Professional Documents

Culture Documents

6 Introduction

Uploaded by

hafizrahimmitCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

6 Introduction

Uploaded by

hafizrahimmitCopyright:

Available Formats

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

CHAPTER-1

INTRODUCTION

Load shedding is a process in which electric power is cutoff on certain lines of power transformers when the demand approaches the system capacity. Load shedding is particularly important in isolated systems since there is no interconnected supply of power if the demand exceeds the power rating of the transformers. Typically load shedding is done by supervisory and monitoring systems such as supervisory control and data acquisition systems known as SCADA systems which continuously monitor vital parameters of the power system. SCADA systems usually shed the appropriate power load keeping a well-balanced system and at the same time maintaining reasonable customer satisfaction. Systems located in a hot climate zone, such as the emirates of Sharjah and Dubai of the United Arab Emirates, have many remotelydistributed transformers throughout the coverage area. During hot days, the peak power consumption is significantly higher than normal days. Even though the power grid is designed to handle such peak loads, it is possible that spurious excessive demand may cause power shutdown.

1.1.OBJECTIVE

Wireless Distributed Load-Shedding Management System which is designed to handle remotely distributed transformers which is located in hot climatic zone, lacking SCADA system using GSM technique. The

Dept of EEE,MESITAM

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

proposed system is used to protect the distributed transformers and proactively involves users in the shedding process.

1.2. SYSTEM DESIGN

The designed system called Wireless Distributed Load-Shedding Management System consists of three main modules. The DCM, the wireless communication module, and the CPM. The DCM is installed at the physical location of the transformer site. It consists of a system status monitor, that continuously records and processes current on each feeder. The wireless communication module consists of a GPRS modem that sends SMS messages over the GSM messages over the GSM network from the control center to the transformer site. This module is the communication backbone of the proposed system. The CPM processes the data, collected and fed-back by the GPRS modem at the transformer site, and sends control signals depending on the situations such as faults and overloads, or by special requests from authorized employees.

1.3 MODES OF OPERATION

The system should be configured to operate in two different modes: standard and caution modes. In the standard mode the system sensors measure the current per feeder, oil temperature and the location temperature of the transformer every hour and send an end-of-day SMS (type-C) to the control center server. Type-C SMS contains transformer number, average current readings on all feeders, and oil temperature readings of the transformer. The purpose of

Dept of EEE,MESITAM 2

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

these end-of-day SMS messages is to increase the reliability of data collection and to frequently update the database. Physical fault at the transformers site, a type-B SMS message is sent to the server. WDL-SMS will operate in caution mode if current loads on any of the transformer feeders exceed a specified preset values. A type-A overload SMS message will be sent to the server. The control center server then searches for respective consumers on that particular feeder inside its database. The server initiates Overload SMS messages to these consumers, asking them to reduce their power consumption. If the load is not reduced within a certain period of time called grace period, the control center asks the DCM at the transformers site to disconnect one or more feeders by sending Disconnect SMS. The system will also operated in caution mode if the oil and/or location temperature of the transformer exceed some preset threshold values.

1.4 COMMUNICATION PROTOCOL

As the systems modules need to interact with each others during system operation, several communications messages are used between modules. These messages include microcontroller-to-server, server-tomicrocontroller, and server-to-consumer messages.

1.4.1 Microcontroller-to-server Messages Microcontroller messages are mainly used in reporting data from the DCM module to the server of the CPM module. Three types of messages are used : Alarm Message

Dept of EEE,MESITAM 3

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Update Message Fault Message Send-on-Request Message

1.4.2 Server-to-microcontroller Messages The server communicates with the microcontroller using three different types of message: Request, Disconnect and Connect. Request Message: Whenever the current reading of the transformer parameters are required by the utility site, a message is sent to the microcontroller Disconnect Message: This message is sent to the microcontroller if the feeders are to be disconnected by the company. Connect Message: This message is sent to the microcontroller if the feeders are to be reconnected by the company.

1.4.3 Server-to-consumer Messages In the event of excess power consumption, the consumer might receive the following alert message Please reduce your power consumption or else you might suffer power loss. Thank you.This message consists of 65 ASCII characters totaling 455 bits per SMS message per alerted customer.

Dept of EEE,MESITAM

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

CHAPTER-2

BLOCK DIAGRAM DESCRIPTION

Fig2.1: Block diagram

Dept of EEE,MESITAM

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

2.1. INTRODUCTION The block diagram comprises of ATMEGA 328, GSM modem, Relay, Interfacing Device(RS 232 Serial port) and Temperature Sensor. Each device in each block has its own duties and functions.

2.2. ATMEGA 328

Micro controller (ATMEGA 328) is the main heart of our system. It operates in 5v supply. All the devices is being connected with microcontroller including Temperature sensor, Relay, GSM modem .The operating conditions were programmed and been loaded in the microcontroller. It will work according to the operating conditions. The relay will be turn on/off according to the instructions that are given by the microcontroller. The GSM modem is connected through interfacing devices known as RS 232 serial port. 2.3. GSM MODEM The GSM modem is being interfaced with microcontroller through RS 232 serial port. It will send early warning messages to the customer for reducing the power consumption. A GSM modem can be a dedicated modem device with a serial, USB or Bluetooth connection, or it may be a mobile phone that provides GSM modem capabilities. A GSM modem exposes an interface that allows applications such as Now SMS to send and receive messages over the modem interface.

Dept of EEE,MESITAM

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

2.4. TEMPERATURE SENSOR (LM35) Temperature sensor will sense atmospheric temperature. The temperature limit can be set in the program itself. Here LM35 is used as the Temperature sensor. If the temperature exceed the fixed value it will send message to the Electricity Board. 2.5. RELAY Relay is an electrical switch that opens and closes under the control of another electrical circuit. In the original form, the switch is operated as an electromagnet to open or close one or more sets of contacts. A Relay is able to control an output circuit of higher power than the input circuit, it can be considered to be, in a broad sense, a form of an electrical amplifier. The relay will turned off if any disturbance occur in the system.

2.6. RS 232 INTERFACE

It is a standard serial interfacing device used for interfacing PIC and GSM modem. It will work with the voltages of -15V to +15V for high and low. The voltage for logic 1 ranges from -3V to -12V and for logic 0 it ranges from +3V to +12V.Modern low-power logic operates in the range of 0V.+3.3V or even lower.

