Professional Documents

Culture Documents

A 90-Nm CMOS Embedded Low Power SRAM Compiler

Uploaded by

Mary BakhoumOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A 90-Nm CMOS Embedded Low Power SRAM Compiler

Uploaded by

Mary BakhoumCopyright:

Available Formats

A 90-nm CMOS Embedded

Low Power SRAM Compiler

Zhao-Yong Zhang, Chia-Cheng Chen * , and Jian-Bin Zheng

Abstract - In this paper a highly flexible low power single

port Static Random Access Memory (SRAM) compiler design

is presented. The Divided Word Line (DWL) and Divided Bit

Line (DBL) scheme were implemented for reducing active

power. Particular emphasis was put to decrease standby

power consumption in word line driver. The forced-stack

devices as pulse generation element was introduced for

sensing enable. This guarantees SRAM can work in low

voltage without losing design margin. A test-chip with 17

embedded SRAMs has been fabricated in UMC 90-nm low

leakage CMOS logic process',

We use the self-timing and replica techniques in the SRAM

circuits design for different memory density, which will give

the SRAM compiler low power and high speed results with its

advantageous characters.

The organization of this paper is as follows. In Section II, a

brief overview of the architecture and the replica self-timing

technique are discussed. Section III discusses the design of

some SRAM circuits including word line driver, sensing

enable pulse generation. Section IV presents the experimental

results on the performance of the test-chip. Section V gives

conclusion of the paper.

II. ARCHITECTURE

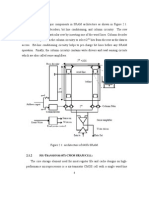

The SRAM is synchronous single port memory. Array core

uses a 6T high threshold voltage SRAM cell with 0.9991lm2

area, which owned by DMC for 90-nm low leakage CMOS

logic process. Different combinations of words, bits, and

aspect ratios BM (Block Multiplexing) can be used to

generate the most desirable configuration. Table I shows the

configuration information of the SRAM compiler.

TABLE I

SINGLE-PORT SRAM COMPILER CONFIGURATION

The SRAM can be organized as containing one to eight

banks (1 to 32 sub-arrays) in a memory by utilizing DWL and

DBL techniques. Each memory array can have maximum of

256 rows (word lines) and 256 columns (bit lines). Fig. 1

presents an architecture diagram by using DWL=2 and

DBL=2 as example. The control circuit and block selector are

used to select one of two blocks (BSI, BS2). Each block

memory array is divided into left and right to decrease access

time [9] as well as data line (SAODT) tiling wire. The DBL

scheme [5], [8] is embedded in the SRAM compiler, which

can divide the bit line into one to four partitions by following

the rule listed in table I. In Fig. 1 the X address highest bit is

used for generating bit line partition signals (BPI, BP2),

which makes bit line be divided into two partitions. So the

SRAM array finally is spit into eight sub-arrays by using

DWL and DBL techniques. The local bit line multiplexing

circuit (column Mux.) is used to connect local bit line to

global bit line, then to the input of sense amplifier.

Index Terms - Low power, SRAM compiler, divided word

line, divided bit line, forced-stack device, part power-gating,

replica technique, self-timing.

I. INTRODUCTION

With the scaling of CMOS transistor, a larger fraction of

chip area is devoted to the embedded SRAM modules.

Simultaneously, the need of lighter portable electronic

applications with extended battery life has made low power

memory circuit design become more and more necessary and

important. SRAM compiler product as a highly flexible

memory generation system can meet many increased demands

of SOC designer for compact, fully diffused embedded

memories [2], [6], [9].

There are numerous techniques to reduce the SRAM power

dissipation [1], [3]-[11]. The DWL [1] and DBL [5], [8]

techniques were employed by our SRAM compiler to reduce

the active power. In this paper a new word line driver circuit

with part power-gating scheme [10] is presented, which can

greatly decrease the standby current. Not only the PVT

(Process, Voltage, and Temperature) conditions will affect the

performance of SRAM generated by compiler, but also the

parameters of configuration or density will affect the final

performance. So a circuit designer of SRAM compiler must

build up a reasonable architecture to deal with those variations.

