Professional Documents

Culture Documents

Back Off Procedures

Uploaded by

hamidrahmanyfardOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Back Off Procedures

Uploaded by

hamidrahmanyfardCopyright:

Available Formats

FISHING TECHNOLOGY

BACK-OFF

Procedures

Bernie Springer, Abu Dhabi, May 5 , 2002

th

A.

Safety Precautions

While applying left hand torque with the rotary slips, the slip handles are to be tied together with a length of wire rope. This will ensure that the slips are not thrown out of the rotary in case the pipe breaks high, causing the pipe to jump due to the instantaneous loss of strain. In cases where the wellbore fluids are not balanced between the inside and outside of the drill string, or where it is suspected that formation fluids may have migrated into the drill string annulus, the string shot is to be run using a wireline lubricator and stuffing box. The wireline safety procedures for perforating operations are to be followed while making up and running the string shot. B. Determining the Free Point

Two techniques are commonly used to determine the free point of a stuck drilling assembly. The first technique simply involves the measurement of pipe stretch for a given over-pull and then calculation of the length of free pipe. The second technique requires the use of an electronic free point indicating system run on electric line. When possible, the free point tool and back off shot should be run in combination. In general, all our back-offs will be performed based on the free point established using the electronic free point indicator. However, the calculated free point from pipe stretch data is useful in planning fishing and subsequent operations since the actual free point will typically be within +/- 500. 1. Determining Free Point based on Pipe Stretch Data

Free point calculations using pipe stretch data are most accurate in vertical holes where the impact of hole drag is minimal. This method may also be used in directorial wells, but will probably underestimate true length of free pipe due to the effects of hole drag. The following procedure is to be followed when using this technique: 1.1. Pick up the drill string to the normal pickup weight and mark the pipe at a convenient reference point. Apply an overpull of 10,000 lbs and return to the normal pickup weight. Make a second mark on the Kelly. The second mark should be distinct from the first. The difference is caused by the friction of the string in the hole. Draw a datum line midway between the two marks.

Page 1 of 22

1.2.

Take an overpull of e.g. 50,000 lbs on the pipe and mark the pipe. Increase overpull by 10,000 lbs (but do not exceed 80% of the minimum yield strength of the pipe) and return to 50,000 lbs. Make a second mark on the Kelly. Draw a datum line midway between the two marks and set the brake. Measure and record the distance (inch) between the two datum lines (amount of stretch that resulted from the over-pull). Estimate the length of free pipe using the following equation: Lf Lf L Ap E P = = = = = = = (L x Ap x E) / (12 x P) length of free pipe, feet length change due to over-pull, inches cross-sectional areas of pipe tube, sq. in. modulus of elasticity, psi 30,000,000 psi for steel applied over-pull force, pounds

1.3. 1.4.

where:

1.5.

The amount of over-pull can be increased if desired, to check the free pipe length calculated. However, it must be remembered to measure the amount of stretch from the initial reference point. Determining Free Point using Electronic Free Point Indicator.

2.

The most accurate and commonly used technique for determining the free point is through the use of an electronic free point indicator. Electronic free point services are offered by Schlumberger and Atlas, as well as a number of other electric logging companies. The technology involves measurement of the axial and torsional strain in the pipe body through application of tension and torque to the drill string. Provided the pipe is completely free, a fixed and measurable degree of strain will be recorded by the system's electronics. Once the degree of strain diminishes, or reduces to zero, the pipe is stuck. To achieve a successful back off, the pipe must be 100% free. The following procedures and guidelines are to be followed determining the free point using electronic instruments. In general, a combination free-point tool / back-off shot should be run unless tool limitations necessitate performing two separate runs. 2.1. When using a bow spring anchored free point tool, be certain a wireline Swivel / expansion joint has been fitted to isolate possible cable movement from the measuring device. This is critical, particularly in directional wells, where the cable will tend to move upward as the pipe is stretched. Lowering the free point tool on depth and then picking up on the logging cable to open the tool to mid-

Page 2 of 22

stroke most effectively uses the expansion joint. If the strain indicating needle jerks when the pipe is tensioned, then the expansion joint will have to be collapsed slightly until the correct space-out is achieved for the amount of pipe tension that is applied. 2.2. If an expanding arm free point tool is used, the expansion joint can still be used, however it is not so critical since these tools firmly anchor the free point tool inside the pipe and are less prone to slippage. Generally the cable is slackened to provide the necessary allowance for pipe movement. When free point readings are being taken, the Drilling Supervisor should be present in the logging unit to witness and supervise the operation. Be certain to maintain a written record of all tool readings as well as tension and torque applied to the drill string. The free point instrument is to be run into the drill string to 1000' below the surface and reference free point readings taken in both tension and torque. These figures will then be used to indicate the degree of free pipe for readings taken close to the stuck point. With the spring bow free point tool used by Schlumberger and Atlas, 100% free pipe is generally taken to be 80 units of meter deflection. Once calibrated, the free point tool is run in to 500 ft above the estimated free point depth calculated using the pipe stretch technique discussed earlier. Once on bottom, tension readings are to be taken first at each measurement point. With the pipe tensioned on surface to the estimated pick-up weight at the stuck point, apply over-pull to the pipe in even load increments (+/- 50,000 lbs) until pipe movement is noted at the free point tool. Smooth deflection of the strain indicating needle should be noted if the tool is functioning properly. If the needle jerks erratically, the cable has probably moved or the springs have slipped causing interference with the instrument reading. Repeat readings as required until a consistent deflection of the free point indicating needle is noted. The repeatability of the reading may not be precisely consistent and, in these cases, the average of the measured readings should be used. The degree of free pipe at any survey point is then taken as a percentage of the free pipe meter deflection measured previously. Half scale deflection would be 50% free, 3/4-scale deflection 75% free, etc.