Dept of EEE,MESITAM

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

CHAPTER-3

HARDWARE DESCRIPTIONS

The main hardware equipments which were employed in our project are Micro controller (ATMEGA 328), LCD Display, GSM modem, Current Transformers (CTs), Relays, Feeders, Loads, Temperature Sensor. Each of them is been briefly explained one by one as follow:

3.1.ATMEGA 328

Fig.2 .ATMEGA 328

Micro controller (ATMEGA 328) is the main heart of our system. It operates in 5v supply. All the devices is being connected with microcontroller including Temperature sensor, Relay, GSM modem .The operating conditions were programmed and been loaded in the microcontroller. It will work according to the operating conditions. The relay will be turn on/off according to the instructions that are given by the microcontroller. The GSM modem is connected through interfacing devices known as RS 232 serial port.

Dept of EEE,MESITAM 8

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Fig. PINOUT DIAGRAM

3.2.PIN DESCRIPTIONS Write something here regarding the pin details below & start all paragraph with a space 3.2.1.VCC Digital supply voltage. 3.2.2 GND Ground. 3.2.3 Port B (PB7:0) XTAL1/XTAL2/TOSC1/TOSC2 Port B is an 8-bit bi-directional I/O port with internal pull-up resistors (selected for each bit). The Port B output buffers have symmetrical drive characteristics with both high sink and source capability. As inputs, Port B pins that are externally pulled low will source current if the pull-up

Dept of EEE,MESITAM

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

resistors are activated. The Port B pins are tri-stated when a reset condition becomes active, even if the clock is not running. Depending on the clock selection fuse settings, PB6 can be used as input to the inverting Oscillator amplifier and input to the internal clock operating circuit. Depending on the clock selection fuse settings, PB7 can be used as output from the inverting Oscillator amplifier. If the Internal Calibrated RC Oscillator is used as chip clock source, PB7...6 is used as TOSC2...1 input for the Asynchronous Timer/Counter2 if the AS2 bit in ASSR is set. 3.2.4 Port C (PC5:0) .Port C is a 7-bit bi-directional I/O port with internal pull-up resistors (selected for each bit). The PC5...0 output buffers have symmetrical drive characteristics with both high sink and source capability. As inputs, Port C pins that are externally pulled low will source current if the pull-up resistors are activated. The Port C pins are tri-stated when a reset condition becomes active, even if the clock is not running. 3.2.5 PC6/RESET If the RSTDISBL Fuse is programmed, PC6 is used as an I/O pin. Note that the electrical characteristics of PC6 differ from those of the other pins of Port C. If the RSTDISBL Fuse is unprogrammed, PC6 is used as a Reset input. A low level on this pin for longer than the minimum pulse length will generate a Reset, even if the clock is not running. 3.2.6 Port D (PD7:0) Port D is an 8-bit bi-directional I/O port with internal pull-up resistors (selected for each bit). The Port D output buffers have symmetrical drive characteristics with both high sink and source capability. As inputs, Port D pins that are externally pulled low will source current if the pull-up resistors

Dept of EEE,MESITAM

10

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

are activated. The Port D pins are tri-stated when a reset condition becomes active, even if the clock is not running.

3.2.7 AVCC AVCC is the supply voltage pin for the A/D Converter, PC3:0, and ADC7:6. It should be externally connected to VCC, even if the ADC is not used. If the ADC is used, it should be connected to VCC through a low-pass filter. Note thatPC6...4 use digital supply voltage, VCC.

3.3. LCD MODULE

Fig.3.LCD Module

Dont under line

A liquid crystal display (LCD) is a thin, flat electronic visual display that uses the light modulating properties of liquid crystals (LCs). LCs does not emit light directly. They are used in a wide range of applications, including computer monitors, television, instrument panels, aircraft cockpit displays, signage, etc. They are common in consumer devices such as video players,

Dept of EEE,MESITAM 11

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

gaming devices, clocks, watches, calculators, and telephones. LCDs have displaced cathode ray tube (CRT) displays in most applications. They are usually more compact, lightweight, portable, less expensive, more reliable, and easier on the eyes] They are available in a wider range of screen sizes than CRT and plasma displays, and since they do not use phosphors, they cannot suffer image burn-in. LCDs are more energy efficient and offer safer disposal than CRTs. Its low electrical power consumption enables it to be used in batterypowered electronic equipment. It is an electronically-modulated optical device made up of any number of pixels filled with liquid crystals and arrayed in front of a light source (backlight) or reflector to produce images in colour or monochrome.

3.4.GSM MODEM

Fig.4.GSM Modem A GSM modem is a specialized modem which accepts SIM card and operates over a subscription to a mobile operator, just like a mobile phone. A GSM modem has a serial connection. A GSM modem exposes an

Dept of EEE,MESITAM 12

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

interface that allows applications such as to send and receive messages over the modem interface. A GSM modem is a wireless modem that works with wireless network. Computers use AT commands (Attention commands) to control modems. The number of SMS that can be processed by a GSM per minute is about 6-10. A GSM modem is a wireless modem that works with a GSM wireless network. A wireless modem behaves like a dial-up modem. The main difference between them is that a dial-up modem sends and receives data through a fixed telephone line while a wireless modem sends and receives data through radio waves. GSM modems can be a quick and efficient way to get started with SMS, because a special subscription to an SMS service provider is not required. The mobile operator charges for this message sending and receiving as if it was performed directly on a mobile phone. 3.4.1. GSM MODEM FEATURES Quad Band GSM/GPRS 850/900/1800/1900Mhz GPRS multi-slot class 10/8 GPRS Mobile station class B Compliant to GSM Phase 2/2+ Class 4 (2W@850/900Mhz) Class 1(1W@1800/1900Mhz) Control via AT commands (GSM 07.07, 07.05 and enhanced AT commands)

Dept of EEE,MESITAM

13

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

3.4.2. INTERFACES RS-232 through D-TYPE 9 pin connector, Serial port baud rate adjustable 1200 to115200 bps (9600 default) Stereo connector for MIC & SPK Power supply through DC socket SMA antenna connector Push switch type SIM holder LED status of GSM / GPRS module

3.3.3. AT COMMANDS

Communication with the GSM modem is by using AT commands. To perform these tasks, a GSM modem must support an "extended AT command set" for sending/receiving SMS messages.