We use memory cells as replica circuits [4] to minimize the

effect of operating and configuration conditions' variability on

the speed and power.

A latch-type sense amplifier is used in our SRAM compiler,

which can give a good result in terms of speed and power

because it is able to amplify a very low bit line swing voltage.

Zhao- Yong Zhang is with the Memory Design Department, AiceStar

Technology Corporation, Suzhou, China (e-mail: brightzhang@aicestar.com).

Chia-Cheng Chen is with the Module Intellectual Property Development,

Faraday Technology Corporation, Hsin-chu City, Taiwan (e-mail:

ccchen@faraday-tech.com).

Jian-Bin Zheng is with the Memory Design Department, AiceStar

Technology Corporation, Suzhou, China (e-mail: rickzheng@aicestar.com).

978-1-4244-3870-9/09/$25.00 2009 IEEE

Parameter

Words

Bits

Bytes

Bit line partitions (DBL)

Aspect ratios (DWL)

Ranges

64b to 32Kb, increment=BMx 16

1b to 128b, increment=l

128b to 1b, decrement=l

1 when 16 ::;WL ::;256

2 when 256 < WL ::;512

3 when 512 < WL ::;768

4 when 768 < WL ::; 1024

Block Mux. (BM) 1, 2, 4, 8

625

The aspect ratio for each configuration can be controlled by

selecting one of four different block multiplexing (BM)

schemes (namely DWL): 1:1, 2:1, 4:1, and 8:1 ratios. The

local bit line multiplexing all are 4:1 in four BM options.

The dual-threshold voltage technique [11] is used to trade

off the high speed and low power operation in the SRAM

compiler. Memory cells use high threshold voltage and

peripheral circuits use regular threshold voltage.

RL Replica word line RL Replica word line Replica word line RL Replica word line RL Replica Global WLDRV

III. CIRCUIT DESIGN

The design of an SRAM consists of three major blocks, the

design of the memory cell, the decoder circuits and the sense

amplifiers. In the following sections, we will have a brief

overview of row decoders and sensing enable circuit. Because

the memory cell is owned by UMC, here we will ignore the

design.

A. Row Decoders

Row decoders are used to assert the word lines based on the

input addresses. The decoder structure mainly consists of an

initial pre-decoder circuit and a word line decoder circuit. Fig.

3 shows an 8 to 256 decoder structure designed for global

word line decoder.

PAO PA7 PC7 pco PB3 PBO

LV Column Muxs

(4:1)

Column Muxs

(4:1)

LV BP2- Global Column Decoder LV

Global WLDRV

Q ----------------

Global WLDRV =

---------------- 5

"C o"C

e ";

j

Column Muxs

(4:1)

ColumnMuxs

(4:1) LV

DGBL(DGBLB)

Block Select (BS)

GWL7

GWLO

,-- ----- --I

: :

: 3t08 :

i

I ,

AX2 AX! AXO

WLDRV8 I

I

___________________________

I

.. L __! :

I

I

I

!..- -- -- --

;-- ----- --I r- ----- --I

i 3 to 8 ;: 2 to 4 i

i predecoder i :predecode:

I I I I

L_T--r--J

AX7 AX6 AX5 AX4 AX3

Fig. 3. Block diagram of global word line decoder with part power-gating.

In the pre-decoder stage, the address inputs AXO - AX2

and internal clock (ICLK) are combined using a 3 to 8 CMOS

static pre-decoding circuit. The ICLK is a self-reset pulse

signal (refer to Fig. 2), which can make the asserted word line

also be a pulse. Other address inputs AX3 - AX? are used to

generate pre-decoding signals PB and PC. The two sets of pre-

decoder outputs are then combined to give the outputs which

drive the NAND gate (PBCO- PBC31) and part power-gating

PMOS (PBCOB- PBC31B). Before asserting a word line the

PB and PC must firstly be enabled for avoiding global word

line glitch. Although this will increase the setup time of

address, it can decrease access time.

Power-gating technique [10] can reduce leakage power by

shutting off the idle blocks. But power-gating technique also

exist some negative effects including a combination of noise,

performance penalty, area and power overhead, etc. In the

t 0

g 0'

Q Q Q

Q

i 5 .....

