Professional Documents

Culture Documents

Sel17 en 311205

Uploaded by

meeng2014Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sel17 en 311205

Uploaded by

meeng2014Copyright:

Available Formats

Atelier Management and Design Consultancy (Vietnam) Co.

,Ltd

SEL17-ELEC !"CAL C#MM"SS"#$"$%&1

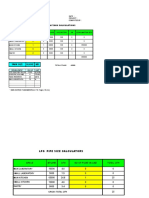

SECTION 17: ELECTRICAL COMMISSIONING 17.1 GENERAL 17.1.1 Functional description A specialist team is to be engaged to carry out the commissioning of the electrical services. This team may consist of the contractors employees, if their experience and aptitude is approved. The commissioning of the electrical systems is a critical stage and the specialist team need to be involved with the project from an early stage. This should be approximately 1 month prior to the availability of permament electrical power to the site. A fully commissioned and documented system is re uired at the end of the project, and this section of the specification describes the minimum activities re uired. 17.1.! "ross references General #efer to the General requirements wor$section. Related Worksections Electrical General Requirements, Freshwater, Hydrants & Hosereels, Pumps, Mechanical Piping, Packaged Air onditioner, , Fans, M! "witchgear, #rans$ormers, "witch%oards, "witch%oard omponents, Motor "tarters, Generating "ets, &ighting, &ightning Protection, Fire detection & Alarms 17.2 COMMISSIONING 17.!.1 %eneral All testing shall be in compliance with Australian &tandards. All testing shall be scheduled and approved. "omplete test and inspection records shall be made and incorporated into a report for each piece of e uipment tested. All readings ta$en shall be recorded. Following established procedure, e uipment will be, energised after certification that the installation is satisfactory. Final operational tests shall determine that the wiring connections are correct. 17.!.! 'nspection and testing S ste! testin" sc#ed$le

Test (ielectric Tests on all electrical cables, components and

(emonstrate

)old point

Atelier Management and Design Consultancy (Vietnam) Co.,Ltd

SEL17-ELEC !"CAL C#MM"SS"#$"$%&'

Test accessories to A&*+,& -.17

(emonstrate

)old point

Functional and operational tests after protective and control devices have been installed and connected Functional testing /perate mechanical devices, relays, programmable logic controllers and logic controls, protection, interloc$ing and alarm e uipment 0erify time*current characteristics and settings on adjustable trip circuit brea$ers after installation and before energisation 'nterconnected systems All systems in accordance with the performance re uired for this project Functional and operational performance 1erformance and interoperability between systems

Material inspection and testing schedule

'nspection*test #e uirement or acceptance criteria Accessories "onduit and cable tray 'nsulation resistance Touch potential 3ighting performance &traight and level &traight and level

2ethod

Fre uency )old*witnes s status /nce on "ompletion completion &ite inspection 1rogress status

&ite inspection &ite inspection

A&*+,& -... A&*+,& -.17 /nce on "ompletion completion Fault loop impedance 3ux*colour A&*+,& -.17 /nce on "ompletion completion 2eter 2eter /nce on "ompletion completion 6 months "ompletion

4mergency and A&*+,& !!5-. evacuation ! lighting

Atelier Management and Design Consultancy (Vietnam) Co.,Ltd

SEL17-ELEC !"CAL C#MM"SS"#$"$%&(

17.!.-

Test instruments All instruments and appliances re uired far testing shall be furnished for the duration of the tests. %auges, thermometers or other instruments specified as a permanent part of the installation may be used for testing purposes. Test instruments shall be tested for accuracy by an approved laboratory and recent test certificates shall be made available prior to testing.

17.!.7

Test report terms The results of all testing shall he submitted in a neat and legible manner.