2.3.

2.4.

2.5.

2.6.

2.7.

Page 3 of 22

2.8.

If the pipe is found to be 100% free at a given survey point, drop down the pipe in +/- 100 ft increments repeating the procedure until the meter deflection reduces to zero. Once the free point in tension has been located, repeat the procedure working up the hole taking torque measurements. Be certain to apply the same amount of torque at each depth, taking note of the number of turns required to achieve the desired torque. Once a reading has been taken at a given depth, completely release the torque prior to taking the next reading.

2.9.

2.10. The depth where both the torque and tension readings indicate 100% free pipe is taken as the free point. This is the depth, above which the pipe should be backed off. When analyzing stuck point readings, the following guidelines will prove useful: In a highly deviated well with a significant degree of hole drag, a wide discrepancy between the degree of axial and torsional deflection of the free point meter may be noted. This will likely be due to an inability to work sufficient torque down the hole to achieve full-scale deflection. In this case attempt to work the torque down and repeat the readings. If the torque cannot be worked down to the right, it will also be difficult to work torque down to the left; therefore, a shallower back-off point should be selected. In cases where the bottom-hole assembly is differentially stuck, a sharp distinction between free pipe and stuck pipe will generally be noted. The length of partially stuck pipe will be short, however the pipe should still be backed off at the point where the pipe is 100% free. In those cases where the formation has progressively fallen in behind the drilling assembly, a very gradual transition between 100% free and 100% stuck will be noted. The tendency here is to try for a deeper back-off. This should not be attempted, as the time wasted trying to back-off below the 100% free depth will generally result in more of the pipe becoming stuck.

2.11. Once the free point is located, pickup to the tool joint that will be backed off and mark the wireline cable for later reference while running in with the string shot.

Page 4 of 22

C.

Determining String Tension Required to Back-Off

Under ideal conditions the desired pipe tension at the back-off point is zero. Recognizing that this cannot be achieved in practice, it is preferred to have the pipe slightly in tension at the back-off point as opposed to compression. Calculation of the required surface tension, and how this tension is applied prior to firing the string shot is critical to successfully backing off the pipe at the intended depth. If too much tension is applied, or if the pipe is in compression, it will probably not back off. If it does, it will probably be further up the string than planned. This may require that the pipe has to be made up again and the back off procedure repeated. To determine the necessary surface tension to optimize the tension at the backoff point, the following information is required. Pickup, slack-off and off bottom rotating weights of the drill sting prior to becoming stuck. These measurements are to be taken with the pumps off. If the pipe became stuck while tripping, the required figures may have to be estimated based on previously recorded pickup, slack-off and rotating weights recorded while drilling at the depth of the stuck point. The weight/foot and length of individual components of the drilling assembly The density of the drilling fluid in the well The average hole inclination through the section of the well where the drilling assembly is stuck. Once the hook load required putting the back-off point in zero tension has been determined, an additional e.g. 5000 lbs of overpull is then applied to ensure that the connection is in tension rather than compression.

Page 5 of 22

The required additional overpull can be calculated as follows: AO Where: AO MW VD JA = = = = Additional Overpull (lb) Mud weight (ppg) Vertical depth at backoff point (ft) Tool Joint Mating Surface Area (sq. inch) = MW * VD * TJA

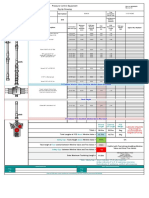

Tool Joint Mating Surface Area (API Spec 7)

Type of Connection NC 23 NC 26 NC 31 NC 35 NC 38 NC 40 NC 44 NC 46 NC 50 NC 56 NC 61 NC 70 NC 77

Mating Surface Area JA inch2 1.653 1.591 2.908 4.609 3.400 4.948 8.151 6.801 6.717 14.116 21.892 23.156 31.678

Type of Connection 2 3/8 REG 2 7/8 REG 3 1/2 REG 4 1/2 REG 5 1/2 REG 6 5/8 REG 7 5/8 REG 5 1/2 FH

Mating Surface Area JA inch2 1.464 2.690 3.095 4.754 8.419 13.290 21.443 8.081

Page 6 of 22

Page 7 of 22

A generalized equation for determining the correct weight indicator reading when the string shot is fired is as follows: Weight Indicator Reading = + = = = Hole Drag of Stuck Tools = Pick-up Weight Buoyed Weight of Stuck Tools Hole Drag of Stuck Tools e.g. 5,000 lbs Over-pull Pickup weight of entire drilling assembly before becoming stuck, lbs Buoyed weight of drilling assembly below back-off point taking account of hole inclination, lbs. Air weight x buoyancy factor x cosine of hole angle Proportion of total pickup drag based on length of stuck tools