I 00

=

DSA

ICLK

GWLIDGWL

Sensing Enable (SAEN)

Fig. 1. Memory architecture block diagram (BM=2, bit line partition=2).

(RL=Replica Local Word line Driver, LD=Local Column MUX driver,

RCM=Replica Column MUX, DCM=Dummy Column MUX)

For ensuring fast and low-power operation, the internal

timing control path uses replica technique and self-timing

scheme to match the data path [4]. Fig. 2 presents the self-

timing read scheme (which uses the replica structure presented

in Fig. 1) waveform. The replica path uses replica word line

cells and bit line cells for tracking memory core cells. The

replica word line cells are the same as core word line cells; the

replica bit line cells are programmed to always store a zero.

Hence, its capacitance is the same as core cells including

gate/junction and wire parasitic capacitances. The replica

schemes can make the global bit line swing be around a tenth

of the supply when the replica bit line cells justly discharge

replica global bit line to around half of the supply during a

read cycle. The replica technique presented in Fig. 1 can vary

with the memory configuration variation.

CK

GBL(GBLB)

LWLIDLWL

Fig. 2. Self-timing read scheme waveform.

626

to local

WLDRV

I

I

0100_0 I

. :

II

I Block Driver i : 1

L.-. -. -. -. -. -. -' -.-.-.-. -. -. -. -. -. -. -. -' -. -. -'-'-'-' -. -. -. -. -. -. -. -' -I - -- - -- - - - - - - - - - - _..J

to local

WLDRV

: ! 11 !! !!!

: :: :: : : :1

! ! Ii !! :::1

! : Ii !!SAEN SA :: ! /

.. ": ---: 11' ! .. '! ---: I

: : I: :: :,

! ! I: !! :1

: :: :: :

:: :/

: : I: i i 11

: :: :: :::/

: : I: Block Driver : : :::I

'--- --'-- L_-----:.. 1_- ----...J - J l====- _

I:

II

i 1

Other Block Control Circuits i I

II

i:

II

i

BSI

BS2

DO

Fig. 4. Sensing enable pulse generating circuits and sense amplifier with data output block diagram (BM=2).

SAOUT

-+- Forced-stack

Long-channel-length

0.60 0.70 0.80 0.90 1.00 1.10 1.20 1.30 1.40 1.50

Voltage (V)

1.10

=

'6iJ

1.05

bll

=

's

1.00

z

<

00

"Cl

0.95

'";

E

.z 0.90

SAEN

Isensingenable(SAEN) timingmargin= Tm/Tp I

(a) Sensing enable (SAEN) timing margin definition.

Tm

(b) Normalized SAEN timing margin simulated in typical condition.

Fig. 6. Definition of SAEN timing margin and its normalization diagram.

Forced-stack effect [7] can be used at sensing enable

generation circuit to solve this problem (IVP and IVN in Fig.

4). Fig. 5 presents the simulation comparison results between

using forced-stack devices and using long channel length

devices to generate signal SAEN under the iso-area condition.

Iso-area is achieved by making the layout area after stack

forcing (IVP in Fig. 5) identical to long channel length (!NV

in Fig. 5). Under high voltage the two methods can get almost

same SAEN pulse width (the ratio is almost equal to 1), but

with the voltage decreasing forced-stack method can get wider

pulse width. This result in SAEN timing margin (defined in

Fig. 6(a)) gets enhanced in low voltage condition (shown in

Fig. 6 (b)).

IV. EXPERIMENTAL RESULTS

A test-chip has been fabricated using UMC's 90-nm low

leakage CMOS logic technology, with 17 memories and

embedded PLL etc. testing circuits which is designed for

SRAM's high speed and timing measurement. Fig. 7 shows

the layout of test-chip, which contains compiled SRAM's

1.25

1.00

_. ---..---

0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8

Voltage

3.75

3.50

3.25

o 3.00

2.75

2.50

"3

Q. 2.25

3 2.00

V'I 1.75

1.50

I- -40"( .. 25"( 125'( r

Fig. 5. Signal SAEN pulse width ratio (ratio = Tsaen_forced_stack /

Tsaen_long_channel_length) waveform. Ratio numbers are obtained

from simulation under iso-area condition.

