Professional Documents

Culture Documents

Fatigue Failure Resulting From Variable Loading

Uploaded by

Timothy MartinezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fatigue Failure Resulting From Variable Loading

Uploaded by

Timothy MartinezCopyright:

Available Formats

BITSPilani

Pilani Campus

VINAYAK KALLURI

BITSPilani

Pilani Campus

Fat i gue Fai l ur e Res ul t i ng

f r om Var i a bl e Loadi ng

BITS Pilani, Pilani Campus

Variable Loading

Variable loading results when the applied load or

the induced stress on a component is not constant

but changes with time

In reality most mechanical components experience

variable loading due to

-Change in the magnitude of applied load

Example: Extrusion process

-Change in direction of load application

Example: a connecting rod

-Change in point of load application

Example: a rotating shaft

BITS Pilani, Pilani Campus

Fatigue

Fatigue is a phenomenon associated with variable

loading or more precisely to cyclic stressing or

straining of a material

ASTMDefinition of fatigue

The process of progressive localized permanent

structural changes occurring in a material subjected

to conditions that produce fluctuating stresses at

some point or points and that may result in cracks or

complete fracture after a sufficient number of

fluctuations.

BITS Pilani, Pilani Campus

Fracture Failure- Mechanism

Three stages are involved in fatigue failure

-Crack initiation

-Crack propagation

-Fracture / Rupture

BITS Pilani, Pilani Campus

Fracture Failure- Mechanism

Crack propagation modes.

BITS Pilani, Pilani Campus

fatigue failure of the crankshaft under pure bending load.

Fatigue failure

BITS Pilani, Pilani Campus

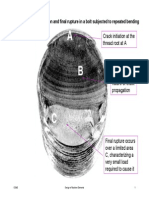

Crack initiation, propagation and rupture in a shaft subjected to repeated bending

Introduction to Fatigue in Metals

Crack initiation at

the outer surface

Beach marks

showing the nature

of crack propagation

Final rupture occurs

over a limited area,

characterizing a very

small load required

to cause it

BITS Pilani, Pilani Campus

Crack initiation at the root of

keyway at B

Final failure over the small

area at C due to sudden

rupture

Crack propagation occurs

over a time period

Introduction to Fatigue in Metals

BITS Pilani, Pilani Campus

Connecting rod failed by fatigue failure

The crack got initiated at the flash line of forging.

Flash line of

forging

Introduction to Fatigue in Metals

BITS Pilani, Pilani Campus

Fatigue failure of a steam engine connecting rod due to PURE TENSION load.

No surface crack.

Crack may initiate

anywhere that is the

weakest or unknown

source of weakness.

In this rod, the crack

initiated due to forging

flake slightly below the

centre line.

The crack propagated radially outward

until some time after which the sudden

rupture occurred.

Radial direction of

crack propagation

Introduction to Fatigue in Metals

BITS Pilani, Pilani Campus

Approach to Fatigue Failure in Analysis and Design

Fatigue life methods

Fatigue strength and endurance limit

Endurance limit modifying factors

Stress concentration and notch sensitivity

Fluctuating stresses

Combination of loading modes

Variable, fluctuating stresses, cumulative fatigue

damage

BITS Pilani, Pilani Campus

Fatigue Life Methods

predict the failure in number of cycles N to failure for a specific type of loading

3 3

10 : (HCF) fatigue cycle High ; 10 1 : (LCF) fatigue cycle Low > N N

Stress life methods

Based on stress levels only

Least accurate of the three, particularly for LCF

It is the most traditional because easiest to implement for a wide range of applications

Has ample supporting data

Represents high cycle fatigue adequately

Strain life methods

Involves more detailed analysis of plastic deformation at localized regions

Good for LCF

Some uncertainties may exist in results because several idealizations get compounded

Hence normally not used in regular practice but only for completeness and special occasions

Linear elastic fracture mechanics methods (LEFM)

Assumes that crack is already present and detected

The crack location is then employed to predict crack growth and sudden rupture with respect to

the stress nature and intensity

Most practical when applied to large structures in conjunction with computer codes and periodic

inspection

BITS Pilani, Pilani Campus

Stress Life Method

R. R. Moore high-speed rotating

beam machine.

BITS Pilani, Pilani Campus

Fatigue tester

Courtesy: Revolution Industries

BITS Pilani, Pilani Campus

pure reversed bending without transverse shear

SFD

BMD

M

b

Stress Life Method

BITS Pilani, Pilani Campus

Stress Life Method

Pure bending by means of weights and no transverse shear.

The specimen shown is very carefully machined and polished with

a final polishing in the axial direction to void circumferential

scratches.

Number of revolutions of the specimen required for failure are

recorded.

The first test is made at a stress that is some what under the

ultimate strength of the material.

Next, the test is repeated for a lower load, and so on.

The results are plotted in the S-N diagram, which is either semi-log

or log-log.