Commands for Reading and Sending SMS is as follows

1. Set SMS mode Command : AT+CMGF=1 2. Send SMS Command : AT+CMGS=<number><Crriagereturn>(new line)(>)<matter> <ctrl+z> 3. Read SMS Command : AT+CMGR=<location>

Dept of EEE,MESITAM

14

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

3.4.4. SIM305/SIM345 (GSM MODEM) The SIM305/345 is a complete Dual-band/Quad-band

GSM/GPRS solution in a compact plug-in module. Featuring an industrystandard interface, the SIM305/345 delivers GSM/GPRS

50/900/1800/1900MHz performance for Voice, SMS, Data, and Fax in a small form factor and with low power consumption.

The leading features of SIM305/345 make it ideal for M2M applications, such as AMR, POS, Security, AVL etc. 3.4.4.1. General features Dual-Band GSM/GPRS 900/1800MHz or Quad-Band GSM/GPRS 850/900/1800/1900MHz GPRS multi-slot class 10 GPRS mobile station class B Compliant to GSM phase 2/2+ Class 4 (2 W @ 850/900MHz) Class 1 (1 W @ 1800/1900MHz) Dimension: 58mm x 32mmx 3.9 mm Weight: <12g SIM application toolkit Supply voltage range 3.4 ... 4.5 V Low power consumption Normal operation temperature: -30C to +80C Restricted operation temperature: -40C to -30C and +80C to +85C

Dept of EEE,MESITAM 15

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Storage temperature: -45C to +90C 3.4.4.2. Specifications for SMS via GSM / GPRS

Point-to-point MO and MT SMS cell broadcast Text and PDU mode

3.5. CURRENT TRANSFORMER

Fig.5.Different Types of Current Transformers Here two Current Transformers are used to measure the current across feeders. It will out the corresponding voltage values by the principle of Electromagnetic Induction. The phase of each feeders were passed through the core of CTs. It is rated to be 5A. A bridge circuit is necessary for connecting the Current Transformers.

Dept of EEE,MESITAM

16

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

It is not possible to use line current directly for measurement and relaying purpose due to its high value and insulation problem. CURRENT TRANSFORMER which is widely known as 'CT ' is a piece of electrical equipment which converts line current (primary current) in to small standard current values which are suitable for the devices to which it is connected e.g. measuring instruments, meters, protection relays.

3.5.1. BASIC FUNCTIONS OF CTs To reduce line current to a value which is suitable for standard measuring instruments, relays etc. To isolate the measuring instruments, meters, relays etc. from line voltage of an installation. To protect measuring instruments against short circuit currents. To sense abnormalities in current and give current signals to protective relays to isolate the defective system Ring type (or rectangular type) CTs are normally preferred over other types of CTs. because they are simple in construction, mechanically stronger and cheaper. In a ring type/bar primary type CTs the working ampere-turns are determined by the primary current and therefore necessarily, the accuracy that can be offered with these CTs becomes progressively inferior as the rated primary current decreases.'-If higher accuracy and burdens are required for CTs of low primary current wound types CTs are used.

Dept of EEE,MESITAM

17

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

3.6. MAX 232 LEVEL CONVERTERS

. Fig.6. MAX 232 pin Fig.7.MAX 232 Interface

For interfacing PIC and GSM modem Serial RS-232 communication is used. It works with voltages 15V to +15V for high and low. On the other hand, TTL logic operates between 0V and +5V . Modern low power consumption logic operates in the range of 0V and +3.3V or even lower. Thus the RS-232 signal levels are far too high TTL electronics, and the negative RS-232 voltage for high cant be handled at all by computer logic. To receive serial data from an RS-232 interface the voltage has to be reduced also the low and high voltage level has to be inverted. RS-232 TTL Logic

-15V -3V +2V +5V High +3V +15V 0V +0.8V Low

Table-1

Dept of EEE,MESITAM

18

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

This module is primary of interest for people building their own electronics with an RS-232 interface. Serial RS-232 communication works with voltages (-15V ... -3V for high ) and +3V ... +15V for low) which are not compatible with normal computer logic voltages. On the other hand, classic TTL computer logic operates between 0V ... +5V (roughly 0V ... +0.8V for low, +2V ... +5V for high). Modern low-power logic operates in the range of 0V ... +3.3V or even lower. So, the maximum RS-232 signal levels are far too high for computer logic electronics, and the negative RS-232 voltage for high can't be grokked at all by computer logic. Therefore, to receive serial data from an RS-232 interface the voltage has to be reduced, and the low and high voltage level inverted. In the other direction (sending data from some logic over RS-232) the low logic voltage has to be "bumped up", and a negative voltage has to be generated, too. RS-232 TTL Logic

-----------------------------------------------15V ... -3V <-> +2V ... +5V <-> high +3V ... +15V <-> 0V ... +0.8V <-> low All this can be done with conventional analog electronics, e.g. a particular power supply and a couple of transistors or the once popular 1488 (transmitter) and 1489 (receiver) ICs. However, since more than a decade it has become standard in amateur electronics to do the necessary signal level conversion with an integrated circuit (IC) from the MAX232 family (typically a MAX232A or some clone). In fact, it is hard

Dept of EEE,MESITAM

19

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

to find some RS-232 circuitry in amateur electronics without a MAX232A or some clone. The MAX232 from Maxim was the first IC which in one package contains the necessary drivers (two) and receivers (also two), to adapt the RS-232 signal voltage levels to TTL logic. It became popular, because it just needs one voltage (+5V) and generates the necessary RS232 voltage levels (approx. -10V and +10V) internally. This greatly simplified the design of circuitry. Circuitry designers no longer need to design and build a power supply with three voltages (e.g. -12V, +5V, and +12V), but could just provide one +5V power supply, e.g. with the help of a simple 78x05 voltage converter.

3.7. RELAY

Fig.8.Relay Here three relays are used, two for two feeders and one for Temperature sensor. A relay is a simple electromechanical switch made up of an electromagnet and a set of contacts. Relays are found hidden in all sorts of devices. In fact, some of the first computers ever built used relays to implement Boolean gates.

