Professional Documents

Culture Documents

Cat 3412e

Uploaded by

Ed CalheOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cat 3412e

Uploaded by

Ed CalheCopyright:

Available Formats

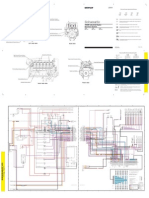

3412 E

548 bkW / 735 bhp 1800 rpm

Industrial CATERPILLAR ENGINE SPECIFICATIONS

V12, 4-Stroke-Cycle Diesel Bore......................................................... 137.2 mm (5.4 in) Stroke...................................................... 152.4 mm (6.0 in) Displacement..................................... 27.03 L (1,649.47 in3) Aspiration................................. Turbocharged / Aftercooled Compression Ratio.................................................... 15.6:1 Rotation (from flywheel end).................... Counterclockwise Capacity for Liquids Cooling System.......................................67.0 L (17.7 gal) Lube Oil System (refill)......................... 139.0 L (36.7 gal) Engine Weight, Net Dry (approximate).. 2,141 kg (4,720 lb) Image shown may not reflect actual engine

FEATURES

Emissions Non-Certified Rating. Meets Tier 1, Stage I emission requirements. Tier 1 refers to EPA (U.S.) standards. Stage I refers to European standards. Full Range of Attachments Wide range of bolt-on system expansion attachments, factory designed and tested. Unmatched Product Support Offered Through Worldwide Caterpillar Dealer Network More than 1,800 dealer outlets Caterpillar factory-trained dealer technicians service every aspect of your industrial engine 99.7% of parts orders filled within 24 hours worldwide Caterpillar parts and labor warranty Preventive maintenance agreements available for repair before failure options

Single Source Supplier Caterpillar - Casts engine blocks, heads, cylinder liners, and flywheel housings - Machines critical components - Assembles complete engine - Factory-designed systems built at Caterpillar ISO 9001:2000 certified facilities Ownership of these manufacturing processes enables Scheduled Oil Sampling program matches your oil Caterpillar to produce high quality, dependable product. sample against Caterpillar set standards to determine: - internal engine component condition - presence of unwanted fluids Testing - presence of combustion by-products Prototype testing on every model: - proves computer design Web Site - verifies system torsional stability - functionality tests every model For all your industrial power requirements, visit www.cat-industrial.com. Every Caterpillar engine is dynamometer tested under full load to ensure proper engine performance.

18 August 2005

4:20 AM

3412 E

INDUSTRIAL ENGINE

548 bkW (735 bhp)

STANDARD ENGINE EQUIPMENT

Air Inlet System Aftercooler core, corrosion resistant coated, Air cleaner, regular duty, dry, service indicators, panel type air cleaners, Dual turbochargers, Jacket water aftercooled Fuel System Fuel filter, RH with service indicators Fuel transfer pump Fuel priming pump

Aftercooler core, corrosion resistant coated, Air cleaner, Instrumentation regular duty, dry, service indicators, cylindrical air Instrument panel, RH cleaners, Turbocharged, Jacket water aftercooled Engine oil pressure gauge Fuel pressure gauge Control System Jacket water temperature gauge Governor, full range electronically controlled, Hydraulic Engine oil temperature electronic unit injection (HEUI) system, Air fuel ratio control, electronic, Electronic control module (ECM) Lube System Crankcase breather, top mounted Cooling System Oil cooler, RH Oil filler in valve cover and dipstick, RH Thermostats and housing, Jacket water pump, gear Oil filter, RH driven, centrifugal, RH Rear sump oil pan Exhaust System Exhaust manifold, dry, Exhaust elbow, dry 203 mm (8 in) Flywheels and Flywheel Housings Flywheel Flywheel Housing, SAE Standard Rotations Mounting System Supports General Paint, Caterpillar yellow Vibration damper Lifting eyes

18 August 2005

4:20 AM

3412 E

INDUSTRIAL ENGINE

548 bkW (735 bhp)

PERFORMANCE CURVES

IND - A (Continuous) - DM2531-01

Torque Nm

Metric

Engine Power kW

BSFC g/kW-hr

Engine Speed - rpm

Engine Speed Engine Power rpm kW 1800 1700 1600 1500 1400 1300 1200 1100 548 546 537 521 499 471 438 400

Torque Nm 2908 3066 3205 3319 3405 3460 3487 3476

BSFC g/kW-hr Fuel Rate L/hr 212.9 216.1 217.8 218.7 219 217.2 216.5 236.5 139.1 140.6 139.4 135.9 130.3 122.0 113.1 112.9

18 August 2005

4:20 AM

3412 E

INDUSTRIAL ENGINE

548 bkW (735 bhp)

RATINGS AND CONDITIONS

IND - A (Continuous) Continuous heavy duty service where the engine is operated at maximum power and speed up to 100% of the time without interruption or load cycling. Time at full load can be up to 100% of the duty cycle. Typical service examples are: pumping, ventilation, customer specs. Engine Performance Engine performance is corrected to inlet air standard conditions of 99 KPA (29.31 IN HG) dry barometer and 25 deg C (77 deg F) temperature. These values correspond to the standard atmospheric pressure and temperature as shown in SAE J1995. Performance measured using a standard fuel with fuel gravity of 35 degrees API having a lower heating value of 42,780 KJ/KG (18,390 BTU/LB) when used at 29 DEG (84.2 DEG F) where the density is 838.9 G/L (7.001 LB/US GAL). The corrected performance values shown for Caterpillar engines will approximate the values obtained when the observed performance data is corrected to SAE J1995, ISO 3046-2 and 8665 and 2288 and 9249 and 1585, EEC 80/1269 and DIN 70020 standard reference conditions.

