Professional Documents

Culture Documents

Fontana PDF

Uploaded by

Anonymous qBWLnoqB0 ratings0% found this document useful (0 votes)

13 views8 pagesFontana.pdf

Original Title

Fontana.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFontana.pdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views8 pagesFontana PDF

Uploaded by

Anonymous qBWLnoqBFontana.pdf

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

!

"#$%&'$-The EU funded RTD project ~HAPTEX addresses

the challenge of developing a Virtual Reality (VR) system for the

realistic and accurate rendering of the physical interactions of

humans with textiles, through the real-time generation of

artificial visual and haptic stimuli. This challenge concerns the

development of both the SW and the HW components of the VR

system, as well as it implies a substantial advancement in the

understanding of the mechanisms underlying the human haptic

perception of fine physical properties like those of textiles.

This paper reports some important details relating to the

technical implementation of the developed HW and SW

components with special emphasis on the issues related to their

integration into a single VR system. Furthermore some

preliminary results relating to the functional tests carried out on

the integrated system are also reported.

()*+, .+%/#-Force and Tactile Rendering, Haptic Interface,

Tactile Actuators, Virtual Reality System.

I. INTRODUCTION

EXTILES are deIormable objects characterized by very Iine

surIace and bulk physical properties, indicated with terms

such as stiIIness, smoothness, soItness, Iullness, crispness,

thickness, weight, etc. Taken as a whole they constitute the so

called Fabric Hand (deIined in |1|) oI a speciIic Iabric, which

is the basis Ior assessing its quality in relation to a given use

(Ior example Ior realizing a man`s winter suit). These

properties can be well distinguished and quantitatively

evaluated by the human haptic sensorial system (related to

sense oI touch), with an important contribution given by the

sense oI sight. There is experimental evidence that the highly

sophisticated mechanoreceptors located in the human skin

have a predominant role in the evaluation, even iI the signals

generated by these sensors are combined in the brain with

those generated by the kinesthetic sensors located in the

physiological articulations and in the muscles. For example,

when gently stroking the Iingertip on a Iabric to evaluate its

smoothness, the kinesthetic sensors give to the brain

* PERCRO Laboratory, Scuola Superiore Sant`Anna, Pisa, Italy Iontana,

marcheschi, tarri, Iabio, bergamasco}sssup.it

# WelIenlab, Institute oI Man-Machine Communication, Leibniz Universitt

Hannover, boettcher, allerkamp, Iew}welIenlab.de

Biomedical Physics Group, School oI Physics, University oI Exeter

alan.c.brady, j.qu, i.r.summers}exeter.ac.uk

inIormation about the Iingertip speed and the global Iorce

exerted on the Iabric while the mechanoreceptors sense the

small local Iluctuation oI the tangential Iorce due to Iriction.

The EU Iunded RTD project 'HAPTEX addresses the

challenge oI developing a VR system intended Ior the visual-

haptic realistic and accurate rendering oI the complex physical

interactions arising during the manipulation oI textiles. Due to

the limitations oI the present technology, since the beginning

it has been decided to Iocus the system simulation capability

on the interactions that can be attained using only two

Iingertips: the ones oI the index and the thumb (see Figure 1).

Figure 1 - Reference scenario of the HAPTEX project.

Taking into account the above considerations, the reIerence

conIiguration Ior the development oI the device responsible

Ior generating the artiIicial mechanical stimuli to be delivered

on the Iingertips(named the Whole Haptic Interface, WHI),

has been conceived as the combination oI two independent

Iorce-controlled manipulators (Force Feedback Device, FFD),

and two arrays oI independently actuated pins (Tactile

Actuator, TA). Each FFD is able to track the movements oI

the Iingertip and to convey the global Iorce oI arbitrary

direction on it, and each TA mounted on the end-eIIector oI

the corresponding manipulator is able to deliver to the surIace

oI the Iingertip skin speciIied spatial and temporal patterns,

(see Figure 2).

Integrating Force and Tactile Rendering

Into a Single VR System

Marco Fontana *, Simone Marcheschi*, Federico Tarri *, Fabio Salsedo *, Massimo Bergamasco *,

Dennis Allerkamp #, Guido Bttcher #, Franz-Erich Wolter #,

Alan C. Brady , Jianguo Qu , Ian R. Summers

T

2007 International Conference on Cyberworlds

0-7695-3005-2/07 $25.00 2007 IEEE

DOI 10.1109/CW.2007.37

277

Figure 2 - Reference configuration of the Whole Haptic

Interface .

II. DESCRIPTION OF THE SYSTEM

A. Svstem Architecture

Achieving a convincing virtual textile simulation requires a

good compromise to be reached between the need oI accuracy

in the material representation and the need oI speed Ior

obtaining visually realistic simulation Irame rates compatible

with real-time perception. These Iactors have to be considered

both in the visual and the haptic Iields. However, the graphics

rendering loop has diIIerent requirements compared to the

haptic rendering loop in terms oI reIresh Irequencies. While in

graphics a reIresh rate oI 30 Ips is quite acceptable, in haptics

a response Irequency oI 300-1000 Hz is needed to ensure

accurate interaction. A dedicated structure has thereIore been

deIined Ior adapting the diIIerent Irame rates required by the

mechanical simulation and the haptic rendering computations.

Two separate computation threads were implemented: The

Iirst is a low-Irequency thread running a complex large-scale

simulation oI the whole cloth surIace achieving quantitative

accuracy oI the diIIicult nonlinear anisotropic behavior oI

cloth in real-time. This simulation has to use nonlinear strain-

stress Iunctions related to the cloth being simulated. An

eIIicient non-linear minimization method computing spline

Iunctions approximating the aIorementioned non-linear strain-

stress curves is presented in |20|. The second thread is a high-

Irequency thread Ior computing the local data necessary Ior

haptic rendering and Ior accurately sending haptic Iorces back

to the mechanical simulation.

