 5to Surface Vendor HTC Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill ROWAN ROWAN Griffith ROWAN ROWAN Serial # B20ZA MBS-80328 675-01441 XOS-60115 XOS-70199 006 7139 MDC-925 DY-243 NMF-60054 NMF-60058 90DP 9HWDP 4746758900 20HWDP DP OD/ID 9 7/8 7 3/4 2 1/4 6 3/4 Tool 6 1/2 3 1/2 6 3/4 2 3/4 6 7/8 Tool 6 7/8 Tool 6 3/4 Tool 7 3 1/4 6 3/4x5 2 7/8 6 3/4x5 2 7/8 5 4.276 5 3 6 1/2 2 3/4 5 3 5 4.276 Connections 6 5/8 REG 6 5/8 REG 4 1/2 REG 4 1/2 REG 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 5 1/2 FH 5 1/2 FH 5 1/2 FH 5 1/2 FH 5 1/2 FH 5 1/2 FH 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF PIN BOX PIN BOX BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX

Job Number IN Depth Date Rig F.N.

40004739

OUT

853 4368 5/15/00 5/17/00 ROWAN Paris

Blade jets = 4 x 16 Length 1.00 1.08 9 3/4 28.95 1.68 2.69 5.52 22.42 27.31 3.12 Cumulated 1.00 2.08 31.03 32.71 35.40 40.92 63.34 90.65 93.77 124.74 155.65 2980.12 3251.13 3283.43 3886.41 3886.41

3.30 3.30

30.97 30.91 2824.47 271.01

1.81

32.30 602.98

WOB GPM RPM Torque BH Temp PSI Off/On

MIN 8 300 60 80 700

MAX 20 450 100 150 1,700

Drilling Parameters

BHA Type Formation Stab. Spacing Directional Driller Steerable Gumbo & Sand Scott Levad Mike Felder Mud Type Spud Mud Mud Wt./ Visc. 10.0 40 PV / YP 9 17 % Solid / Sand 9 .25 Chlorides 10000 None 5.25 No TD None HookLoad Pick Up Wt. Slack Off Wt. Wt. Below Jars Wt. Above Jars Total Air Wt. 110 120 100 67,100 24,660 106,581 7/8 1.5 No

Sliding Rotating Footage 1047 2468 % 29.79% 70.21% Hours 0:00:00 ROP ? ? IADC 117 Max DLS 11.42

Performance

Drill / Circ Hrs 35.50 Inc In/Out 25.51 Azimuth In/Out 106.20 Build/Walk Rate Clearance In/Out 0.12 Bit Wear Grade 11.00 86.90 67.22 Rotor Jet Bit to Bend PDM Fail? Trip Reason Hrs Lost PDM 1-1-WT-A-E-N-NO-TD Pwr Sect/RS Reg Bends / ABH 1.5 Brg Lube/Dump Mud DP Size 5 DP Conn 4 1/2 IF DP Grade G-105

Purpose: Build @ 10/100to 82.18 then drill Tangent Section and finnish off @ 4/100to 89.78 Latteral Point. Comments: Bit to M10 Survey = 76.63/ Bit to GST Gamma = 9.20/ Bit to GST Resistivity = 5.31

Good Run. Landed Objective Sand.

Version 4.1

Slide Sheet for BHA #3

Client DEVON Energy Well lease OCS-G-02021 Well A-17 Location West Cameron

Date S/R From To Tool Face

Job Number

40004739

#587

Footage Slide Rotate

BHA Type Steerable Bit Description 9-7/8Bit MX-C1; TFA= .79 PDM Description 675-01441

Survey Inc Azi WOB RPM GPM

Rig ROWAN Paris Directional Scott Levad Drillers Mike Felder

Torque PSI Off PSI On

MD

DLS

Comments

5/15/2000 S S S S S R S R S R S R S S R S R S R S R S S S R S Avg. Slide Avg. Rotate

9 7/8pilot hole.