Where: Pickup Weight Buoyed Weight of Stuck Tools

The following examples illustrate the correct calculation procedure for determining the required hook load for backing off. 1. VERTICAL WELL In this example it will be assumed that the drilling assembly has become differentially stuck while drilling on bottom. Well depth: Hole size: Drill String: Mud weight: Buoyancy Factor: Pickup Weight: Slack-off Weight: Rotating Weight: Weight of Blocks: Stuck Point: Avg. Hole Angle: 10,500' MD (vertical well) 12-1/4" 500' x 5" x 150 1b/ft drill collars 450' x 5 x 50 lb/ft HWDP 9,450' x 5 x 19.5 lb/ft S-135 drill pipe 10.5 ppg 0.84 370,000 lbs *) 335,000 lbs *) 350,000 lbs *) 100,000 lbs *) 9,900' MD (top of drill collars) 0 deg.

*) Includes weight of blocks, hook, etc.

Page 8 of 22

In this example it will be assumed that the hole drag is distributed uniformly along the length of die drilling assembly, that 5,000 lbs of tension will be maintained in the pipe at the back-off point when the string shot is fired, and that the pipe will be backed off at the stuck point (i.e. 9,900' MD). 1.1. Calculate buoyed weight of drill collars below stuck point: Air Weight of Drill Collars: Buoyancy factor: Buoyed weight: Cosine (0 deg): Net buoyed weight: 1.2. 90,000 lbs 0.84 75,600 lbs 1.00 75,600 lbs

Calculate hole drag of stuck BHA: The hole drag figure to use here is the drag experienced while picking up the drilling assembly since the pipe will be picked up to the correct weight indicator reading to perform the back-off. Total hole drag moving up: Length of drilling assembly: Hole drag per 1,000 feet: Length of stuck pipe: Hole drag along stuck BHA: 20,000 lbs 10,500 ft 1,905 lbs 600 ft 1,143 lbs

1.3.

Calculate required weight indicator reading at time string shot is fired: Total Pickup weight: Minus BHA weight: Minus hole drag: Plus over-pull requirement: Required pickup weight: 370,000 lbs -75,600 lbs - 1,143 lbs + 5,000 lbs 298,257 lbs

Therefore, prior to firing the string shot, the pipe will be slacked off to below the initial slack-off weight and then picked up and tensioned to a weight indicator reading of 298,257 lbs. For practical purposes this figure can be rounded off to 298,000 lbs. It should be noted that in order to apply the correct pick-up weight, the weight of all tools and equipment that were suspended below the hook are accounted for in this pickup weight calculation. For instance, if the kelly has been removed, this weight must be subtracted from the required pickup weight.

Page 9 of 22

2.

Directional Well In this example it will be assumed that the drilling assembly has become differentially stuck while making a connection on bottom. Well depth: Hole size: Drill string: Mud Weight: Buoyancy Factor: Pickup Weight: Slack-off Weight: Rotating Weight: Weight of Blocks: Stuck point: Kick-off Point: End of Build: Hole Angle: *) 12,500' MD (directional well) 8-1/2" 400' x 5-1/2" x 90 ppf drill collars 1,000' x 5" X 5O ppf HWDP 11,100 x 5" x 19.5 ppf S-135 DP 12.5 ppg 0.809 355,000 lbs *) 160,000 lbs *) 295,000 lbs *) 100,000 lbs 12,200' MD (300 above bit) 2,000' MD 4,000' MD 45 Deg. (below KOP to TD)

Includes weight of blocks, hook, etc.

In this example it will be assumed that the hole drag is distributed uniformly along the length of the drilling assembly and that 5000 lbs of tension will be maintained in the pipe at the back-off point when the string shot is fired. As with the previous example, the required weight indicator reading when the string shot is fired will be determined by deducting the weight of the section of BHA to be left in the well taking account of hole inclination. 2.1. Calculate buoyed weight of BHA to be left in hole following back-off: Air weight of DC Below stuck point: Cosine of 45 deg.: New air weight of DC: Buoyancy factor: Net buoyed weight of DC fish: 27,000 lbs 0.707 19,089 lbs 0.809 5,443 lbs

Page 10 of 22

2.2.

Calculate hole drag of pipe to be left in hole: The hole drag figure to use here is the drag experienced while picking up the drilling assembly since the pipe will be picked up to the correct weight indicator reading to perform the back-off. Hole drag moving up: Total length of drilling assembly: Hole drag per 1000 ft (moving up): Length of stuck pipe: Hole drag along stuck pipe: 60,000 lbs 12,500 ft 4,800 lbs 300 ft 1,440 lbs

2.3.