Textile

Simulation

Thread

Textile

Simulation

Thread

Local

Simulation

Thread

Local

Simulation

Thread

Force

Feedback

Thread

Force

Feedback

Thread

running at

60Hz

running at

300Hz

running at

1kHz

bordering geometry

Local

Geometry

bordering geometry bordering geometry

Local

Geometry

force generation Force

Extrapolation

Force

Feedback

Device

Force

Feedback

Device

forces positions

Motion

Estimation

movements

Visual

Display

Visual

Display

global mesh adaption

Fingertip

Model

contact

formulation

deform refine

Tactile

Rendering

Thread

Tactile

Rendering

Thread

Tactile

Array

Tactile

Array

contact area

force distribution, velocity

amplitudes

Figure 3 - Different threads within the HAPTEX system

Although the threads allow parallelizing oI the computation,

we also need some synchronization oI the threads. ThereIore,

the synchronization works as Iollows. In the initial stage all

threads are running at their dedicated update rates. The Iorce

Ieedback thread is constantly Ietching new positions Irom the

Iorce Ieedback device. These positions are processed to

predict the user`s motion and to estimate the next position. At

the same time the (global) textile simulation thread is

computing the deIormations caused only by gravity, whereas

the local simulation thread waits Ior any new local geometries

to be simulated. At each simulation step oI the global thread

the local thread receives Iingertip dimensions, the current and

predicted position. The global thread analyses its underlying

mesh with respect to potential collisions with the Iingertip Ior

the next time step. These regions including their physical

states are sent to the local thread in order to be geometrically

reIined and inserted into the local simulation. AIterwards both

simulation threads continue to run according to their data.

With the newly added local mesh, the local thread checks iI

any collision has taken place in between a local simulation

time step. In case oI a contact the occurring deIormation oI the

local part oI the textile is computed according to the Iingertip

model being used. The Iorces at the Iingertip generated during

the contact are sent to the Iorce Ieedback thread.

The contact area estimated by the contact model is transmitted

to the tactile renderer whereby Ior each pin a contact Iorce is

computed. According to the deIined positions oI the pins on

the Iinger the local velocity is also provided.

The schematic in Figure 3 shows the separation oI the

computational tasks into the diIIerent threads.

B. Force Renderer

The Iorce-Ieedback renderer is responsible Ior the modeling oI

the interaction between the Iingertip and the Iabric. This

implies the computation oI Iorces occurring at the contact,

considering the physical properties oI the objects involved. In

the haptics literature there exist several approaches to render

contact Iorces. In |17| an eIIective point-based rendering

algorithm was Iirstly introduced and constantly improved by

others, i.e. |19||18|.Ruspini et al. |15||16|extended the

algorithm to support contacts oI arbitrary shapes. In contrast to

the well known proxy method a recent approach (see |14|)

suggests to compute the contact Iorces by solving the

Signorini contact problem employing Iinite elements.

Although the latter method models the deIormation oI the

Iingertip at the contact appropriately, it is demanding oI

precious computation time because it requires iteratively

solving non-linear equation systems. A good compromise

between accuracy and computational eIIort is oIIered by a

penetration- or penalty-Iorce based method. The penetration-

or penalty-Iorce-model computes the Iorce as a result oI the

contact proportional to the penetration depth or intersecting

volume. The depth is given as the length oI the vector deIining

the shortest translation oI the colliding bodies to a touch

situation. For computational reasons we use the penetration

depth Ior Iorce calculations.

The mechanical equivalent to the aIorementioned situation can

be described by a spring attached to both bodies enIorcing a

repulsion in case oI a collision. The Iorces being applied on

both bodies are computed by the length oI the depth vector

and diIIer only in the direction. II no additional external Iorces

are applied, then aIter several simulation steps the bodies will

reach a Iorce equilibrium as depicted in Figure 4.

278

d

d

finge rt ip

s phe re

x

d x

v

n

x

v

n+ 1

F

C

n

F

C

n+ 1

node s of t e xt ile

d

d

node s of t e xt ile

finge rt ip

s phe re

x

d x

v

x

v

n

n+ 1

F

C

F

C

n

n+ 1

d

d

finge rt ip

s phe re

x

d x

v

n

x

v

n+ 1

F

C

n

F

C

n+ 1

node s of t e xt ile

d

d

node s of t e xt ile

finge rt ip

s phe re

x

d x

v

x

v

n

n+ 1

F

C

F

C

n

n+ 1

Figure 4 - Initial state (left) and final state (right) of the

penetration algorithm

At this stage the bodies are still intersecting. In this strategy

the Iingertip is modeled as a rigid sphere being the Iirst

contact body. Due to its shape, a Iast collision test with the

textile can be made. The Iingertip collides with a textile

particle n with position

v

n

x iI

d d v

n

d x x < holds.

Both Iingers are in collision under the Iollowing condition:

d d d

d x x 2

1 0

< .

To distinguish between static and kinetic Iriction we separate

the Iorce resultant

r

v

F into tangential

T

v

f and normal

N

v

f

components applied to a textile particle v. The Iorce

r

v

F is the

sum oI the internal Iorce

J

v

F , penetration Iorce

C

v

F and

Iriction Iorce.

II both Iorces satisIy the stick condition equation Ior static

Iriction as seen below.

N

v S

t

v

f f <

Then we have

v

N

v

r

v

T

v

r

v v

N

v

n f F f

F n f

=

=

In this state the particles are not moving relatively to the

Iingertip. The position is set according to the Iingertip

movement. Forces oI the remaining Iree particles oI the textile

have to be recomputed. Otherwise, iI the stick condition is not

met, the kinetic Iriction is added to the particle.

The Iorce sent to the Iorce Ieedback device is determined by

the reaction Iorce oI the contacting particles and the second

Iingertip

D

F . This leads to the Iollowing equation

rel

rel

v

N

v

v v rel

rel N

v S

C

v

D d

v

v

F

v

v

f F F F

K

K

S

s

=

where v indexes the particles being in contact with the

Iingertip and v

S

and v

K

deIining the particles respective to

their Iriction state.