Dept of EEE,MESITAM

20

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

A simple electromagnetic relay consists of a coil of wire surrounding a soft iron core, an iron yoke which provides a low reluctance path for magnetic flux, a movable iron armature, and one or more sets of contacts (there are two in the relay pictured). When an electric current is passed through the coil it generates a magnetic field that attracts the armature and the consequent movement of the movable contact(s) either makes or breaks (depending upon construction) a connection with a fixed contact. If the set of contacts was closed when the relay was de-energized, then the movement opens the contacts and breaks the connection, and vice versa if the contacts were open. Relays are used to and for: Control a high-voltage circuit with a low-voltage signal, as in some types of modems or audio amplifiers, Control a high-current circuit with a low-current signal, as in the starter solenoid of an automobile, Detect and isolate faults on transmission and distribution lines by opening and closing circuit breakers (protection relays). 3.8. LOADS

Fig.9. Electrical Appliances

Dept of EEE,MESITAM

Fig.10. 60V bulb

21

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

The various loads were connected at the feeder side. When the consumption of power exceed the feeder is overloaded .Now a days various electrical appliances like bulb, mixy , motor consuming huge amount of power in residual areas .In industries huge power consumption devices like motors, transformers require large power for working .For working of the hardware one 40V bulb and one 60V bulb is used.

According to the type of load using consumption of power varies. For starting of the certain equipment require large power. During hot days, the peak power consumption is significantly higher than normal loads. Even though the power grid is designed to handle such peak loads, it is possible that spurious excessive demand may cause power shutdown. Together with ambient temperature, this could be leveraged to give enough lead time to take the necessary measures to avoid excess load and potentially massive power outages.

Dept of EEE,MESITAM

22

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Use SAME FONT & FONT SIZE FOR ALL DOC & Align all paragraph like this below

According to the type of load using consumption of power varies. For starting of the certain equipment require large power. During hot days, the peak power consumption is significantly higher than normal loads. Even though the power grid is designed to handle such peak loads, it is possible that spurious excessive demand may cause power shutdown. Together with ambient temperature, this could be leveraged to give enough lead time to take the necessary measures to avoid excess load and potentially massive power outages.

Dept of EEE,MESITAM

23

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

CHAPTER-4

CIRCUIT EXPLANATIONS

In circuit explanation we are explaining about the various inter connections of each device. Each pin in each device has its own functions. 4.1. POWER SUPPLY

CON3 D2 1 2 3 J1 D3 LED 1N4007 R2 1.2K +12v 1

1000uF/25V

U1 LM7805C/TO220 IN

GND

+5 VCC OUT 3 C4 103 C1 100uF/16V

C3

C2 104

Fig11:Power supply circuit The above figure shows the power supply circuit. Input is given through DC adaptor. Diode IN4007 is to avoid the polarity inversion when plugging. LED is for displaying the status. Capacitive filters are used to eliminate ripples. 1000uF capacitor is electrolytic and 0.1uF is disc capacitor. The capacitor filter should be rated at a minimum of 1000uF for each amp of current drawn and at least twice the input voltage. The 0.1uF

Dept of EEE,MESITAM 24

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

capacitor eliminates any high frequency pulses that could otherwise interfere with the operation of the regulator. Voltage regulators are very robust. They can withstand over-current draw due to short circuits and also over-heating. In both cases the regulator will shut down before damage occurs. The only way to destroy a regulator is to apply reverse voltage to its input. A IN4004, 1 amp power diode is connected in series with the power supply. If the supply is connected the wrong way around, the regulator will be protected from damage. The LM78XX series of three terminal regulators is available with several fixed output voltages making them useful in a wide range of applications. One of these is local on card regulation, eliminating the distribution problems associated with single point regulation. The voltages available allow these regulators to be used in logic systems, instrumentation, HiFi, and other solid state electronic equipment. Although designed primarily as fixed voltage regulators these devices can be used with external components to obtain adjustable voltages and currents. The LM78XX series is available in an aluminum TO-3 package which will allow over 1.0A load current if adequate heat sinking is provided. Current limiting is included to limit the peak output current to a safe value. Safe area protection for the output transistor is provided to limit internal power dissipation. If internal power dissipation becomes too high for the heat sinking provided, the thermal shutdown circuit takes over preventing the IC from overheating. Considerable effort was expanded to make the LM78XX series of regulators easy to use and minimize the number of external components. It is not necessary to bypass the output, although this does improve transient response. Input bypassing is needed only if the regulator is located far from the filter capacitor of the power supply

Dept of EEE,MESITAM 25

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

4.2. LCD DISPLAY The LCD module is a parallel interface sixteen pin module. The first three pins of LCD module are used for contrast adjusting. Here the first pin is connected to ground, second to the voltage supply and third to the variable resistor. The pins, seven to fourteen are data lines (D0 to D7). In this particular circuit the data lines D4 to D7 are used because the LCD driver available is 4 line data bus. 15th pin is connected to the 5 volt supply. Pin 4, 5, 6 are control pins, R/W, RS and enable respectively. 16th pin is connected to the ground through a transistor. The voltage from pic16f877a turn on the transistor and it in turn turns on the LCD backlight .Resistor R9 controls the voltage supplied to the transistor. 4.2.1. PINOUT LCD modules may have a parallel or serial interface. The module discussed here has a 14-pin parallel interface. The pin out for this module is shown below. 4.2.1.1. Enable (E) : This line allows access to the display through R/W and RS lines. When this line is low, the LCD is disabled and ignores signals from R/W and RS. When (E) line is high, the LCD checks the state of the two control lines and responds accordingly.

Dept of EEE,MESITAM

26

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

SL.NO.

SYMBOL

FUNCTION

1 2

Vss Vcc

Ground +5V

3 4 5 6 7 8 9 10 11 12 13 14

VEE RS R/W E DB0 DB1 DB2 DB3 DB4 DB5 DB6 DB7

Contrast H=Data, L=Instruction H=Read, L=Write Latch, HL LSB

MSB Table-2

4.2.1.2. Read/Write (R/W): This line determines the direction of data between the LCD and microcontroller. When it is low, data is written to the LCD. When it is high, data is read from the LCD.

Dept of EEE,MESITAM 27

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

4.2.1.3. Register select (RS) : With the help of this line, the LCD interprets the type of data on data lines. When it is low, an instruction is being written to the LCD. When it is high, a character is being written to the LCD.

4.2.1.4. Contrast: A variable voltage applied to this pin controls the contrast. Use a potentiometer and adjust until you see the background. 4.2.1.5. DB0-DB7: Apply the data or commands to these pins.