BITS Pilani, Pilani Campus

The S-N Diagram for steel (UNS G41300), normalized, S

ut

=812 MPa.

Endurance Limit,

It is the stress at which the

component can sustain

infinite number of cycles

Stress Life Method: S-N Diagram

BITS Pilani, Pilani Campus

The plot in the S-N diagram never becomes horizontal

for non-ferrous metals and alloys

For non-ferrous metals and alloys, stress at a specific

number of cycles, normally at 5*10

8

cycles, must be

used as fatigue strength

Endurance limit for non-ferrous metals and alloys

BITS Pilani, Pilani Campus

For different aluminium alloys (which is non-ferrous)

For non-ferrous metals and alloys, the S-N diagram never becomes horizontal and

hence they do not have endurance limit. Therefore, a stress at a specific number

of cycles, normally at 5*10

8

cycles, must be used as fatigue strength

Stress Life Method: S-N Diagram

BITS Pilani, Pilani Campus

Instead of referring to experimental data-bank each time,

it should be possible to quickly estimate the value of

endurance limit using some kind of formula

To enable that, data has been generated for different

types of steels, for endurance limit with respect to the

ultimate tensile strength

This plot seemed to closely follow a combination of two

straight lines, of which the second being almost

horizontal at S

ut

=1460 MPa

Estimation of Endurance Limit

BITS Pilani, Pilani Campus

Estimation of Endurance Limit

For steels, Endurance limit :

conditions loading actual in the limit Endurance

bending reverse in obtained limit Endurance

1460 700

1460 5 0

'

'

=

=

>

=

e

e

ut

ut ut

e

S

S

MPa S for MPa

MPa S for S .

S

BITS Pilani, Pilani Campus

Endurance limit (Se) is only for rotational bending of

round bar at idealistic conditions (prepared very

carefully and tested under closely controlled conditions).

Endurance strength (S

e

) is for all other types of loading,

geometry and operating conditions.

Endurance limit Vs. Endurance strength

Endurance limit Endurance strength

BITS Pilani, Pilani Campus

Endurance limit modifying factors

'

e e d c b a e

S k k k k k S =

strength endurance i.e. use of condition and geometry

the in part machine a of location critical at the limit endurance S

limit endurance specimen test beam - otary S

factor on modificati m

factor r

factor on modificati

factor on modificati load

factor on modificati size

factor on modificati condition surface

e

'

e

=

=

=

=

=

=

=

=

r

effects us iscellaneo k

eliability k

e temperatur k

k

k

k

f

e

d

c

b

a

BITS Pilani, Pilani Campus

b

ut a

aS k =

Table 6.2; page:288

Surface condition modification factor (k

a

)

The surface modification factor depends on the quality of the finish of

the actual part surface and on the tensile strength of the part material.

BITS Pilani, Pilani Campus

Size modification factor, k

b

( )

1. effect, size no loading axial For

254 51 000837 . 0 859 . 0

51 79 . 2 24 . 1 62 . 7 /

: only torsion and bending in bars CS circular rotating For

107 . 0

107 . 0

=

=

=

b

b

k

mm d if d

mm d if d d

k

etc. section cross channel section, - I r, rectangula circular,

but rotating - non are that bars about What

BITS Pilani, Pilani Campus

( ) | |

d d

d A

d d d A

Case

e

e e e

37 . 0 (2) and (1) Equation

), 2 ( 01046 . 0

i.e 0.95d of spacing a having chords parallel two of

outside area the twice is area stress percent 95 the

rounds, solid g nonrotatin For

), 1 ( 0766 . 0 95 . 0

4

circular rotating for : 1

2

95 . 0

2

2

2

95 . 0

=

=

= =

K

K

K

b

for non-rotating shapes

Effective dimension is used

Effective dimension d

e

obtained by equating the volume of

material stressed at and above 95 percent of the maximum stress

to the same volume in the rotating-beam specimen

Table 6-3; page:290

BITS Pilani, Pilani Campus

Load modification factor, k

c

=

torsion

axial

bending

k

c

, 59 . 0

, 85 . 0

, 1

Actually the k

c

is dependent on

the S

ut

of the material. Tables 6-

11 to 6-14 (page no. 333) in

Text Book give the details. The

above values are average

values.

BITS Pilani, Pilani Campus

Temperature modifying factor, k

d

When operating temperatures are below room

temperature, brittle fracture is a strong possibility and

should be investigated first.

When the operating temperatures are higher than room

temperature, yielding should be investigated first because

the yield strength drops off so rapidly with temperature.

Any stress will induce creep in a material operating at

high temperatures

BITS Pilani, Pilani Campus

Temperature modifying factor, k

d

( ) ( ) ( ) ( )

F T

where

T T T T k

o

F

F F F F d

1000 70

10 595 . 0 10 104 . 0 10 115 . 0 10 432 . 0 975 . 0

4 12 3 8 2 5 3

+ + =

145 tests of 21 different carbon and alloy steels results a

fourth-order polynomial curve fit to the data underlying

BITS Pilani, Pilani Campus

Temperature modifying factor, k

d

( ) ( ) ( ) ( )

F T

where

T T T T k

o

F

F F F F d

1000 70

10 595 . 0 10 104 . 0 10 115 . 0 10 432 . 0 975 . 0

4 12 3 8 2 5 3

+ + =

Effect of Operating Temperature on the Tensile Strength of Steel.