853 863 905 943 975 1000 1005 1035 1038 1064 1069 1094 1101 1131 1160 1163 1227 1230 1280 1286 1312 1317 1440 1495 1561 1568 26.85 50.37

863 905 943 975 1000 1005 1035 1038 1064 1069 1094 1101 1131 1160 1163 1227 1230 1280 1286 1312 1317 1440 1495 1561 1568 1600

20L 20L 20L 15L 15L 20L 20L 25L 15L 25L 25L 28L 25L 30L 90L 100L 120L Total %

10 42 38 32 25 5 30 3 26 5 25 7 30 29 3 64 3 50 6 26 5 123 55 66 7 32 1047 29.8% 2468 70.2%

919.9

31.38

105.95

10.45

1014.8

41.95

102.58

11.34

1109.2

51.56

99.54

10.44

1201.4

61.73

96.30

11.42

1292.2 1387.2 1481.5

71.00 78.54 83.58

94.12 91.91 88.33

10.44 8.25 6.52

1576.0

84.61

81.18

7.61 MIN MAX

10 10 10 15 15 8 20 8 20 8 20 8 20 20 8 20 8 12 8 12 8 20 20 20 8 12 5 25

60 60 60 60

60 60 60 60

60 50 100

300 300 300 300 300 300 300 300 300 300 300 300 350 350 350 350 350 350 350 350 350 350 350 350 350 350 300 450

80 80 80 80

80 80 80 80

80 80 150

600 600 600 600 600 550 600 550 600 600 600 600 800 800 800 800 800 800 800 800 800 800 800 800 800 800

700 700 700 700 700 700 750 700 750 750 750 750 900 900 900 900 900 900 900 900 900 900 900 900 900 900

Comments

Version 4.1

Page 1

Slide Sheet for BHA #3

Client DEVON Energy Well lease OCS-G-02021 Well A-17 Location West Cameron

Date S/R From To Tool Face

Job Number

40004739

#587

Footage Slide Rotate

BHA Type Steerable Bit Description 9-7/8Bit MX-C1; TFA= .79 PDM Description 675-01441

Survey Inc Azi WOB RPM GPM

Rig ROWAN Paris Directional Scott Levad Drillers Mike Felder

Torque PSI Off PSI On

MD

DLS

Comments

S R S R S R 5-15-2000 S 5-16-2000 R S R S R S R R S S R R S R R S R S R Avg. Slide Avg. Rotate

9 7/8pilot hole.

1568 1600 1610 1631 1641 1663 1673 1694 1705 1725 1736 1757 1767 1782 1851 1881 1891 1906 1943 2030 2038 2125 2195 2210 2221 2228 26.85 50.37

1600 1610 1631 1641 1663 1673 1694 1705 1725 1736 1757 1767 1782 1851 1881 1891 1906 1943 2030 2038 2125 2195 2210 2221 2228 2317

120L 120L 120L 90L 90L 85L 88L

32 10 21 10 22 10 21 11 20 11 21 10 15 69 30

1576.0

84.61

81.18

7.61

1672.2

82.60

75.69

6.04

1765.1

82.30

70.32

5.74

1856.9

81.11

69.66

1.48

60L 90L

10 15 37 87 1951.4 2046.5 2143.0 81.63 82.27 81.37 66.52 66.58 66.38 3.33 0.68 0.95

5R

8 87 70

10R 20R Total %

15 11 7 1047 29.8% 89 2468 70.2% 2237.2 83.16 67.98 2.54 MIN MAX

12 8 12 8 12 8 10 8 10 6 12 6 12 6 10 10 12 8 12 10 12 12 12 12 12 10 5 25

60 60 60 60 60 60 60 60

60 60 50 50 50 100 50 100

350 350 350 350 350 350 350 350 350 350 350 350 350 350 350 350 350 300 300 300 300 300 300 300 300 300 300 450

80 80 80 80 80 80 80 80

90 90 100 100 100 100 80 150

800 800 800 800 800 800 800 800 800 800 800 800 800 800 900 900 900 700 700 700 700 700 700 700 700 700

900 900 900 900 900 900 900 900 900 900 900 900 900 900 1000 1000 1000 800 800 800 800 800 800 800 800 800

1694 @ MN

Comments

Version 4.1

Page 2

Slide Sheet for BHA #3

Client DEVON Energy Well lease OCS-G-02021 Well A-17 Location West Cameron

Date S/R From To Tool Face

Job Number

40004739

#587

Footage Slide Rotate

BHA Type Steerable Bit Description 9-7/8Bit MX-C1; TFA= .79 PDM Description 675-01441

Survey Inc Azi WOB RPM GPM

Rig ROWAN Paris Directional Scott Levad Drillers Mike Felder

Torque PSI Off PSI On

MD

DLS

Comments

R R R R S R R S R R R R S R R R R S R R S R R S R S Avg. Slide Avg. Rotate

9 7/8pilot hole.