LCDs are more energy efficient and offer safer disposal than CRTs. Its low electrical power consumption enables it to be used in batterypowered electronic equipment. It is an electronically-modulated optical device made up of any number of pixels filled with liquid crystals and arrayed in front of a light source (backlight) or reflector to produce images in colour or monochrome. The earliest discovery leading to the development of LCD technology, the discovery of liquid crystals, dates from 1888.By 2008, worldwide sales of televisions with LCD screens had surpassed the sale of CRT units

Dept of EEE,MESITAM

28

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

4.3. MAX232 It consists of 16 pins.pin 1&3connected by a capacitor. Pin 4&5 connected through a capacitor. Pin 11 &12 connected to a 24&25 pin of PIC. Pin 14&13 are connected to 2&3 pin of RS232. Pin 6 of MAX232and pin 5 of RS232 to GND through a capacitor C7.Pin 2 is connected to supply through a capacitor

+-----v-----+

C1+-|1 16|- Vcc V+ -|2 15|- GND C1--|3 14|- T1out C2+-|4 13|- R1in C2--|5 12|- R1out V- -|6 11|- T1in T2o-|7 10|- T2in R2i-|8 9|- R2out +-------+ Fig.13.Pin Layout of MAX 232(A) DIP Package The MAX232(A) has two receivers (converts from RS-232 to TTL voltage levels) and two drivers (converts from TTL logic to RS-232 voltage levels). This means only two of the RS-232 signals can be converted in each direction. The old MC1488/1498 combo provided four drivers and receivers. There are not enough drivers/receivers in the MAX232 to also connect the DTR, DSR, and DCD signals. Usually these signals can be omitted when e.g. communicating with a PC's serial interface. If the DTE really requires these signals either a second MAX232 is needed, or some

Dept of EEE,MESITAM 29

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

other IC from the MAX232 family can be used (if it can be found in consumer electronic shops at all). An alternative for DTR/DSR is also given below. Maxim's data sheet explains the MAX232 family in great detail, including the pin configuration and how to connect such an IC to external circuitry. This information can be used as-is in own design to get a working RS-232 interface. Maxim's data just misses one critical piece of information: How exactly to connect the RS-232 signals to the IC one. 4.4. RS232 SERIAL PORT It consists of 6 pins, out of this pin 3&2 are connected to 13&14 of MAX232. Pin 5 is connected to gnd.

MAX232 to RS232 DB9 Connection as a DCE MAX232 Pin No. 7 8 9 10 11 12 13 14 MAX232 Pin Name T2out R2in R2out T2in T1in R1out R1in T1out Signal Voltage DB9 Pin RTS CTS CTS RTS TX RX TX RX RS-232 RS-232 TTL TTL TTL TTL RS-232 RS-232 8 7 n/a n/a n/a n/a 3 2

Dept of EEE,MESITAM

30

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

15

GND Table-3

GND

4.5. FEEDERS 3 relays were used, out of this two for 2 feeders and one for transformer. Relay has 3 pins N0, NC,C. if the switch is closed position then connected to NC. Three resistors were connected across 3 relays. 3 resistor pin connections were connected to 16,17,18 pin of PIC. A 12v supply is taken from power supply circuit.

4.6.CIRCUIT FABRICATION AND SOLDERING DETAIL 4.6.1.Pcb fabrication Printed Circuit Broad (PCB) is a mechanical assembly consisting of layers of fiberglass sheet laminated with etched copper patterns. It is used to mount electronic parts in a rigid manner suitable for packaging. The type of integrated circuit components used in the fabrication process has an important role in the design of PCB. The conductor width, spacing between the signal conductors etc, are calculated to give optimum wave impedance of the conductor's lines. Optimum wave impedance gives minimum delay or rising and trailing edge of the pulse in digital circuit.

Dept of EEE,MESITAM

31

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

4.6.2.Soldering Soldering is an important skill for electrical technician. Good soldering is important for proper operation of equipment.Solder is an alloy of tin and lead. The solder that is most used is60/40 solder. This means that it is made from 60% tin and 40% lead. Solder melts at a temperature of about 400 degree Fahrenheit. For solder to adhere to join, the parts must to enough to melt the solder. Rosin flux is contained inside the solder. It is called rosin-core solder. A good mechanical joint must be made when soldering. Heat is then applied until the material rare hot. When they are hot, solder is applied to the joint. The heat of the metal parts is used to melt the solder. Only a small amount of heat should be used sparingly. The joint should appear smooth and thin. If it does not, it could be a "cold" solder joint. This is called a cold joint". Care should be taken not to damage PCB when soldering parts on to them. Small, low wattage irons should be used with PCB and semiconductor devices

Dept of EEE,MESITAM

32

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Fig.14.Board connection

Change with a new figure

Dept of EEE,MESITAM

33

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Fig.15.Circuit diagram of hardware

Dept of EEE,MESITAM

34

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

CHAPTER-5

SOFTWARE DEVELOPMENT TOOLS

Write about the software and how did you burn the program to MC

Program codes are generally shown in appendix 1 or 2 Clarify this the project coordinator

5.1. PROGRAM FOR MICROCONTROLLER: #include<16f877a.h> #include"pic1.h" #include"lcd1.h" #define transformer rc1 #define fr1 rc2 #define fr2 rc3 int count,p,pflg=0,t; int fr1flg=1,fr2flg=1,trflg=1,f1,f2,afl; char kseb[]="9486669772"; void sms_send(void) { putchar(26); delay_ms(200); }

Dept of EEE,MESITAM

35

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

void sms_start_kseb(char*ch) { printf("AT+CMGF=1\r"); printf("AT+CMGS="); printf("\"+91"); printf("%s\"\r",ch); } #int_RTCC RTCC_isr() { count++;

if (count>100000) { count=0; fr1 flg=1,fr2flg=1,trflg=1; fr1=fr2=transformer=afl=1; set_timer0(0x00); } } float feeder1() { set_adc_channel(0); delay_us(20); if(fr1flg&&trflg) return(read_adc());

Dept of EEE,MESITAM 36

// Checking status of F1

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

} float feeder2() { set_adc_channel(1); delay_us(20); if(fr2flg&&trflg) return(read_adc()); } float temp() { set_adc_channel(2); delay_us(20); if(trflg) // Checking status of F2

return(read_adc()*5.0/255*100); }

void grace_period() { pflg=0; while(p<18) { p=p+1; delay_ms(2000); go(64); print(p); delay_ms(300);