(S

T

= tensile strength at operating temperature; S

RT

= tensile strength at room temperature)

Table 6.4; page :291

RT

T

d

S

S

k =

BITS Pilani, Pilani Campus

a e

z k 08 . 0 1 =

Reliability factor, k

e

Table 65

BITS Pilani, Pilani Campus

Accounts for

Residual stress due to shot-peening, hammering

etc.

Corrosion

Coating failure

Spraying etc.

Miscellaneous effects factor, k

f

BITS Pilani, Pilani Campus

Estimate the endurance strength of the given material for the following two cases

1. A32 mm diameter shaft made of hot rolled AISI 1040 steel. The shaft surfaces are grinded. The shaft is

subjected to reverse torque and to be used for a part that sees 250C in service at 99.99%reliability.

2. A solid 20 mm side-square rod is cantilevered at one end. The rod supports a completely reverse axial load at

the other end. The material is AISI 1015 cold-drawn steel. The expected reliability of the rod is 90%.

Problem

BITS Pilani, Pilani Campus

Two steels are being considered for manufacture of forged

connecting rods. One is AISI 4340 Cr-Mo-Ni steel capable of

being heat-treated to a tensile strength of 1820 MPa. The other

is a plain carbon steel AISI 1040 with an attainable S

ut

of 790

MPa. If each rod is to have a size giving an equivalent diameter

of 20 mm, is there any advantage to using the alloy steel for this

fatigue application?

Problem

For 4340 Cr-Mo-Ni steel, S

ut

= 1820 MPa

For 1040 HR steel, S

ut

= 790 MPa

899 . 0 ) 20 ( 24 . 1 24 . 1

107 . 0 107 . 0

= = =

d k

b

155 . 0 ) 1820 ( 272

995 . 0

= = =

b

ut a

S a k

385 . 0 ) 730 ( 272

995 . 0

= = =

b

ut a

S a k

. 1 ; 1 ; 1 ; 899 . 0 = = = =

e d c b

k k k k

. 1 ; 1 ; 1 = = =

e d c

k k k

MPa S

e

54 . 97 ) 700 ( ) 1 ( ) 1 ( ) 1 ( ) 899 . 0 ( ) 155 . 0 ( = =

MPa S

e

75 . 136 ) 395 ( ) 1 ( ) 1 ( ) 1 ( ) 899 . 0 ( ) 385 . 0 ( = =

BITS Pilani, Pilani Campus

The single most influential factor leading to high

possibility of crack initiation

Stress concentration can be due to

Function of geometry (sudden change in

size/diameter; holes in the structure etc.

and surface texture (surface finish, presence of

disintegrations etc.)

Stress concentration

BITS Pilani, Pilani Campus

K

t

=Theoretical stress concentration factor

Stress concentration (K

t

)-revised

stress Nominal

stress Maximum

=

t

K

( )

FEM as such simulation numerical

or s experiment through Determined

stress Nominal

max

=

=

=

t

nom t

K

K

t d w

P

d w

BITS Pilani, Pilani Campus

K

f

is a reduced value of K

t

and it is also called as fatigue

strength reduction factor

Actual / Fatigue stress concentration factor, K

f

factor) (geometric factor ion concentrat stress l Theoretica

21) - 6 & 20 - 6 Fig. (from y value sensitivit notch

=

=

t

K

q

( ) ( ) 1 1 1 1 + = + =

ts shear fs t f

K q K or K q K

specimen free - notch in stress

specimen notched in stress maximum

=

f

K

Stress-concentration factors for a variety of geometries under different

loading conditions can be found in Table A15 (page:1026-1032)

BITS Pilani, Pilani Campus

Notch Sensitivity plot for Steels and UNS A92024-T wrought Al alloys

Fig: 6-20 ; page : 295

(Reverse bending or reverse axial loads)

BITS Pilani, Pilani Campus

Fig: 6-21 ; page : 296

Notch Sensitivity plot for Steels and UNS A92024-T wrought Al alloys

(Reversed torsion condition)

BITS Pilani, Pilani Campus

Estimation of K

f

K

f

= 1+q(K

t

-1).

When q=0, the material has no sensitivity to notches, and hence K

f

=1.

When q=1, or when notch radius is large for which q is almost equal

to 1, the material has full notch sensitivity, and K

f

= K

t

.

For all grades of cast iron, use q=0.20.

Use the different graphs as given to obtain q for bending/axial and

torsional loading.

Whenever the graphs do not give values of q for certain combinations

of data, use either Neuber equation or Heywood equation.

