Professional Documents

Culture Documents

SteelTubeHandbook February201211111

Uploaded by

mukeshkumarjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SteelTubeHandbook February201211111

Uploaded by

mukeshkumarjCopyright:

Available Formats

TDC standards 10294-1

Steel grade

Testing and certificates

Marking Longitudinally on tube paint stenciling die stamping label on tube Label on bundle (OD < 45 mm) Data: producer steel grade condition OD x ID standard EN identif. number inspector +H and cast number (EN 10297-1)

Other TDC

Surface protection Packing without bundle upon agreement 300 3500 kg

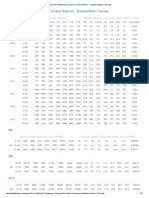

Name Condition Surface Testing Certificate Specific: visually miss- cast analysis E355 + AR EN 10204 less adequate tensile test E355 J2 +N 3.1 to production impact test E420 J2* +N mode. ((if possible)) E 470* + AR dimensions *steel type Cold finished visual 20MnV6 + N alebo + SR Non - specific: Mandatory: 10297-1 E235 + AR, + N EN 10204 cast analysis E275 + AR, + N 2.1 (2.2.) tensile test E315 + AR, + N impact test ((if possible)) E355 + AR, + N Specific: dimensions E470 + AR EN 10204 visual E275K2 +N 3.1 (3.2) material identification E355K2 +N (for alloyed steel) E460K2 +N (See also E420J2 +N page 10) Optional: C22E +N upon agreement C35E +N Table 17 of standard C45E +N C60E +N 38Mn6 +N 41Cr4 + QT (+ N) 25CrMo4 + QT (+ N) 30CrMo4 + QT (+ N) 34CrMo4 + QT (+ N) 42CrMo4 + QT (+ N) C10E + N (+A) C15E + N (+A) C15R + N (+A) 20NiCrMo2-2 + N (+A) 16MnCr5 +N EN 10083-2 - C steel C 22, 35, 40, 45, 55, 60; CxyE a CxyR - 22, 35, 40, 45, 50, 55, 60 a 28Mn6 EN 10083-3 - Alloy steels (see overview page 21 and comparison of steels) EN 10084 - CxyE a CxyR - 10, 15, 16 and alloy steels These standards are presented only informatory. Steel tubes produced from steels from these standards are included in EN 10297-1 daje - vi str. 23 1629 1630 visual 17200 ocele typu: Hot finishedU DIN 50049 dimensions 17204 C22 as rolled 2.2, 3.1.B other test upon agreement Ck22 Cold finished Cm22 +NBK, +BK 17210 C10* tensile test 6323/1,3 HFS 3 (360) Hot finished Compliance flattening HFS 4 (410) as rolled with standard impact test HFS 5 (490) certificate drift expanding HFS 8 (540) hydrotest or NDT upon agreement

each tube small diameter by label

without upon agreement

Steel with boron content (kind 20MnB5) upon agreement. * List of steel see table of chemical composition at pages 20, 21. This group of tubes can be delivered also according to DS for exact tubes (cold drawn) see page 60 and other. ** Tubes are not mechanically worked. D tolerance upon agreement.

Steel designation according to EN: steel for tubes for mechanical treatment: steel E355 + AR, E 355 + N E steel for machine parts, 355 minimum yield strength in N/mm2 , +AR heat treatment is not required, +N normalising annealed or formed steel 20MnV6 steel designated by chemical composition guaranteed mean C content 0,20%, guaranteed content Mn and V +AR heat teratment is not required, +N normalising annealed or formed steel for machine parts: steel without heat treatment after mechanical treatment non-alloy steel E 235, E275, E315, E355 Condition +AR or +N steel with specific impact qualities (fine-grain) E275K2, E355K2 K2 guaranteed characteristic of impact energy 40 J (K) by temperature 20 C steel with heat treatment after mechanical treatment steel C22E C steel with carbon content 0,22%, E reference to maximum checked content of S and P steel 38Mn6 guaranteed mean C content and guaranteed Mn content

17

You might also like

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- DIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84Document2 pagesDIN 1626-84 WELDED CIRCULAR TUBES OF NON ALLOY STEELS WITH SPECIAL USt 37.0 - ST 37.0 - ST 44.0 - ST 52.0 - DIN1.0253 - 1.0254 1.0256 1.0256 1.0421 DIN1626-84nunosobralNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Sermo 13 de Tempore (2 Feb in Praes)Document1 pageSermo 13 de Tempore (2 Feb in Praes)GeorgesEdouardNo ratings yet

- Comparison en 10277Document4 pagesComparison en 10277Ardeleana TisaNo ratings yet

