Professional Documents

Culture Documents

Underground Cable Rev4 15oct09

Uploaded by

najiruddinshaikCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Underground Cable Rev4 15oct09

Uploaded by

najiruddinshaikCopyright:

Available Formats

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION

UP TO AND INCLUDING 33kV

PART B-05 TITLE: SPECIFICTION NO: INCEPTION DATE: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV B-05 AFTER GAZETTING (WORKING DOCUMENT FOR A 3 YEAR PERIOD)

AMENDMENTS / REVISIONS DATE PAGE PARAGRAPH DESCRIPTION ORIGINATOR APPROVED

Infrastructure Technical Standards

Page B-05:1

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

TABLE OF CONTENTS PAGE

1.

SCOPE ............................................................................................................................................ 3

2. UNDERGROUND CABLE AND CABLE ACCESSORIES FOR MEDIUM VOLTAGES UP TO AND INCLUDING 33KV. ........................................................................................................................ 6 2.1 2.2 2.3 2.4 2.5 2.6 XLPE DISTRIBUTION CABLES ...................................................................................................... 6 PVC DISTRIBUTION CABLES ........................................................................................................ 6 PILC DISTRIBUTION CABLES ....................................................................................................... 7 CABLE ACCESSORIES (3.3, 6.6, 11, 22, 33KV) ............................................................................. 7 CABLE JOINTS (3.3, 6.6, 11, 22, 33KV) ....................................................................................... 8 CABLE TERMINATIONS (3.3, 6.6, 11, 22, 33KV) ............................................................................ 8

3. UNDERGROUND CABLE AND CABLE ACCESSORIES FOR LOW VOLTAGES UP TO AND INCLUDING 400V. .................................................................................................................................. 9 3.1 3.2 3.3 3.4 3.5 4. ARMOURED 4-CORE LV CABLES ................................................................................................... 9 SINGLE CORE LV CABLES/CONDUCTORS ...................................................................................... 9 BARE STRANDED COPPER CONDUCTOR ........................................................................................ 9 LV CABLE JOINTS AND TERMINATIONS .......................................................................................... 9 LV CABLES AND CONDUCTOR ACCESSORIES ............................................................................... 10

HANDLING AND LAYING OF UNDERGROUND CABLES UP TO AND INCLUDING 33KV. ... 11 4.1 4.2 4.3 4.4 4.5 4.6 4.7 4.8 4.9 4.10 4.11 4.12 4.13 4.14 4.15 4.16 GENERAL.................................................................................................................................. 11 CABLE ROUTES AND POSITIONING .............................................................................................. 11 HANDLING AND LAYING OF CABLES ............................................................................................. 11 TRENCHING .............................................................................................................................. 12 BEDDING .................................................................................................................................. 13 LAYING ..................................................................................................................................... 13 BACKFILLING............................................................................................................................. 14 PROTECTION OF CABLES ........................................................................................................... 14 ROAD CROSSINGS .................................................................................................................... 14 OPENING UP OF EXISTING CABLES .......................................................................................... 14 SLEEVES/CABLE DUCTS ......................................................................................................... 14 CAPACITY OF CABLE CONDUITS (SLEEVES) .............................................................................. 15 KICK PIPES ............................................................................................................................ 15 TRENCH EARTH WIRES ........................................................................................................... 15 SEALING OF ENDS.................................................................................................................. 15 CABLE MARKERS ................................................................................................................... 15

5.

INSTALLATION OF EARTHING SYSTEMS FOR UNDERGROUND CABLES. ......................... 16

Infrastructure Technical Standards

Page B-05:2

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

1. SCOPE This part of the specification deals with the material requirements, installation, testing and commissioning of medium and low voltage underground cables in accordance with the following standards listed below:

GENERAL INFORMATION The following Standards and Acts shall take precedence: National Electricity Act of Namibia Quality of Service Standard Quality of Supply Standard NamPower Specifications for the Erection of Overhead Power Lines NamPower Specifications and General Conditions for Survey and Route Clearing for New Power Lines The following Standard shall be used as reference: NRS 033 : Electricity Distribution Guidelines for the application design, planning and construction of medium voltage overhead power lines up to and including 33kV, using wooden pole structures and bare conductors. : Guidelines for the provision of electrical distribution networks in residential areas.

NRS 034

NRS 043

: Code of practice for the joint use of structures for power and telecommunication lines : Recommendations to minimize problems associated with the theft of transformer neutral and neutral earthing copper conductors : Code of practice for clearances for electrical systems with rated voltages up to and including 145kV, for the safety of persons : Recommended maintenance policy for electricity networks : Overhead power lines for conditions prevailing in South Africa

NRS 059

NRS 060

NRS 082 SANS 10280

Infrastructure Technical Standards

Page B-05:3

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

UNDERGROUND DISTRIBUTION CABLES Regional Standards NRS 013 NRS 074 SANS 1411-1 SANS 1411-2 : Medium voltage cables : Low voltage (600/1000 V) cable systems for underground electrical distribution : Materials of insulated electric cable and flexible cords Part 1: Conductors : Materials of insulated electric cable and flexible cords Part 2: Polyvinyl Chloride (PVC) : Materials of insulated electric cable and flexible cords Part 3: Elastomers : Materials of insulated electric cable and flexible cords Part 4: Cross-linked Polyethylene (XLPE) : Materials of insulated electric cable and flexible cords Part 5: Halogen free, flame retardant materials : Materials of insulated electric cable and flexible cords Part 6: Armour : Materials of insulated electric cable and flexible cords Part 7: Polyethylene (PE) : Electric cables with extruded solid dielectric insulation for fixed installations (300/500V to 1900/3300V) : Electric cables with extruded solid dielectric insulation for fixed installations (300/500V to 1900/3300V) Part 1: General : Electric cables with extruded solid dielectric insulation for fixed installations (300/500V to 1900/3300V) Part 2: Wiring cables : Electric cables with extruded solid dielectric insulation for fixed installations (300/500V to 1900/3300V) Part 3: PVC Distribution Cables : Electric cables with extruded solid dielectric insulation for fixed installations (300/500V to 1900/3300V) Part 4: XLPE Distribution Cables : Electric cables with extruded solid dielectric insulation for fixed installations (300/500V to 1900/3300V) Part 5: Halogen-free distribution cables : Electric cables with extruded solid dielectric insulation for fixed installations (300/500V to 1900/3300V) Part 6: Service Cables