BITS Pilani, Pilani Campus

Use the Neuber equation when the notch is circular/cylindrical.

Estimation of K

f

( )

radius notch

strength. ultimate of function i.e ), (

constant material a is and constant Neuber is a where

1 1

1

1

=

=

+ =

+

=

r

S f a

K q K and

r

a

q

ut

t f

For steel, with S

ut

in kpsi, the Neuber constant can be approximated

by a third-order polynomial fit of data as

3 8 2 5 3

3 8 2 5 3

) 10 ( 67 . 2 ) 10 ( 35 . 1 ) 10 ( 51 . 2 19 . 0 :

) 10 ( 67 . 2 ) 10 ( 51 . 1 ) 10 ( 08 . 3 246 . 0 :

ut ut ut

ut ut ut

S S S a Torsion

S S S a axial or Bending

+ =

+ =

BITS Pilani, Pilani Campus

Use Heywood equation when the notch is NOT circular/cylindrical

but is a tranverse hole or shoulder or groove.

Estimation of K

f

( )

335 page 15; - 6 Table the in given are values

1 2

1

a

where

r

a

K

K

K

K

t

t

t

f

+

=

r= hole/ shoulder/groove size

BITS Pilani, Pilani Campus

Fluctuating Stress

2

stress e or variabl amplitude

2

stress mean or midrange

stress of range

stress maximum

stress minimum

min max

min max

min max

max

min

= =

+

= =

= =

=

=

a

m

r

BITS Pilani, Pilani Campus

Reversed: mean stress is zero;

equal reversals on both sides;

useful in conducting experiments

Repeated: minimum stress is zero;

mean stress equal to half of the

range stress

Fluctuating: maximum, minimum

and mean stress are all non-zero

and arbitrary

Three specific types of cyclic loading:

BITS Pilani, Pilani Campus

Design for Infinite life under cyclic loading

f yt

m

e

a

n S S

1

= +

1 = +

yt

m

e

a

S

S

S

S

1 = +

ut

m

e

a

S

S

S

S

1

2

=

|

|

\

|

+

ut

m

e

a

S

S

S

1

2

2

=

|

|

\

|

+

|

|

\

|

yt

m

e

a

S

S

S

S

BITS Pilani, Pilani Campus

Different fatigue failure models

yielding) static for

checking for (only line Langer

1

line Elliptic ASME

1

line Gerber

1

line Goodman Modified

1

line Soderberg

1

2 2

2

2

K

K

K

K

K

y yt

m

yt

a

f yt

m

e

a

f ut

m

f

e

a

f ut

m

e

a

f yt

m

e

a

n S S

n S S

n S

n

S

n S S

n S S

= +

|

|

\

|

=

|

|

\

|

+

|

|

\

|

=

|

|

\

|

+

= +

= +

Where

ao f a mo f m

K and K = =

BITS Pilani, Pilani Campus

Modified Goodman and

Langer Failure Criteria

Amplitude and Steady Coordinates of Strength and Important

Intersections in First Quadrant

BITS Pilani, Pilani Campus

Gerber and Langer

Failure Criteria

Amplitude and Steady Coordinates of Strength and Important

Intersections in First Quadrant

BITS Pilani, Pilani Campus

ASME-Elliptic and Langer

Failure Criteria

Amplitude and Steady Coordinates of Strength and Important

Intersections in First Quadrant

BITS Pilani, Pilani Campus

Results based on Smiths tests (72 tests on torsion

strength) and confirmation by Joerres of Associated

Spring-Barnes Group, the following relation is

used to identify the shear ultimate strength from

tensile strength.

From distortion energy theory,

ut su

S 0.67 S =

yt sy

S 0.577 S =

Torsional Fatigue Strength

BITS Pilani, Pilani Campus

An AISI 1020 cold drawn steel shaft of diameter 30

mm is welded to a fixed support at one end and

another end is subjected to a bending moment

varying from 25 Nm to 100 Nm. Fatigue stress

concentration factor under bending (K

f

) is 1.6. Find

the factor of safety using the Gerber failure criteria.

Problem:

BITS Pilani, Pilani Campus

( )

( )

( )

( )

.

38 . 6

1

470

73 . 37

196.8

64 . 22

1

S S

equation; failure fatigue Gerber

MPa 196.8 = S k k k = S

1 = k

0.958 30) 1.24(0.37 = ) 1.24(d = k

drawn) cold for -0.265 = b and 4.51 = (a 0.874 = aS = k

MPa 235 = 0.5S = S

64 . 22 15 . 14 6 . 1

73 . 37 58 . 23 6 . 1

15 . 14

58 . 23

43 . 9

30

10 25 32 32

72 . 37

30

10 100 32 32

390 470 S ; Steel CD 1020 AISI For

2

2

ut

m

e

a

1

e c b a e

c

0.107 - 0.107 -

e b

b

ut a

ut

1

e

3

3

3

min

3

3

3

max

ut

safety factor high with designed over is member The

n

n

n

n

n

MPa K

MPa K

MPa stress bending Variable

MPa stress bending Mean

MPa

d

M

stress bending Minimum

MPa

d

M

stress bending Maximum

MPa S and MPa

f

f

f

f

f

ba f a

bm f m

ba

bm

y

= =

|

\

|

+

=

|

|

\

|

+

=

= = =

= = =

= =

= =

=

= =

=

= =

= =

BITS Pilani, Pilani Campus

Different types of cyclic loads may be applied in

combination, for example, bending, axial and torsional

on machine components

When the loads and in-phase, the maximum values of

loads occurs at the same time and so are the minimum

values.