SRAM compiler we only use the power-gating method for the

final inverter of the global word line driver and local word

line driver. The part power-gating technique doesn't require

long wakeup time and status retention circuits because a

PMOS (MPO) only connecting eight inverters (IVO - IV7),

which makes the parasitic capacitance of virtual power supply

very low. During standby mode only 1 of 32 WLDRV8s is

active; the others can decrease the standby current because

related PMOS devices are shut off. Hspice simulation results

shown that a shut-off WLDRV8 can decrease 80% standby-

current in high temperature condition with the expense of

about 5% area overhead and about 8% speed penalty.

B. Sensing Enable

The bit line decoupled latch type sense amplifier (SA) [9] is

used in the SRAM compiler. Fig. 4 shows the SA block

diagram and sensing enable pulse generating circuits, of

which output signal SAEN is used for switching all SAs

located at the same block. A latch circuit (keeper) is shared by

the SA located at Block 1 and Block 2. During the activation

of signal SAEN, SA will drive the sensing result to SAOUT

and make the new data latched by the keeper. With power

supply decreasing the drive ability of SA also will become

weak, but the parasitic capacitance of wire SAOUT is almost

invariable. This problem necessitates keeping enough design

margins in the design of the sensing enable.

627

Fig. 7. Test-chip layout.

ranging from 64b to 5l2kb in a variety of aspect ratios. The

features of test-chip can be found in table II.

32768X16 8192X8

Configuration BM

I

CM BM

I

CM

Area (mrrr') 0.852

I

0.686 0.146

I

0.108

Area Comparison +24.20% + 35.18%

Static Current (IlA) 9.661

I

8.277 1.320

I

1.187

DC Comparison + 16.72% + 11.20%

Dynamic Current (mA/MHz) 0.029

I

0.041 0.011

I

0.019

AC Comparison - 29.27% -42.11%

REFERENCES

[1] M. Yoshimoto, K. Anami, H. Shinohara, T. Yoshihara, H. Takagi, S.

Nagao, S. Kayano, and T. Nakano, "A divided word-line structure in the

static RAM and its application to a 64K full CMOS RAM," IEEE

Journal of Solid-State Circuits, vol. SC-18, no. 5, pp. 479-485, Oct.

1983.

[2] 1. C. Tou, P. Gee, 1. Duh, and R. Eesley, "A submicrometer CMOS

embedded SRAM compiler," IEEE Journal of Solid-State Circuits, vol.

27, no. 3,pp. 417-424, Mar. 1992.

[3] 1. S. Caravella, "A low voltage SRAM for embedded applications,"

IEEE Journal of Solid-State Circuits, vol. 32, no. 3, pp. 428-432, Mar.

1997.

[4] B. S. Amrutur and M. A. Horowitz, "A replica technique for wordline

and sense control in low-power SRAM's," IEEE Journal of Solid-State

Circuits, vol. 33, no. 8, pp. 1208-1219, Aug. 1998.

[5] A. Karandiskar and K. K. Parhi, "Low power SRAM design using

hierarchical divided bit-line approach," Proceeding International

Conference on Computer Design: VLSI in Computers and Processors,

pp. 82-88, Oct. 1998.

[6] M. Jagasivamani and D. S. Ha, "Development of a low-power SRAM

compiler," IEEE International Symposium on Circuits and Systems

(ISCASj, vol. 4, pp. 498-501, May 2001.

[7] S. Narendra, S. Borkar, V. De, D. Antoniadis, and A. Chandrakasan,

"Scalling of stack effect and its application for leakage reduction,"

Proceedings of the International Symposium on Low Power Electronics

and Design, pp. 195-200, Aug. 2001.

[8] B. Yang and L. Kim, "A low-power SRAM using hierarchical bit line

and local sense amplifiers," IEEE Journal ofSolid-State Circuits, vol. 40,

no. 6,pp. 1366-1376, Jun. 2005.