Calculate required weight indicator reading at the time string shot is fired: Pickup weight of drilling assembly: Minus along-hole weight of DC fish: Minus hole drag: Plus over-pull requirement: Required Pick Up Weight: 355,000 lbs - 15,443 lbs - 1,440 lbs + 5,000 lbs 343,117 lbs

Therefore, prior to firing the string shot, the pipe will be slacked off to below the initially recorded slack-off weight and then picked up to a weight indicator reading of 343,117 lbs. For practical purposes this figure can be rounded off to 343,030 lbs. D. String Shot Charge Size

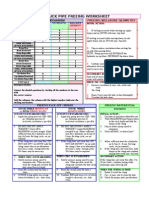

The size of the explosive used to make-up the string shot is critical to creating sufficient hammer effect to cause the tool joint to break at the desired connection. As a rule, the number of strands of primacord to the used for a specific connection should be 2 - 3 greater than the number specified by either Schlumberger or Atlas. The primacord selected should be an 80 gm/ft RDX or HDX specification. The RDX explosive is good to a nominal maximum bottom-hole temperature of 325 deg, while the HDX charge can be used up to 400 deg. F. The following table gives nominal primacord requirements for back-off operations. Again, the actual number of primacords used should be 2 - 3 more than listed.

Page 11 of 22

MEASURED DEPTH TO BACK-OFF POINT (FEET) CONNECTION 0 to 3,000 3,000 to 6,000 6,000 to 9,000 9,000 to 12,000 over 12,000

TUBING 2-3/8 2-7/8 3-1/2 4 & 4-1/2 DRILL PIPE 2-3/8 & 2-7/8 3-1/2 & 4 4-1/2 to 6-9/16 6-5/8 DRILL COLLARS 3-1/2 & 4 4-1/8 5-1/2 5-3/4 7 7-1/4 to 8-1/2 CASING 4-1/2 to 5-1/2 6 to 7 7-5/8 8-5/8 3 3 4 5 3 3 4 5 3 3 4 5 3 4 4 5 3 4 5 5 24 24 36 4-6 25 36 48 5-9 37 48 5 10 6 - 12 38 4 10 6 12 7 - 15 45 5 12 7 15 8 18 1 2 2 3 2 3 34 4-5 23 34 46 5-7 34 46 59 6 - 10 45 58 6 12 7 14 1 1 1 2 1 1 2 2 1 2 2 2 2 2 3 3 2 3 3 3

Page 12 of 22

E.

Working Right Hand Torque Down the Hole

Prior to performing a downhole back-off it will be necessary to be certain sufficient make-up torque has been applied to the pipe to avoid a shallow back-off or a deep open hole back-off at the incorrect depth. The correct amount of right hand torque to work down the drill string will depend on several factors including well depth, wellbore profile, and degree of hole drag in both tension and torsion. The correct string tension to be applied at the surface in order to effectively work torque down to the back-off point should have been determined while locating the free point. In this regard, it does not necessarily follow that the pipe should be worked between the calculated pickup and slack-off weights at the back-off point. For this reason the torque measurements taken while determining the free point should be used as an indicator of the correct surface tension to use for applying both left hand and right hand torque. When working right hand torque down the hole, the following practices are to be followed: 1. The amount of right hand torque that must be worked into the pipe should be sufficient to generate a full scale torque reading on the free point tool at the planned back-off depth plus 30%. This will ensure that maximum left hand torque can be applied to the pipe when the string shot is fired. The torque is to be worked down the pipe from surface to the free point. Since tool joints can only be torqued correctly with minimum axial tension the pipe is to be raised and lowered between the calculated free pipe pickup weight at the planned back-off point and zero surface tension while progressively increasing the applied right hand torque. The torque is to be applied in 3 -4 steps until the maximum make up torque has been worked into the string. Be certain to record the number of total turns necessary to achieve maximum make up torque, as well as the number of turns that can be anticipated when the required left hand torque is applied. 4. Complete make up of all connections will be indicated when no loss of trapped torque occurs as the pipe is cycled between the range of pick-up and slackoff weights being used.

2.

3.

Page 13 of 22

F.

Working Left Hand Torque down the Hole

The amount of left hand torque to work down the hole should be the maximum possible within the constraint of avoiding a premature or shallow back-off. This is a hazardous operation and safety precautions as outlined must be closely followed. When working left hand torque down the hole the following guidelines and procedures have to be followed. 1. 2. As a rule of thumb, the amount of left hand torque applied at the surface should not exceed 70% of the right hand makeup torque. Since a tool joint is more inclined to break when the axial tension on the connection is zero, left hand torque should be worked down the hole stating with maximum surface tension and working progressively down to planned back-off tension. This should be performed in several stages starting with approximately half of the required left hand torque. Only when a given amount of torque has been worked into the entire string, the torque should be increased to the next stage. Be certain to maintain a record of the number of cumulative left hand turns that have been put in the pipe as the torque is worked down to the planned back-off point. The string shot is to be loaded into the drill string prior to applying any torque at surface. Do not load the string shot into the string shot while torque is trapped in the pipe. This could result in serious injury to personnel if the pipe were to break prematurely and backlash at surface. Running the String Shot and Backing Off

3.

4.

G.

Once the number of turns required to work the desired left hand torque downhole has been determined, the string shot can be loaded into the pipe in preparation for running downhole. 1. With the surface torque on the pipe completely released, load the string shot and collar locator assembly into the drill string and run in to 1000 ft below surface. Do not run in deeper since if the pipe were to back-off shallow, the wireline cable may be severely damaged or part downhole resulting in another fishing job.