Dept of EEE,MESITAM 37

//20000

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

} pflg=1; clrscr(); }

void sms_start_c(char*ch) { printf("AT+CMGF=1\r"); printf("AT+CMGS="); printf("\"+91"); printf("%s\"\r",ch); printf("Please reduce your power consumption\r"); printf(" or else you might suffer Power Loss!\r"); printf("Thank You...."); sms_send(); }

void main() { int k,i,f1,f2,f1flg; char msg[ ]="WDL SMS"; char F1C1[ ]="9791668561"; char F1C2[ ]="9655166177"; char F1C3[ ]="9787239229"; char F2C1[ ]="7708311801"; char F2C2[ ]="9487449774"; char F2C3[ ]="9496369807";

Dept of EEE,MESITAM 38

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

char trsf[ ]="Transformer is Off"; trisd=0x00; trisc1=trisc2=trisc3=0; enable_interrupts(global); enable_interrupts(INT_RTCC); setup_adc_ports(ALL_ANALOG); setup_adc(ADC_CLOCK_INTERNAL); setup_timer_0 (RTCC_INTERNAL|RTCC_DIV_256); set_timer0(0x00); TRISB=0X00; fr1=fr2=transformer=1; lcdinit(); go(4); prints(msg); delay_ms(800); clrscr(); afl=0; f1flg=1; while(1) {

f1=feeder1(); f2=feeder2(); if(f2>200) f1flg=0; else f1flg=1;

Dept of EEE,MESITAM 39

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

pflg=0; go(0); printc("F1="); go(3); //clrscr(); if(!f1flg) f1=0; print(f1); delay_ms(700); go(8); printc("F2="); go(11); //clrscr(); print(f2); delay_ms(700); t=temp(); go(67); printc("Temp="); go(73); print(t); delay_ms(200) if(t>45) { sms_start_kseb(kseb); printf("High Temp : TRANSOFRMER IS OFF\r"); sms_send(); transformer=fr1=fr2=0;

Dept of EEE,MESITAM 40

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

trflg=0; go(64); prints(trsf); delay_ms(500); clrscr();

} if(f1>140) delay_ms(200); if(f1>140) { if(!pflg) { clrscr(); go(68); printc("F1 HIGH"); delay_ms(200); sms_start_c(F1C1); sms_send(); sms_start_c(F1C2); sms_send(); sms_start_c(F1C3); sms_send(); } p=0; grace_period(); }

Dept of EEE,MESITAM 41

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

if(f2>230) { delay_ms(200); if(f2>230) { if(!pflg) { clrscr(); go(68); printc("F2 HIGH"); delay_ms(200); sms_start_c(F2C1); sms_send(); sms_start_c(F2C2); sms_send(); sms_start_c(F2C3); sms_send(); } p=0; grace_period(); } } if(pflg) { f1=feeder1();

if(f1>140)

Dept of EEE,MESITAM 42

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

{ fr1=0; fr1flg=0; pflg=0; sms_start_kseb(kseb); printf("Feeder1 Is OFF"); sms_send(); clrscr(); printc("Feeder1 Is OFF"); delay_ms(500); clrscr(); } } if(pflg) { f2=feeder2(); if(f2>230) { fr2=0; fr2flg=0; pflg=0; sms_start_kseb(kseb); printf("Feeder2 Is OFF"); sms_send(); clrscr(); printc("Feeder2 Is OFF"); delay_ms(500);

Dept of EEE,MESITAM 43

// If Feeder1 off

//If Feeder2 off

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

clrscr(); } } }

Dept of EEE,MESITAM

44

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

CHAPTER-6

CONCLUSION

Wireless Distributed Load Shedding Management System (WDL-SMS) was implemented and tested. It was verified to operate successfully under standard and caution modes. GSM network was successfully used in remote monitoring and control .Recent advances in the technology can be leveraged in order to make WDL-SMS more stable and feature-rich.

NOT NEEDED Here we are glad to present the project titled as WIRELESS DISTRIBUTED LOAD SHEDDING MANAGEMENT SYSTEM. We have introduced our project in small scale manner to expose large ideas in transformer side.

We are sure that this project is very useful and needful one to all.

Dept of EEE,MESITAM

45

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

CHAPTER-7

FUTURE SCOPE

In the future the system could call the mobile technicians and use a pre-recorded voice to tell the fault rather than sending SMS .It can also E-mail a summary of readings of all transformers to employees on a regular basis. It can monitor, record and update transformer parameters more frequently. In future an Artifical Neural Network(ANN)can be used in forecasting, or predicting overloads and abnormal conditions.ANN can be configured to recognize specific pattern or data classification, through a learning process.

Dept of EEE,MESITAM

46

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

DONT PUT CHAPER NO FOR APPENDIX , Just write it as APPENDIX I or APPENDIX II CHAPTER-8

APPENDICES 8.1.USART The Universal Synchronous Asynchronous Receiver Transmitter module is one of the two serial I/O modules The USART can be configured as a full duplex asynchronous system or it can be configured as a half duplex synchronous

8.1.1.USART MODULE The USART can be configured in these modes: Asynchronous (full duplex) Synchronous - Master (half duplex) Synchronous - Slave (half duplex) Bit SPEN (RCSTA<7>) and bits TRISC<7:6> have to be set to configure pins RC6/TX/CK and RC7/RX/DT as the USART The USART module also has a multi-processor communication capability using 9-bit address detection.

8.1.2.FULL DUPLEX ASYNCHRONOUS OPERATION The most common use of the USART in asynchronous mode is to communicate to a PC serial port using the RS-232 protocol. The UART can both transmit and receive

Dept of EEE,MESITAM 47

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Full duplex operation - Both transmission and reception can occur at the same time The USART Asynchronous module consists of Sampling Circuit Asynchronous Transmitter Asynchronous Receiver

8.1.3.BAUD RATE FORMULA Formulas for baud rate Baud rate = Fosc/(16(SPBRG+1)), BRGH=1 Baud rate = Fosc/(64(SPBRG+1)), BRGH=0

Formulas for SPBRG SPBRG = (Fosc/(16 x Baud rate)) - 1, BRGH=1 SPBRG = (Fosc/(64 x Baud rate)) - 1, BRGH=0

8.2.MC78XX/LM78XX/MC78XXA 3 Terminal 1A positive voltage regulator

8.2.1.FEATURES: Output current up to 1A Output voltage of 5,6,8,9,10,12,15,18,24V Thermal overload protection

Dept of EEE,MESITAM 48

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Short circuit protection Output transistor safe operating area protection

Dept of EEE,MESITAM

49

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Table-5

Dept of EEE,MESITAM

50

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

8.3. CAD SOFT EAGLE

EAGLE (Easily Applicable Graphical Layout Editor) is a proprietary ECAD program produced by Cad Soft in Germany (American marketing division: Cad Soft USA). It is very commonly used by private electronics enthusiasts, because there is a free limited version for non-profit use and it is available in English and German. Cad Soft has released versions for Microsoft Windows, Linux, and Mac OS X.