17.!.8

'nfra red thermographic tests 'nfra red thermographic tests shall be conducted after 1ractical "ompletion as follows9 :a; <hen the electrical system is loaded to 8.= of its maximum demand or, 1. to 1! wee$s after practical completion, whichever occurs first. :b; /ne month before the expiry of the <arranty period. :c; &ubse uently, after the expiry of the <arranty period, at six monthly periods, at rates to be negotiated. :d; 'f >)otspots> or overheating is suspected from the results of the tests carried out under :a; to :c; above, the defective components shall be rectified and another thermographic test shall be conducted after rectification of the fault. 'n this case? the test can be limited only to the faulted e uipment. Thermographic scanning shall be conducted only after the electrical installation has been under load for a minimum period of one hour. Tests shall be conducted on the main switchboard, busducts, distribution boards and all electrical connections and components rated at, or greater than, 6.A per - phase? or 8.A per single phase. The test instrument used shall provide computerised processing of images and be able to record actual temperature profiles of the component under test to produce a "/3/@# image. &ubmit a detailed report, complete with hard copy printouts A photographs of the installation, ta$en as normal images and as "/3/@# infra red images.

17.!.6

3ighting levels #ecord lighting levels in all areas on a 8m x 8m grid. Tabulate results against specified design levels.

17.!.7

"ompletion General %eneral9 <hen the installation is complete, commission the installation by

Atelier Management and Design Consultancy (Vietnam) Co.,Ltd

SEL17-ELEC !"CAL C#MM"SS"#$"$%&)

putting it into wor$ing order and operating it for at least the designated running period. 2a$e the adjustments necessary to achieve the designated performance under continuous operating service conditions, including balancing, setting the controls, chec$ing the operation of overload and safety devices, and correcting malfunctions. 17.!.B "leaning General At practical completion, clean the following9 &witchgear and contactors, and other electrical contacts. Adjust as necessary. 4nsure all e uipment re uiring dust or water protection is suitably protected. 1repare a schedule of all such e uipment and certify the installation is satisfactory. 17.!.5 Training O%eration 1rovide instruction and operating procedures to be adopted for this project 17.!.1. &pares Re&$ired s%ares sc#ed$le

Tools C all systems

&upply one set of special installation, operation and servicing tools 1rovide - spare lamps and one lamp extractor per 1. indicating lights. 3ocate in spares cabinet 1rovide - spare lamps, lamp remover, screen remover :if applicable;, mounted on clips in the assembly enclosure or in spares cabinet 1rovide - spare fuse lin$s for each rating of fuse lin$ on each assembly. 2ount spares on clips within the spares cabinet

'ndicator lights

Alarm annunciators

Fuse lin$s

17.!.11

2aintenance Re"$lar !aintenance 2a$e service visits and carry out the following procedures, as applicable9 &ervice items of e uipment.

Atelier Management and Design Consultancy (Vietnam) Co.,Ltd

SEL17-ELEC !"CAL C#MM"SS"#$"$%&*

"hec$ e uipment items for operation, calibration, performance compliance, temperature and energy consumption, and record values. "hec$ motors and machinery for excessive operating temperature, bearing noise and excessive vibration. #ecord current draw of motors. "hec$ condition of insulation, and repair. "hec$ electrical and control systems, including safety limits for temperature, pressure and humidity.

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 11.08.08 - Tinh Size TankDocument4 pages11.08.08 - Tinh Size Tankmeeng2014No ratings yet

- Honeywell DDC Panel ManualDocument512 pagesHoneywell DDC Panel ManualSyed ZakiuddinNo ratings yet

- T13 ALBANY PLUS Tech PDFDocument44 pagesT13 ALBANY PLUS Tech PDFmeeng2014No ratings yet

- Socket Outlets Ed.1Document2 pagesSocket Outlets Ed.1meeng2014No ratings yet

- Cleanroom Technology HandbookDocument108 pagesCleanroom Technology Handbookmeeng2014100% (1)

- BMS PresentationDocument19 pagesBMS Presentationmeeng2014No ratings yet

- Chilled Water System Sequence of OperationsDocument6 pagesChilled Water System Sequence of Operationsmeeng2014No ratings yet