Page 14 of 22

NOTE: In cases where a combination free point/back-off shot have been run, the tool assembly should be pulled up to 1000 ft below the rotary table prior to working left hand torque into the string. 2. Apply left hand torque to the pipe and work it downhole to the planned back-off point. The toque will be completely worked down to the back off point when the number of previously measured left hand turns have been achieved. If holding the torque with the rotary or top drive, make sure to lock the rotary table or power swivel once the final torque is achieved. Apply left hand torque to the pipe and work it downhole to the planned back-off point. The torque will be completely worked down to the back-off point when the number of previously measured left hand turns have been achieved. If holding the torque with the rotary or a top drive, make sure you lock the rotary table or power swivel once the final torque is achieved. Run in with the string shot and position the charge opposite the planned back-off point. Clear all personnel from the rotary table area. Fire the string shot and monitor the torque gauge for a loss of torque. If successful, DO NOT unscrew the pipe. Pull the wireline cable back to +/- 1000 feet. Release the trapped left hand torque and make note of the number of right hand turns necessary to reduce the torque to zero. POOH with the wireline and pull the logging cable clear.

3.

4. 5. 6.

7. 8.

BACKOFF STRING-SHOT Running Hardware

9.

Page 15 of 22

10.

Reduce string tension to anticipate rotating weight at back-off point and rotate pipe to the left to complete back-off. Pick up on string and check the pick-up weight. 10.1. If pipe backed off at planned depth, POOH. 10.2. If the pipe backed off high, screw into connection looking up and repeat entire back-off procedure. Since the pipe backed off high, it may be necessary to increase the amount of right hand torque, work the torque down for a longer period, and/or adjust the string tension to be held when the string shot is fired. If the pipe backed off close to the planned back-off point, check the pickup, slackoff and rotating string weights prior to screwing back into the fish These measurements should then be used to determine the correct pickup and slackoff weights for working torque down the hole, as well as the correct tension to hold when the string shot is fired. NOTE: In certain cases where the pipe has backed off high, it may be desirable to pull out of the hole and run an alternative fishing assembly. This will be decided on a case by case basis following consultation with the drilling superintendent.

Page 16 of 22

Technical Data

Page 17 of 22

Page 18 of 22

Page 19 of 22

Page 20 of 22

Page 21 of 22

Standard Fishing Tool Inventory

Fishing Tools for 26"-17-1/2" & 12-1/4" holes 8" hydraulic jar, 6-5/8" reg pin x box 8" accelerator, 6-5/8" reg pin x box 8" fishing bumper sub 6-5/8" reg pin x box 11.1/4" overshot c/w extension subs and 15"-22" guides to catch 9-1/2" and 8-1/4 DC and 5" DP with 6-3/8" tool joints 9-1/2" junk sub 6-5/8" reg pin x box 8-1/8 overshot c/w extension sub and 11"-15" guides to catch 5" DP and 6-3/8" tool joints Junk mills (as required) 6-5/8" reg. pin ADT Hydraulic junk retriever Crossover subs - as required Fishing Tools for 8-1/2" Hole 6-1/4" hydraulic jar, 4-1/2" IF pin x box 6-1/4" accelerator, 4-1/2" IF pin x box 6-1/4" fishing bumper sub, 4-1/2" IF pin x box 8-1/8" overshot c/w extension subs to catch 5" DP, 6-1/4 DC and 6-3/8" OD tool joints. 7" junk sub 4-1/2" reg box x pin Be sure required crossovers are available 8-3/8" junk mill 4.1/2" reg pin ADT hydraulic junk retriever Fishing Tools for 6" Hole 4-3/4" hydraulic jar, 3-1/2" IF pin x box 4-3/4" accelerator, 3-1/2" IF pin x box 4-3/4" fishing bumper sub, 3-1/2" IF pin x box Crossover subs 5-3/4" overshot c/w extension subs to catch 3-1/2" DP and 4-3/4" DC + tool joints 5-1/2" junk sub 3-1/2" reg box x pin 5-15/16" junk mill, 3.1/2" reg pin ADT Hydraulic Junk Retriever

Page 22 of 22

You might also like

- Back Off Procedures by Weatherford PDFDocument23 pagesBack Off Procedures by Weatherford PDFWailin Phyo397No ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 9 - Free Point and Backoff - (Houston)Document29 pages9 - Free Point and Backoff - (Houston)Usama Bin Sabir100% (2)

- Freeing Stuck PipeDocument24 pagesFreeing Stuck PipePavel Yanev100% (3)

- Drilling Practice Stuck PipeDocument81 pagesDrilling Practice Stuck PipeAhmed Ajeeb100% (2)

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersFrom EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNo ratings yet

- Jar Best PracticesDocument35 pagesJar Best PracticesDanish KhanNo ratings yet

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Stuck Pipe Book by DrillingFormulasDocument60 pagesStuck Pipe Book by DrillingFormulasumairNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Well Control BPDocument498 pagesWell Control BPcristianoclem100% (1)

- Tripping Operations - Best PracticesDocument3 pagesTripping Operations - Best PracticesYougchu Luan100% (1)

- Horizontal Well Drill String DesignDocument27 pagesHorizontal Well Drill String DesignTarek HassanNo ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- 39 Drilling JarsDocument26 pages39 Drilling JarsnjileoNo ratings yet

- The Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbFrom EverandThe Guide to Oilwell Fishing Operations: Tools, Techniques, and Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (11)