EAGLE contains a schematic editor, for designing circuit diagrams and a PCB layout editor, which allows back annotation to the schematic. EAGLE includes a basic but functional autorouter, or alternatively manual routing can be performed. PCBs designed in EAGLE are accepted by a large amount of PCB fabrication houses without the need to export. EAGLE is very popular with hobbyists because both a basic free edition (with a lower feature set) and a low cost non-profit edition are available. Schematic capture or schematic entry is a step in the design cycle of electronic design automation (EDA) at which the electronic diagram, or electronic schematic of the designed electronic circuit is created by a designer. This is done interactively with the help of a schematic capture tool also known as schematic editor.

Dept of EEE,MESITAM

51

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

Fig.19 The circuit design is the very first step of actual design of an electronic circuit. Typically sketches are drawn on paper, and then entered into a computer using a schematic editor. Therefore schematic entry is said to be a front-end operation Therefore schematic entry is said to be a frontend operation of several others in the design flow. Despite the complexity of modern components huge ball grid arrays and tiny passive components schematic capture is easier today than it has been for many years. CAD software is easier to use and is available in full-featured expensive packages, very capable mid-range packages that sometimes have free versions and completely free versions that are either open source or directly linked to a printed circuit board fabrication company.

Dept of EEE,MESITAM 52

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

In past years, schematic diagrams with largely discrete components were fairly readable however with the newer high pin-count parts and with the almost universal use of standard letter-sized paper, schematics have become less so. Many times, there will be a single large part on a page with nothing but pin reference keys to connect it to other pages. Readability levels can be enhanced by using buses and super buses, related pins can be connected into a common bus and routed to other pages. Buses don't need to be just the traditional address or data bus directly linked pins. A bus grouping can also be used for related uses, such as all analog input or all communications related pin functions.

Dept of EEE,MESITAM

53

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

REFERENCES

1. A.Saffarian,M.Sanaye pasand,H.Asadi,Performance Investigation of New combinational load shedding schemes,joint Internatonal Conference on Power System Technology and IEEE power India Conference,2008

2. Architecture of PIC Micro controller , www.microchip.com

3. Dellon.T.Horn How to test almost anything electronics

4. F. Capitanescu , B. Otomega,H. Lefebvre ,V. Sermanson,T.Van Cutsem, Decentralized tap changer blocking and load shedding against voltage instability: Prospective tests on the RTE system ,Electrical Power and Energy Systems. 5. IEEE,Guide for loading mineral-oil immersed transformers,,IEEE std.C57.91-1995.

6. http://robosoftsystems.co.in/roboshop/index.php/electronicscomponents/led-display/16x2-alphanumeric-lcd-hd44780 LCD Display

7. http://en.wikipedia.org/wiki/555_timer_IC , Working details of 555 Timer IC

Dept of EEE,MESITAM 54

WIRELESS DISTRIBUTED LOAD SHEDDIND MANAGEMENT SYSTEM

8. J. J.Ford ,H. Bevrani ,G. Ledwich ,Adaptive Load shedding and regional protection ,International Journal of electrical power and energy systems.

9. Ubald Fundamentals Of Electronics

10.Voltage regulator LM 7805, http://www.national.com/search/ LM7805.html

Dept of EEE,MESITAM

55

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- KODIYATUDocument1 pageKODIYATUhafizrahimmitNo ratings yet

- Ledger PDFDocument1 pageLedger PDFhafizrahimmitNo ratings yet

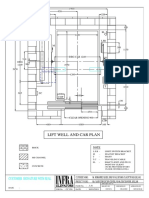

- Infra: Lift Well and Car PlanDocument1 pageInfra: Lift Well and Car PlanhafizrahimmitNo ratings yet

- Infra: Customer Signature With SealDocument1 pageInfra: Customer Signature With SealhafizrahimmitNo ratings yet

- Infra: Lift SpecificationsDocument1 pageInfra: Lift SpecificationshafizrahimmitNo ratings yet

- KODIYATTUDocument1 pageKODIYATTUhafizrahimmitNo ratings yet

- Proposal s8Document1 pageProposal s8hafizrahimmitNo ratings yet

- Tour Schedule (S5Eee) : Tour To - COORG-MYSORUDocument1 pageTour Schedule (S5Eee) : Tour To - COORG-MYSORUhafizrahimmitNo ratings yet

- Application For Renewal of Electrical Contractor LicenceDocument1 pageApplication For Renewal of Electrical Contractor LicencehafizrahimmitNo ratings yet

- TKM Institute of Technology: Lecture PlanDocument3 pagesTKM Institute of Technology: Lecture PlanhafizrahimmitNo ratings yet

- Electrical Machines LaboratoryDocument3 pagesElectrical Machines LaboratoryhafizrahimmitNo ratings yet

- Electrical LabDocument11 pagesElectrical LabhafizrahimmitNo ratings yet

- Electrical PDFDocument4 pagesElectrical PDFhafizrahimmitNo ratings yet

- Maintain Your Hot EquipmentDocument2 pagesMaintain Your Hot EquipmenthafizrahimmitNo ratings yet

- TKM Institute of Technology: Karuvelil.P.O, KollamDocument1 pageTKM Institute of Technology: Karuvelil.P.O, KollamhafizrahimmitNo ratings yet

- SUB: Permission For Displaying FlexDocument1 pageSUB: Permission For Displaying FlexhafizrahimmitNo ratings yet

- Vaibhav: RJ HuntDocument3 pagesVaibhav: RJ HunthafizrahimmitNo ratings yet

- 1 Female 2 Female 3 Female: Niranjana A Arathy Sreekumar Susmitha SugathanDocument1 page1 Female 2 Female 3 Female: Niranjana A Arathy Sreekumar Susmitha SugathanhafizrahimmitNo ratings yet

- TKM Institute of Technology, Karuvelil Department of Computer Sceince & Engineering S7 CSE (2013-2017) BATCHDocument4 pagesTKM Institute of Technology, Karuvelil Department of Computer Sceince & Engineering S7 CSE (2013-2017) BATCHhafizrahimmitNo ratings yet