C. Tactile Renderer

The tactile renderer is based on vibrations that play an

important role in the tactile exploration oI Iine surIaces. To

produce appropriate excitation patterns we use an array oI

vibrating contactor pins as described in Section II-E.

The tactile renderer generates 24 drive signals Ior the

individual contactors oI a single tactile stimulator, on the basis

oI the Iollowing inputs:

small scale description oI the textile surIace: a single

'tile oI the textile weave pattern, speciIied as a

pseudo-topology at 0.1 mm resolution over the 2D

surIace oI the tile (derived Irom Kawabata

measurements oI roughness and/or Iriction);

large-scale description oI the textile surIace: a

representation oI the non-uniIormity oI the textile

surIace, speciIied as a pseudo-amplitude at 1 mm

resolution over the 2D surIace oI the 200 mm 200

mm sample oI virtual textile (derived Irom optical

imaging);

position and orientation oI the Iinger pad on the

virtual textile;

speed and direction oI the movement oI the Iinger

pad over the virtual textile.

Figure 5 - The tactile renderer. Input and ouput data are

specified in 25 ms timesteps.

Figure 5 shows an overview oI the process using the input data

are used to speciIy the output drive signals. Taking into

account oI the direction oI the movement, a spatial-Irequency

spectrum is calculated Irom the pseudo topology oI the small-

scale description oI the virtual surIace. InIormation on the

speed oI movement oI the Iinger pad is used to convert spatial-

Irequency components into temporal-Irequency components.

The resulting temporal- Irequency spectrum is reduced to only

two amplitudes, A

40

and A

320

, by applying appropriate

bandpass Iilter Iunctions (see |21|), corresponding to the 40-

Hz and 320-Hz channels. Amplitudes Ior the 40- Hz

279

component in the drive signals Ior each oI the 24 channels are

obtained Irom A

40

by weighting according to data Irom the

large-scale description oI the virtual surIace, Ior the 24

locations on the Iinger where the contactors oI the tactile

stimulator are positioned. Similarly, amplitudes Ior the 320-Hz

component in the drive signals Ior each oI the 24 channels are

obtained Irom A

320

by weighting according to data Irom the

large-scale description oI the virtual surIace.

D. Force Feedback Device

In the scope oI the HAPTEX project the Force Feedback

Device (FFD) is responsible Ior tracking the global

movements oI the user`s index and thumb Iingertips,

delivering controlled Iorces on them as evaluated by the Force

Renderer Module and holding the Tactile Actuators. In order

to allow early integration oI the diIIerent components oI the

HAPTEX system, it has been decided to develop two diIIerent

types oI FFD, the Iirst one derived Irom an existing device

(named 'FFD in conIiguration A) and the second one

designed Irom scratch (named 'FFD in conIiguration B).

Although the two conIigurations use very diIIerent basic

solutions and hardware implementations, they have quite

similar Iunctionalities, even iI the related perIormances are

substantially diIIerent. In both cases, one oI the main

requirements in their development has been the achievement

oI a highly accurate Iorce Ieedback. This requirement derives

directly Irom the stated goal oI allowing the discrimination oI

the Iine mechanical properties oI the textiles. From the

technical point oI view this implies the accurate generation

and control oI Iorces that can be oI the order oI Iew grams

(0.01 N), as they arise during the natural manipulation oI

textiles.

To address this challenge, a new explicit Iorce control has

been developed making use oI purpose-designed highly

sensitive multi-component Iorce sensors, placed directly in

contact with the user`s Iingertips.

The Iollowing paragraphs describe in detail the two

conIigurations and report some experimental data relating to

their perIormances.

1) FFD in Configuration A

The FFD in conIiguration A has been derived Irom the GRAB

system (a detailed description is reported in |2|), developed by

the PERCRO Laboratory in the Iramework oI the

homonymous European RTD Project. The system is composed

oI two identical robotic arms, each having 6 DOF oI which the

Iirst 3 translational DOF are instrumented and actuated, while

the remaining 3 orientational DoF are only passive. Each

robotic arm is Iunctionally equivalent to the well known

Phantom |3| haptic interIace but has larger workspace.

Figure 6 - Picture of the sensor-equipped gimbal.

With respect to the original GRAB system, the FFD in

conIiguration A uses new gimbals (see Figure 6) mounted on

the robotic arm, each equipped with 3 rotational position

sensors (encoders) Ior the measurement oI the Iingertip

orientation and with a 3 component highly sensitive Iorce

sensor speciIically conceived Ior the application, and an

explicit Iorce control making use oI the said Iorce sensor.

Explicit Iorce control algorithm consists oI an inner velocity

loop-outer Iorce loop scheme (see Figure 7). The mechanical

model oI the device and the criteria Ior the dimensioning oI

the controller are described in detail in |5| and in. |6| Due to

the presence oI elasticity in the transmission oI the Iorce Irom

the actuator to the moving mass, the bandwidth oI the Iorce

controller has been limited to 3 Hz in order to ensure the

stability oI the system.

d F

f K Kv V1 F (s)

(s) F

V2

m F

s

Xm

Velocity Loop

(s) F

f

Fu

Force Loop Plant Force Loop Plant

Figure 7 - Scheme of the force control

Furthermore, investigations on the attachments oI the device

with the Iingertips have been carried out. Indeed, during the

natural handling with the textiles the interaction Iorces can be

oI the order oI Iew grams. This implies that the attachment oI

the Iingertip with the device has to be so to not hinder the high

sensitivity oI the human mechanoreceptors located in the skin.

