Professional Documents

Culture Documents

Chapter 5 Trusses: Typical Roof Structure

Uploaded by

GoanengineerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 5 Trusses: Typical Roof Structure

Uploaded by

GoanengineerCopyright:

Available Formats

Handbook of Structural Steelwork 3rd Edition - Chapter 5 Trusses Discuss me ...

CHAPTER 5

5.1

TRUSSES

Introduction

Created on 02 June 2007 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Steelbiz Licence Agreement

A truss is a triangulated framework of members in which loads are primarily resisted by axial forces in the individual members. The most commonly used truss is single span, simply supported and statically determinate with joints assumed to act as pins. Trusses can be pitched with sloping rafters as shown in Figure 5.1 or can have parallel top and bottom chords. Trusses with parallel chords are often referred to as lattice girders.

Roof covering Purlins Rafter

Main tie

Internal bracing members

Figure 5.1 Typical roof structure

5.2

Typical uses

A common application of pitched trusses is for roofs. Lattice girders have a wider variety of uses including support of roofs and floors particularly with longer spans or heavier loads. The support of long span flat roofs is generally accomplished by using trusses with parallel chords. Pitched roofs are normally supported by pitched trusses, even for modest spans, the exception being the specialised area of pitched roof portal frames. Portal frames are beyond the scope of this publication and will not be considered further. One advantage of trusses is that they can be delivered to site as one complete unit, as several smaller units or even as individual elements. The choice will depend upon the size of the truss, the ease of transport between the fabrication shop and the site and the availability of space on site.

72

Handbook of Structural Steelwork 3rd Edition - Chapter 5 Trusses Discuss me ...

5.2.1 Spans

The most efficient form of truss to be employed in any given situation is usually controlled by the span to be covered. Figure 5.2 shows a variety of pitched roof trusses together with the spans over which they are customarily used. For spans in excess of these values, lattice girders may be more practical. However, lattice girders are used for a whole range of spans (greater than approximately 7 m).

Created on 02 June 2007 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Steelbiz Licence Agreement

Figure 5.3 shows two types of lattice girder the N-girder or Pratt truss and the Warren girder. These trusses have depth to span ratios typically in the range of 1:10 to 1:14.

<7 m 7 - 11 m

11 - 17 m

17 - 25 m

11 - 17 m

17 - 25 m

25 - 31 m

25 - 31 m

Figure 5.2 Typical roof trusses and associated spans

Compression chord

Tension chord a) N-girder or Pratt truss Compression chord

Tension chord b) Warren girder

Figure 5.3 Lattice girders

73

Handbook of Structural Steelwork 3rd Edition - Chapter 5 Trusses Discuss me ...

5.3

Design concept

Typical roof trusses are plane frames consisting of sloping rafters which meet at the apex or ridge of the frame (see Figure 5.1). The lower ends of the rafters are prevented from spreading by a horizontal main tie, whilst internal bracing members triangulate the truss and carry primarily axial forces. The internal members also reduce the segment lengths of the chords which enables lighter weight and therefore more efficient chords to be used.

Created on 02 June 2007 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Steelbiz Licence Agreement

5.3.1 Roof arrangement

The roof coverings may be made from a variety of materials ranging from traditional slates or tiles, profiled steel sheeting or more exotic materials. These coverings are supported on purlins (members running between the trusses), which are supported by the rafters and therefore apply loads to the rafters. The purlins also provide out of plane stability-to-the truss. Stability to the truss must be provided at all times, including during erection, when temporary bracing may be used. The spacing of the purlins (which can range from as little as 900 mm to over 3.5 m) is normally dictated by the roofing material. If the purlins are only located at points where internal members meet, (the panel points) then the truss members will be subjected primarily to axial forces. However, if the spacing is such that the purlins are supported between the panel points, then rafters will need to be designed for combined axial load and bending. Figure 5.4 shows the two possible options.

Local bending action

a) Purlins at panel points b) Purlins between panel points

Figure 5.4 Purlins at or between panel points 5.3.2 Pre-cambering

Deflections of nominally flat trusses (Pratt trusses or Warren trusses) must be considered if ponding and therefore overloading are to be avoided. Two possible solutions are to either pre-camber the truss or to have a shallow slope in the top chord. The concept of pre-cambering is often extended to longer span pitched roof trusses where the nominally horizontal bottom chord may in

74

Handbook of Structural Steelwork 3rd Edition - Chapter 5 Trusses Discuss me ...

fact slope upwards slightly from the supports. This is carried out so that under loading, the bottom chord does not deflect below the horizontal.

