Professional Documents

Culture Documents

Base Plate Design

Uploaded by

rajarshiboseOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Base Plate Design

Uploaded by

rajarshiboseCopyright:

Available Formats

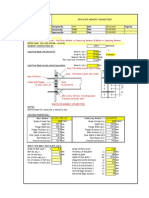

BAGGING TOWER SUPPORT - JPL

DESIGN OF BASE PLATE

Colm. Memb. Size :- Box MC200

FOR MAX Base Pressure

1410 113 DL+LL+ MATL. LOAD+SL Z-

Max. Compression =

15.66

Max Moment - X =

4.92

TM

Max Moment - Z =

Try Size Base Plate

0.00

TM

46

cm x

27

cm

Base Area =

1242

Zxx =

9522

Zzz =

5589

Bearing pressure(Bp)=

64.26 Kg/cm

Grade of conc. For fdn. =

M30

Permissible stress in compression =

106 Kg/cm kg/sq.cm >

c

64.26 kg/sq.cm

O.K

36 F HD BOLTS

4 nos

a

b

t2

10 mm

270

2

t1

ISMC 200

10 mm

340

460

Here

c

=

120 mm

d

=

95 mm

a

=

60 mm

b

=

110 mm

For Panel-1

a /d

=

0.632

a3 = 0.0784

For Panel-2

c/b =

1.091

a3 =

a1/d1

0.5

a3

0.6

0.7

0.6

0.7

0.8

0.9

1.2

1.4

0.074

0.088

.

1

1.2

0.112

0.12

0.1156

Allowable compression for M30 (for DL+LL) =

80 Kg/cm

Allowable bearing at Base plate (for DL+LL) =

1850 Kg/cm

Allowable compression for M30 (wind/Seismic) =

80 x 1.33 =

106 Kg/cm

Allowable bearing at Base plate (wind/Seismic) = 1850 x 1.33 = 2460 Kg/cm

Allowable tension in HD bolt (wind/seismic), Pt = 1200 x 1.25 = 1500 Kg/cm

Allowable shear in HD bolt (wind/seismic), Ps =

800 x 1.25 = 1000 Kg/cm

Check for Thickness

For panel - 1

M2 = a 3*Bp*d2 =

Required thickness(t) =

For panel - 2

M2 = a 3*Bp*b2 =

Required thickness(t) =

454.80015

kg-cm/unit width

(6M2/2460)^0.5 = 1.053218 cm

899.12592

kg-cm/unit width

(6M2/2460)^0.5 = 1.480875 cm

CHECK FOR BASE PLATE THICKNESS FOR BOLT TENSION:

60

60

0.060 0.074 0.088 0.097 0.107 0.112 0.120 0.126 0.132

Tension per Bolt = 7.18 T

Moment due to tension ,Mt = 43080 Kg-cm

Effective width, b = 12 cm

Thickness required = (6Mt/2460*b)^0.5

= 2.96 cm

2.1

0.133

60

60

Now provided Base plate thickness =

32 mm

Design for stiffner t1 =

Moment = M1*b1

=

101787.84

kg-cm

Using thickness =

10 mm

Required depth of stiffener = d, say

Hence, (6 x 101787.84(/1650 x10/10))

Depth =

19.239 cm

Design for stiffner t2 =

Moment = M2*(c1+d1/2)

= 7617.902513 kg-cm

Using thickness =

10 mm

Required depth of stiffener = d, say

Hence, (6 x 7617.9025125(/1650 x10/10))

Depth =

5.2632 cm

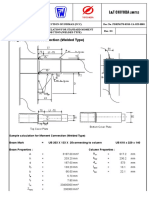

Design for Shear :- 1410 136 DL+LL+TL+SL Z+

CRITICAL CASE

Fx = 0.16 T

Fz = -2.535 T Fr = [ Fx^2+Fz^2 ]^0.5 = 2.54 T

Calculated Shear(S) =

2.54 T

Effective Shear =

2.54 T

Capacity of bolts in lateral shear= 0.4*fy =

1000 Kg/cm

shear force =

0.63 T per Bolt

Shear stress = 62.411 < 1000 Kg/cm2

Hence safe

Check for Bolt Tension:

Case 1: Tension at one edge, compression at another

L/C : Node:1411 Load:138 DL+LL+TL+SL Z5.74 N/mm

(Tension)

185.3 mm

4.79 N/mm

(Compression)

340 mm

Total Tension due to upward pressure

= 5.74 x 185.3 x 270 x

= 143617.74 N

= 14.36 T

During uplift, any two bolts will take up the tension.