From this point oI view the thimble-like attachment,

commonly used by the existing haptic interIace, is not well

suited because it produces a pre-stress oI the skin reducing the

sensitivity oI the mechanoreceptors. In order to address this

issue, diIIerent alternative solutions Ior the Iingertip

attachment have been investigated (a bare plate, a plate with

elastic strip, a plate with eccentric thimble). As expected the

experimental test demonstrated that the human sensitivity is at

best when the bare plate is used, even iI this solution is the

worst Ior the transmission oI the torques required Ior the

orientation oI the gimbal.

280

Finally a Iield test investigating the system capability to track

the Iinger motion with minimal resistance Iorce has been

carried out. The subjects were asked to move their Iingers at

constant velocity and the system was set to display no Iorces.

The maximum module oI the acquired resistant Iorce was

about one tenth oI a Newton (10 grams Iorce), as it can be

observed in Figure 8.

2) FFD in configuration B. development of the hand

exoskeleton

The FFD in conIiguration B consists oI a Hand Exoskeleton

(HE) expressly conceived Ior the accurate generation oI light

Iorces.

0 2 4 6 8 10 12 14 16

-0.2

-0.15

-0.1

-0.05

0

0.05

0.1

0.15

0.2

Time (s)

F

o

r

c

e

(

N

)

Figure 8 - Plot of the resistant force versus time during

finger tracking at constant velocity

Several works (Ior example |4|, |7| and |8| can be Iound in the

literature addressing the development oI HEs.

According to their type oI Iunctionality, the existing HE can

be grouped in two diIIerent categories,:

- Multi-phalanx HEs: they can generate Iorces on each

phalanx oI the Iinger along a Iixed direction with respect to

the phalanx (e.g. normal to the phalanx);

- Fingertip HEs: they can generate Iorces only on the (the

Iingertips along arbitrary direction in 3 D space.

Considering the application addressed by the HAPTEX

project, the second type oI Iunctionality has been selected.

A scheme oI quasi-anthropomorphic kinematics has been

selected Ior the implementation oI the Iinger exoskeleton. This

solution allows exploiting the beneIits oI anthropomorphic

kinematics, like the maximum ratio oI the available over the

needed workspaces and minimum encumbrance oI the

linkages, while avoiding at the same time the singularity that

would occurs when the Iinger is completely extended.

In Figure 9 a CAD model oI the HE is shown. It can be

noticed that the encumbrance oI the device has been mainly

located in the dorsal side with the aim oI allowing the

complete closing oI the hand. This has been achieved through

the use oI Remote Centre oI Rotation Mechanisms that

implement rotational joints having the axes located outside the

linkages.

The whole mechanism has 4 Degrees OI Freedom (DoF), even

iI it is actuated with only three motors, thanks to the coupling

oI the last DoF (end-eIIector Joint) with the previous one. The

coupling is acceptable because also in the human hand the last

phalanx can be rarely moved independently Irom the middle

phalanx during natural movements.

The HE is equipped with three electrical motors with low

speed reduction ratios (1:14). The actuators are placed at the

base oI the Iinger exoskeleton in proximity oI the dorsal side

oI the palm. The joints are actuated through steel cables

working in tension.

For the position sensing common incremental encoders

located on the axis oI the motors have been used while Ior the

Iorce sensing a compact highly sensitive 3 component Iorce

sensor, placed directly in contact with the user`s Iingertip, has

been expressly conceived Ior the application.

The purposely developed electronics Ior the sensor acquisition

and the driving oI the motors have been located inside the

motor box. The communication with the control PC takes

place through standard RS-232 serial cable.

The device is capable oI exerting a continuous Iorce on the

Iingertips oI 5N with a resolution oI 0.005 N.

At present, several parts oI the device have been realized and

other ones are being manuIactured.

A Iurther development will be the integration oI the dorsal

tactile array described in Section III on the dorsal side oI the

last phalanx oI the exoskeleton.

Figure 9 - CAD model of the Hand Exoskeleton.

E. Tactile Actuator

Two designs oI stimulator array have been developed as the

tactile component oI the HAPTEX system, hereaIter reIerred

to as conIigurations 'A and 'B. Both conIigurations use

identical actuators and have the same contactor layout, and

each has been designed to be used with the FFD.

The conIiguration 'A actuator has been designed to display a

2D tactile pattern on a single Iingertip. In contrast, the type

'B actuator (pictured in Iigure 10) is suitable Ior use in a pair,

displaying tactile inIormation to both the Iinger and thumb in

a grasp conIiguration.

In an ideal device, the Iingertip would be completely covered

with contactors. The spacing oI these would be around 1 per

square millimeter, matching the spatial acuity oI the

mechanoreceptors in the skin |9|. In reality, the number oI

actuators is limited by the space available and the complexity

oI the drive electronics and the wiring. A pin spacing oI 2 mm

has been used, as it is believed that Ior many tactile tasks this

is indistinguishable Irom a 1 mm spacing |10|. 24 pins are

arranged in 64 grid, with Iixed pins in interstitial positions to

localise the stimulation sites on the skin, and to transIer Iorces

Irom the FFD to the Iinger. The height oI the active pins is set

such that they indent slightly into the skin when the Iinger pad

is gently pressed into the Iixed pins and the surround.

281

Both designs are driven by piezo-electric bimorphs, chosen Ior

their simplicity, ease oI assembly and low cost. The

dimensions oI the bimorphs were selected by numerical

modelling and experiment.

The Iree-length oI the bimorphs was chosen such that their

resonant Irequency (100 Hz, rising to 120Hz when loaded by

the skin) lies between the two working Irequencies oI the

renderer (40 Hz and 320 Hz), and such that the Iirst anti-

resonance (450 Hz) is not too close to the upper working

Irequency. The response is designed such that the roll-oII

above resonance counteracts the increase in sensitivity oI the

human Iingertip |11|. This balances the perceived intensity at

a given drive signal, and reduces the dynamic range required

Irom the drive electronics.

The width oI each bimorph is a compromise must be struck

between the amount oI Iorce the actuator could deliver and the

overall size oI the device. A pair oI commercially available

2.1 mm wide actuators (APC International), arranged in

parallel, was chosen. This gave a width oI 4.2 mm and a static

blocked Iorce oI 0.5 mN/volt.