- 0 Intro STK Pipe PDFDocument10 pages0 Intro STK Pipe PDFNabil Benmakhlouf100% (9)

- Ads Bdte ManualDocument428 pagesAds Bdte ManualWanwaniouan Pomme100% (9)

- Applied Drilling Circulation Systems: Hydraulics, Calculations and ModelsFrom EverandApplied Drilling Circulation Systems: Hydraulics, Calculations and ModelsRating: 5 out of 5 stars5/5 (4)

- 4 - Best Practices FDocument46 pages4 - Best Practices FAlvaro Gutiérrez TrocheNo ratings yet

- Common Well Control Hazards: Identification and CountermeasuresFrom EverandCommon Well Control Hazards: Identification and CountermeasuresRating: 4.5 out of 5 stars4.5/5 (4)

- Kick-Off Techniques: Hassan AlemiDocument52 pagesKick-Off Techniques: Hassan Alemimagoankit50% (2)

- L11-Leak Off Test, Kick Tolerance & Kick Circulation MethodsDocument45 pagesL11-Leak Off Test, Kick Tolerance & Kick Circulation MethodsLaxmi Kant PrasadNo ratings yet

- Drill String DesignDocument13 pagesDrill String DesignTarek Hassan67% (3)

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementFrom EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementRating: 4.5 out of 5 stars4.5/5 (2)

- Best Practices Drilling 26 inDocument6 pagesBest Practices Drilling 26 inmanuelperdomotNo ratings yet

- Air and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHFrom EverandAir and Gas Drilling Manual: Applications for Oil, Gas, Geothermal Fluid Recovery Wells, Specialized Construction Boreholes, and the History and Advent of the Directional DTHNo ratings yet

- LD2 Drilling Practices & Lessons Learned - A.boubeniaDocument8 pagesLD2 Drilling Practices & Lessons Learned - A.boubeniaAli BoubeniaNo ratings yet

- JAR-KING 1 Operations ManualDocument20 pagesJAR-KING 1 Operations ManualkrishnsgkNo ratings yet

- Stuck Pipe ChartDocument3 pagesStuck Pipe ChartJorge Luis Ortiz100% (2)

- Drill String DesignDocument12 pagesDrill String DesignAhmed BakrNo ratings yet

- A120 Series 70 150 Overshot ManualDocument48 pagesA120 Series 70 150 Overshot ManualHamdi SaidNo ratings yet

- Torque and Drag CalculationsDocument67 pagesTorque and Drag Calculationssivakmu100% (22)

- Rotary Bha Ingold r3xDocument56 pagesRotary Bha Ingold r3xUsama Bin Sabir100% (2)

- Triaxial Stress AnalysisDocument7 pagesTriaxial Stress Analysisbymohamed100% (1)

- 2018 Drilling Motor HandbookDocument186 pages2018 Drilling Motor HandbookNemanja MilićevićNo ratings yet

- Off-Bottom Drilling PracticesDocument3 pagesOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyNo ratings yet

- Casing String Design ModelDocument120 pagesCasing String Design ModelAry Rachman100% (2)

- Drilling Jar ManualDocument33 pagesDrilling Jar ManualJohnSmith80% (5)

- Distance Learning Drilling Calculations Part 2Document188 pagesDistance Learning Drilling Calculations Part 2Kolawole AdisaNo ratings yet

- BOP Test Procedure - Drilling - Mud Docs & JobsDocument7 pagesBOP Test Procedure - Drilling - Mud Docs & Jobskrishnsgk100% (1)

- IWCF WI - 2 - Principles & ProceduresDocument110 pagesIWCF WI - 2 - Principles & Proceduresharishan sathNo ratings yet

- Auto TrakDocument118 pagesAuto Traksaeed6575% (4)

- Torque & DragDocument66 pagesTorque & Dragjoonak konwar91% (11)

- Stuck Pipe PreventionDocument20 pagesStuck Pipe PreventionDavid Ortega100% (1)

- Drilling With Casing 04Document15 pagesDrilling With Casing 04Dian Sikumbang100% (2)

- Pipe Sticking PDFDocument5 pagesPipe Sticking PDFAnimeshNo ratings yet

- Horizontal Well Drill String DesignDocument23 pagesHorizontal Well Drill String DesignTarek HassanNo ratings yet

- Wireline OperationsDocument132 pagesWireline OperationsJude80% (5)

- Well CommanderDocument8 pagesWell Commanderice_PLNo ratings yet

- Adv Intro MWDDocument21 pagesAdv Intro MWDShamia Essam100% (2)

- Study 196 - Executive - SummaryDocument4 pagesStudy 196 - Executive - SummaryhamidrahmanyfardNo ratings yet

- Study 198 Executive SummaryDocument6 pagesStudy 198 Executive SummaryhamidrahmanyfardNo ratings yet

- Study 194 Executive SummaryDocument5 pagesStudy 194 Executive SummaryhamidrahmanyfardNo ratings yet

- ESG For The Energy SectorDocument3 pagesESG For The Energy SectorhamidrahmanyfardNo ratings yet

- Future Options For Alberta's Bitumen ResourcesDocument6 pagesFuture Options For Alberta's Bitumen ResourceshamidrahmanyfardNo ratings yet