- Plates - S420G2 MDocument2 pagesPlates - S420G2 MAdisak AumpiemNo ratings yet

- AISI SteelDocument7 pagesAISI SteelEtiNo ratings yet

- Chinese To DinDocument7 pagesChinese To Dindnageshm4n244No ratings yet

- Structurals and Standard Pipe: ProducersDocument4 pagesStructurals and Standard Pipe: ProducersRudyNo ratings yet

- Materialqualitaeten EDocument2 pagesMaterialqualitaeten EjvilamaiorNo ratings yet

- Ruukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Document6 pagesRuukki Hot Rolled Steels Standard Steel Grades Comparison Designation and Codes1Cad AutocadNo ratings yet

- Bar STDDocument8 pagesBar STDtushk20100% (1)

- Henan BEBON International Co.,ltd: Chemical Analysis - % by MassDocument1 pageHenan BEBON International Co.,ltd: Chemical Analysis - % by Massado31No ratings yet

- Cold Drawn Seamless Steel Tubes For Mechanical ApplicationsDocument8 pagesCold Drawn Seamless Steel Tubes For Mechanical ApplicationsDiego TrinidadNo ratings yet

- Annex 1.8 I Beams European GradesDocument12 pagesAnnex 1.8 I Beams European GradesAbdullah NajjarNo ratings yet

- Standard Normative ReferencesDocument2 pagesStandard Normative ReferencesAleksandar GochevskiNo ratings yet

- Steel Grades For Tube ProductionDocument2 pagesSteel Grades For Tube ProductionTomislav FilipovicNo ratings yet

- Marcegaglia Yangzhou Plant en SlideDocument38 pagesMarcegaglia Yangzhou Plant en SlidelucidbaseNo ratings yet

- Steel Supply Sub-Grades To EC3Document22 pagesSteel Supply Sub-Grades To EC3Anonymous iS33V5No ratings yet

- Din Equivalent MaterialsDocument3 pagesDin Equivalent Materialspadmgovi23No ratings yet

- TL-DSV 2012-05 Engl Br-1Document5 pagesTL-DSV 2012-05 Engl Br-1Dorota HONo ratings yet

- Cold Rolled 2010 DUNAFER HungriaDocument12 pagesCold Rolled 2010 DUNAFER HungriaBeatriz RizzoNo ratings yet

- Cold Drawn Seamless Steel Tubes For Hydraulic CylindersDocument8 pagesCold Drawn Seamless Steel Tubes For Hydraulic Cylindersvijayasarathy2013No ratings yet

- 000 L Ee 0020129Document2,433 pages000 L Ee 0020129avaisharmaNo ratings yet

- Structurals and Standard Pipe EngDocument4 pagesStructurals and Standard Pipe EngUuka UkaNo ratings yet

- Chinese To DinDocument7 pagesChinese To DinDamla KaymakçıNo ratings yet

- HydraulicCylinders PDFDocument6 pagesHydraulicCylinders PDFseaqu3stNo ratings yet

- En 10025 S235JR SteelDocument1 pageEn 10025 S235JR SteelNestor OliNo ratings yet

- EN 10025: 2004 Is The New European Standard For Structural Steel.Document6 pagesEN 10025: 2004 Is The New European Standard For Structural Steel.Alin DavidNo ratings yet

- Tubes and PipesDocument40 pagesTubes and Pipesyngwhi100% (1)

- Alloy Non-Alloy SteelDocument3 pagesAlloy Non-Alloy SteelSasa ZivkovicNo ratings yet

- 3 SpringDocument66 pages3 Springall_meca_allNo ratings yet

- Marcegaglia Cold-Drawn-Bars en Gen11Document13 pagesMarcegaglia Cold-Drawn-Bars en Gen11lucidbaseNo ratings yet

- JIS Seamless PipeDocument8 pagesJIS Seamless PipeJay PanalanginNo ratings yet

- En 10025 2004 BDocument10 pagesEn 10025 2004 BPrasanna RajaNo ratings yet

- Untitled 1 PDFDocument35 pagesUntitled 1 PDFRAVI KANT BARANWALNo ratings yet

- Specification 201 Rev - 12 - Supply and Fabrication Steel StructuresDocument38 pagesSpecification 201 Rev - 12 - Supply and Fabrication Steel Structures'Izzad AfifNo ratings yet

- ISF Aachen Welding Technology Part II PDFDocument140 pagesISF Aachen Welding Technology Part II PDFscott2355No ratings yet

- List of Standards & Their Usage: SL - No. DecriptionDocument8 pagesList of Standards & Their Usage: SL - No. DecriptionSumeet MahajanNo ratings yet