SANS 1411-3 SANS 1411-4

SANS 1411-5

SANS 1411-6 SANS 1411-7 SANS 1507

SANS 1507-1

SANS 1507-2

SANS 1507-3

SANS 1507-4

SANS 1507-5

SANS 1507-6

SANS 10198-1 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 1: Definitions and statutory requirements SANS 10198-2 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 2: Choice of cable type and methods of installation SANS 10198-3 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 3: Earthing systems general provisions SANS 10198-4 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 4: Current ratings

Infrastructure Technical Standards

Page B-05:4

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

SANS 10198-5 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 5: Determination of thermal and electrical resistivity of soil SANS 10198-6 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 6: Transportation and storage SANS 10198-7 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 7: Safety Precautions SANS 10198-8 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 8: Cable laying and installation SANS 10198-9 : The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 9: jointing and termination of extruded solid dielectric insulated cables up to 3.3kV SANS 10198-10: The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 10: Jointing and termination of paper-insulated SANS 10198-11: The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 11: Jointing and termination screened polymeric insulated cables SANS 10198-12: The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 12: Installation of earthing system SANS 10198-13: The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 13: Testing, commissioning and fault location SANS 10198-14: The selection, handling and installation of electric power cables of rating not exceeding 33kV Part 14: Installation of aerial bundled conductor (ABC) SANS 97 : Electric Cables- Impregnated paper insulated metal sheathed cables for rated voltages 3.3/3.3kV to 19/33kV (Excluding pressure assisted cables) : Electric cables- Cross linked polyethylene (XLPE) insulated cables for rated voltages 3.8/6.6kV to 19/33kV

SANS 1339

International Standards BS 6004 IEC 60189 IEC 60055 IEC 60183 IEC 60227 IEC 60228 IEC 60502 : Electric cables. PVC insulated, non-armoured cables for voltages up to and including 450/750 V, for electric power, lighting and internal wiring : Low Frequency Cables and wires with PVC Sheeth : Paper Insulated Metal-Sheathed Cables for Rated Voltages up to 36kV : Guide to the selection of high voltage cables : Polyvinyl chloride insulated cables of rated voltages up to and including 1kV : Conductors of insulated cables : Power cables with extrudedinsulation and their accessories for rated voltages from 1kV up to and including 36kV

Infrastructure Technical Standards

Page B-05:5

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

2. UNDERGROUND CABLE AND CABLE ACCESSORIES FOR MEDIUM VOLTAGES UP TO AND INCLUDING 33KV. 2.1 XLPE Distribution Cables The cable shall be of the cross linked polyethylene (XLPE) insulated type in conformity with SANS 1339, SANS 1507-4 and NRS 013 Conductor size As required for Design Specifications and in accordance with SANS 10198-2, and SANS 10198-4 Stranded copper or aluminium XLPE in accordance with SANS 1411-4 3 up to 33 kV depending on design specifications A or B (individually screened) Conductor, extruded semi-conductive conductor screen, XLPE insulation, extruded semi-conductive core screen, core identification, individual core copper tape earth screen. The three cores laid up with fillers, binder tape and covered with a non-permeable PVC sheath

Conductor material Insulation Number of cores Operating voltage Type Construction

2.2 PVC Distribution Cables The cable shall be of the Polyvinyl Chloride (PVC) insulated type in conformity with NRS 013 and SANS1507-3.

Conductor size

As required for Design Specifications and in accordance with SANS 10198-2, and SANS 10198-4 Stranded copper or aluminium PVC in accordance with SANS 1411-2 3 up to 3.3 kV depending on design specifications A or B (individually screened) copper conductor insulated with compounds of polymers or of co-polymers of vinyl chloride (PVC)

Conductor material Insulation Number of cores Operating voltage Type Construction

Infrastructure Technical Standards

Page B-05:6

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

2.3 PILC Distribution Cables The cable shall be of the Paper Insulated Lead Sheathed Cable (PILC) type in conformity with NRS 013 and SANS 97. The following cables are covered by this standard: Fully impregnated, general purpose, single core cables of rated voltages 3,8/6,6kV , 6.35/11kV, 12,7/22kV and 19/33kV; Fully impregnated, heavy duty, or drained general purpose, single core cables of rated voltages 3,8/6,6kV and 6.35/11kV; Fully impregnated, general purpose, three core belted cables of rated voltages 3,8/6,6kV , 6,6/6,6kV, 6,35/11kV and 11/11kV; Fully impregnated, general purpose, three core screened cables of rated voltages 6,35/11kV , 12,7/22kV and 19/33kV; Fully impregnated, heavy duty, or drained general purpose, three core belted cables of rated voltages 3,3/3,3kV, 3,8/6,6kV 6,6/6,6kV, 6,35/11kV and 11/11kV; Fully impregnated, heavy duty, or drained general purpose, three core screened cables of rated voltages 6,35/11kV .

Conductor size

As required for Design Specifications and in accordance with SANS 10198-2, and SANS 10198-4 Copper or Aluminium and Lead Sheaths Paper in accordance with SANS 97 3 up to 33 kV depending on design specifications A or B (individually screened) Single core or three core impregnated paper insulated metal sheathed cables.

Conductor material Insulation Number of cores Operating voltage Type Construction

2.4 Cable Accessories (3.3, 6.6, 11, 22, 33kV) The cable accessories shall be designed to ensure satisfactory operation under the site conditions specified and under normal and fault conditions. All current carrying connectors and insulating materials shall be of ample section and surface area and shall have been tested for carrying the currents and for providing the insulation corresponding to the cable size specified. Reference shall be made to SANS 10198-5 when determining thermal and electrical resistivity of soil. Cable laying accessories shall conform to SANS 10198-8.