2228 2317 2412 2507 2598 2618 2693 2787 2802 2882 2975 3065 3156 3171 3242 3338 3428 3519 3539 3609 3699 3716 3790 3880 3900 3975 26.85 50.37

2317 2412 2507 2598 2618 2693 2787 2802 2882 2975 3065 3156 3171 3242 3338 3428 3519 3539 3609 3699 3716 3790 3880 3900 3975 3990

89 95 95 91 35L 20 75 94 HS 15 80 93 90 91 95L 15 71 96 90 91 65L 20 70 90 17 74 90 HS HS Total % 20 75 15 1047 29.8% 2468 70.2%

2237.2 2331.3 2424.5 2517.3 2611.0 2707.1 2800.9 2893.5 2984.2 3071.5 3162.0 3258.5 3350.0 3441.3 3529.9 3621.2 3711.4 3803.0 3897.3 3990.0

83.16 82.56 81.69 81.31 82.27 81.86 83.13 83.28 82.91 82.76 83.05 82.93 81.77 81.18 82.07 82.51 81.26 80.47 81.46 82.73

67.98 67.98 68.46 68.70 68.14 66.79 67.87 68.35 68.62 68.95 67.84 67.60 67.90 67.96 66.68 66.47 65.62 65.42 65.74 65.66

2.54 2.54 1.06 0.48 1.18 1.46 1.77 0.54 0.50 0.41 1.26 0.72 1.31 0.65 1.75 0.53 1.67 0.89 1.10 1.37 MIN MAX

10 8 10 10 15 10 10 15 8 8 8 8 20 5 8 10 10 25 10 5 20 5 10 20 12 20 5 25

100 60 60 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 50 100

300 300 300 450 300 450 450 300 450 450 450 450 300 450 450 450 450 300 450 450 300 450 450 300 450 450 300 450

100 100 120 120 120 150 150 150 150 150 150 150 150 150 150 150 150 150 150 80 150

700 800 800 1350 700 1400 1400 800 1400 1400 1400 1400 800 1500 1500 1600 1600 850 1600 1600 850 1600 1600 850 1600 1600

800 900 900 1450 800 1500 1500 900 1500 1500 1500 1500 950 1600 1600 1700 1700 1000 1700 1700 1000 1700 1700 950 1700 1700

Comments

Version 4.1

Page 3

Slide Sheet for BHA #3

Client DEVON Energy Well lease OCS-G-02021 Well A-17 Location West Cameron

Date S/R From To Tool Face

Job Number

40004739

#587

Footage Slide

BHA Type Steerable Bit Description 9-7/8Bit MX-C1; TFA= .79 PDM Description 675-01441

Survey Inc Azi WOB RPM GPM

Rig ROWAN Paris Directional Scott Levad Drillers Mike Felder

Torque PSI Off PSI On

S R R R S R S R S R S R R

3975 3990 4068 4161 4230 4240 4262 4274 4294 4307 4324 4336 4348

3990 4068 4161 4230 4240 4262 4274 4294 4307 4324 4336 4348 4368

HS

15

Rotate

MD

DLS

Comments

3990.0 4083.3 4177.4

82.73 82.58 82.41

65.66 65.86 66.23

1.37 0.27 0.43

78 93 69 HS HS HS HS 10 22 12 20 13 17 12 12 20

4270.5 4291.7

84.08 85.07

67.08 67.22

2.01 4.72

20 12 12 12 20 12 20 12 20 12 20 12 12

100 100 100 100 100 100 100 100

450 450 450 320 320 320 320 320 320 320 320 320 320

150 150 150 150 150 150 150 150

1600 1600 1600 950 950 950 950 950 950 950 950 950 950

1700 1700 1700 1050 1050 1050 1050 1050 1050 1050 1050 1050 1050

TD f/ 9 5/8 csg.