[9] S. Singh, S. Azmi, N. Agrawal, P. Phani, and A. Rout, "Architecture and

design of a high performance SRAM for SOC design," Design

Automation Conference, pp. 447-451,2002.

[10] H. Jiang, M. M. Sadowska, and S. R. Nassif, "Benefits and costs of

power-gating technique," Proceedings of the 2005 International

Conference on Computer Design, pp. 559-566, 2005

[11] 1. T. Kao and A. P. Chandrakasan, "Dual-threshold voltage techniques

for low-power digital circuits," IEEE Journal ofSolid-State Circuits, vol.

35, no. 7, pp. 1009-1018, July 2000.

v. CONCLUSION

A highly configurable embedded low power SRAM

compiler based on an industrial 90-nm CMOS process has

been demonstrated. The SRAMs compiled can greatly reduce

dynamic current by combining DWL and DBL techniques

with the help of replica and self-timing scheme. Enough

margin simulation and verification with the help of robust

circuits further guarantee the SRAMs compiled with wider

margin for correct functionality and accurate characterization.

The measurement results of test-chip have proved the design

correctness and low power efficiency.

ACKNOWLEDGMENT

It is our pleasure to thank Teddy and James for help with

the test-chip design, W. T. and Jason for testing of the chips,

Willis, Jack, Alex and Ya-Qi for helpful discussion on the

circuits design.

UMC

90-nmlP9M low leakage CMOS

90-nm IP5M

1.2V

4000Jlmx 4000Jlm

QFP 208

TABLE II

FEATURES OF TEST-CHIP

Foundry

Process

SRAM macros

Supply voltage

Die size

Package

Table III gives the power measurement results at the

operating voltage of 1.2 Y for two SRAM macros (in the table

column BM) in the test-chip. The data of CM (Column Mux.)

macros (with bit line partition architecture) come from

Faraday commercial SRAM compiler datasheets. The results

show that this design can reduce dynamic current by 29% for

the 5l2Kb SRAM and by 42% for the 64Kb SRAM. The

static current actually has a little increasing in this work due to

additional circuits overhead for the DWL implementation.

However, the total average current dissipation is still reduced

as it is dominated by dynamic current dissipation.

TABLE III

COMPARISON WITH OTHER WORKS

PLL

Silicon measurement confirmed complete functionality over

voltage (0.9 - 1.8Y) and temperature (-40 - 125C) ranges

with all memories. The SCAN, March C- and March C+

patterns were utilized by memory BIST (Built-in Self-Test)

embedded in the test-chip. An embedded PLL was used for

SRAM timing measurements and high speed memory BIST

(maximum frequency can reach 500MHz) testing.

628

You might also like

- Worksheet 5 Sound WavesDocument1 pageWorksheet 5 Sound WavesMary Bakhoum0% (1)

- EECS 141 SRAM Design Project Phase IDocument9 pagesEECS 141 SRAM Design Project Phase IChristopher Patterson100% (1)

- Practical Reverse Engineering: x86, x64, ARM, Windows Kernel, Reversing Tools, and ObfuscationFrom EverandPractical Reverse Engineering: x86, x64, ARM, Windows Kernel, Reversing Tools, and ObfuscationNo ratings yet

- Worksheet 3 WavesDocument2 pagesWorksheet 3 WavesMary Bakhoum0% (1)

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960From EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960No ratings yet

- 8k Bit Using 6t SramDocument8 pages8k Bit Using 6t SramSwati Navdeep AggarwalNo ratings yet

- BIST Algorithm For Embedded-DRAM CoresDocument4 pagesBIST Algorithm For Embedded-DRAM CoresespskcNo ratings yet

- Design and VLSI Implementation of 8 MB Low Power SRAM in 90nmDocument10 pagesDesign and VLSI Implementation of 8 MB Low Power SRAM in 90nmcnnprem_eeeNo ratings yet

- Low Power Sram Design Using Block PartitioningDocument4 pagesLow Power Sram Design Using Block PartitioningesatjournalsNo ratings yet