Hence no. of bolts effective in tension =

2

Tension/bolt =

14.36/2 = 7.18 T

Area of bolt =

3.14/4 x 3.6^2 = 10.179 cm

Effective area of bolt = 3.14/4 x (0.85 x 3.6)^2 = 7.354 cm

(Considering 0.85D)

Tensile capacity of bolt =

7.354 x 1500 = 11031 Kg = ###### > 7.18 T

Hence OK

Allowable bond stress for M30 Grade Concrete =

1.0 N/mm

Allowable bond stress for Seismic/wind load case = 1.333 x 1 =

1.333 N/mm

Anchorage length required = 7.18 x 10000/(3.14 x 36 x 1.333) =

476.26 mm

CHECK FOR COMBINED TENSION AND SHEAR

Actual shear force per bolt =

0.635 T

Allowable shear per bolt = 3.14/4 x (0.85 x 3.6)^2 x 1000 =

=

Actaul tension in each bolt =

7.18 T

Allowable tension per bolt =

11.03 T

7354.15 Kg

7.354 T

Actual shear/Allowable Shear = 0.635/7.354 =

0.086

Actual Tension/Allowable Tension =

7.18/11.031 =

0.651

Hence, 0.086+0.651 =

0.737

OK

SUPPORT REACTION SUMMARY FOR BAGGING TOWER SUPPORTING STRUCTURE

Node

Max Fx

Min Fx

Max Fy

Min Fy

Max Fz

Min Fz

Max Mx

Min Mx

Max My

Min My

Max Mz

Min Mz

1410

1413

1410

1411

1411

1410

1411

1411

1411

1412

1410

1410

Horizontal

Fx Mton

L/C

137 DL+LL+TL+SL X135 DL+LL+TL+SL X+

113 DL+LL+ MATL. LOAD+SL Z121 0.9DL+SL Z138 DL+LL+TL+SL Z136 DL+LL+TL+SL Z+

138 DL+LL+TL+SL Z127 0.9(DL+MATL. LOAD) +SL Z+

140 DL+LL+TL+WL Z+

140 DL+LL+TL+WL Z+

100 DL+LL

100 DL+LL

Max Fy =

Min Fy =

Max Mx =

Min Mx =

Max Mz =

Min Mz =

ABS Max Mx =

ABS Max Mz =

Max Bearing Pressure =

Min Bearing Psessure =

Max Shear Force =

Vertical Horizontal

Moment

Fy Mton Fz Mton

Mx MTon-m Mz MTon-m

2.436

-2.437

0.048

0.058

0.116

0.156

0.116

-0.031

0.067

-0.076

0.093

0.093

11.195

11.069

15.658

-6.403

-5.922

-4.207

-5.922

13.113

6.063

5.997

3.944

3.944

15.658 T

-6.403 T

5.016 TM

-4.729 TM

0.000 TM

0.000 TM

5.016 TM

0.000 TM

6.43 N/mm

-5.74 N/mm

2.54 T

1410

1411

1411

1411

1410

1410

-0.201

-0.201

2.291

2.396

2.53

-2.535

2.53

-2.377

-1.241

-1.222

-0.101

-0.101

-0.025

-0.025

4.918

4.765

5.016

-4.665

5.016

-4.729

-2.331

-2.293

0.163

0.163

113 DL+LL+ MATL. LOAD+SL Z121 0.9DL+SL Z138 DL+LL+TL+SL Z127 0.9(DL+MATL. LOAD) +SL Z+

137 DL+LL+TL+SL X137 DL+LL+TL+SL X-

1410 113 DL+LL+ MATL. LOAD+SL Z1411 138 DL+LL+TL+SL Z1410 136 DL+LL+TL+SL Z+

0

0

0

0

0

0

0

0

0

0

0

0

Base Plate Size

Length (L) Width (W) Base Area

mm

mm

mm

270

460

124200

270

460

124200

270

460

124200

270

460

124200

270

460

124200

270

460

124200

270

460

124200

270

460

124200

270

460

124200

270

460

124200

270

460

124200

270

460

124200

Zxx

Zzz

mm

9522000

9522000

9522000

9522000

9522000

9522000

9522000

9522000

9522000

9522000

9522000

9522000

mm

5589000

5589000

5589000

5589000

5589000

5589000

5589000

5589000

5589000

5589000

5589000

5589000

Bearing Pressure Resultant

shear

MAX

MIN

N/mm N/mm

T

0.93

0.88

2.44

0.92

0.86

2.45

6.43

-3.9

2.29

4.49

-5.52

2.4

4.79

-5.74

2.53

4.56

-5.24

2.54

4.79

-5.74

2.53

6.02

-3.91

2.38

2.94

-1.96

1.24

2.89

-1.93

1.22

0.49

0.15

0.14

0.49

0.15

0.14

You might also like