- AISI 4140 - AISI 4142mod.: Product DescriptionDocument3 pagesAISI 4140 - AISI 4142mod.: Product Description2shaenNo ratings yet

- Equivalences Between Different Designations: Chemical CompositionDocument2 pagesEquivalences Between Different Designations: Chemical CompositionSuleman KhanNo ratings yet

- ST 12 - Echivalenta DC01Document12 pagesST 12 - Echivalenta DC01mariussinhoNo ratings yet

- Katalog 2011 enDocument278 pagesKatalog 2011 ener_wenNo ratings yet

- Springs - 02Document130 pagesSprings - 02kindbagusNo ratings yet

- Standard Steels HR 2 3 02 01 2010 - ENDocument6 pagesStandard Steels HR 2 3 02 01 2010 - ENBigman1983No ratings yet

- Vac Heat Treatment MonoTherm 2009 Engl (Kompatibilitätsmodus)Document33 pagesVac Heat Treatment MonoTherm 2009 Engl (Kompatibilitätsmodus)AmitNo ratings yet

- DX51D Galvanized Coils For Cold Forming: Product DescriptionDocument2 pagesDX51D Galvanized Coils For Cold Forming: Product DescriptionsachedalNo ratings yet

- European Steel and Alloy Grades: X6Crniti18-10 (1.4541)Document3 pagesEuropean Steel and Alloy Grades: X6Crniti18-10 (1.4541)farshid KarpasandNo ratings yet

- 1303287208Document27 pages1303287208Anurag JainNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Basic Noise CalculationsDocument15 pagesBasic Noise Calculationsapi-270822363No ratings yet

- Fan TerminologyDocument12 pagesFan TerminologymukeshkumarjNo ratings yet

- Use of Dissipative SilencersDocument9 pagesUse of Dissipative SilencersmukeshkumarjNo ratings yet

- 1 25Document18 pages1 25Charu ChhabraNo ratings yet

- Noise SourcesDocument22 pagesNoise SourcesmukeshkumarjNo ratings yet

- Tray Support 2Document28 pagesTray Support 2pankajskecNo ratings yet

- Metric - Cap and Domed Nuts Hex Dome NutsDocument1 pageMetric - Cap and Domed Nuts Hex Dome NutsmukeshkumarjNo ratings yet

- Noise CalculatorDocument9 pagesNoise CalculatormukeshkumarjNo ratings yet

- Dear Smriti, A Very Happy New Year!!!! With Love, AadishreeDocument1 pageDear Smriti, A Very Happy New Year!!!! With Love, AadishreemukeshkumarjNo ratings yet

- Pipe and Tube MaterialDocument1 pagePipe and Tube MaterialmukeshkumarjNo ratings yet

- Catalogue - EasySteel - Steel Book 2012 PDFDocument112 pagesCatalogue - EasySteel - Steel Book 2012 PDFIvan BuhiinzaNo ratings yet

- CW & CCW CW CCW (Normal) Mod. 1 Mod. 2Document2 pagesCW & CCW CW CCW (Normal) Mod. 1 Mod. 2mukeshkumarjNo ratings yet

- Achieving The ImpossibleDocument5 pagesAchieving The ImpossiblemukeshkumarjNo ratings yet

- ANSI B36.10 - Pipe Dimension With Wt.Document1 pageANSI B36.10 - Pipe Dimension With Wt.RAVI1972No ratings yet

- Flu/P: D. K. Instruments Pvt. LTDDocument3 pagesFlu/P: D. K. Instruments Pvt. LTDmukeshkumarjNo ratings yet

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsDocument3 pagesPre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjNo ratings yet

- AISI304Document2 pagesAISI304tony_abNo ratings yet

- Structural Analysis of ICS 3d PanelDocument32 pagesStructural Analysis of ICS 3d PanelajivakkomNo ratings yet

- 10 23Document1 page10 23mukeshkumarjNo ratings yet

- Gandhi TubesDocument6 pagesGandhi TubesmukeshkumarjNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)mukeshkumarjNo ratings yet

- Irctcs E-Ticketing Service Electronic Reservation Slip (Personal User)Document1 pageIrctcs E-Ticketing Service Electronic Reservation Slip (Personal User)mukeshkumarjNo ratings yet

- Airtel 2014-02-07Document2 pagesAirtel 2014-02-07mukeshkumarjNo ratings yet

- Link 3 - Introduction To Motor Bus TransferDocument14 pagesLink 3 - Introduction To Motor Bus TransferMohamed Abdel KhalekNo ratings yet