Avg. Slide Avg. Rotate

9 7/8pilot hole.

26.85 50.37

Total %

1047 29.8%

2468 70.2%

MIN MAX Comments

5 25

50 100

300 450

80 150

Version 4.1

Page 4

Bottom Hole Assembly #4

Client DEVON Energy Well lease OCS-G-02021 Well A-17 OH Location West Cameron Block 587

Description Bit # 12 1/4 12 1/4 Hole Hole Opener Opener 3-cutter; TFA= 1.33 12 1/4Near Bit Stabilizer Cross Over Sub NM Flex Collar NM Flex Collar 90 Jnts. G DP 5 9 Jnts HWDP (5 ) Jars (Hyd/Mech) 20Jnts HWDP (5 ) G DP 5to Surface Vendor Jets = 3x16 & 3x18 Anadrill Anadrill Anadrill Anadrill ROWAN ROWAN Griffith ROWAN ROWAN Serial # HOC-333 775369 XOS-80129 NMF-60054 NMF-60058 90DP 9HWDP 4746758900 20HWDP DP OD/ID 8 2 7/8 7 7/8 2 7/8 8 2 7/8 6 3/4x5 2 7/8 6 3/4x5 2 7/8 5 4.276 5 3 6 1/2 2 3/4 5 3 5 4.276 Connections 6 5/8 REG 6 5/8 REG 6 5/8 REG 6 5/8 REG 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF PIN BOX PIN BOX BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX

Job Number IN Depth Date Rig F.N. 0.78 2.07 1.51 3.30 3.30

40004739

OUT

800 4368 5/17/00 5/18/00 ROWAN Paris

Blade Length 6.27 4.70 3.00 30.97 30.91 2824.47 271.01 Cumulated 6.27 10.97 13.97 44.94 75.85 2900.32 3171.33 3203.63 3806.61 3806.61

12 1/4

1.81

32.30 602.98

WOB GPM RPM Torque BH Temp PSI Off/On Footage % Hours ROP IADC Max DLS

MIN 1 800 120 150 1,950 Sliding

MAX 6 800 120 150 1,950 Rotating 3568 100.00% ? HO

Drilling Parameters

BHA Type Formation Stab. Spacing Directional Driller Drill / Circ Hrs Inc In/Out Azimuth In/Out Build/Walk Rate Clearance In/Out Bit Wear Grade Hole Opener Gumbo & Sand Scott Levad Mike Felder Mud Type Spud Mud Mud Wt./ Visc. 10.0 40 PV / YP 9 17 % Solid / Sand 9 .25 Chlorides 10000 HookLoad Pick Up Wt. Slack Off Wt. Wt. Below Jars Wt. Above Jars Total Air Wt. 110 120 100 83,985 97,378

Performance

Rotor Jet Bit to Bend PDM Fail? Trip Reason Hrs Lost PDM 2-2-WT-A-E-N-PN-TD Pwr Sect/RS Bends / ABH Brg Lube/Dump DP Size 5 DP Conn 4 1/2 IF DP Grade G-105

TD

Purpose: Open 9 7/8Pilot Hole to 12 1/4 Comments: Good run

Version 4.1

Bottom Hole Assembly #5

Client DEVON Energy Well lease OCS-G-02021 Well A-17 OH Location West Cameron Block 587

Description Bit # Milled Milled Tooth Tooth Bit Bit 3 GT-MG1; TFA= .52 A675M - GST w/ 1.25 Bend 7/8 R/S; Nozzle= None Float Sub Cross Over Sub Receiver Sub CDR Tool MWD Tool Filter Sub NM Flex Collar NM Flex Collar 126 Jnts. G DP 5 30 Jnts HWDP (5 ) G DP 5to Surface Vendor HTC Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill Anadrill ROWAN ROWAN ROWAN Serial # Y23XL 675-1135 XOS-60115 XOS-70199 006 7139 MDC-925 DY-243 NMF-60054 NMF-60058 126DP 30HWDP DP OD/ID 8 1/2 6 3/4 Tool 6 1/2 3 1/2 6 3/4 2 3/4 6 7/8 Tool 6 3/4 Tool 6 3/4 Tool 7 3 1/4 6 3/4x5 2 7/8 6 3/4x5 2 7/8 5 4.276 5 3 5 4.276 Connections 4 1/2 REG 4 1/2 REG 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 5 1/2 FH 5 1/2 FH 5 1/2 FH 5 1/2 FH 5 1/2 FH 5 1/2 FH 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF 4 1/2 IF PIN BOX BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX PIN BOX

Job Number IN Depth Date Rig F.N.