Hence in such cases, we can estimate the maximum and

minimum von-Mises stress values and then estimate the

mean and amplitude von-Mises stresses. Then fatigue

criterion may be applied.

Combination of loading modes

BITS Pilani, Pilani Campus

Combined loading

For the common case of a shaft with bending stresses, torsional shear

stresses, and axial stresses, the von Mises stress is

Considering that the bending, torsional, and axial stresses have

alternating and midrange components, the von Mises stresses for the

two stress elements can be written as

For plane stress

| |

2

1

2

2 2

'

3

xy y y x x

+ + =

| |

2

1

2

2

'

3

xy x

+ =

( ) ( ) ( )

( )

( ) ( ) | |

( ) ( ) ( ) ( ) | | ( ) ( ) | | { }

2 / 1

2 2

'

2 / 1

2

2

'

3

3

85 . 0

torsion

mo

torsion

fs

axial

mo

axial

f

bending

mo

bending

f m

torsion

ao

torsion

fs

axial

ao

axial

f

bending

ao

bending

f a

K K K

K K K

+ + =

+

(

+ =

BITS Pilani, Pilani Campus

Calculate von Mises stresses for alternating and

midrange stress states,

a

and

m

.

Apply stresses to fatigue criterion i.e Soderberg,

Modified-Goodman, Gerbers or ASME Elliptic criteria

by replacing

a

and

m

with

a

and

m

respectively

Conservative check for localized yielding using von

Mises stresses i.e

Design for Combined loading

BITS Pilani, Pilani Campus

Fig shows clutch-testing machine. The steel shaft rotates at a constant speed

. An axial load is applied to the shaft and is cycled from zero to P. The

torque T induced by the clutch face onto the shaft

where D and d are defined in the figure and f is the coefficient of friction of

the clutch face. The shaft is machined with S

y

= 800 MPa and S

ut

= 1000

MPa. The theoretical stress concentration factors for the fillet are 3.0 and 1.8

for the axial and torsional loading, respectively.

Assume the load variation P is synchronous

with shaft rotation. With f = 0.3, find the

maximum allowable load P such that the shaft

will survive a minimum of 10

8

cycles with a

factor of safety of 3. Use the modified

Goodman criterion.

Prob:6-57

BITS Pilani, Pilani Campus

Solution

BITS Pilani, Pilani Campus

Solution

BITS Pilani, Pilani Campus

Practice problem

In the figure shaft A, made of AISI 1010 hot-rolled steel, is welded to a

fixed support and is subjected to loading by equal and opposite forces F via

shaft B. In addition, the shaft is also subjected to a study compressive force

of P. The length of shaft A from the fixed support to the connection at shaft

B is 1 m. If the load F cycles from 0.5 to 2kN and P= 1 kN, For shaft Afind

the factor of safety for infinite life using (a) the modified Goodman fatigue

failure criterion. (b) Gerber fatigue failure criterion.

BITS Pilani, Pilani Campus

Strain-Life method is used to estimate fatigue

strength for high cycle fatigue (i.e. N>10

3

cycles)

Fatigue strength

If a completely reversed stress(

rev

) in given, the

number of cycles to failure can be expressed as

( )

|

|

\

|

= =

=

e

ut

e

ut

b

f

S

fS

b

S

fS

a

where N a S

log

3

1

&

2

Fatigue strength calculation / Design for finite life

b

rev

a

N

1

|

\

|

=

Where f is fatigue strength

fraction depends on S

ut

from

Figure 6-18; page:285

BITS Pilani, Pilani Campus

Fatigue strength fraction

Figure 6-18; page:285

BITS Pilani, Pilani Campus

A 25-mm-diameter solid round bar has a groove 2.5-mm

deep with a 2.5-mm radius machined into it. The bar is

made of AISI 1020 CD steel and is subjected to a purely

reversing torque of 200 N-m. For the S-N curve of this

material, let f = 0.9.

(a) Estimate the number of cycles to failure.

(b) If the bar is also placed in an environment with a

temperature of 450

0

F, estimate the number of cycles to

failure.