Infrastructure Technical Standards

Page B-05:7

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

2.5 Cable Joints (3.3, 6.6, 11, 22, 33kV) Cable through joints shall be of the heat shrink type approved by the Engineer as per item 3.4 below, for XLPE type cables. Through joints shall be suitable for jointing the cable specified supplied with sleeve, all insulating, electrical field stress relieving and jointing materials, conductor jointing sleeves (ferrules) and instructions. Approved joints as per item 3.4 below shall be used. Each kit shall be packed in a separate box containing all materials required to make a complete installation. The following standards are to be adhered to: SANS 10198-10 SANS 10198-11 : Jointing and termination of paper insulated cables. : Jointing and termination of screened polymeric insulated cables.

2.6 Cable Terminations (3.3, 6.6, 11, 22, 33kV) The cable terminations shall be terminated using heat shrink type approved cables by the engineer in accordance with NRS 013. Terminations shall be suitable for terminating the cable at terminals on switchgear and transformers positioned outdoor and indoor, and on overhead lines. The terminations shall be supplied in kit form complete with gland. All stress relieving field guide and insulating materials as well as boots and sleeves for obtaining a complete installation. The following standards shall be adhered to: SANS 10198-10 SANS 10198-11 : Jointing and termination of paper insulated cables. : Jointing and termination of screened polymeric insulated cables.

Infrastructure Technical Standards

Page B-05:8

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

3. UNDERGROUND CABLE AND CABLE ACCESSORIES FOR LOW VOLTAGES UP TO AND INCLUDING 400V. 3.1 Armoured 4-core LV cables Cables shall be manufactured in accordance with SANS 1507 and shall be constructed as follows: (a) Armoured cables: PVC-insulated/PVC-bedded/steel wire armoured/black extruded PVC onto sheath (PVC/PVC/SWA/PVC). The PVC insulation and covering shall be ultra violet stabilized and manufactured to SANS 1411 Part 2. The insulation shall be general purpose PVC, 600/1000V grade. The bedding shall consist of a continuous impermeable sheath of PVC extruded to fit the core or cores closely and in the case of multi-core cables, to fill the interstices between cores. Armouring shall consist of one layer of galvanized steel wire in the case of multi-core cables and shall conform to SANS 1411 Part 6.

(b)

(c) (d)

(e)

3.2 Single core LV cables/conductors Single core cables and conductors shall be manufactured in accordance with SANS 1507, and shall be constructed as follows: (a) (b) PVC insulated/unsheathed in accordance with SANS 1411 Part 2. The PVC insulation shall be ultra violet stabilized and manufactured to SANS 1411 Part 2. The conductor shall be of high conductivity annealed stranded copper. The insulation shall be general purpose PVC, 600/1000 V grade.

(c) (d)

3.3 Bare stranded copper conductor (a) (b) (c) Bare stranded copper conductors shall be used as earth continuity conductors. The conductors shall be of hard drawn stranded copper compliant to SANS 182. The bare stranded copper conductors shall be supplied and delivered in rolled lengths.

3.4

LV cable joints and terminations Joints in underground cables, and terminations, shall be made by means of approved epoxyresin pressure type jointing kits or products equally approved by the Engineer. Joints must be made by competent cable jointers and entirely in accordance with the manufacturers instructions using only the materials stipulated in such instructions. Each end of the cables to

Infrastructure Technical Standards

Page B-05:9

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

be jointed must have a minimum of 1000mm of slack disposed in a loop without stress. Backfilling under joints must be firmly tamped to prevent any subsequent settling. LV cables shall be made off with sealing glands and materials specially designed for this purpose in compliance with SANS 10198-9.

3.5 3.5.1

LV cables and conductor accessories Cable glands for armoured cable (a) Glands to be used for terminating PVC/PVC/SWA/PVC cables shall be of the adjustable type. Glands shall be suitable for general purpose 600/1000V grade 4-core cable with steel armouring. The glands shall be made of nickel-plated bronze. The glands shall consist of a barrel carrying a cone bush screwed into one end and a nickel-plated brass nipple carrying a nickel-plated brass or a heavy galvanized steel locknut screwed into the other end. The galvanizing shall comply with SANS 121. Non-watertight glands must be easily converted to watertight glands by means of a waterproofing shroud and inner seal kit. On the cable entry side of the barrel a concave groove shall be provided to accommodate the top rim of the waterproofing shroud. The shrouds shall be made of non-deteriorating neoprene or other synthetic rubber, and shall be resistant to water, oil and sunlight. The shrouds shall fit tightly around the glands and cable. Glands shall be provided with ISO threads and shall be suitable for the specified cable sizes. Glands shall be brands approved by the engineer in accordance with SANS 1213. Each gland shall be supplied with a shroud and water-proofing kit.

(b)

(c) (d)

(e)

(f)

(g)

(h) (i) 3.5.2

Cable termination lugs Termination lugs shall be tinned copper brand for copper conductors, approved by the engineer. All cable lugs and ferrules shall comply with NRS 028 and IEC 61238.

3.5.3

Cable hoods (a) Cable hoods for the protection of the cable terminations at tap-offs from the overhead ABC conductors to an underground cable shall be used (from 35mm up to 50mm x 4-core cable, for cable sizes above 50mm cable boots shall be used.) The tenderer must include specifications of the cable hood offered. (b) The cable hood shall be suitable for mounting onto a wood pole.

Infrastructure Technical Standards

Page B-05:10

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

4. HANDLING AND LAYING OF UNDERGROUND CABLES UP TO AND INCLUDING 33KV. 4.1 General Cable work shall be done in accordance with SANS 10198 and to the satisfaction of the Client and the Engineer. The storage, transportation, handling and laying of underground cables shall conform to SANS 10198 and to BS 6004, and the Contractor shall have adequate and suitable equipment (SANS 10142) and labour to ensure that no damage is done to cables during such operations. Twisted or kinked cables, or cables damaged in any other way, will be rejected.