40004739

OUT

4368 5450 6/3/00 6/4/00 ROWAN Paris

Blade Jets= 3x15 8 3/8 Length 0.80 29.15 1.68 2.69 5.52 22.42 27.31 3.12 Cumulated 0.80 29.95 31.63 34.32 39.84 62.26 89.57 92.69 123.66 154.57 4109.81 5014.05 5014.05

3.30 3.30

30.97 30.91 3955.24 904.24

WOB GPM RPM Torque BH Temp PSI Off/On Footage % Hours ROP IADC Max DLS

MIN 6 344 50 280 1,550 Sliding 17 1.57% ?

MAX 35 442 50 400 1,650 Rotating 1065 98.43% 0:00:00 ? 117 3.35

Drilling Parameters

BHA Type Formation Stab. Spacing Directional Driller Drill / Circ Hrs Inc In/Out Azimuth In/Out Build/Walk Rate Clearance In/Out Bit Wear Grade Steerable Sand G. Wiygul Mike Felder Mud Type Thixsal Plus Mud Wt./ Visc. 10.4 48 PV / YP 19 28 % Solid / Sand 14 tr Chlorides 216000 None 4.25 No TD None HookLoad Pick Up Wt. Slack Off Wt. Wt. Below Jars Wt. Above Jars Total Air Wt. 115 165 75 107,209 124,747 7/8 1.25 No

Performance

10.00 85.07 67.22 Rotor Jet Bit to Bend PDM Fail? Trip Reason Hrs Lost PDM 2-2-WT-A-E-1/16-NO-TD 7.00 90.89 69.90 Pwr Sect/RS Reg Bends / ABH 1.25 Brg Lube/Dump Mud DP Size 5 DP Conn 4 1/2 IF DP Grade G-105

Purpose: Drill lateral. Comments: Bit to: GST Res=4.15/ GST GR=8.55/ GST incl=9.25/// CDR Res=45.53 / CDR GR=56.53 / MWD Dir&Incl=75.55

Good Run, Made 2 slides on the complete run. Able to control inclination with weight on bit and pump volume.

Version 4.1

Slide Sheet for BHA #5

Client DEVON Energy Well lease OCS-G-02021 Well A-17 Location West Cameron

Date S/R From To Tool Face

Job Number

40004739

#587

Footage Slide Rotate

BHA Type Steerable Bit Description Milled Tooth Bit GT-MG1; TFA= .52 PDM Description 675-1135

Survey Inc Azi WOB RPM GPM

Rig ROWAN Paris Directional G. Wiygul Drillers Mike Felder

Torque PSI Off PSI On

MD

DLS

Comments

6-4-2000

R S R R R R S R R R R R R R R R R R R R R R R R R R Avg. Slide

4368 4373 4383 4413 4424 4445 4465 4472 4609 4619 4688 4735 4807 4826 4838 4917 4984 5007 5020 5068 5101 5150 5166 5225 5291 5302 8.50 42.60

4373 4383 4413 4424 4445 4465 4472 4609 4619 4688 4735 4807 4826 4838 4917 4984 5007 5020 5068 5101 5150 5166 5225 5291 5302 5385

5 O HS 10 30 11 21 20 180 7 137 10 69 47 72 19 12 79 67 23 13 48 33 49 16 59 66 11 83 1065 98.4% 4485.2 4576.5 4666.9 4757.4 89.51 89.31 89.05 88.94 67.36 67.72 67.95 68.20 0.45 0.45 0.38 0.30 4424.7 89.51 67.63 3.35