5.3.3 Typical sections

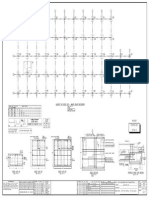

The sections used for the members of a typical roof truss may be single angles, double angles (single angles fastened back to back), single channels, double channels or single T sections. For members with more than one component (double angles or double channels), the elements may be connected directly to each other. Alternatively a gusset plate may be inserted between them which enables a connection to be made to other members so that eccentricities at the connections are minimised. For single component members this is not possible and a lapped joint with its consequent eccentricity is unavoidable. If, as is normally the case, the members consist of angles, channels and T sections then the axial loads should be determined assuming that the joints are pinned. The moments caused by eccentricities at the ends need not be considered explicitly and the individual members may be checked using Clauses 4.7.10 to 4.7.13 of BS 5950-1. These clauses give values for the effective lengths to be taken for buckling about the various axes. Care must be taken to ensure that all possible axes of buckling are recognised and this will often involve consideration of buckling about the a-a, b-b, u-u and v-v axes. The assumption implied in this approach is that the members may be represented by lines meeting at a point located at the nodes. If the frame is welded, it is customary to detail the frame so that the centroidal axes of the members lie on these lines. If the frame is bolted, then it is usual to ensure that the lines of the bolt holes meet at the nodes. Any moments arising from minor eccentricities are allowed for in the choice of effective lengths. Figure 5.5 shows some typical details from an example of bolted roof truss, using back to back angles for the members, with gusset plates at the connections. Figure 5.6 shows a welded truss using T sections, detail 2 show that the members node without any eccentricity. Figures 5.5 and 5.6 are only examples of a number of typical details from a wide variety of solutions which may be adopted.

Created on 02 June 2007 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Steelbiz Licence Agreement

75

Handbook of Structural Steelwork 3rd Edition - Chapter 5 Trusses Discuss me ...

1

Created on 02 June 2007 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Steelbiz Licence Agreement

Detail 2

Detail 1

Figure 5.5 Bolted roof truss and typical details

3

Detail 1

Detail 2

Detail 3

Figure 5.6 Welded roof truss and typical details

76

Handbook of Structural Steelwork 3rd Edition - Chapter 5 Trusses Discuss me ...

5.3.4 Joint Capacities

The detailing of the joints is a vital part of truss design. The capacity of the truss may be controlled by the capacity of the joints as much as by the capacity of the members If members are selected so that their capacity is almost fully utilised, the resulting joint details required to transmit the applied forces, can be very impractical. The joints should therefore be considered at an early stage in the design, in conjunction with the selection of the members. As mentioned above, the joint eccentricities will effect design of the truss and its members. The joints adopted in practice must not invalidate the assumptions made at the design stage.

Created on 02 June 2007 This material is copyright - all rights reserved. Use of this document is subject to the terms and conditions of the Steelbiz Licence Agreement

77

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- General SpecificationDocument241 pagesGeneral Specificationcyong7788No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Goa Board of Secondary & Higher Secondary EducationDocument4 pagesGoa Board of Secondary & Higher Secondary EducationGoanengineerNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- RCC To STR 960Document1 pageRCC To STR 960GoanengineerNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Basic Definitions of Soils PDFDocument7 pagesBasic Definitions of Soils PDFAntónio FontesNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Standard Slab System Helical Anchorage ReinforcementDocument2 pagesStandard Slab System Helical Anchorage ReinforcementGoanengineerNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Design of Deep Beam Using Strut and Tie MethodDocument17 pagesDesign of Deep Beam Using Strut and Tie Methodsuman33100% (2)

- RCC Design SheetsDocument69 pagesRCC Design SheetsFahim H bepari100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Chapter 5 Trusses: Typical Roof StructureDocument6 pagesChapter 5 Trusses: Typical Roof StructureGoanengineerNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Study On Resource Planning in Highway Construction ProjectsDocument8 pagesA Study On Resource Planning in Highway Construction Projectsabimranf39No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Un Bonded Tendons Realistic RequirementsDocument10 pagesUn Bonded Tendons Realistic RequirementsGoanengineerNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Checking slenderness limits of PEB structuresDocument1 pageChecking slenderness limits of PEB structuresjamilNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Design and DetailingDocument7 pagesDesign and DetailingVarun ChandrasekaranNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Guidelines for Designing Heavy-Duty Railway FormationsDocument75 pagesGuidelines for Designing Heavy-Duty Railway Formationsselva_651950100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Prof Indemnity-Proposal Form For ArchitectengDocument3 pagesProf Indemnity-Proposal Form For ArchitectengGoanengineerNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Deviation DiaphragmDocument1 pageDeviation DiaphragmGoanengineerNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Expansion JointDocument1 pageExpansion JointGoanengineerNo ratings yet

- Crown FarmsDocument4 pagesCrown FarmsGoanengineerNo ratings yet

- Box Pier CapDocument1 pageBox Pier CapGoanengineerNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Fabrication DrawingDocument1 pageFabrication DrawingGoanengineerNo ratings yet

- Additional Guidelines for Design of Flexible Pavements for Low Volume Rural RoadsDocument1 pageAdditional Guidelines for Design of Flexible Pavements for Low Volume Rural RoadsArunashish MazumdarNo ratings yet

- Pune City Development Plan AppraisalDocument4 pagesPune City Development Plan AppraisalGoanengineerNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- GUJARAT ENERGY TRANSMISSION CORPORATION LTD PILE CONSTRUCTION FQPDocument18 pagesGUJARAT ENERGY TRANSMISSION CORPORATION LTD PILE CONSTRUCTION FQPGoanengineer100% (1)