- Base Plate Design for Bagging Tower SupportDocument9 pagesBase Plate Design for Bagging Tower SupportbuildconNo ratings yet

- Moment Connection Design-BS CODEDocument5 pagesMoment Connection Design-BS CODEMuthukumaran SivalingamNo ratings yet

- Moment Connection Portal FrameDocument18 pagesMoment Connection Portal Frametmssorin100% (1)

- End Plate-Splice ConnectionDocument76 pagesEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- Hollow Section Bracing Connetion - LRFDDocument5 pagesHollow Section Bracing Connetion - LRFDkalpanaadhiNo ratings yet

- Base Plate Design Fixed RevisedDocument8 pagesBase Plate Design Fixed RevisedEngDbt80% (5)

- BASE PLATE DESIGN OPTIMIZATIONDocument45 pagesBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- Shear Connection - Beam - Steel Column - Fin PlateDocument30 pagesShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Combined Gusset Plate DesignDocument3 pagesCombined Gusset Plate Designkalpanaadhi100% (3)

- End Plate-Beam To Column Moment ConnectionDocument81 pagesEnd Plate-Beam To Column Moment ConnectionHemant Ramesh Narkar50% (6)

- Typ-Base PlateDocument11 pagesTyp-Base PlateManoj Jaiswal100% (2)

- Bolted Moment ConnectionDocument3 pagesBolted Moment Connectionprabhu81100% (3)

- End Plate DesignDocument4 pagesEnd Plate DesignAgnon Fung100% (4)

- Base Plate With Moment & Axial CompressionDocument2 pagesBase Plate With Moment & Axial CompressionAnonymous b3NKZUb100% (3)

- Rafter Splice DesignDocument2 pagesRafter Splice DesignkalpanaadhiNo ratings yet

- Design of I-Shape Column Base PlateDocument6 pagesDesign of I-Shape Column Base PlatebuildconNo ratings yet

- 6-Bracing Connection - TDocument2 pages6-Bracing Connection - TMUTHUKKUMARAMNo ratings yet

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDocument1 pageCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- Moment Connection Beam Column IS & BS SECTION FOR IS800Document29 pagesMoment Connection Beam Column IS & BS SECTION FOR IS800pjuvvadi86% (7)

- RD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryDocument25 pagesRD, 1 RD, 2 RD, 3 RD, 4 RD, 5 RD, 6 RD, 7 RD, 8: Doc. ID-Code Rev. CategoryHanuman Sharma83% (6)

- 321 Chapter 5 Splice DesignDocument91 pages321 Chapter 5 Splice DesignHemant Ramesh NarkarNo ratings yet

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- Base Plate Design for Column SupportDocument180 pagesBase Plate Design for Column Supportbuildcon62% (13)

- 4-Base Plate - Pin ConnectionDocument3 pages4-Base Plate - Pin ConnectionMUTHUKKUMARAMNo ratings yet

- End Plate ConnectionDocument10 pagesEnd Plate ConnectionMohamed Tahar Allagui100% (1)

- Shear Steel ConnectionDocument3 pagesShear Steel ConnectionНемања Караклајић100% (1)

- Double Angle Connection Design ChecksDocument13 pagesDouble Angle Connection Design ChecksrunkirNo ratings yet

- Design Calculation For Column (Staad Member No. 1219) : Section PropertiesDocument63 pagesDesign Calculation For Column (Staad Member No. 1219) : Section PropertiesSreeraja SreevilasanNo ratings yet

- Structural design calculations of splice plate and base plateDocument24 pagesStructural design calculations of splice plate and base plateAkshay Patil100% (1)