4.2

Cable routes and positioning The contractor shall follow the routes indicated on the specification drawings as accurately as possible. Deviations from the routes laid down shall not be made without the engineers approval. The final position of cable relative to kerbs, boundaries, and other services shall, where necessary, be indicated to the contractor by the engineer on site and shall be strictly adhered to. The cable route drawings issued with the inquiry documents are for tender purposes only and the routes may be amended before work on any particular section of the route commences. In general, where obstacles not provided for in the specification drawings are encountered, cables shall circumvent such obstacles by being laid in as smooth a path as possible around the obstacles and by retaining maximum separation between cables. Laying depths of cables specified are to final levels of the streets and sidewalks. All levels shall be obtained by the contractor from the Local Authority.

4.3

Handling and laying of cables The contractor must satisfy himself that the levels of the trenches excavated are suitable and are wide enough to enable him to carry out the work in accordance with SANS 10198-8. The contractor shall be responsible to draw in, lay, thread through pipes, circumvent obstacles, fix in position clamp and saddle where required to walls, poles or switch gear all cables set out in the contract. Best accepted practice is to be adopted in the handling and laying of cables and the work shall be carried out by persons experienced in the class of work. In particular, attention is drawn to the following: (1) Cable drums shall not be dropped off transport vehicles but shall be hoisted off with approved equipment. Cable shall be rolled off drums in the indicated direction, the drums being supported on approved equipment. When cables are laid out, it shall be supported at points at such a distance apart that the cable is not dragged along the ground and that it is not kinked.

(2)

(3)

Infrastructure Technical Standards

Page B-05:11

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

(4)

Cables shall be drawn into position or laid, using a sufficient number of rollers and suitable equipment, for negotiating corners to avoid excess bending or damage to the cable. Cables shall be drawn through cable pipe sleeves so as to ensure minimum damage to cables. Approved equipment, including suitable cable harnesses, shall be used. Cables shall not be bent in any event to radii smaller than 15 times the overall diameter of the cable. Cables shall be rolled off drums in the same direction, to prevent corresponding phase cores being crossed at joints.

(5)

(6)

(7)

4.4

Trenching 11kV cables shall generally be laid at a minimum depth of 1000mm below ground level. Main LV feeder cables, unless otherwise instructed, shall be laid at a minimum depth of 800mm below ground level. Trenches shall not be less than 300mm wide for single and multiple LV service connection cables, and the trench width shall be increased where more than two LV feeder or service connection cables are laid together so that the cables may be placed at least 150mm apart throughout the run. Streetlight cables buried in trenches under un-tarred roads shall be buried in a trench with minimum depth of 600mm and 300mm wide. Trenches under tarred roads shall be buried a minimum of 500mm deep, and normally in HDPE corrugated sleeving of applicable size, quantity and required spare quantities. Where the nature of the ground does not permit the excavation of the cable trenches to the specified depth, the engineer may authorize trenches not less than 500mm deep. Such authority shall be given in writing. The Contractor must take all the necessary precautions to prevent trenching work being in any way a hazard to the public, and to safeguard all structures, roads, railways, sewer works or other property from any risk of subsidence and damage. Soil type shall be graded by the engineer. The engineers decision shall be final.

Infrastructure Technical Standards

Page B-05:12

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

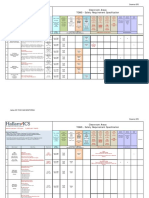

The following table represents the minimum standards to be applied in respect of 11, 22 and 33kV, 400V feeder, 400V Street light and 230V service connection cables. TRENCH DETAIL FOR CABLE SETUP NEEDED Single 11,22,33kV 2 Parallel 11,22,33kV 3 Parallel 11,22,33kV Single 400V Feeder 2 parallel 400V Feeder 3 parallel 400V Feeder Single/multiple service connections Streetlight Un-tarred Streetlight Tarred Combination of Multiple Cables Combination of single cables 4.4.1 TRENCH DEPTH TRENCH WIDTH Width between 11,22,33kV Cable n/a 600mm 600mm n/a n/a n/a n/a Width between 400V Cable n/a n/a n/a n/a 150mm 150mm None

1000mm 1000mm 1000mm 800mm 800mm 800mm 600mm

450mm 800mm 1400mm 450mm 450mm 600mm 300mm

600mm 500mm 800mm 800mm

300mm 300mm 1200mm 700mm

n/a n/a 500mm n/a

None None 150mm 150mm

Excavation of joint chambers Jointing pits shall be excavated to a depth of 1.2m and shall be rectangular in shape and large enough for the cable jointer to work comfortably and in an efficient manner. The minimum size of a joint pit shall be 2.5m long x 1.5m wide, the pit shall be 3m x 2m for two joints. The cost to excavate joint chambers shall be allowed for in the trenching rate as part of the Bill of Quantities and shall be based on a quantity to be same as the measured through joints.

4.5

Bedding All cables shall be laid in a bedding of soft sand or sifted soil, 50mm below and 150mm above the cable. Clay soil will not be accepted as bedding.

4.6

Laying Cable shall be removed from the drum in such a way that no twisting, tension or mechanical damage is caused, and must be adequately supported at short intervals during the whole operation. Particular care must be exercised where it is necessary to draw cables through pipes and ducts, to avoid abrasion, elongation or distortion of any kind. The ends of such pipes and ducts shall be sealed to approval after the drawing in of the cables.

Infrastructure Technical Standards

Page B-05:13

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

4.7

Backfilling Backfilling after bedding is to be carried out with a proper grading of the material to ensure settling without voids, and the material is to be tamped down after the addition of every 150mm. The surface is to be made good as required.