The design oI the type 'A is a logical development oI earlier

systems |12|,|13|, with the piezoelectric actuators located

below the palmar surIace oI the Iingertip. It is suitable Ior use

with a single Iinger in a 2D environment, and has been used to

develop the drive electronics and soItware, and Ior testing the

tactile renderer.

Figure 10 - Early prototype of the configuration ~B,

showing the two different orientations of the piezo-beams

The design oI the type 'B actuator TA was constrained by the

need to move the actuators out Irom underneath the Iingertip

to reduce the depth oI the device below the Iingertip, and so

allow Ior a grasp conIiguration. In addition, the device had to

accommodate and integrate with the Iorce sensor Ior the FFD,

and to Iit the FFD mechanism.

In the type 'A conIiguration, the Iingertip rests on a planar

surIace. The contactor pins are arranged to be perpendicular to

this plane. The type 'B conIiguration uses a curved contact

plate which Iollows the shape oI the Iinger pad. Contactor pins

are approximately normal to the contact plate (illustrated in

Figure 11), with diIIerent orientations oI the drive mechanism

Ior diIIerent rows oI pins. As a result, some oI the drive links

have to Iollow relatively complex paths. Subjective tests oI

this conIiguration have shown that the perIormance is good.

Figure 11 - This end on sketch of the fingertip shows the

orientation of the contactor pins and the direction in which

they are driven.

III. SYSTEM INTEGRATION

A. Mechanical Integration of TA with FFD

The integration oI the FFD with the TA requires the resolution

oI non-trivial problems that have implications Ior the most

appropriate mutual mechanical arrangement oI the diIIerent

parts constituting the two devices. This arrangement should be

so to allow, on one hand, the delivery to the Iingertip oI the

mechanical stimulations that each device can generate and on

the other, to comply with the speciIic capabilities and

requirements oI the devices. In particular the TA pins can

produce dynamic indentation oI the skin, but the Iorces

(normal to the surIace) that they can deliver are relatively

small (in the range oI Iew grams).

Figure 12 - Scheme of the force transmission between

fingertip and plate

Furthermore they cannot withstand lateral Iorces acting on the

pin because these Iorces would produce their deIlection. In

short the mechanical arrangement has to be so to prevent the

loading oI the pins with relatively high Iorces. Vice versa the

FFD can deliver to the skin relatively high Iorce in every

direction, but in order to guarantee a high accurate Iorce

Ieedback these Iorces must be sensed by the 3 component

Iorce sensor (see scheme in Figure 12).

Figure 13 - Mechanical Integration of FFD and TA

282

The FFD in conIiguration A and the TA in conIiguration B

have been successIully integrated in order to realize the

development level 4 (DL4) oI the HAPTEX system (see

Figure 13).

B. Integration of the Force and Tactile Renderer

For the computation oI the Iorce-Ieedback the haptic renderer

already requires among others the contact point, the velocity

oI the Iingertip relative to the Iabric and the normal Iorce (cI.

|20|). Instead oI a single contact point the tactile renderer

requires a contact area to decide which contactor pins have to

be activated. Also a single normal Iorce is not suIIicient Ior a

convincing tactile simulation. Rather a distribution oI the

normal Iorce over the whole contact area is needed by the

tactile renderer.

For each contactor pin, the geometry oI the tactile actuator

determines the point on the Iingertip where the stimulation

caused by that pin occurs. These points have been included in

the model oI the Iingertip. Employing the contact model the

position (in local coordinates oI the Iabric) and the normal

Iorce at each point is computed. The velocity is computed by

applying a discrete diIIerential operator.

The tactile renderer is called every 25 ms, i.e. it runs in a 40

Hz loop. However, the contact data is computed by the haptic

renderer every millisecond and the data needs to be resampled.

To avoid aliasing the data is passed through a digital

antialiasing Iilter that suppresses Irequency components above

20 Hz.

In the stand-alone version oI the tactile renderer the Iabric was

assumed to be planar. Furthermore the Iinger was assumed to

always being in contact with the plane oI the Iabric (see |9|).

However, in the integrated case the Iabric may have Iolds and

wrinkles, resulting in a more complex contact geometry. The

Iingertip deIorms due to the contact pressure, also inIluence

the shape oI the contact area. As a consequence not all pins oI

the tactile actuator should be activated, only those inside the

contact area. The shape oI each Iinger`s contact area is

provided by the Iorce-Ieedback renderer. Note that a contact

area may not exist, i.e. in that case the Iinger does not touch

the Iabric.

While moving a Iingertip over a rough surIace we experience

a tactile sensation. Its intensity also depends on the Iorce with

which the Iinger is pressed against the Iabric. For relatively

small Iorces a linear dependency between the Iorce and the

sensation seems to be reasonable. ThereIore the amplitudes

computed by the tactile renderer are multiplied by k

F

F

beIore they are transmitted to the tactile actuator. F denotes

the Iorce between the Iinger and the Iabric and k

F

is a constant

relating the Iorce to the intensity. Previous to the integration

there was no possibility to assess the contact pressure between

the Iingertip and the Iabric. ThereIore a constant Iorce normal

to the Iabric was assumed implicitly by the tactile renderer.

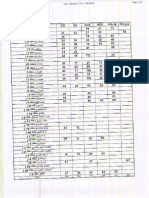

IV. PRELIMINARY TESTS

Extensive tests have been perIormed to assess the mechanical

and electrical disturbance induced by the vibration and the

electrical noise generated by the TA on the measure oI the

interaction Iorce, because oI its potential negative impact on

the accuracy oI the Iorce Ieedback. The tests have been

perIormed activating only one speciIic pin oI the TA array at a

time and acquiring the resulting measured Iorce signal. The

Irequency spectrum oI the signal has been then evaluated

using the Discrete Fourier TransIormation (see Figure 14).