4847.6 4938.5

89.63 90.11

69.06 69.23

1.22 0.56

5032.6 5127.4 5221.2 5317.0 5365.5

90.03 90.29 90.89 90.86 90.89

69.45 69.47 69.83 69.96 69.90

0.25 0.28 0.75 0.14 0.14 MIN MAX

Avg. Rotate

Total %

17 1.6%

20 30 16 10 10 8 35 6 8 8 8 18 12 10 18 10 14 18 18 10 16 10 18 12 12 16 6 35

50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50 50

369 364 344 369 393 442 393 393 418 442 393 369 442 442 369 432 432 369 418 418 393 423 393 418 403 418 344 442

400 300 300 300 300 300 280 280 280 330 300 320 360 340 340 320 360 360 380 300 360 340 340 360 280 400

1250 1200 1150 1300 1300 1650 1400 1400 1550 1675 1475 1300 1800 1800 1375 1750 1750 1350 1700 1700 1500 1750 1550 1750 1650 1750

1300 1250 1250 1350 1350 1725 1450 1450 1600 1725 1525 1400 1850 1850 1500 1800 1850 1500 1800 1750 1650 1800 1650 1800 1700 1825

Comments

Version 4.1

Page 1

West Cameron Horizontal Time Comparison

40.0 200.0

Planned Cumulative Planned

35.0

Actual Cumulative Actual

175.0

30.0 Drill and Completion Time, days

150.0 Cumulative Project Time, days

25.0

125.0

20.0

100.0

15.0

75.0

10.0

50.0

5.0

25.0

0.0 Total Well A-11 Total Well A-12 Total Well A-8 Total Well A-9 Total Well A-15 Total Well A-16 Total Well A-17

0.0

West Cameron Horizantal TVD vs Vertical Section Comparison

0 0

1000

2000

3000

4000

5000

6000

7000

500

3 to 1 ratio 2 to 1 ratio

1000

1500

2000

2500

3000

3500

You might also like

- ZohaiB CV Shabbir SBDocument3 pagesZohaiB CV Shabbir SBZ Babar KhanNo ratings yet

- Supply Chain Management Assignment-1Document2 pagesSupply Chain Management Assignment-1Z Babar KhanNo ratings yet

- Sets and Numbering Systems Topic 1Document6 pagesSets and Numbering Systems Topic 1Z Babar KhanNo ratings yet

- Roller Cone Bit GeometryDocument7 pagesRoller Cone Bit GeometryZ Babar KhanNo ratings yet

- Questions WellcontrolDocument10 pagesQuestions WellcontrolZ Babar KhanNo ratings yet

- Bab 1111Document1 pageBab 1111Z Babar KhanNo ratings yet

- Rock Failure MechanismsDocument11 pagesRock Failure MechanismsZ Babar KhanNo ratings yet

- Ofs Permit To Work FormDocument2 pagesOfs Permit To Work FormZ Babar KhanNo ratings yet

- PDC Cutters InfoDocument3 pagesPDC Cutters InfoZ Babar KhanNo ratings yet

- Parenting AdvantageDocument14 pagesParenting AdvantageZ Babar Khan100% (2)

- Training Couses CatalogueDocument99 pagesTraining Couses CatalogueZ Babar KhanNo ratings yet

- Bit Types and Iadc ClassificationsDocument11 pagesBit Types and Iadc ClassificationsZ Babar KhanNo ratings yet

- Dusel: Working Group #9 Preliminary OutlineDocument15 pagesDusel: Working Group #9 Preliminary OutlineZ Babar KhanNo ratings yet

- Competing On The EdgeDocument6 pagesCompeting On The EdgeZ Babar KhanNo ratings yet

- Marion V Williams: Foreign Exchange Reserves - How Much Is Enough?Document12 pagesMarion V Williams: Foreign Exchange Reserves - How Much Is Enough?Z Babar KhanNo ratings yet

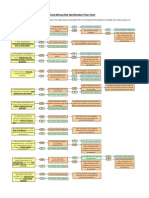

- Coal Mining Risk Identification Flow ChartDocument1 pageCoal Mining Risk Identification Flow ChartZ Babar Khan100% (1)

- MBL 915 Assignment 2 FinalDocument19 pagesMBL 915 Assignment 2 FinalZ Babar KhanNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CN101A Timer ManualDocument2 pagesCN101A Timer ManualMauricioVilalvaJr.0% (1)