- ASIC-System On Chip-VLSI Design - SRAM Cell Design PDFDocument8 pagesASIC-System On Chip-VLSI Design - SRAM Cell Design PDFGowtham SpNo ratings yet

- Design AnalysisDocument4 pagesDesign AnalysispradeepkarraNo ratings yet

- Sram 6TDocument5 pagesSram 6Taashish kumarNo ratings yet

- The International Journal of Engineering and Science (The IJES)Document7 pagesThe International Journal of Engineering and Science (The IJES)theijesNo ratings yet

- 8x4 SRAM in TSMC 0.25 M Technology: NtroductionDocument6 pages8x4 SRAM in TSMC 0.25 M Technology: NtroductionAdib NahiyanNo ratings yet

- ,hrfikadsz NJSDFMV M VZDocument5 pages,hrfikadsz NJSDFMV M VZpalakNo ratings yet

- Cache Perform AnseDocument6 pagesCache Perform AnseDado Fabrička GreškaNo ratings yet

- A 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsDocument4 pagesA 64 KB Approximate SRAM Architecture For Low Power Video ApplicationsRamanathanNo ratings yet

- (New Paper On Sram) v39-15Document5 pages(New Paper On Sram) v39-15Pratap SaurabhNo ratings yet

- Design and Analysis of 4Kb Sram Array Cell For The Development of Sram ChipDocument8 pagesDesign and Analysis of 4Kb Sram Array Cell For The Development of Sram ChipRohit KumarNo ratings yet

- AbstractDocument5 pagesAbstractKurushNishanthNo ratings yet

- Column Decoder Using PTL For Memory: M.Manimaraboopathy, S.Sivasaravanababu, S.Sebastinsuresh A. RajivDocument8 pagesColumn Decoder Using PTL For Memory: M.Manimaraboopathy, S.Sivasaravanababu, S.Sebastinsuresh A. RajivInternational Organization of Scientific Research (IOSR)No ratings yet

- Sram Low Power DecoderDocument7 pagesSram Low Power DecoderKedhar MallaNo ratings yet

- Abstract-A 1.2-V 72-Mb Double Data Rate 3 (DDR3) SRAMDocument9 pagesAbstract-A 1.2-V 72-Mb Double Data Rate 3 (DDR3) SRAMMahesh SoniNo ratings yet

- PXC 3873796Document6 pagesPXC 3873796Sai PraveenNo ratings yet

- Analysis of Low Power 6T SRAM Using 45 NM Technology: Shatrughan SinghDocument5 pagesAnalysis of Low Power 6T SRAM Using 45 NM Technology: Shatrughan SinghShruti DasNo ratings yet

- High Speed Content Addressable Memory: AbstractDocument4 pagesHigh Speed Content Addressable Memory: AbstractjayachandarNo ratings yet

- Design Simulation and Analysis of 5T-Sram Cell Using Different FoundriesDocument6 pagesDesign Simulation and Analysis of 5T-Sram Cell Using Different FoundriesPreeti SinghNo ratings yet

- SRAM Access Delay and SRAM SizeDocument11 pagesSRAM Access Delay and SRAM SizenobinmathewNo ratings yet

- 3.1 Static Random Access Memory (SRAM)Document6 pages3.1 Static Random Access Memory (SRAM)VigneshInfotechNo ratings yet

- Welcome To International Journal of Engineering Research and Development (IJERD)Document6 pagesWelcome To International Journal of Engineering Research and Development (IJERD)IJERDNo ratings yet

- Chapter 5-The Memory SystemDocument84 pagesChapter 5-The Memory SystemupparasureshNo ratings yet

- SRAM Circuit Design and Operation: Prepared By: Mr. B. H. NagparaDocument49 pagesSRAM Circuit Design and Operation: Prepared By: Mr. B. H. NagparaBharatNo ratings yet

- Module-5-Final GMITDocument20 pagesModule-5-Final GMITmvs sowmyaNo ratings yet

- Sense AmplifiersDocument6 pagesSense AmplifierskeerthiNo ratings yet

- Nguyen Masters Report15Document1 pageNguyen Masters Report15PhiPhiNo ratings yet