- Drainage - Junctions in DrainsDocument2 pagesDrainage - Junctions in Drainsmeeng2014No ratings yet

- ELEC 3105 Building Services - Plumbing Services - 1-3 - Rev 1Document36 pagesELEC 3105 Building Services - Plumbing Services - 1-3 - Rev 1meeng2014No ratings yet

- Calculate ETTV and Green Mark PointsDocument8 pagesCalculate ETTV and Green Mark Pointsmeeng2014No ratings yet

- LPG tank and pipe size calculationsDocument2 pagesLPG tank and pipe size calculationsmeeng2014No ratings yet

- A Basic Design Guide For Clean Room ApplicationsDocument61 pagesA Basic Design Guide For Clean Room ApplicationsAlex Chin67% (3)

- Typical HVAC Rules of ThumbDocument2 pagesTypical HVAC Rules of Thumbmeeng2014No ratings yet

- Introduction and Welcome: David Barwell (2 Minutes)Document39 pagesIntroduction and Welcome: David Barwell (2 Minutes)meeng2014No ratings yet

- Cleanroom Technology HandbookDocument108 pagesCleanroom Technology Handbookmeeng2014100% (1)

- Honeywell DDC Panel ManualDocument512 pagesHoneywell DDC Panel ManualSyed ZakiuddinNo ratings yet

- 22.hvac Controls - InvensysDocument62 pages22.hvac Controls - Invensysmeeng2014No ratings yet

- Design Procedures ManualDocument77 pagesDesign Procedures Manualmeeng2014No ratings yet

- Ielts Essay Text Write Com Topic 1Document28 pagesIelts Essay Text Write Com Topic 1enesdertli100% (1)

- English Grammar - IELTS 2002 Handbook PDFDocument0 pagesEnglish Grammar - IELTS 2002 Handbook PDFNada AlaaNo ratings yet

- Balancing of Distribution SystemDocument35 pagesBalancing of Distribution Systemebru_alpaslan50% (2)

- Chilled Water System PresentationDocument119 pagesChilled Water System Presentationceo123456100% (4)

- Honeywell Engineering Manual of Automatic Control For Commercial BuildingsDocument518 pagesHoneywell Engineering Manual of Automatic Control For Commercial Buildingsmubashirhasan67% (3)

- C0498a-E17 (H) DWGDocument1 pageC0498a-E17 (H) DWGmeeng2014No ratings yet

- C0498a-E14 (B) DWGDocument1 pageC0498a-E14 (B) DWGmeeng2014No ratings yet

- C0498a-E16 (C) DWGDocument1 pageC0498a-E16 (C) DWGmeeng2014No ratings yet

- C0498a-E14 (B) DWGDocument1 pageC0498a-E14 (B) DWGmeeng2014No ratings yet

- C0498a-E07 (Q) DWGDocument1 pageC0498a-E07 (Q) DWGmeeng2014No ratings yet

- C0498a-E13 (E) DWGDocument1 pageC0498a-E13 (E) DWGmeeng2014No ratings yet

- C0498a-E07 (Q) DWGDocument1 pageC0498a-E07 (Q) DWGmeeng2014No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Z-SH1N EATON MOELLER Fuse Disconnectors, 1pole+n, 10 X 38Document1 pageZ-SH1N EATON MOELLER Fuse Disconnectors, 1pole+n, 10 X 38co_stel817842No ratings yet

- Install Outdoor Air Conditioner UnitsDocument82 pagesInstall Outdoor Air Conditioner UnitsJoseph NgNo ratings yet

- Efields PDFDocument73 pagesEfields PDFsydonai416No ratings yet

- SVS COLLEGE EEE QUESTION BANK UNIT I TRANSMISSION LINE PARAMETERSDocument20 pagesSVS COLLEGE EEE QUESTION BANK UNIT I TRANSMISSION LINE PARAMETERSFurqan WarisNo ratings yet