Problem : 6-12

BITS Pilani, Pilani Campus

D= 25 mm ; d= 20 mm ; r= 2.5 mm

r/d =2.5/20 = 0.125; D/d= 1.25

From figure: K

ts

= 1.4

Solution

BITS Pilani, Pilani Campus

MPa S and kpsi MPa

y

390 ) 68 ( 470 S ; Steel CD 1020 AISI For

ut

= =

Solution

BITS Pilani, Pilani Campus

( )

cycles

a

N

S

fS

b

S

fS

a

MPa

b

a

se

su

se

su

22472

169 . 0 log

3

1

94 . 913

315 S 0.67 S

MPa 87.94 = S k k k = S

0.59 = k

0.726 0) 2 1.24( = ) 1.24(d = k

drawn) cold for -0.265 = b and 4.51 = (a 0.874 = aS = k

MPa 235 = 0.5S = S

1

2

ut su

1

e c b a e

c

0.107 - 0.107 -

e b

b

ut a

ut

1

e

=

|

\

|

=

=

|

|

\

|

=

= =

= =

=

Solution

BITS Pilani, Pilani Campus

You might also like

- Mechanical SpringsDocument76 pagesMechanical SpringsTimothy MartinezNo ratings yet

- 1033 Ijarse PDFDocument12 pages1033 Ijarse PDFAsr FlowerNo ratings yet

- AISC Seismic Design-Module2-Moment Resisting Frames Vol 3Document75 pagesAISC Seismic Design-Module2-Moment Resisting Frames Vol 3Percy Romero Murillo100% (1)

- Fatigue DesignDocument56 pagesFatigue Designarrow_inspectNo ratings yet

- Creep and FatigueDocument30 pagesCreep and FatigueAyush ShahNo ratings yet

- Fatigue Failure Resulting From Variable Loading 1-2Document24 pagesFatigue Failure Resulting From Variable Loading 1-2Rahul SinghNo ratings yet

- From BS5950 To EC3Document40 pagesFrom BS5950 To EC3bsitlerNo ratings yet

- 33.thomas Murray-Conexiones Edificios de Acero 1Document109 pages33.thomas Murray-Conexiones Edificios de Acero 1nestor javier agudelo cNo ratings yet

- Springs (Compatibility Mode)Document50 pagesSprings (Compatibility Mode)srwickedsunnyNo ratings yet

- Chapter 5: Steel: FEMA 356Document10 pagesChapter 5: Steel: FEMA 356mrea130No ratings yet

- The Design of Fiber Reinforced Polymers For Struc Strengthening ACI 440 PDFDocument109 pagesThe Design of Fiber Reinforced Polymers For Struc Strengthening ACI 440 PDFWelcomePopeFrancisNo ratings yet

- PSC Design (Aashto-Lrfd Tyu07) TutorialDocument44 pagesPSC Design (Aashto-Lrfd Tyu07) TutorialMohammad Tawfiq WaraNo ratings yet

- Wallace - PEER - Coupling Beams - Wallace - Oct 13 2009 FinalDocument41 pagesWallace - PEER - Coupling Beams - Wallace - Oct 13 2009 FinalStef22100% (1)

- Analytical and Experimental Stu Dy of Structural Units and Syste MsDocument33 pagesAnalytical and Experimental Stu Dy of Structural Units and Syste MsDeep ShahNo ratings yet

- Fatigue Failure Is Characterized by Three StagesDocument37 pagesFatigue Failure Is Characterized by Three StagesRohit MunaNo ratings yet

- Diseño de Conexiones PCIDocument102 pagesDiseño de Conexiones PCIj-balderasNo ratings yet

- ACI ITG/T1.1R-99: Reported by ACI Innovation Task Group 1 and CollaboratorsDocument7 pagesACI ITG/T1.1R-99: Reported by ACI Innovation Task Group 1 and CollaboratorsCorui Mihai ValerNo ratings yet

- Axially Loaded RC Column DesignDocument17 pagesAxially Loaded RC Column DesignBert EngNo ratings yet

- Transmission Monopole PDFDocument71 pagesTransmission Monopole PDFHariprasad gantyala100% (3)

- Bonney Forge Sifs Various FittingsDocument45 pagesBonney Forge Sifs Various FittingsKevinNo ratings yet

- STATIC LOAD TEST - การทดสอบการรับน้ำหนักของเสาเข็มDocument11 pagesSTATIC LOAD TEST - การทดสอบการรับน้ำหนักของเสาเข็มWilrutstien WilrutstienNo ratings yet

- Fatique Lecture NotesDocument41 pagesFatique Lecture NotesMarcel SilvaNo ratings yet

- Design and Uses of Prestressed Concrete Columns: by Raymond ItayaDocument8 pagesDesign and Uses of Prestressed Concrete Columns: by Raymond ItayaVegetable BunNo ratings yet

- How To Design Plain Concrete Footing For R.C.C CoDocument1 pageHow To Design Plain Concrete Footing For R.C.C CoDumoluhle SibiyaNo ratings yet