- A Novel Column-Decoupled 8T Cell For Low-PowerDocument14 pagesA Novel Column-Decoupled 8T Cell For Low-PowerSaikiran RaghuNo ratings yet

- Modified 1 Bit Sram Architecture Design &Document13 pagesModified 1 Bit Sram Architecture Design &B.n. Srinivasa RaoNo ratings yet

- Manage Enhancing Energy G.sakanaDocument10 pagesManage Enhancing Energy G.sakanaBESTJournalsNo ratings yet

- b322005-065(2021)Document9 pagesb322005-065(2021)Chandra Shekar MedarNo ratings yet

- Rom/Prom/Eprom: Jen-Sheng HwangDocument9 pagesRom/Prom/Eprom: Jen-Sheng Hwangkumkum_parishitNo ratings yet

- Pardazeshgar Digital Project English TextDocument10 pagesPardazeshgar Digital Project English Textkazem.khaari77No ratings yet

- QB UT3portionsDocument2 pagesQB UT3portionspreethikabhaskarNo ratings yet

- A 10T Non-Precharge Two-Port SRAM For 74% Power Reduction in Video ProcessingDocument6 pagesA 10T Non-Precharge Two-Port SRAM For 74% Power Reduction in Video ProcessingSreyas MohanNo ratings yet

- Bicta2012 Submission 94Document23 pagesBicta2012 Submission 94Gurinder Pal SinghNo ratings yet

- A Novel Design For Low-Power, High Performance and Space Efficient AddressDocument10 pagesA Novel Design For Low-Power, High Performance and Space Efficient AddressIJRASETPublicationsNo ratings yet

- Designand Analysisof Low Power MTCMOSDocument10 pagesDesignand Analysisof Low Power MTCMOSseshu bradyNo ratings yet

- Efficient STT-RAM Last-Level-Cache Architecture To Replace DRAM CacheDocument10 pagesEfficient STT-RAM Last-Level-Cache Architecture To Replace DRAM CacheKARAN KARHALENo ratings yet

- A 32 KB 10T Sub-Threshold Sram Array With Bit-Interleaving and DiDocument10 pagesA 32 KB 10T Sub-Threshold Sram Array With Bit-Interleaving and DiSreyas MohanNo ratings yet

- 06-Designing The Memory SystemDocument13 pages06-Designing The Memory SystemKhoa Pham0% (1)

- A Design For High-Speed Low-Power CMOS Fully Parallel Content-Addressable Memory MacrosDocument13 pagesA Design For High-Speed Low-Power CMOS Fully Parallel Content-Addressable Memory MacrosHao WuNo ratings yet

- Ahb To Memory InterfaceDocument5 pagesAhb To Memory InterfaceSuhas ShirolNo ratings yet

- Redundancy, RepairDocument8 pagesRedundancy, RepairSabarish IttamveetilNo ratings yet

- I Nternational Journal of Computational Engineering Research (Ijceronline - Com) Vol. 2 Issue. 7Document4 pagesI Nternational Journal of Computational Engineering Research (Ijceronline - Com) Vol. 2 Issue. 7International Journal of computational Engineering research (IJCER)No ratings yet

- Sharifkhani 2007Document10 pagesSharifkhani 2007chirag gargNo ratings yet

- Low Power Approaches in SRAM: Vikas Nehra and Rajeev KamalDocument5 pagesLow Power Approaches in SRAM: Vikas Nehra and Rajeev KamalRakeshconclaveNo ratings yet

- Anjali Kumari ReportDocument8 pagesAnjali Kumari ReportGirdhar Gopal GautamNo ratings yet

- Complied Memory Patent IntroDocument9 pagesComplied Memory Patent IntroddamitNo ratings yet

- V K Mehta, Rohit Mehta - Principles of Power System (0, Schand Publisching)Document40 pagesV K Mehta, Rohit Mehta - Principles of Power System (0, Schand Publisching)Jaswanth KadaNo ratings yet

- Ultra-Low Leakage Static Random Access Memory DesignDocument10 pagesUltra-Low Leakage Static Random Access Memory DesignIJRES teamNo ratings yet