The disturbances produced by 4 diIIerent pins, having

diIIerent locations in the TA array and mechanical coupling

conditions (Iree-moving or in contact with the Iorce plate

hole) have been investigated. The tests evidenced that the

disturbance produced by the vibration is predominant with

respect to the electrical noise and that Iree-moving pins

produce about 10 times less disturbance than produced by pins

in contact. The magnitude oI the disturbance on the excitation

Irequency (40Hz and 320 Hz) is about 200 times greater Ior

the Iree-moving pin with respect to the base noise than when

the pin is not activated. Furthermore a system test has been

also perIormed in order to assess the global consequence oI

the induced noise on the accuracy oI the Iorce Ieedback. No

meaningIul eIIects have been detected due to the low

bandwidth oI the Iorce Ieedback (about 3 Hz).

Figure 14 - Typical Discrete Fourier Transform of the

disturbance produced by one TA pin vibrating at 40Hz on

the force measure.

V. CONCLUSIONS AND FUTURE WORK

In this paper we have reported the preliminary work

perIormed towards the realization oI a system able to simulate

the visual and haptic interaction with Iabrics.

The manipulation oI Iabrics is a very complex perceptual

experience that is associated with a lot oI stimuli that are very

hard to simulate and to reproduce virtually.

The system that has been realized integrates two kinds oI

stimulation devices: a Tactile Array (TA) Ior the tactile

stimulation oI the Iingertip and a Force Feedback Device

(FFD) Ior delivering the interaction Iorces. In this work we

Iocused on the issue oI the integration oI these two devices

Irom the soItware and the hardware point oI views.

From the soItware point oI view the main issue is to generate

simultaneously the signals to be provided to the FFD and the

TA complying with real time speciIications. To achieve this

two separate soItware components called the Force Feedback

Renderer and the Tactile Renderer, were realized and

integrated.

283

For what concerns the hardware, the real challenges consist oI

realizing a device able to convey both the delicate and Iine

interaction Iorces that are involved with the manipulation oI

textiles and deliver the associated tactile stimulus. It has been

shown that the integration oI these two devices can raise

several issues like the electrical and mechanical cross-talk

between the two Ieedback devices and the issue oI how to

deliver the Iorce to the user`s Iingertip whilst not transmitting

it to the pins oI the array. This has lead to the design oI a

purposely developed haptic-tactile integrated device.

The preliminary tests on the integrated system have shown

that the global perIormances oI the device are acceptable and

the major issues associated with the integration have been

successIully overcome.

In the near Iuture we will set up the complete system Ior two

Iinger interaction and perIorm several tests.

The next step will be the realization oI a portable wearable

FFD and to integrate it with the tactile array.

ACKNOWLEDGMENT

The project HAPtic sensing oI virtual TEXtiles (HAPTEX)

is a research project Iunded under the Sixth Framework

Programme (FP6) oI the European Union (Contract No. IST-

6549). The Iunding is provided by the Future and Emerging

Technologies (FET) Programme, which is part oI the

InIormation Society Technologies (IST) programme and

Iocuses on novel and emerging scientiIic ideas. Its mission is

to promote research that is oI a long-term nature or involves

particularly high risks, compensated by the potential oI a

signiIicant societal or industrial impact.

REFERENCES

|1| H. Behery, EIIect oI Mechanical and Physical Properties on Fabric

Hand, Publisher: Taylor & Francis Ltd, 2005.

|2| Avizzano C. A., Marcheschi S., Angerilli M., Fontana M., Bergamasco

M.: 'A Multi-Finger Haptic InterIace Ior Visually Impaired People. In

Proceedings oI the 2003 IEEE International Workshop on Robot and

Human Interactive Communication, Vol. 31, (2003), 165- 170.

|3| Thomas H. Massie and J. K. Salisbury., 'The PHANTOM Haptic

InterIace: A Device Ior Probing Virtual Objects Proceedings oI the

ASME Winter Annual Meeting, Symposium on Haptic InterIaces Ior

Virtual Environment and Teleoperator Systems, Chicago, IL, Nov. 1994.

|4| Bouzit M., Popescyu G., Burdea G., Bioan R.: 'The Rutger Master II-nd

Force Feedback Glove, In Proc. IEEE Vr. Haptic Sysmposium, Vol.7

(March 2002) 256-263.

|5| Eppinger S., Seering, W.: 'Understanding bandwidth limitations in robot

Iorce control. In Proc.Robotics and Automation ConIerence, 1987

IEEE International ConIerence on , Vol.4 (1987), 904- 909.

|6| Volpe R., Khosla P., 'A theoretical and experimental investigation oI

explicit Iorce control strategies Ior manipulators. In IEEE Transactions

on Automatic Control, vol.38, 11 (1993), 1634-1650.

|7| Wege, A.; Kondak, K.; Hommel, G., Mechanical design and motion

control oI a hand exoskeleton Ior rehabilitation Mechatronics and

Automation, 2005 IEEE International ConIerence, Vol.1, Iss., 29 July-1

Aug. 2005, Pages: 155- 159 Vol. 1

|8| Virtual Technologies Inc., Cyber Grasp User Guide, 1999..

|9| K.O. Johnson, T. Yoshioke, F. Vega-Bermudez, 'Tactile Iunctions oI

mechanoreceptive aIIerents innervating the hand, J. Clin.