4.8

Protection of cables (a) Danger tape to specification shall be placed 400mm above all MV and main feeder cables along the entire length of the trench. Where so directed by the Engineer, a concrete layer shall be placed over the bedding layer in order to give the cable additional protection. At road crossings, cable sleeves shall be installed at a minimum depth of 1000mm, and as instructed by the Engineer. The danger tape shall be 150mm wide yellow plastic with lightning flash printed onto the tape at intervals. The tape shall comply with SANS 1091.

(b)

(c)

(d)

4.9

Road Crossings Cable sleeves for road crossings shall not be installed less than 1000mm below the final street level. Unless otherwise specified two additional sleeves all of the same size shall be installed for future use at each road crossing. Galvanized steel draw wire, 2.0mm in diameter shall be installed in all sleeves and shall protrude 1500mm on each side of the sleeve. On completion of the installation of sleeves all ends shall be sealed to prevent the ingress of dirt and moisture, after installation of the cables the sleeves shall be resealed. After installation of the sleeves the trench shall be backfilled and tamped down in layers of 50mm to achieve a density of 95% modified AASHTO. Sleeve end positions shall be marked with an approved cable marker, a letter E shall be cut on either side of the road on the kerbstones where these are in existence.

4.10

Opening up of existing cables Where it is necessary to expose existing buried cables for any purpose, or when excavating in the vicinity of existing buried cables, pipes, etc., every care is to be exercised and only labourers experienced in such work, and duly warned by the Contractor, shall be employed thereon. The Contractor shall be responsible for making good any damage caused by his work.

4.11

Sleeves/cable ducts (a) (b) uPVC Class 6 pipes shall be used as sleeves/cable ducts, for example under roads. The pipe shall be supplied in 6m lengths.

Infrastructure Technical Standards

Page B-05:14

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

(c)

One end of each pipe and bend shall be fluted to form a female coupling so that pipes can be easily joined. One spare sleeve per cable duct is to be installed and plugged with PVC sheeting.

(d)

4.12

Capacity of cable conduits (sleeves) Where cables are to be drawn into sleeve pipes separate cable conduit runs are to be provided for each main distribution cable. The maximum number of cable to be accommodated in a single cable conduit shall be 3 plus the trench earth i.e. 3 service cables or main cable plus street lighting and/or service cable.

4.13

Kick pipes (a) HDPE Class 6 pipes shall be used as kick pipes for distribution cables on poles. Suitable diameter pipes shall be supplied in 3m lengths. 20mm x 0.72mm stainless steel bandit strapping shall be used for fixing of kick pipes against poles. Galvanized steel saddles shall be used for fixing of cables against poles.

(b)

(c)

4.14

Trench earth wires Bare copper earth wire is to be run with all underground cables constituting part of a low voltage distribution system. The BCEW shall have a cross sectional area equal to at least half that of one phase conductor of the cable, but shall not be less than 10mm. A single earth conductor shall be used as earth continuity conductor for two or more cables run together, branch earth wires being brazed on where required. The earth continuity conductor is to be bonded to the cable armouring at each termination of the cable, as well as to local earth bars. At road crossings, cable sleeves shall be installed at a minimum depth of 1000mm, and as instructed by the Engineer. Coastal or corrosive environments may require stainless steel rod together with multiple point earthing distribution points. Contractors should contact the supply authority in coastal areas or corrosive areas in order to enquire about the earthing requirements.

4.15

Sealing of ends Where cables are cut and not immediately made off, the ends are to be sealed without delay.

4.16

Cable markers Cable route markers of approved manufacture shall be provided at each end of an underground cable route and at all points where such routes deviate from a straight line. Joints in the cable shall be marked and the maximum distance between route markers shall not exceed 100m.

Infrastructure Technical Standards

Page B-05:15

STANDARD SPECIFICATION FOR MEDIUM AND LOW VOLTAGE ELECTRICITY DISTRIBUTION WORKS PART B-05: UNDERGROUND CABLE DISTRIBUTION UP TO AND INCLUDING 33kV

The cable markers shall be tapered blocks cast from concrete in accordance with approved detail drawings Each cable marker shall be buried with its upper face 100mm above the natural ground level. Marking of cable markers shall also be in accordance with approved detail drawings.

5. INSTALLATION OF EARTHING SYSTEMS FOR UNDERGROUND CABLES. Refer to SANS 10198-7 for earthing requirements regarding the following cable components: Metal Sheaths Multi Core Cables Metal Sheaths Single Core Cables Metal Screens Armour Cross Bonding

Refer to SANS 10198-7 for requirements regarding Protective Multiple Earthing Cables as well as Combined / Neutral Cables.

Infrastructure Technical Standards

Page B-05:16

You might also like

- STS202-5 Edition1 Nov 2017 - (Payment Systems - Standard Transfer Specification)Document9 pagesSTS202-5 Edition1 Nov 2017 - (Payment Systems - Standard Transfer Specification)Hendi WibowoNo ratings yet

- SANS 10198 - Earthing Systems Under 33kV - General Provisions - 2004Document14 pagesSANS 10198 - Earthing Systems Under 33kV - General Provisions - 2004James0% (1)

- PCM Reference: SCOT Study Committee Number/NameDocument47 pagesPCM Reference: SCOT Study Committee Number/NameUmerNo ratings yet

- Operational and Maintenance Instructions Manual For Medium and Low Voltage Power Control & DistributDocument48 pagesOperational and Maintenance Instructions Manual For Medium and Low Voltage Power Control & DistributSherif HelmyNo ratings yet

- Final LUS EvaluationDocument36 pagesFinal LUS EvaluationNextgenNo ratings yet

- Airports Dubai Airport Power SupplyDocument1 pageAirports Dubai Airport Power SupplySharik KhanNo ratings yet

- Botswana - The Morupule B Power ProjectDocument33 pagesBotswana - The Morupule B Power Projectsrigirisetty208No ratings yet

- Srds Document 2 LatestDocument266 pagesSrds Document 2 LatestPhilvic Nkonga100% (1)