- New Microsoft Word DocumentDocument12 pagesNew Microsoft Word DocumenthafizrahimmitNo ratings yet

- Study of The Further Reduction of Shaft Voltage of Brushless DC Motor With Insulated Rotor Driven by PWM InverterDocument6 pagesStudy of The Further Reduction of Shaft Voltage of Brushless DC Motor With Insulated Rotor Driven by PWM InverterhafizrahimmitNo ratings yet

- Tour Report s8Document2 pagesTour Report s8hafizrahimmitNo ratings yet

- Roll List S2 ECDocument11 pagesRoll List S2 EChafizrahimmitNo ratings yet

- Current AffairsDocument2 pagesCurrent AffairshafizrahimmitNo ratings yet

- First Name Second Name E Mail Id Talia Jude Reshma VP Haripriya S Anjali A Sambhu Mohan Jaisal ThomasDocument1 pageFirst Name Second Name E Mail Id Talia Jude Reshma VP Haripriya S Anjali A Sambhu Mohan Jaisal ThomashafizrahimmitNo ratings yet

- Mechanical s2 Roll ListDocument2 pagesMechanical s2 Roll ListhafizrahimmitNo ratings yet

- ELECTRICAL LAB Attendance Statement S2ME Feb 16Document9 pagesELECTRICAL LAB Attendance Statement S2ME Feb 16hafizrahimmitNo ratings yet

- Mechanical s2 Roll ListDocument2 pagesMechanical s2 Roll ListhafizrahimmitNo ratings yet

- ELECTRICAL LAB Attendance Statement S2ME Feb 16Document9 pagesELECTRICAL LAB Attendance Statement S2ME Feb 16hafizrahimmitNo ratings yet

- S 8 EiDocument11 pagesS 8 EihafizrahimmitNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hevi-Bar II and Safe-Lec 2Document68 pagesHevi-Bar II and Safe-Lec 2elkabongscribdNo ratings yet

- A Study On Traditional Medicinal Herbs Used by The Ethnic People of Goalpara District of Assam, North East IndiaDocument6 pagesA Study On Traditional Medicinal Herbs Used by The Ethnic People of Goalpara District of Assam, North East IndiaDr. Krishna N. SharmaNo ratings yet

- T.A.T.U. - Waste Management - Digital BookletDocument14 pagesT.A.T.U. - Waste Management - Digital BookletMarieBLNo ratings yet

- Resume: Satyam KumarDocument3 pagesResume: Satyam KumarEr Satyam Kumar KrantiNo ratings yet

- DIVAR IP All-In-One 7000 3U Datasheet 51 en 66297110155Document5 pagesDIVAR IP All-In-One 7000 3U Datasheet 51 en 66297110155Javier RochaNo ratings yet

- PANASONIC - WebCam-TQZJ402 - TY-CC20W PDFDocument188 pagesPANASONIC - WebCam-TQZJ402 - TY-CC20W PDF123anthonyNo ratings yet

- Kinder DLL Week 8Document15 pagesKinder DLL Week 8Jainab Pula SaiyadiNo ratings yet

- Petersen Coils Basic 20principle and ApplicationDocument3 pagesPetersen Coils Basic 20principle and ApplicationasotozuazuaNo ratings yet

- EXCEL For Pump DesignDocument2 pagesEXCEL For Pump Designkad-7No ratings yet

- ACR39U-U1: (USB Type A) Smart Card ReaderDocument8 pagesACR39U-U1: (USB Type A) Smart Card Readersuraj18in4uNo ratings yet

- Maritime Management SystemsDocument105 pagesMaritime Management SystemsAndika AntakaNo ratings yet

- Carrefour-SA Shopping Center TurkeyDocument2 pagesCarrefour-SA Shopping Center TurkeyVineet JogalekarNo ratings yet

- Colour FastnessDocument37 pagesColour FastnessSivakumar K100% (1)

- Synthesis Essay Coming To Grips With GenesisDocument11 pagesSynthesis Essay Coming To Grips With Genesisapi-259381516No ratings yet

- The 10 Most Famousfilipino Artists and Their MasterworksDocument3 pagesThe 10 Most Famousfilipino Artists and Their MasterworksGina MagtibayNo ratings yet

- English2 Q2 Summative Assessment 4 2Document4 pagesEnglish2 Q2 Summative Assessment 4 2ALNIE PANGANIBANNo ratings yet

- Bagpipe LV 1-5Document228 pagesBagpipe LV 1-5Sathia Kdms100% (2)

- CS402 Mcqs MidTerm by Vu Topper RMDocument50 pagesCS402 Mcqs MidTerm by Vu Topper RMM. KhizarNo ratings yet

- Automatic Train OperationDocument6 pagesAutomatic Train OperationAnupam KhandelwalNo ratings yet

- Pusheen With Donut: Light Grey, Dark Grey, Brown, RoséDocument13 pagesPusheen With Donut: Light Grey, Dark Grey, Brown, RosémafaldasNo ratings yet

- Pitot/Static Systems: Flight InstrumentsDocument11 pagesPitot/Static Systems: Flight InstrumentsRoel MendozaNo ratings yet

- Lima Indiana Oil FieldDocument32 pagesLima Indiana Oil FieldCHARLES PATULAYNo ratings yet

- 988611457NK448908 Vehicle Scan ReportDocument5 pages988611457NK448908 Vehicle Scan ReportVictor Daniel Piñeros ZubietaNo ratings yet

- BITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball TesterDocument10 pagesBITS Pilani: Determination of Extreme Pressure, Wear Preventive Characteristics of Lubricants Using Four Ball Testerakash chNo ratings yet

- CulvertsDocument18 pagesCulvertsAmmar A. Ali100% (1)

- Eco Exercise 3answer Ans 1Document8 pagesEco Exercise 3answer Ans 1Glory PrintingNo ratings yet

- 3 Curvilinear MotionDocument50 pages3 Curvilinear Motiongarhgelh100% (1)

- Presentation AcetanilideDocument22 pagesPresentation AcetanilideNovitasarii JufriNo ratings yet

- Welcome To Our 2Nd Topic: History of VolleyballDocument6 pagesWelcome To Our 2Nd Topic: History of VolleyballDharyn KhaiNo ratings yet

- Us Navy To Evaluate Anti Submarine Warfare Training SystemDocument2 pagesUs Navy To Evaluate Anti Submarine Warfare Training SystemVictor PileggiNo ratings yet