Neurophysiol., vol. 17, 2000, pp. 539558.

|10| I.R. Summers, C.M. Chanter, A.L. Southall and A.C. Brady, 'Results

Irom a Tactile Array on the Fingertip in Proc. Eurohaptics 01,

Birmingham, 2001, pp. 2628

|11| R.T. Verillo, A .J. Fraioli, R. L. Smith, 'Sensation magnitude oI

vibrotactile stimuli, Perception & Psychophysics, vol. 6, pp. 366372,

1969.

|12| I.R. Summers, C.M. Chanter, 'A broadband tactile array on the

Iingertip, J. Acoust. Soc. Am., vol. 112, pp. 21182126, 2002.

|13| I.R. Summers, A.C. Brady, M. Syed, C.M. Chanter, 'Design oI Array

Stimulators Ior Synthetic Tactile Sensations, in Proc. World

Haptics`05, Pisa, 2005, pp. 586587.

|14| Duriez C. et al.: Realistic Haptic Rendering oI Interacting DeIormable

Objects in Virtual Environments, IEEE Transactions on Visualization

and Computer Graphics (2006), pp. 36-47

|15| Ruspini D.C. et al.: Haptic interaction in virtual environments, Proc.

IEEE/RSJ int. conI. on Intel. Robots & Systems (1997), Vol.3

|16| Ruspini D.C. et al. : The haptic display oI complex grapical

environments, Proc. 24th annual. ConI. on Computer Graphics and

Interactive Techniques (1997)

|17| Zilles C.B., Salisbury J.K.: A constraint-based god-object method Ior

haptic display, Proc. IEE/RSJ Int. conI. on Intel. Robots & Systems

(1995), Vol.3, pp. 146-151

|18| Ho C.H., Basdogan C., Srinivasan M.A.: EIIicient point-based rendering

techniques Ior haptic display oI virtual objects, Presence: Teleoperators

and Virtual Environments (1999), Vol. 8

|19| Morgenbesser, H., and Srinivasan, M. Force shading Ior haptic shape

perception. In Proceedings oI the ASME Dynamics Systems and Control

Division (1996), vol. 58, pp. 407--412.

|20| Volino P. et al.: From measured physical parameters to the haptic Ieeling

oI Iabric, Proc. OI HAPTEX`05

|21| Dennis Allerkamp, Guido Bttcher, Franz-Erich Wolter, Alan C. Brady,

Jianguo Qu, and Ian R. Summers. A vibrotactile approach to tactile

rendering. Vis. Comput., 23(2):97108, 2007

284

You might also like

- 1 Hearing TruaxDocument2 pages1 Hearing TruaxAnonymous qBWLnoqBNo ratings yet

- Application Guidelines for Postgraduate Curatorial Studies ProgramDocument28 pagesApplication Guidelines for Postgraduate Curatorial Studies ProgramAnonymous qBWLnoqBNo ratings yet

- PhD in the Arts GuideDocument16 pagesPhD in the Arts GuideAnonymous qBWLnoqBNo ratings yet

- PHD Practical GuideDocument16 pagesPHD Practical GuideAnonymous qBWLnoqBNo ratings yet

- Hotel VoucherDocument2 pagesHotel VoucherAnonymous qBWLnoqBNo ratings yet

- Listening Through The Noise: The Aesthetics of Experimental Electronic MusicDocument3 pagesListening Through The Noise: The Aesthetics of Experimental Electronic MusicAnonymous qBWLnoqBNo ratings yet

- Artificial Intelligence: Dave Murray-Rust, Alan SmaillDocument25 pagesArtificial Intelligence: Dave Murray-Rust, Alan SmaillAnonymous qBWLnoqBNo ratings yet

- Sound Studies and Sonic Arts Mastersprogram Information 20170125-DigiDocument5 pagesSound Studies and Sonic Arts Mastersprogram Information 20170125-DigiAnonymous qBWLnoqBNo ratings yet

- Ethnomusicologie en FlyerDocument2 pagesEthnomusicologie en FlyerAnonymous qBWLnoqBNo ratings yet

- Deutschland Studienangebote International Programmes enDocument6 pagesDeutschland Studienangebote International Programmes enAnonymous qBWLnoqBNo ratings yet

- BP9629Document2 pagesBP9629Anonymous qBWLnoqBNo ratings yet

- FU Berlin Visual Media AnthropologyDocument5 pagesFU Berlin Visual Media AnthropologyAnonymous qBWLnoqBNo ratings yet

- Dakhabrakha / Dengue Fever / Red Baraat Barzakh Festival: Peymani, ShaahinDocument2 pagesDakhabrakha / Dengue Fever / Red Baraat Barzakh Festival: Peymani, ShaahinAnonymous qBWLnoqBNo ratings yet

- Ethnomusicologie en FlyerDocument2 pagesEthnomusicologie en FlyerAnonymous qBWLnoqBNo ratings yet

- BP9629Document2 pagesBP9629Anonymous qBWLnoqBNo ratings yet

- Video Installation Art: The Body, The Image, and The Space-in-BetweenDocument14 pagesVideo Installation Art: The Body, The Image, and The Space-in-BetweenAnonymous qBWLnoqBNo ratings yet

- CVDocument4 pagesCVAnonymous qBWLnoqBNo ratings yet

- International Artist Residency at CCI FabrikaDocument14 pagesInternational Artist Residency at CCI FabrikaAnonymous qBWLnoqBNo ratings yet

- Writing Grant ProposalDocument2 pagesWriting Grant ProposalAzzad Diah Ahmad ZabidiNo ratings yet

- Matris Co. - AIO Pricelist - Professional Series Date: 1395/07/03Document5 pagesMatris Co. - AIO Pricelist - Professional Series Date: 1395/07/03Anonymous qBWLnoqBNo ratings yet

- ظهرDocument2 pagesظهرAnonymous qBWLnoqBNo ratings yet

- Flire BXDocument2 pagesFlire BXAnonymous qBWLnoqBNo ratings yet

- Flire BXDocument2 pagesFlire BXAnonymous qBWLnoqBNo ratings yet

- Using A Depth Camera As A Touch Sensor: Microsoft Research Redmond, WA 98052 USADocument4 pagesUsing A Depth Camera As A Touch Sensor: Microsoft Research Redmond, WA 98052 USAAnonymous qBWLnoqBNo ratings yet