- Esmeraldas Electrical Rehabilitation - RFP For Site Survey Engineering Feb 2014 v1 DraftDocument46 pagesEsmeraldas Electrical Rehabilitation - RFP For Site Survey Engineering Feb 2014 v1 DraftOmar GraterolNo ratings yet

- MV Cable System DST 34-1175Document77 pagesMV Cable System DST 34-1175Chris MostertNo ratings yet

- Company Profile by Louis TwelveDocument10 pagesCompany Profile by Louis TwelveDavid D'bayuNo ratings yet

- 11KV Kiosk Panel (Indoor) - VCBDocument4 pages11KV Kiosk Panel (Indoor) - VCBSharafat AliNo ratings yet

- Electriciam SHE Plan 14 Oct 2015Document13 pagesElectriciam SHE Plan 14 Oct 2015Pieter HerbstNo ratings yet

- Survey of Smart Metering Communication Technologies: July 2013Document11 pagesSurvey of Smart Metering Communication Technologies: July 2013barretimufuNo ratings yet

- LOT 1 Narok Bomet Environmental and Social Management Plan PDFDocument35 pagesLOT 1 Narok Bomet Environmental and Social Management Plan PDFGkou DojkuNo ratings yet

- Solar PV Inverter Test ProceduresDocument62 pagesSolar PV Inverter Test ProceduresskylarksNo ratings yet

- Risk Assessment Annotation PDFDocument2 pagesRisk Assessment Annotation PDFapi-315029028100% (1)

- Mechanical Engineering Safety HandbookDocument207 pagesMechanical Engineering Safety HandbookjamesNo ratings yet

- TSP 474-218 PDFDocument46 pagesTSP 474-218 PDFMaiChiThoNo ratings yet

- Omega Resistivity Meter ManualDocument16 pagesOmega Resistivity Meter ManualLouie Raymond Abbas FernandezNo ratings yet

- Arc Flash Analysis: Electrical SafetyDocument16 pagesArc Flash Analysis: Electrical SafetyOsha InstructorsNo ratings yet

- Mini Project On Cross Culture in MNC'S: Subitted by P.Kalyan Kamalesh B.V.Karthik MohanrajDocument17 pagesMini Project On Cross Culture in MNC'S: Subitted by P.Kalyan Kamalesh B.V.Karthik MohanrajKarthik ReddyNo ratings yet

- Relay and Multifunctional Substation Test System: Sverker 900Document12 pagesRelay and Multifunctional Substation Test System: Sverker 900Stelvio QuizolaNo ratings yet

- Underground Electrification SystemDocument90 pagesUnderground Electrification Systemhashmisahib48No ratings yet

- QA/QC Responsibilities: InspectionsDocument1 pageQA/QC Responsibilities: InspectionsVenkata Suresh MandavaNo ratings yet

- Raychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVDocument4 pagesRaychem Screened, Separable Connection System RSTI-68 800 A Up To 42 KVgiovany_vq91No ratings yet

- Construction of A Transmission LineDocument7 pagesConstruction of A Transmission LineDamodharan ChandranNo ratings yet

- Tricks For Cable Accessories InstallationDocument30 pagesTricks For Cable Accessories InstallationcxfuentesNo ratings yet

- Vol 3 Saj Tech SpecDocument132 pagesVol 3 Saj Tech SpecMallikarjun MVNo ratings yet

- 0526-E-015-Plant Earthing MatDocument15 pages0526-E-015-Plant Earthing MatSandipNo ratings yet

- Method Statement For PFC BoardDocument13 pagesMethod Statement For PFC BoardSARAVANAN ANo ratings yet

- REM615 Appl 756885 ENlDocument168 pagesREM615 Appl 756885 ENlwilsonpamintuNo ratings yet

- Secovac 12-24kvDocument21 pagesSecovac 12-24kvUrsula JohnsonNo ratings yet

- Compact Round Concentric-Lay-Stranded Copper Conductors: Standard Specification ForDocument3 pagesCompact Round Concentric-Lay-Stranded Copper Conductors: Standard Specification ForCarlos HerreraNo ratings yet

- IEC 62271200 HV Switchgear and Controlgear EEPDocument3 pagesIEC 62271200 HV Switchgear and Controlgear EEPMohammed MadiNo ratings yet

- Qualification of TBEA Tianjin Transformers PDFDocument6 pagesQualification of TBEA Tianjin Transformers PDFtranthienphongNo ratings yet

- MDB Specs PDFDocument9 pagesMDB Specs PDFAbdElrahman AhmedNo ratings yet

- Speed Control System With Rfid Equipped VehicleDocument27 pagesSpeed Control System With Rfid Equipped VehicleAnonymous L9fB0XUNo ratings yet

- ABW Air Circuit BreakerDocument28 pagesABW Air Circuit BreakerDerargh100% (1)

- Swot Analysis Strength WeaknessesDocument1 pageSwot Analysis Strength WeaknessesAngela Mora AnchetaNo ratings yet

- Quotation CT PT Isolators AB Switches DO Fuse Set Horn Gap VCB SMC Boxes Deep Drawn BoxesDocument8 pagesQuotation CT PT Isolators AB Switches DO Fuse Set Horn Gap VCB SMC Boxes Deep Drawn BoxesShokautNo ratings yet

- Cable FaultsDocument7 pagesCable FaultsNh Chuminda YapaNo ratings yet

- Constrution of SubstationDocument24 pagesConstrution of SubstationHassan100% (1)

- Cable Handbook RevisedDocument55 pagesCable Handbook RevisedMahmoud HegazyNo ratings yet

- DocumentDocument46 pagesDocumentGary FortuinNo ratings yet

- Bsti Standard CatalogDocument288 pagesBsti Standard CatalogAziz Bin Josim0% (1)

- Load Break SwitchDocument32 pagesLoad Break SwitchMatijaDebogović0% (1)

- Tender Document Part2Document325 pagesTender Document Part2Muhd FaiqNo ratings yet

- Quality Control Policies and ProceduresDocument35 pagesQuality Control Policies and ProceduresjesicaNo ratings yet