- TysonsDocument2 pagesTysonsGoanengineerNo ratings yet

- Well Pile Foundation PDFDocument17 pagesWell Pile Foundation PDFlingamkumarNo ratings yet

- QF2Document2 pagesQF2GoanengineerNo ratings yet

- UpvcDocument35 pagesUpvcGoanengineerNo ratings yet

- RCF Trombay Foundation Construction Price BidDocument6 pagesRCF Trombay Foundation Construction Price BidGoanengineerNo ratings yet

- TysonsDocument2 pagesTysonsGoanengineerNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- TowsonDocument4 pagesTowsonGoanengineerNo ratings yet

- Peugeot dw8 Checks and AdjustmentsDocument3 pagesPeugeot dw8 Checks and AdjustmentsAlvaro RochaNo ratings yet

- Revolutionizing Underwater Travel with SupercavitationDocument20 pagesRevolutionizing Underwater Travel with SupercavitationRoshan ThimmaiahNo ratings yet

- Catálogo de Pecas - MotorDocument29 pagesCatálogo de Pecas - MotorHenriqueNo ratings yet

- Examples: 238 17 PsychrometricsDocument12 pagesExamples: 238 17 PsychrometricsJunior Ferrel AlvarezNo ratings yet

- Ab-522 Standard Pneumatic Test Procedure Requirements PDFDocument17 pagesAb-522 Standard Pneumatic Test Procedure Requirements PDFMarizta Perdani PutriNo ratings yet

- Repair Parts Catalog: FOR Sunnen Vertical Honing MachineDocument48 pagesRepair Parts Catalog: FOR Sunnen Vertical Honing MachineLucas Isaias da Silva100% (1)

- CMC Ready ReckonerxlsxDocument3 pagesCMC Ready ReckonerxlsxShalaniNo ratings yet

- ARTESIAN VFD DRIVES FOR CENTRIFUGAL PUMPSDocument1 pageARTESIAN VFD DRIVES FOR CENTRIFUGAL PUMPScristobal_tl2277No ratings yet

- RX135 4TL4Document52 pagesRX135 4TL4Shibu Kumar S83% (6)

- 374D Excavator Electrical System - Attachment - AccuGrade Gen2 (Interactive) PDFDocument12 pages374D Excavator Electrical System - Attachment - AccuGrade Gen2 (Interactive) PDFTom SouzaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Caddy Rod LockDocument16 pagesCaddy Rod LockcrisalevNo ratings yet

- Unit I MCQ SD IiiDocument18 pagesUnit I MCQ SD IiiKiran BandeNo ratings yet

- PROBLEM 9.31: SolutionDocument10 pagesPROBLEM 9.31: Solutionjuan felipeNo ratings yet

- Sheet Metal 2-01-09Document9 pagesSheet Metal 2-01-09Adrianne AstadanNo ratings yet

- PETROLAND PL 2 INVENTORY RIGDocument9 pagesPETROLAND PL 2 INVENTORY RIGmantenimiento keruiNo ratings yet

- 2356 cptg007 En-Web PDFDocument24 pages2356 cptg007 En-Web PDF7esabat7033No ratings yet

- RSC-1650C, H, HR Service Manual (061208)Document56 pagesRSC-1650C, H, HR Service Manual (061208)JamesNo ratings yet

- Concrete and Composite Poles Construction and Design GuideDocument18 pagesConcrete and Composite Poles Construction and Design GuideJayabalan R KNo ratings yet

- Forces, Motion, and Energy: ScienceDocument39 pagesForces, Motion, and Energy: ScienceElizabeth Inocencio Facundo - SagotNo ratings yet

- Cold Formed Steel DesignDocument2 pagesCold Formed Steel DesignkiplingkipNo ratings yet

- Phy Lab ManualDocument18 pagesPhy Lab Manualkaeshav manivannanNo ratings yet

- Compressor Torque Manual GES089Document93 pagesCompressor Torque Manual GES089Jeff LNo ratings yet

- Tabela TROUBLESHOOTING FT 2010Document14 pagesTabela TROUBLESHOOTING FT 2010Lucas TavaresNo ratings yet

- Annular RaftDocument8 pagesAnnular RaftBhaskar Reddy100% (2)

- Kayaba MedidasDocument24 pagesKayaba MedidasPilar TorquemadaNo ratings yet

- Global PositioningDocument6 pagesGlobal PositioningAkash BansalNo ratings yet

- Technical Data PM50-6ADocument3 pagesTechnical Data PM50-6ADodi HermawanNo ratings yet

- TRANE Product Report - ERTAF 355 HE - 5.6 - 11.2Document1 pageTRANE Product Report - ERTAF 355 HE - 5.6 - 11.2ZeeshanNo ratings yet

- Inst Headers Install TitianDocument3 pagesInst Headers Install TitianhuntersgreenNo ratings yet

- Track Calc - Staircase - 152X152X23Document13 pagesTrack Calc - Staircase - 152X152X23Ranjit S KashyapNo ratings yet

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsFrom EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNo ratings yet

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityFrom EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityRating: 4.5 out of 5 stars4.5/5 (115)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)