- Tourist ChecklistDocument2 pagesTourist ChecklistmukeshkumarjNo ratings yet

- Anchor BoltsDocument16 pagesAnchor BoltsmukeshkumarjNo ratings yet

- Boarding PassDocument1 pageBoarding PassmukeshkumarjNo ratings yet

- Acoustic ExplanationDocument1 pageAcoustic ExplanationmukeshkumarjNo ratings yet

- Ticket ReturnDocument1 pageTicket ReturnmukeshkumarjNo ratings yet

- Vibrations - NptelDocument3 pagesVibrations - NptelMSK65No ratings yet

- CDM816DSpare Parts Manual (Pilot Control) 2Document55 pagesCDM816DSpare Parts Manual (Pilot Control) 2Mohammadazmy Sobursyakur100% (1)

- 14 WosDocument6 pages14 WosATUL KURZEKARNo ratings yet

- 2014 An125hkl4Document69 pages2014 An125hkl4El Turco ChalabeNo ratings yet

- Monthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)Document20 pagesMonthly Exam Part I Aurora English Course 1 (KD 1, KD2, PKD3)winda septiaraNo ratings yet

- Business Model Navigator Whitepaper - 2019Document9 pagesBusiness Model Navigator Whitepaper - 2019Zaw Ye HtikeNo ratings yet

- 9446 - Data Sheets Final PDFDocument17 pages9446 - Data Sheets Final PDFmarounNo ratings yet

- Vol07 1 PDFDocument275 pagesVol07 1 PDFRurintana Nalendra WarnaNo ratings yet

- Theology of Work and Practical ImplicationsDocument28 pagesTheology of Work and Practical ImplicationsVinicius CardosoNo ratings yet

- Noxim MANUALDocument5 pagesNoxim MANUALSAI NRUSIMHA DEEPAK BURRA SAI NRUSIMHA DEEPAK BURRANo ratings yet

- Ultimate GuideDocument33 pagesUltimate GuidemrosamusicNo ratings yet

- Tim Ingold - From The Transmission of Representations To The Education of Attention PDFDocument26 pagesTim Ingold - From The Transmission of Representations To The Education of Attention PDFtomasfeza5210100% (1)

- Diablo Watch Newsletter, FALL 2009 Save Mount DiabloDocument16 pagesDiablo Watch Newsletter, FALL 2009 Save Mount DiabloIoannqisHatzopoulosNo ratings yet

- Tamil NaduDocument64 pagesTamil Nadushanpaga priyaNo ratings yet

- Faujifood Pakistan PortfolioDocument21 pagesFaujifood Pakistan PortfolioPradeep AbeynayakeNo ratings yet

- Eoi QAMDocument6 pagesEoi QAMPeeyush SachanNo ratings yet

- Science 10 Quarter 2 Module 4Document6 pagesScience 10 Quarter 2 Module 4Jess Anthony Efondo100% (4)

- The Failed Rotator CuffDocument307 pagesThe Failed Rotator Cufforthofitness2017No ratings yet

- Laporan Pelayanan Rawat Jalan Tingkat Pertama (RJTP)Document10 pagesLaporan Pelayanan Rawat Jalan Tingkat Pertama (RJTP)dede komalasariNo ratings yet

- Streamline SWR (S) - Rev - 00-04-2019 PDFDocument2 pagesStreamline SWR (S) - Rev - 00-04-2019 PDFarjun 11No ratings yet

- The Explanation of The Fundamentals of Islamic BeliefDocument95 pagesThe Explanation of The Fundamentals of Islamic BeliefbooksofthesalafNo ratings yet

- Calabano Clinical Bacteriology Exercise 1Document5 pagesCalabano Clinical Bacteriology Exercise 1MarkJasperCalabanoNo ratings yet

- Homophones WorksheetDocument3 pagesHomophones WorksheetAmes100% (1)

- Tech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPDocument39 pagesTech Manual 1396 Rev. B: 3.06/4.06" 15,000 Psi ES BOPEl Mundo De Yosed100% (1)

- Electric Bike Monitoring and Controlling System Based On Internet of ThingsDocument8 pagesElectric Bike Monitoring and Controlling System Based On Internet of ThingsEarl PhamtonhiveNo ratings yet

- Microsoft Word - IRN Fab Transfer PCN NoticeDocument22 pagesMicrosoft Word - IRN Fab Transfer PCN NoticeJadilson PradoNo ratings yet

- Amc 20-21Document33 pagesAmc 20-21Vasco M C SantosNo ratings yet

- ELC609F12 Lec0 IntroductionDocument16 pagesELC609F12 Lec0 IntroductionMohammed El-AdawyNo ratings yet

- Solid Mens ModuleDocument158 pagesSolid Mens ModuleAzha Clarice VillanuevaNo ratings yet