- Beam SpliceDocument17 pagesBeam SpliceBoddu Ramakrishna100% (1)

- Beam To Beam Web - Shear ConnectionDocument2 pagesBeam To Beam Web - Shear ConnectionGautam SharmaNo ratings yet

- Weld ConnectionDocument70 pagesWeld ConnectionSudhakar KrishnamurthyNo ratings yet

- Bolts For Base PlateDocument12 pagesBolts For Base Platehemantkle2u50% (2)

- Base Plate With Shear KeyDocument3 pagesBase Plate With Shear Keyvpjagannaath100% (1)

- Att-5 - End-Plate Shear ConnectionDocument7 pagesAtt-5 - End-Plate Shear Connectioncravikumar1971100% (3)

- Gusset Plate Design for Cleveland Clinic Abu DhabiDocument4 pagesGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- Moment Connection DETAIL 2Document5 pagesMoment Connection DETAIL 2way2vaseemNo ratings yet

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Fin Plate - Beam To ColumnDocument78 pagesFin Plate - Beam To ColumnHemant Ramesh NarkarNo ratings yet

- Column Base Plate (Hinge Type)Document7 pagesColumn Base Plate (Hinge Type)Ernest NavarroNo ratings yet

- Base Plate and Anchor Bolt DesignDocument9 pagesBase Plate and Anchor Bolt DesignShaikh Muhammad Ateeq100% (2)

- Ub 254 Fin Plate To Column Web - LRFDDocument10 pagesUb 254 Fin Plate To Column Web - LRFDihpeterNo ratings yet

- Insert Plate DesignDocument1 pageInsert Plate DesignDivya MohanNo ratings yet

- Anchor Bolt Design IS Code LSDDocument33 pagesAnchor Bolt Design IS Code LSDdebjyoti_das_663% (8)

- Connection Design MomentDocument4 pagesConnection Design MomentAkshit Dhawan100% (1)

- 16 BDocument4 pages16 BmaheshbandhamNo ratings yet

- Welded Connection With I BeamDocument8 pagesWelded Connection With I BeamНемања КараклајићNo ratings yet

- Moment ConnectionDocument39 pagesMoment ConnectionRitwick MishraNo ratings yet

- Horizontal Bracing Connection Bolted Type - IS800-2007Document55 pagesHorizontal Bracing Connection Bolted Type - IS800-2007Nitesh SinghNo ratings yet

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Base Connection Design DetailsDocument11 pagesBase Connection Design DetailsmaheshbandhamNo ratings yet

- Steel Section Design as per IS 800:2007Document12 pagesSteel Section Design as per IS 800:2007vishalnalwar100% (1)

- Base Plate Design (Fixed Base)Document3 pagesBase Plate Design (Fixed Base)Saravana NNo ratings yet

- Moment ConnectionDocument15 pagesMoment Connectionnitin400No ratings yet

- 1410 113 DL+LL+ MATL. LOAD+SL Z-: Bagging Tower Support - JPLDocument3 pages1410 113 DL+LL+ MATL. LOAD+SL Z-: Bagging Tower Support - JPLAshlin AarthiNo ratings yet

- Design of Welded Plate GirderDocument25 pagesDesign of Welded Plate GirderJinshad UppukodenNo ratings yet

- 5L DesignDocument23 pages5L Designsam 08No ratings yet

- Design of Splicing of RafterDocument3 pagesDesign of Splicing of Rafterkeerthivasan_mrvNo ratings yet

- Base Plate Design Is 800-2007Document6 pagesBase Plate Design Is 800-2007Suneesh P91% (11)

- Sera Vuter Golpo by Various Famous WrittersDocument55 pagesSera Vuter Golpo by Various Famous WrittersrajarshiboseNo ratings yet

- Bending-Shear Interaction of Longitudinally Stiffened GirdersDocument16 pagesBending-Shear Interaction of Longitudinally Stiffened GirdersrajarshiboseNo ratings yet

- Design of Steel Truss STAADDocument50 pagesDesign of Steel Truss STAADrebtagg100% (12)

- Design of ReservoirDocument40 pagesDesign of ReservoirrajarshiboseNo ratings yet

- What Is Learning Anyway? A Topographical Perspective ConsideredDocument18 pagesWhat Is Learning Anyway? A Topographical Perspective ConsideredCristian SalazarNo ratings yet