- Lattice An ADC DAC-less ReRAM-based Processing-In-Memory Architecture For Accelerating Deep Convolution Neural NetworksDocument6 pagesLattice An ADC DAC-less ReRAM-based Processing-In-Memory Architecture For Accelerating Deep Convolution Neural NetworksYu QianNo ratings yet

- FPGA Based On Integration of Memristors and CMOS DevicesDocument4 pagesFPGA Based On Integration of Memristors and CMOS DevicesbismuthsunilNo ratings yet

- Gain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipFrom EverandGain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipNo ratings yet

- Worksheet 1Document1 pageWorksheet 1Mary BakhoumNo ratings yet

- Worksheet 7 Light WavesDocument1 pageWorksheet 7 Light WavesMary BakhoumNo ratings yet

- Worksheet 4 Waves Boundary BehaviorDocument2 pagesWorksheet 4 Waves Boundary BehaviorMary BakhoumNo ratings yet

- Worksheet 2 - WavesDocument1 pageWorksheet 2 - WavesMary BakhoumNo ratings yet

- 3 Newton's Laws of Motion PDFDocument8 pages3 Newton's Laws of Motion PDFMary BakhoumNo ratings yet

- 2 Work PDFDocument6 pages2 Work PDFMary BakhoumNo ratings yet

- 1 ForcesDocument16 pages1 ForcesMary BakhoumNo ratings yet

- Context-Aware Driving Assistance PDFDocument11 pagesContext-Aware Driving Assistance PDFMary BakhoumNo ratings yet

- 2 Newton's Laws of Motion PDFDocument8 pages2 Newton's Laws of Motion PDFMary BakhoumNo ratings yet

- Rich Monitoring of Road and Traffic Conditions Using Mobile SmartphonesDocument14 pagesRich Monitoring of Road and Traffic Conditions Using Mobile SmartphonesMary BakhoumNo ratings yet

- Recent Trends in Driver Safety Monitoring Systems PDFDocument15 pagesRecent Trends in Driver Safety Monitoring Systems PDFMary BakhoumNo ratings yet

- Intelligent Traffic Monitoring System PDFDocument11 pagesIntelligent Traffic Monitoring System PDFMary BakhoumNo ratings yet

- Monitoring The Tire Pressure at Cars Using Passive SAW Sensors PDFDocument4 pagesMonitoring The Tire Pressure at Cars Using Passive SAW Sensors PDFMary BakhoumNo ratings yet

- Assignment 6 - Strategic Planning DEFINITIONSDocument1 pageAssignment 6 - Strategic Planning DEFINITIONSMary BakhoumNo ratings yet

- Assignment 6 - Strategic PlanningDocument3 pagesAssignment 6 - Strategic PlanningMary BakhoumNo ratings yet

- 8x8 SRAM: Wing Chan Mahavir Sheth Junghoon Kang Shalin ShahDocument21 pages8x8 SRAM: Wing Chan Mahavir Sheth Junghoon Kang Shalin ShahMary BakhoumNo ratings yet

- Satellite Communications: Noise Jamming & Frequency Hopping Anti JammingDocument10 pagesSatellite Communications: Noise Jamming & Frequency Hopping Anti JammingMary BakhoumNo ratings yet

- A 2.2GHz 32×4 Bit 6T-SRAM Design in 45nm CMOS (Report)Document3 pagesA 2.2GHz 32×4 Bit 6T-SRAM Design in 45nm CMOS (Report)Mary BakhoumNo ratings yet

- A 90-Nm CMOS Embedded Low Power SRAM CompilerDocument4 pagesA 90-Nm CMOS Embedded Low Power SRAM CompilerMary BakhoumNo ratings yet

- 65nm Low-Power High-Density SRAM Operable atDocument3 pages65nm Low-Power High-Density SRAM Operable atMary BakhoumNo ratings yet

- CamDocument29 pagesCamMary BakhoumNo ratings yet

- 8x8 SRAM: Wing Chan Mahavir Sheth Junghoon Kang Shalin ShahDocument21 pages8x8 SRAM: Wing Chan Mahavir Sheth Junghoon Kang Shalin ShahMary BakhoumNo ratings yet