- Wire and CableDocument5 pagesWire and CablejosemartinpenatorresNo ratings yet

- Total Technical Specs PDFDocument259 pagesTotal Technical Specs PDFBhavesh KeraliaNo ratings yet

- Method Statement For UPS System Testing and CommissioningDocument12 pagesMethod Statement For UPS System Testing and Commissioningshegaw firewNo ratings yet

- BNE Electrical ProfileDocument7 pagesBNE Electrical ProfileJamie O'BrienNo ratings yet

- Indian Standard: Application Guide For Electrical Relays For Ac SystemsDocument61 pagesIndian Standard: Application Guide For Electrical Relays For Ac SystemsMayank VyasNo ratings yet

- Support Structures: Substation Design InstructionDocument9 pagesSupport Structures: Substation Design InstructionTony PedaNo ratings yet

- 7UT612 ProcedureDocument10 pages7UT612 ProcedureTufail AlamNo ratings yet

- 002 - 66-33kv, 30 45mva Auxiliary Main Transformer DraftDocument21 pages002 - 66-33kv, 30 45mva Auxiliary Main Transformer DraftPRAGATHI REDDYNo ratings yet

- Tan Delta PDFDocument4 pagesTan Delta PDFArturo Santivañez Sanchez100% (1)

- Performance of High-Voltage D.C. (HVDC) Systems - Part 2 Faults and SwitchingDocument85 pagesPerformance of High-Voltage D.C. (HVDC) Systems - Part 2 Faults and SwitchingChristian MarquezNo ratings yet

- Composite Insulators Rev 4Document22 pagesComposite Insulators Rev 4milosevicsasa11No ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument12 pagesSafety Data Sheet: Section 1. IdentificationCarlos MadridNo ratings yet

- Gaspro™ Tem-3700: Ultra-High Purity Nickel 316L In-Line FilterDocument2 pagesGaspro™ Tem-3700: Ultra-High Purity Nickel 316L In-Line FilternajiruddinshaikNo ratings yet

- Flo-Rite Series FR Flowmeters Flo-Rite Series FR Flowmeters: Ordering Information 5 Inch ScaleDocument4 pagesFlo-Rite Series FR Flowmeters Flo-Rite Series FR Flowmeters: Ordering Information 5 Inch ScalenajiruddinshaikNo ratings yet

- Central Loose Tube Armoured External Cable: ComplianceDocument2 pagesCentral Loose Tube Armoured External Cable: CompliancenajiruddinshaikNo ratings yet

- App GuideDocument216 pagesApp Guidetarottaurus549254No ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument11 pagesSafety Data Sheet: Section 1. IdentificationnajiruddinshaikNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument12 pagesSafety Data Sheet: Section 1. IdentificationnajiruddinshaikNo ratings yet

- Calculation Method For The Analysis and Prevention of Overpressure During Refilling of Cryogenic Tanks With Rupture Disk (S)Document51 pagesCalculation Method For The Analysis and Prevention of Overpressure During Refilling of Cryogenic Tanks With Rupture Disk (S)najiruddinshaikNo ratings yet

- Design Considerations and Guidance For The Safe Use of Medical Gas ViprDocument21 pagesDesign Considerations and Guidance For The Safe Use of Medical Gas ViprnajiruddinshaikNo ratings yet

- Code of Practice 5: The Design and Construction of Manifolds Using Acetylene Gas FROM 1.5 TO 25 Bar REVISION 3: 2016Document36 pagesCode of Practice 5: The Design and Construction of Manifolds Using Acetylene Gas FROM 1.5 TO 25 Bar REVISION 3: 2016Justin ChongNo ratings yet

- HYCO Plant Gas Leak Detection and Response Practices: AIGA 110/20Document19 pagesHYCO Plant Gas Leak Detection and Response Practices: AIGA 110/20najiruddinshaik100% (1)

- Safe Design and Operation of Cryogenic Enclosures: AIGA 079/18Document31 pagesSafe Design and Operation of Cryogenic Enclosures: AIGA 079/18najiruddinshaikNo ratings yet

- Vacuum-Jacketed Piping in Liquid Oxygen Service: AIGA 106/19Document24 pagesVacuum-Jacketed Piping in Liquid Oxygen Service: AIGA 106/19najiruddinshaikNo ratings yet

- Bcga Code of Practice CP 22: Bulk Liquid Argon or Nitrogen Storage at Production SitesDocument45 pagesBcga Code of Practice CP 22: Bulk Liquid Argon or Nitrogen Storage at Production SiteszhangjieNo ratings yet

- Code of Practice 5: The Design and Construction of Manifolds Using Acetylene Gas FROM 1.5 TO 25 Bar REVISION 3: 2016Document36 pagesCode of Practice 5: The Design and Construction of Manifolds Using Acetylene Gas FROM 1.5 TO 25 Bar REVISION 3: 2016Justin ChongNo ratings yet

- CP26 PDFDocument47 pagesCP26 PDFrafik1995No ratings yet

- Code of Practice 18 The Safe Storage, Handling and Use of Special GasesDocument63 pagesCode of Practice 18 The Safe Storage, Handling and Use of Special GasesJustin ChongNo ratings yet

- Flo-Rite Series FR Flowmeters Flo-Rite Series FR Flowmeters: Ordering Information 5 Inch ScaleDocument4 pagesFlo-Rite Series FR Flowmeters Flo-Rite Series FR Flowmeters: Ordering Information 5 Inch ScalenajiruddinshaikNo ratings yet

- Cleanroom Areas TGMS - Safety Requirement Specification: Strawman SRSDocument3 pagesCleanroom Areas TGMS - Safety Requirement Specification: Strawman SRSnajiruddinshaikNo ratings yet

- Code of Practice 6: The Safe Distribution of Acetylene in The Pressure Range 0 - 1.5 BAR Revision 3: 2015Document51 pagesCode of Practice 6: The Safe Distribution of Acetylene in The Pressure Range 0 - 1.5 BAR Revision 3: 2015Justin ChongNo ratings yet