- Wreck It Ralph ScreenplayDocument114 pagesWreck It Ralph ScreenplayRebekah Sommerville100% (4)

- ALL-Q (Coenzyme Q10) Plus - PDSDocument3 pagesALL-Q (Coenzyme Q10) Plus - PDSMarlon2370No ratings yet

- Godrej Group Is An Indian Conglomerate Headquartered in MumbaiDocument4 pagesGodrej Group Is An Indian Conglomerate Headquartered in MumbairahulbastyNo ratings yet

- Adime NoteDocument2 pagesAdime Noteapi-384503305100% (1)

- 51-11-15-001-Data Recording of Allowable Damage and Repairs-A320Document6 pages51-11-15-001-Data Recording of Allowable Damage and Repairs-A320FredNo ratings yet

- Abb 60 PVS-TLDocument4 pagesAbb 60 PVS-TLNelson Jesus Calva HernandezNo ratings yet

- Electroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneDocument48 pagesElectroconvulsive Therapy: Presented By: Shweta Surwase F.Y. M.Sc. (Mental Health Nursing) MIMH, PuneShweta KateNo ratings yet

- Emc SCADA PresentationDocument36 pagesEmc SCADA Presentationerode els erodeNo ratings yet

- The Global Commitment 2021 Progress ReportDocument39 pagesThe Global Commitment 2021 Progress ReportComunicarSe-ArchivoNo ratings yet

- Lake Lanao Policy StudyDocument30 pagesLake Lanao Policy StudyGodfrey MordenoNo ratings yet

- Apple Environmental Responsibility Report 2014Document29 pagesApple Environmental Responsibility Report 2014fdgdfgdfgNo ratings yet

- Outrider Character SheetDocument6 pagesOutrider Character SheetColin ZachauNo ratings yet

- Begone!: Short Story With Vocabulary For Talking About Love (Level B1-B2)Document5 pagesBegone!: Short Story With Vocabulary For Talking About Love (Level B1-B2)Hitesh MishraNo ratings yet

- Certification Shop Test 3Document13 pagesCertification Shop Test 3sanyam dhawanNo ratings yet

- Somatic Psychology Linda Hartley Review PDFDocument8 pagesSomatic Psychology Linda Hartley Review PDFAndres SanabriaNo ratings yet

- Mil STD 785BDocument90 pagesMil STD 785BLaura Encinas EscobarNo ratings yet

- ACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualDocument164 pagesACS560 Drives (0.75 To 160 KW, 1.0 To 215 HP) : Hardware ManualNutan PowerNo ratings yet

- Geometry Dba Study Guide 07.07Document3 pagesGeometry Dba Study Guide 07.07Tyler CosgroveNo ratings yet

- Protein Significance Analysis Tools for Proteomics ExperimentsDocument47 pagesProtein Significance Analysis Tools for Proteomics ExperimentsGisele WiezelNo ratings yet

- LPVDDocument12 pagesLPVDPardha SaradhiNo ratings yet

- Power Mode Selection SystemDocument3 pagesPower Mode Selection SystemOficina FernandinhoNo ratings yet

- BIOpolitics PDFDocument3 pagesBIOpolitics PDFalpar7377No ratings yet

- Installation Manual flexES 798980.GB0Document64 pagesInstallation Manual flexES 798980.GB0gius uddinNo ratings yet

- Instruction Manual: Alfa Laval SB Anti Vacuum ValveDocument30 pagesInstruction Manual: Alfa Laval SB Anti Vacuum ValveMichail KostarevNo ratings yet

- Moral vs Non-Moral Standards ExplainedDocument2 pagesMoral vs Non-Moral Standards ExplainedLee PascuaNo ratings yet

- Effect of Heat Treatment On Curcuminoid, Colour Value and Total Polyphenols of Fresh Turmeric RhizomeDocument8 pagesEffect of Heat Treatment On Curcuminoid, Colour Value and Total Polyphenols of Fresh Turmeric RhizomeMuhammad Maulana SidikNo ratings yet

- Columbus United Methodist Church: in This IssueDocument11 pagesColumbus United Methodist Church: in This IssueColumbusUMCNo ratings yet

- Project Report On Employee Management SystemDocument58 pagesProject Report On Employee Management Systemprivate69raghavNo ratings yet

- Practicing Oil AnalysisDocument62 pagesPracticing Oil AnalysisCristian SNo ratings yet