- CE 3100: Structural Engineering Lab: February 4Document12 pagesCE 3100: Structural Engineering Lab: February 4Sarankumar ThathuruNo ratings yet

- RCC 06Document29 pagesRCC 06Engr SwapanNo ratings yet

- Pipe Stress Amp SupportDocument24 pagesPipe Stress Amp Supportaap1No ratings yet

- IEEE Tutorial Sag Tension CalculationDocument33 pagesIEEE Tutorial Sag Tension CalculationvthiyagainNo ratings yet

- Pipe Stress PDFDocument24 pagesPipe Stress PDFMichael Jones100% (1)

- Le.H Insulation CoordinationDocument19 pagesLe.H Insulation CoordinationDes LawlessNo ratings yet

- Transmission Mono Poles-SERCDocument49 pagesTransmission Mono Poles-SERCtmmsekar100% (2)

- Engineering Design CHAPTER 3 UpdatedDocument25 pagesEngineering Design CHAPTER 3 UpdatedvenkeekuNo ratings yet

- Transmission MonopoleDocument71 pagesTransmission Monopolepavithra2796% (23)

- Design of Machine Elements (DOME) MENG 375: Instructor Dr. Riaz MuhammadDocument123 pagesDesign of Machine Elements (DOME) MENG 375: Instructor Dr. Riaz MuhammadLoay MohammedNo ratings yet

- Design of MicropilesDocument38 pagesDesign of MicropilesHRCNo ratings yet

- Lessons Learned From Forensic FEA of Failed RC Structures PDFDocument22 pagesLessons Learned From Forensic FEA of Failed RC Structures PDFYan HuangNo ratings yet

- Concentrically Loaded Masonry WallsDocument13 pagesConcentrically Loaded Masonry WallsPankaj SainiNo ratings yet

- MME501 Tutorial Topic3 v1.4Document25 pagesMME501 Tutorial Topic3 v1.4Zain KhanNo ratings yet

- Fatigue FailureDocument47 pagesFatigue FailureOmar KhanNo ratings yet

- 8 Stressing PDFDocument14 pages8 Stressing PDFKaushal K SharmaNo ratings yet

- Software Verification PDFDocument917 pagesSoftware Verification PDFPauccar Rhp Hp100% (2)

- Principle of PTDocument30 pagesPrinciple of PTJimmy ChungNo ratings yet

- Multi - Storey Buildings - III AnalysisDocument35 pagesMulti - Storey Buildings - III AnalysisMohamed El MotazNo ratings yet

- Etabs Software VerificationDocument535 pagesEtabs Software VerificationJohn G Jose100% (2)

- Rectangular Reinforced Concrete BeamDocument60 pagesRectangular Reinforced Concrete BeamMedianna Novita100% (1)

- PCI 6th Edition - Connection DesignDocument102 pagesPCI 6th Edition - Connection DesignjeovanNo ratings yet

- Seismic-Resistant Design - CBFs PDFDocument31 pagesSeismic-Resistant Design - CBFs PDFciviliiiNo ratings yet

- Quy Trinh PipeStress Amp SupportDocument24 pagesQuy Trinh PipeStress Amp SupportVuong BuiNo ratings yet

- FsafDocument24 pagesFsafpvmssonNo ratings yet

- Basic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandBasic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 4 out of 5 stars4/5 (4)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Initial Update Commands For UbuntuDocument1 pageInitial Update Commands For UbuntuTimothy MartinezNo ratings yet

- Chapter 7Document25 pagesChapter 7Timothy MartinezNo ratings yet

- Business Week 2004 Rankings of US B-SchoolsDocument3 pagesBusiness Week 2004 Rankings of US B-Schoolsrachana29No ratings yet

- Chapter 01Document30 pagesChapter 01Timothy MartinezNo ratings yet

- Indian PaintersDocument23 pagesIndian PaintersTimothy Martinez100% (1)

- J-Bubbler PC: The Ultimate OptionDocument2 pagesJ-Bubbler PC: The Ultimate OptionTimothy MartinezNo ratings yet

- Warren Buffett 1998 BRK Annual Letter To ShareholdersDocument17 pagesWarren Buffett 1998 BRK Annual Letter To ShareholdersBrian McMorrisNo ratings yet

- Rolling Element BearingsDocument45 pagesRolling Element BearingsTimothy Martinez100% (1)

- Welded JointsDocument47 pagesWelded JointsTimothy MartinezNo ratings yet

- Lubrication & Journal BearingsDocument43 pagesLubrication & Journal BearingsTimothy MartinezNo ratings yet

- Gears-Fundametals (Compatibility Mode)Document52 pagesGears-Fundametals (Compatibility Mode)Timothy MartinezNo ratings yet

- Failures Resulting From Static LoadingDocument36 pagesFailures Resulting From Static LoadingTimothy MartinezNo ratings yet