- Cell Biology: Science Explorer - Cells and HeredityDocument242 pagesCell Biology: Science Explorer - Cells and HeredityZeinab ElkholyNo ratings yet

- Entity Framework Interview Questions With AnswersDocument16 pagesEntity Framework Interview Questions With AnswersShivprasad Koirala100% (5)

- 02 Minerals Library Basic Objects 5p1s4aDocument113 pages02 Minerals Library Basic Objects 5p1s4aman_y2k100% (1)

- Sony SDM-N50R PDFDocument76 pagesSony SDM-N50R PDFFöldi BélaNo ratings yet

- Assignment 1 - Spring2006: SolutionDocument31 pagesAssignment 1 - Spring2006: SolutionMuhammad UmairNo ratings yet

- Panasonic MINAS A5Document478 pagesPanasonic MINAS A5Vaikuntam Ramamurthy100% (1)

- Gree Dehumidifier Service ManualDocument58 pagesGree Dehumidifier Service Manualjdv1234No ratings yet

- Ericsson Command LineDocument39 pagesEricsson Command LinejulescarrelNo ratings yet

- Exercises Conditional SentencesDocument2 pagesExercises Conditional SentencesDivine GuancoNo ratings yet

- Dead and Live LoadDocument5 pagesDead and Live LoadBhuwesh PantNo ratings yet

- PLCC-28: FeaturesDocument5 pagesPLCC-28: Features肖磊No ratings yet

- Applications of Linear Algebra in Computer ScienceDocument8 pagesApplications of Linear Algebra in Computer ScienceSameed Ahmed Rafi100% (2)

- Infinera 7100 Series: Compact and Flexible Packet Optical Transport For The MetroDocument2 pagesInfinera 7100 Series: Compact and Flexible Packet Optical Transport For The MetroTaha AlhatmiNo ratings yet

- Connecting Piping Design in AutoCAD Plant 3D To Piping Fabrication Through Spoolgen-Ian Matthew-AU2018Document12 pagesConnecting Piping Design in AutoCAD Plant 3D To Piping Fabrication Through Spoolgen-Ian Matthew-AU2018Gabriel DezoutterNo ratings yet

- Power Window Four Windows: Modul ControlsDocument2 pagesPower Window Four Windows: Modul ControlsHery IswantoNo ratings yet

- Abb Sattcon ComliDocument17 pagesAbb Sattcon Comlilgrome73No ratings yet

- 5-EN 4050-A (Dig) - 2F1CDocument9 pages5-EN 4050-A (Dig) - 2F1Cabuzer1981No ratings yet

- Cooling Unit SpecDocument4 pagesCooling Unit Specmirali74No ratings yet

- HKV-8 Valve Catalog SPLRDocument128 pagesHKV-8 Valve Catalog SPLRCabrera RodriguezNo ratings yet

- Chemistry Note Form 5Document9 pagesChemistry Note Form 5SofiyyahOpieNo ratings yet

- Data Sheet Cummins BT5,9-G6Document4 pagesData Sheet Cummins BT5,9-G6acere18100% (1)

- Project Robot ArmDocument62 pagesProject Robot ArmTechs Solutions RobotsNo ratings yet

- ANSYS Tutorial Design OptimizationDocument9 pagesANSYS Tutorial Design OptimizationSimulation CAE100% (4)

- Mechanics of Structure IIDocument3 pagesMechanics of Structure IIvenkata369No ratings yet

- Partial Differential Equations (Pdes)Document5 pagesPartial Differential Equations (Pdes)uploadingpersonNo ratings yet

- Bread and Pastry ProductionDocument9 pagesBread and Pastry Productionwhite newgatesNo ratings yet

- Identification - of - Vulkan Vulastik-L CouplingsDocument2 pagesIdentification - of - Vulkan Vulastik-L CouplingsBill NevisNo ratings yet

- Maquinaria Forestal..Document14 pagesMaquinaria Forestal..Juan G ContrerasNo ratings yet

- Topic: Partnership: Do Not Distribute - Highly Confidential 1Document7 pagesTopic: Partnership: Do Not Distribute - Highly Confidential 1Tharun NaniNo ratings yet