- Sub-Surface Master Development Plan-Phase 12Document69 pagesSub-Surface Master Development Plan-Phase 12hamidrahmanyfardNo ratings yet

- Ai SP Man 803Document271 pagesAi SP Man 803hamidrahmanyfardNo ratings yet

- Fishing Services Catalog PDFDocument163 pagesFishing Services Catalog PDFEduardo Oyarzun50% (2)

- Well InterventionsDocument124 pagesWell InterventionsTrue Story100% (1)

- Basic Slickline 1Document60 pagesBasic Slickline 1Fauzan Rahman Haq100% (11)

- Lufkin Gas Lift CatalogDocument36 pagesLufkin Gas Lift CatalogMilena PuertoNo ratings yet

- Trinity Plugs For Well CompletionDocument50 pagesTrinity Plugs For Well CompletionEspion BenNo ratings yet

- Coil TubingDocument14 pagesCoil TubingMAKTAR5422100% (3)

- Slick Line Rig UpDocument1 pageSlick Line Rig UpWookie VanNo ratings yet

- Directional Drilling With Casing SPE-IADC-79914 PDFDocument10 pagesDirectional Drilling With Casing SPE-IADC-79914 PDFWailin Phyo397No ratings yet

- TIC Catalog de HerramientasDocument408 pagesTIC Catalog de HerramientasWilsonPuertasNo ratings yet

- Winchdrum Pd02: Application - Cased HoleDocument1 pageWinchdrum Pd02: Application - Cased HolefelipeNo ratings yet

- Safety ValvesDocument22 pagesSafety ValvesJabbarKaddemNo ratings yet

- Workover Programme - Tubing Change OutDocument11 pagesWorkover Programme - Tubing Change OutE_Amr_SorourNo ratings yet

- Tezar Agustian: Slickline Chief OperatorDocument3 pagesTezar Agustian: Slickline Chief OperatorPurnomoEbeNo ratings yet

- Coiled Tubing BHA Manual PDFDocument12 pagesCoiled Tubing BHA Manual PDFSantiago Zárate0% (1)

- Design and Application of An Integral Jet Pump/Safety Valve in A North Sea OilfieldDocument18 pagesDesign and Application of An Integral Jet Pump/Safety Valve in A North Sea OilfieldHatem FaroukNo ratings yet

- HL OltDocument9 pagesHL OltAfonso MatondoNo ratings yet

- Haimson, Cornet 2003 Hydrofrac PDFDocument10 pagesHaimson, Cornet 2003 Hydrofrac PDFAlexandre GomesNo ratings yet

- ZEiTECS Shuttle BrochureDocument4 pagesZEiTECS Shuttle BrochureRoii RoyyNo ratings yet

- GSE - RODE-1 - 8.5in - Fishing OperationDocument10 pagesGSE - RODE-1 - 8.5in - Fishing OperationMansour MohamedTNo ratings yet

- PerforatingDocument78 pagesPerforatingامير العذاريNo ratings yet

- Well Workover and InterventionDocument27 pagesWell Workover and InterventionAndrewNo ratings yet

- P1R8789A Well Completion & Workover Manual Volume1Document416 pagesP1R8789A Well Completion & Workover Manual Volume1mbhadel50% (2)

- SLK SWI Wire Test - FIT - 7070651 - 01Document26 pagesSLK SWI Wire Test - FIT - 7070651 - 01Ramal OmarovNo ratings yet

- Capillary Injection Sytem Halib ValveDocument26 pagesCapillary Injection Sytem Halib Valvebahar1991No ratings yet

- CoringDocument63 pagesCoringsabra muneer100% (1)

- Tapon FSG - RZG - FWGDocument12 pagesTapon FSG - RZG - FWGArenita WrightNo ratings yet

- Workover Class NotesDocument47 pagesWorkover Class NotesSorin100% (1)

- Slickline TenderDocument10 pagesSlickline Tender李四江No ratings yet

- Well Test PlanningDocument16 pagesWell Test PlanningLaw100% (1)

- Plunger LiftDocument4 pagesPlunger LiftChristian AvilaNo ratings yet

- Body Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialFrom EverandBody Confidence: Venice Nutrition's 3 Step System That Unlocks Your Body's Full PotentialRating: 4 out of 5 stars4/5 (2)

- How Can I Get Her to Wrestle With Me? Careful What You Ask For. Mid-April 2024From EverandHow Can I Get Her to Wrestle With Me? Careful What You Ask For. Mid-April 2024No ratings yet

- Man 2.0 Engineering the Alpha: A Real World Guide to an Unreal LifeFrom EverandMan 2.0 Engineering the Alpha: A Real World Guide to an Unreal LifeNo ratings yet

- Strength Training Over 40: The Only Weight Training Workout Book You Will Need to Maintain or Build Your Strength, Muscle Mass, Energy, Overall Fitness and Stay Healthy Without Living in the GymFrom EverandStrength Training Over 40: The Only Weight Training Workout Book You Will Need to Maintain or Build Your Strength, Muscle Mass, Energy, Overall Fitness and Stay Healthy Without Living in the GymRating: 4 out of 5 stars4/5 (6)