- Electronic Circuits Lab Manual 13-12-11 PDFDocument54 pagesElectronic Circuits Lab Manual 13-12-11 PDFREMALLI KeerthiNo ratings yet

- Topic 5 Power Meters 1Document9 pagesTopic 5 Power Meters 1PhanitAminoVichianratNo ratings yet

- Instrumentation Cable BSDocument42 pagesInstrumentation Cable BSShivaniNo ratings yet

- Survey of Control Methods For DC-DC Converters: KeywordsDocument6 pagesSurvey of Control Methods For DC-DC Converters: KeywordsBernardo GalvanoNo ratings yet

- Responce for Consultant's CommentsDocument189 pagesResponce for Consultant's Commentswsiim5718No ratings yet

- Kit 17. LM386 Low Voltage Audio Amplifier: Circuit DescriptionDocument2 pagesKit 17. LM386 Low Voltage Audio Amplifier: Circuit Descriptionszolid79No ratings yet

- rg6 Gripper Datasheet PDFDocument6 pagesrg6 Gripper Datasheet PDFRaj RajNo ratings yet

- BZX85 - C62Document5 pagesBZX85 - C62Luis Enrique PariapazaNo ratings yet

- Realization of Gates Using Discrete ComponentsDocument6 pagesRealization of Gates Using Discrete ComponentskishorebabNo ratings yet

- BP Res U2 Elect Symbols Outlets NoteDocument23 pagesBP Res U2 Elect Symbols Outlets NoteEdev Paula De VeraNo ratings yet

- Fas BoqDocument2 pagesFas Boqعامر شیخNo ratings yet

- Anna University Lab Manuals For Engineering Students Open Circuit & Short Circuit Test On A Single Phase TransformerDocument9 pagesAnna University Lab Manuals For Engineering Students Open Circuit & Short Circuit Test On A Single Phase TransformerLeonardoXanMNo ratings yet

- Havells ConsumerCables2020Document6 pagesHavells ConsumerCables2020juga2013No ratings yet

- Manual de Instalación Smart Energy Controller Sec1000 HybridDocument7 pagesManual de Instalación Smart Energy Controller Sec1000 HybridJavier Barranco LaraNo ratings yet

- Cables - Guide For Non-Destructive Diagnosis of Distribution Cable SystemsDocument72 pagesCables - Guide For Non-Destructive Diagnosis of Distribution Cable SystemscadtilNo ratings yet

- Circuit Elements and ParametersDocument30 pagesCircuit Elements and ParametersCarl PNo ratings yet

- EMC Plan For Metro PsDocument14 pagesEMC Plan For Metro PsXavi deMikaelNo ratings yet

- IJCRT1803270Document13 pagesIJCRT1803270Chandra Shekhar SahuNo ratings yet

- GE Mac 400 - Quick Guide PDFDocument7 pagesGE Mac 400 - Quick Guide PDFNur CholisNo ratings yet

- 1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECDocument61 pages1MRK505265-BEN - en Product Guide Busbar Protection REB650 IECRobert RocafuerteNo ratings yet

- Delvo Main CatDocument68 pagesDelvo Main CatVinhNo ratings yet

- PrayerDocument11 pagesPrayerJayson AttabanNo ratings yet

- 3M™ Scotchcast™ Flexible Power Cable Splicing Kits 82-F and 82-BF SeriesDocument3 pages3M™ Scotchcast™ Flexible Power Cable Splicing Kits 82-F and 82-BF SeriesTiyok HariNo ratings yet

- Manual Temporizador TH3M PDFDocument10 pagesManual Temporizador TH3M PDFMauricio Barraza FigueroaNo ratings yet

- Enter The Data Below: Sample PDF Only From Excel CalculationDocument1 pageEnter The Data Below: Sample PDF Only From Excel CalculationWilson (Electrical Engineer)No ratings yet

- Foundation, Electric Installation, Operation, and Maintenance GuideDocument32 pagesFoundation, Electric Installation, Operation, and Maintenance Guideapi-279886039No ratings yet