- Siting Gas Detectors BS023 3Document8 pagesSiting Gas Detectors BS023 3najiruddinshaikNo ratings yet

- Cleanroom DesignDocument12 pagesCleanroom Designthawitchai100% (1)

- Code of Practice 6: The Safe Distribution of Acetylene in The Pressure Range 0 - 1.5 BAR Revision 3: 2015Document51 pagesCode of Practice 6: The Safe Distribution of Acetylene in The Pressure Range 0 - 1.5 BAR Revision 3: 2015Justin ChongNo ratings yet

- White Paper: Toxic Gas Monitoring System DesignDocument15 pagesWhite Paper: Toxic Gas Monitoring System DesignnajiruddinshaikNo ratings yet

- Compressed Air - ApplicationsDocument66 pagesCompressed Air - ApplicationsBrendan ClarkNo ratings yet

- CAGI ElectHB ch7Document259 pagesCAGI ElectHB ch7Alejandro GilNo ratings yet

- Sample TGMS Annual Maintenance and Service Plan Hallam-ICSDocument2 pagesSample TGMS Annual Maintenance and Service Plan Hallam-ICSnajiruddinshaikNo ratings yet

- White Paper: Toxic Gas Monitoring Systems (TGMS)Document14 pagesWhite Paper: Toxic Gas Monitoring Systems (TGMS)najiruddinshaikNo ratings yet

- Chapter 2 - Compressed Air ProductionDocument79 pagesChapter 2 - Compressed Air ProductionGandhiNo ratings yet

- Cagi Electhb ch3Document40 pagesCagi Electhb ch3Merge e-mail JAGNNo ratings yet

- Betobar 2021Document44 pagesBetobar 2021berliani navitasNo ratings yet

- EE537 Advanced Power System Protection DR C BoothDocument10 pagesEE537 Advanced Power System Protection DR C BoothRajendra Prasad ShuklaNo ratings yet

- Switch Yard Breakers Interconnection Details27714 PDFDocument1 pageSwitch Yard Breakers Interconnection Details27714 PDFAshwinKumar GoswamiNo ratings yet

- Eaton Cutler HammerDocument174 pagesEaton Cutler Hammerlj_treels100% (1)

- Electrical Energy AuditDocument27 pagesElectrical Energy AuditGH Eco RJNo ratings yet

- Dhaka Electric Supply Company Limited (DESCO) Load Shedding Schedule On 11 KV FeedersDocument15 pagesDhaka Electric Supply Company Limited (DESCO) Load Shedding Schedule On 11 KV Feedersisti1No ratings yet

- ИБП ZXDU68 B301 (V5.0R02M12)Document32 pagesИБП ZXDU68 B301 (V5.0R02M12)Инга ТурчановаNo ratings yet

- Tariff 2Document117 pagesTariff 2kennyarthurNo ratings yet

- Wiring Diagram: CMS7094ELDocument164 pagesWiring Diagram: CMS7094EL季全No ratings yet

- Zigzag Transformer - Some New Applications With A Note To Energy EfficiencyDocument15 pagesZigzag Transformer - Some New Applications With A Note To Energy EfficiencydoriaNo ratings yet

- 1600kva-33kv-0.324kv Dual Sec Dry TypeDocument5 pages1600kva-33kv-0.324kv Dual Sec Dry TypeSarang PremalwarNo ratings yet

- Guide Efficiency PowerQualityDocument57 pagesGuide Efficiency PowerQualityKevin GurungNo ratings yet

- Recruitment and Selection ProcessDocument119 pagesRecruitment and Selection ProcessAlin Iustinian Toderita100% (1)

- Modeling of Grid-Forming and Grid-Following Inverters For Dynamic Simulation of Large-Scale Distribution SystemsDocument11 pagesModeling of Grid-Forming and Grid-Following Inverters For Dynamic Simulation of Large-Scale Distribution SystemspouyanNo ratings yet

- Hgass WindDocument13 pagesHgass Windhadush gebreNo ratings yet

- Lighting Circuits PDFDocument24 pagesLighting Circuits PDFShadi AbdelsalamNo ratings yet

- Lecture Notes Unit 1 Smart GridDocument10 pagesLecture Notes Unit 1 Smart GridSaurabh Bhardwaj100% (1)

- ECO Conductors Low Loss Conductor SolutionDocument2 pagesECO Conductors Low Loss Conductor SolutionBalaji_Rajaman_2280No ratings yet

- MODULE 3 (B) : Domestic WiringDocument70 pagesMODULE 3 (B) : Domestic WiringBOBAN05No ratings yet

- 03 - Power Arrester, 100KA-SPD3P100K-O-MH Technical SpecificationDocument9 pages03 - Power Arrester, 100KA-SPD3P100K-O-MH Technical SpecificationhammoumiNo ratings yet

- Catalog - Energy Storage System ProjectsDocument40 pagesCatalog - Energy Storage System ProjectsCarlos Rafael Acosta MolinaNo ratings yet

- HTM 06 01 PartADocument155 pagesHTM 06 01 PartAMaher Al LobnanyNo ratings yet

- Ontario Electrical Safety Authority SPEC 003 R5Document39 pagesOntario Electrical Safety Authority SPEC 003 R5Duke MoitaNo ratings yet

- Well-Site Power Supply and Distribution System User ManualDocument14 pagesWell-Site Power Supply and Distribution System User ManualYugandhar YuguNo ratings yet

- Illustrated Guide To Electrical Building Services 3rd EditionDocument85 pagesIllustrated Guide To Electrical Building Services 3rd EditionMihaela AntonNo ratings yet

- CEER Benchmark Report For Electricity DistributionDocument23 pagesCEER Benchmark Report For Electricity DistributionnmzaheerNo ratings yet

- Session 2002: 21, Rue D'artois, F-75008 Paris © CigréDocument6 pagesSession 2002: 21, Rue D'artois, F-75008 Paris © Cigrébudi hermawanNo ratings yet