- Beastmode Calisthenics: A Simple and Effective Guide to Get Ripped with Bodyweight TrainingFrom EverandBeastmode Calisthenics: A Simple and Effective Guide to Get Ripped with Bodyweight TrainingNo ratings yet

- Juicing for Beginners: Unlock Vitality and Vigor with Nutritious, Detoxifying, and Flavorful Juices [COLOR EDITION]From EverandJuicing for Beginners: Unlock Vitality and Vigor with Nutritious, Detoxifying, and Flavorful Juices [COLOR EDITION]Rating: 5 out of 5 stars5/5 (16)

- How to Gain Weight and Build Muscle for Skinny Guys: 30 lbs of MeatFrom EverandHow to Gain Weight and Build Muscle for Skinny Guys: 30 lbs of MeatRating: 4 out of 5 stars4/5 (6)

- Hero Maker: 12 Weeks to Superhero Fit: A Hollywood Trainer's REAL Guide to Getting the Body You've Always WantedFrom EverandHero Maker: 12 Weeks to Superhero Fit: A Hollywood Trainer's REAL Guide to Getting the Body You've Always WantedRating: 4 out of 5 stars4/5 (1)

- Roxane Gay & Everand Originals: Built for This: The Quiet Strength of PowerliftingFrom EverandRoxane Gay & Everand Originals: Built for This: The Quiet Strength of PowerliftingRating: 4.5 out of 5 stars4.5/5 (133)

- Roxane Gay & Everand Originals: Built for This: The Quiet Strength of PowerliftingFrom EverandRoxane Gay & Everand Originals: Built for This: The Quiet Strength of PowerliftingRating: 4.5 out of 5 stars4.5/5 (19)

- April Powers 2024 Part II Women Defeat Men at Wrestling, Fighting & Self-DefenseFrom EverandApril Powers 2024 Part II Women Defeat Men at Wrestling, Fighting & Self-DefenseNo ratings yet

- Summary of Thinner Leaner Stronger: The Simple Science of Building the Ultimate Female Body by Michael MatthewsFrom EverandSummary of Thinner Leaner Stronger: The Simple Science of Building the Ultimate Female Body by Michael MatthewsRating: 4 out of 5 stars4/5 (9)

- Workout: 33 Best Science-Based Workout HacksFrom EverandWorkout: 33 Best Science-Based Workout HacksRating: 4 out of 5 stars4/5 (31)

- Strength Training Thresholds: The Key to Consistent Strength GainsFrom EverandStrength Training Thresholds: The Key to Consistent Strength GainsRating: 4 out of 5 stars4/5 (4)

- Build Muscle, Burn Fat: A Beginner's Guide to the Science of Strength TrainingFrom EverandBuild Muscle, Burn Fat: A Beginner's Guide to the Science of Strength TrainingRating: 4.5 out of 5 stars4.5/5 (2)

- April Powers 2024: Women Defeat Men at Wrestling, Fighting & Self-DefenseFrom EverandApril Powers 2024: Women Defeat Men at Wrestling, Fighting & Self-DefenseNo ratings yet

- Strong Like Her: A Celebration of Rule Breakers, History Makers, and Unstoppable AthletesFrom EverandStrong Like Her: A Celebration of Rule Breakers, History Makers, and Unstoppable AthletesRating: 4 out of 5 stars4/5 (9)

- Summary of Sal Di Stefano's The Resistance Training RevolutionFrom EverandSummary of Sal Di Stefano's The Resistance Training RevolutionNo ratings yet

- 20:TWELVE:20 advanced,adaptive,diet and pyramid training systemFrom Everand20:TWELVE:20 advanced,adaptive,diet and pyramid training systemRating: 5 out of 5 stars5/5 (2)

- Weight Training for Complete BeginnersFrom EverandWeight Training for Complete BeginnersRating: 5 out of 5 stars5/5 (1)

- Spartan Warrior Workout: Get Action Movie Ripped in 30 DaysFrom EverandSpartan Warrior Workout: Get Action Movie Ripped in 30 DaysRating: 4 out of 5 stars4/5 (4)

- The New Encyclopedia of Modern Bodybuilding: The Bible of Bodybuilding, Fully Updated and RevisFrom EverandThe New Encyclopedia of Modern Bodybuilding: The Bible of Bodybuilding, Fully Updated and RevisRating: 4.5 out of 5 stars4.5/5 (62)

- Mind Gym: An Athlete's Guide to Inner ExcellenceFrom EverandMind Gym: An Athlete's Guide to Inner ExcellenceRating: 3 out of 5 stars3/5 (18)

- Strength Training For Runners: 3 Basics Of Weight Training For RunnersFrom EverandStrength Training For Runners: 3 Basics Of Weight Training For RunnersNo ratings yet

- How To Powerlift For Beginners: Your Step By Step Guide To Powerlifting For BeginnersFrom EverandHow To Powerlift For Beginners: Your Step By Step Guide To Powerlifting For BeginnersNo ratings yet

![Juicing for Beginners: Unlock Vitality and Vigor with Nutritious, Detoxifying, and Flavorful Juices [COLOR EDITION]](https://imgv2-1-f.scribdassets.com/img/word_document/579641066/149x198/3cc3790d1c/1715551396?v=1)