- L&T SCR ReportDocument123 pagesL&T SCR ReportBhaskar VishalNo ratings yet

- SynchronisationDocument53 pagesSynchronisationTimothy MartinezNo ratings yet

- L&TAnnalReview 2008 09Document38 pagesL&TAnnalReview 2008 09hashim60No ratings yet

- When Karl Met Lollo The Origins and Consequences of Karl Barths Relationship With Charlotte Von KirschbaumDocument19 pagesWhen Karl Met Lollo The Origins and Consequences of Karl Barths Relationship With Charlotte Von KirschbaumPsicoorientación FamiliarNo ratings yet

- Internship Report-2020Document77 pagesInternship Report-2020Hossen ImamNo ratings yet

- Swimming Pool - PWTAG CodeofPractice1.13v5 - 000Document58 pagesSwimming Pool - PWTAG CodeofPractice1.13v5 - 000Vin BdsNo ratings yet

- A Social Movement, Based On Evidence, To Reduce Inequalities in Health Michael Marmot, Jessica Allen, Peter GoldblattDocument5 pagesA Social Movement, Based On Evidence, To Reduce Inequalities in Health Michael Marmot, Jessica Allen, Peter GoldblattAmory JimenezNo ratings yet

- Virulence: Factors in Escherichia Coli Urinary Tract InfectionDocument49 pagesVirulence: Factors in Escherichia Coli Urinary Tract Infectionfajar nugrahaNo ratings yet

- 2011 Physics B Form B Scoring GuidelinesDocument16 pages2011 Physics B Form B Scoring GuidelinesMichael CNo ratings yet

- SANCHEZ V DEMETRIOUDocument3 pagesSANCHEZ V DEMETRIOUShenna SunicoNo ratings yet

- Pi 100 Book ReviewDocument10 pagesPi 100 Book ReviewBianca CacnioNo ratings yet

- Chapter 1 (Research)Document6 pagesChapter 1 (Research)Salome CarpioNo ratings yet

- PrinciplesIntuitiveEating2017 PDFDocument2 pagesPrinciplesIntuitiveEating2017 PDFCristina Cousinard100% (2)

- Handout For Chapters 1-3 of Bouchaud: 1 DenitionsDocument10 pagesHandout For Chapters 1-3 of Bouchaud: 1 DenitionsStefano DucaNo ratings yet

- t10 2010 Jun QDocument10 pagest10 2010 Jun QAjay TakiarNo ratings yet

- The Squeezing Potential of Rocks Around Tunnels Theory and PredictionDocument27 pagesThe Squeezing Potential of Rocks Around Tunnels Theory and PredictionprazNo ratings yet

- Learn JQuery - Learn JQuery - Event Handlers Cheatsheet - CodecademyDocument2 pagesLearn JQuery - Learn JQuery - Event Handlers Cheatsheet - Codecademyilias ahmedNo ratings yet

- Mission Veng 29th, 2019Document4 pagesMission Veng 29th, 2019Lasky ChhakchhuakNo ratings yet

- Research in NursingDocument54 pagesResearch in Nursingrockycamaligan2356No ratings yet

- Allusions and References - 5Document3 pagesAllusions and References - 5Matthew HallingNo ratings yet

- Projectile Motion PhysicsDocument3 pagesProjectile Motion Physicsapi-325274340No ratings yet

- Basic Foundation of Iv TherapyDocument10 pagesBasic Foundation of Iv Therapyjanna mae patriarcaNo ratings yet

- Lesson 2: Osmosis Lab Data: Student Name: Nguyen Duc MinhDocument2 pagesLesson 2: Osmosis Lab Data: Student Name: Nguyen Duc MinhMinh Nguyen DucNo ratings yet

- A Re Ection On The Dominant Learning Theories: Behaviourism, Cognitivism and ConstructivismDocument13 pagesA Re Ection On The Dominant Learning Theories: Behaviourism, Cognitivism and Constructivismchill protocolNo ratings yet

- Ethics - FinalsDocument18 pagesEthics - Finalsannie lalangNo ratings yet

- Unit 12 - Gerund and Infinitive (Task)Document1 pageUnit 12 - Gerund and Infinitive (Task)AguNo ratings yet

- Malaria SymptomsDocument3 pagesMalaria SymptomsShaula de OcampoNo ratings yet

- My AnalysisDocument4 pagesMy AnalysisMaricris CastillanoNo ratings yet

- Operate A Word Processing Application BasicDocument46 pagesOperate A Word Processing Application Basicapi-24787158267% (3)

- Birnbaum - 2006 Registration SummaryDocument14 pagesBirnbaum - 2006 Registration SummaryEnvironmental Evaluators Network100% (1)

- 5 Reported Speech - T16-6 PracticeDocument3 pages5 Reported Speech - T16-6 Practice39 - 11A11 Hoàng Ái TúNo ratings yet

- All New Keys DictionaryDocument7 pagesAll New Keys DictionaryvishntNo ratings yet

- Assignment in Legal CounselingDocument4 pagesAssignment in Legal CounselingEmmagine E EyanaNo ratings yet