- Interactive Digital Art Using Sensor TechnologyDocument5 pagesInteractive Digital Art Using Sensor TechnologyAnonymous qBWLnoqBNo ratings yet

- Fici 2016 enDocument3 pagesFici 2016 enAnonymous qBWLnoqBNo ratings yet

- Texcomp10 Koissin PDFDocument6 pagesTexcomp10 Koissin PDFAnonymous qBWLnoqBNo ratings yet

- Advanced TextilesDocument2 pagesAdvanced TextilesÅkï MËhtåNo ratings yet

- Conditions of Competition Tricky Women 2017Document4 pagesConditions of Competition Tricky Women 2017Anonymous qBWLnoqBNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Computer Graphics in Medicine: From Visualization To Surgery SimulationDocument5 pagesComputer Graphics in Medicine: From Visualization To Surgery SimulationRocking RidzNo ratings yet

- NAV-VIR: An Audio-Tactile Virtual Environment To Assist Visually Impaired PeopleDocument4 pagesNAV-VIR: An Audio-Tactile Virtual Environment To Assist Visually Impaired Peoplexiaoying huangNo ratings yet

- Resonant Interface: Steven HeimDocument11 pagesResonant Interface: Steven HeimDeepak DahiyaNo ratings yet

- UNICEF The Metaverse Extended Reality and Children 1685849539Document35 pagesUNICEF The Metaverse Extended Reality and Children 1685849539TheMoneyMitraNo ratings yet

- BLIND READER: An Intelligent Assistant For Blind: Shahed Anzarus Sabab Md. Hamjajul AshmafeeDocument6 pagesBLIND READER: An Intelligent Assistant For Blind: Shahed Anzarus Sabab Md. Hamjajul AshmafeeVinod KumarNo ratings yet

- Laura U Marks Touch Sensuous Theory and Multisensory MediaDocument283 pagesLaura U Marks Touch Sensuous Theory and Multisensory MediaSangue CorsárioNo ratings yet

- HABOSDocument6 pagesHABOSjagrutiNo ratings yet

- Media and Information Literacy: Quarter 2 - Module 2Document22 pagesMedia and Information Literacy: Quarter 2 - Module 2Dustin SiguanNo ratings yet

- Feeling Your Data - Deborah LuptonDocument16 pagesFeeling Your Data - Deborah Luptonmattia paganelliNo ratings yet

- Obstacle Avoidance Using Haptics and A Laser Rangefinder: Daniel Innala Ahlmark, Håkan Fredriksson, Kalevi HyyppäDocument6 pagesObstacle Avoidance Using Haptics and A Laser Rangefinder: Daniel Innala Ahlmark, Håkan Fredriksson, Kalevi HyyppäagebsonNo ratings yet

- Haptic Technology (Touch The VirtualDocument19 pagesHaptic Technology (Touch The VirtualShashank SharmaNo ratings yet

- Artificial Intelligence, Augmented Reality and Mixed 82Document196 pagesArtificial Intelligence, Augmented Reality and Mixed 82Cristiana OliveiraNo ratings yet

- UNREALHAPTICS - A Plugin-System For High Fidelity Haptic Rendering in The Unreal EngineDocument9 pagesUNREALHAPTICS - A Plugin-System For High Fidelity Haptic Rendering in The Unreal EngineJexiaNo ratings yet

- Universal DesignDocument26 pagesUniversal DesignVeena SNo ratings yet

- Unit-2 Hardware and Software ConceptDocument45 pagesUnit-2 Hardware and Software ConceptBinod AdhikariNo ratings yet

- Haptic Tech: Touch Feedback in VR & BeyondDocument21 pagesHaptic Tech: Touch Feedback in VR & Beyondniks1209No ratings yet

- Documentation Haptic TechnologyDocument24 pagesDocumentation Haptic TechnologyjoeNo ratings yet

- Haptic Technology: Manisha MohantyDocument6 pagesHaptic Technology: Manisha MohantyDurga Charan PradhanNo ratings yet

- Advanced Technologies in Modern Robotic PDFDocument428 pagesAdvanced Technologies in Modern Robotic PDFAlexander Rueda OrduzNo ratings yet

- Experience Driven Design Report 2017Document24 pagesExperience Driven Design Report 2017Collaborative and Industrial design Master programmeNo ratings yet

- Coordinated and Force-Feedback Control of Hydraulic ExcavatorsDocument9 pagesCoordinated and Force-Feedback Control of Hydraulic ExcavatorsTewaney GedamuNo ratings yet

- Evaluation Techniques and Universal DesignDocument64 pagesEvaluation Techniques and Universal DesignEbisa EdessaNo ratings yet

- Lab 3 Abowd and Beale's FrameworkDocument5 pagesLab 3 Abowd and Beale's FrameworkDana Franchesca Dichoso100% (2)

- Restaurant InteriorDocument80 pagesRestaurant InteriorJhony Seban100% (1)

- HAPTICS Seminar ReportDocument34 pagesHAPTICS Seminar ReportAlok RanjanNo ratings yet

- Feeling Through Sight Zooming in Zooming OutDocument19 pagesFeeling Through Sight Zooming in Zooming OutYUE ZHONGNo ratings yet

- The Haptik Library 1.0 - Developer - S ManualDocument134 pagesThe Haptik Library 1.0 - Developer - S ManualFares MentseurNo ratings yet

- Unit-2 Computers in HCIDocument15 pagesUnit-2 Computers in HCIDurgavajjala KarthikNo ratings yet

- Tactile Object Recognition in Early Phases of Grasping Using Underactuated Robotic HandsDocument13 pagesTactile Object Recognition in Early Phases of Grasping Using Underactuated Robotic HandsxingjqixhNo ratings yet

- Empowering Navigation: Sight Sense - A Customizable Assistive Device For The Visually ImpairedDocument11 pagesEmpowering Navigation: Sight Sense - A Customizable Assistive Device For The Visually ImpairedInternational Journal of Innovative Science and Research Technology100% (1)