Engine Dimensions

(1) Length (2) Width (3) Height 1995.4 mm 1483.4 mm 1496.1 mm

Note: Do not use for installation design. See general dimension drawings for detail (Drawing # 1362115 ).

Performance Number: DM2531-01 Feature Code: 412DI04 Materials and specifications are subject to change without notice. 5332206

2005 Caterpillar All rights reserved.

The International System of Units (SI) is used in this publication.

You might also like

- 3512B 1500RPM 1300KW BrochureDocument4 pages3512B 1500RPM 1300KW BrochuresalembatopNo ratings yet

- C15 Acert Spec SheetDocument4 pagesC15 Acert Spec SheetMalasquez Leon XavierNo ratings yet

- Cat 3306B DITA PropulsionDocument40 pagesCat 3306B DITA PropulsionStroe VladNo ratings yet

- 368kW Yanmar 6HY Marine Diesel PowerhouseDocument2 pages368kW Yanmar 6HY Marine Diesel PowerhouseRudy PriatnaNo ratings yet

- C32 Project Guide 1 PDFDocument32 pagesC32 Project Guide 1 PDFSyamsuri Sam100% (1)

- Mitsubishi S12a2-Mptk SpecsDocument1 pageMitsubishi S12a2-Mptk Specssilvia100% (2)

- Ds Pf8v71nDocument2 pagesDs Pf8v71nEsteban Medina Lemos100% (1)

- Basic Engine Model Curve Number: Marine Cummins EngineDocument2 pagesBasic Engine Model Curve Number: Marine Cummins EngineVincen Lim100% (2)

- Cylinder Head: SpecificationsDocument5 pagesCylinder Head: SpecificationsFares100% (1)

- fr4212 KTA19-G4Document4 pagesfr4212 KTA19-G4acere18No ratings yet

- Diesel Generator Sets Inventory ListingDocument4 pagesDiesel Generator Sets Inventory ListingIvan DumontNo ratings yet

- MEK Marine Yanmar Engine Spare PartsDocument6 pagesMEK Marine Yanmar Engine Spare PartsMEK Marine100% (1)

- S6a3mptk PDFDocument3 pagesS6a3mptk PDFYudhi PrasetyoNo ratings yet

- Specification D683 234.5KW 2300rpm Marine Engine PDFDocument31 pagesSpecification D683 234.5KW 2300rpm Marine Engine PDFKIJETYNo ratings yet

- SG Governor: This Manual Replaces Manual 04022Document56 pagesSG Governor: This Manual Replaces Manual 04022pcatruongNo ratings yet

- Mitsubishi S6B3 Operation & Maintenance ManualDocument120 pagesMitsubishi S6B3 Operation & Maintenance ManualRonald Booc100% (1)

- Kaluga Me STBDDocument8 pagesKaluga Me STBDLusy Gusti EfendiNo ratings yet

- Volvo Penta 200 KW TAD753GE EPA Tier 3 Emissions Engine Spec SheetDocument13 pagesVolvo Penta 200 KW TAD753GE EPA Tier 3 Emissions Engine Spec SheetJoanne CordesNo ratings yet

- M2000Document7 pagesM2000kylegazeNo ratings yet

- Caterpillar C15 FTH000001Document3 pagesCaterpillar C15 FTH000001Hendra MechanicNo ratings yet

- Cummins Part ListDocument134 pagesCummins Part ListOunna Pech100% (1)

- 6ltaa8.9g2 CPL43079 So30123Document12 pages6ltaa8.9g2 CPL43079 So30123Alexis SanchezNo ratings yet

- Overhaul (Major) : Manual de Operación y MantenimientoDocument3 pagesOverhaul (Major) : Manual de Operación y Mantenimientozona amrullohNo ratings yet

- V222TI Marine Engine Specs & RatingsDocument2 pagesV222TI Marine Engine Specs & RatingscmendezNo ratings yet

- Cylinder Head Options For G3412 EnginesDocument3 pagesCylinder Head Options For G3412 Enginesmuhammad arifNo ratings yet

- Static Injector TimingDocument12 pagesStatic Injector TimingMohamed Mohamed100% (1)

- C32 Acert 1300Bhp 2100rpm SpecDocument17 pagesC32 Acert 1300Bhp 2100rpm SpecAidel MustafaNo ratings yet

- K38 Rocker HousingDocument13 pagesK38 Rocker HousinghindraNo ratings yet

- CAT 3412 General InformationDocument7 pagesCAT 3412 General InformationCEVegaO100% (1)

- Cummins K38, KT38, KTA38 Inframe-Overhaul Engine Rebuild KitDocument2 pagesCummins K38, KT38, KTA38 Inframe-Overhaul Engine Rebuild Kitfelix amador100% (2)

- Water PumpDocument6 pagesWater PumpblujekNo ratings yet

- Oil ValveDocument4 pagesOil ValveGolbert GolbiNo ratings yet

- Eliminator™ FilterDocument35 pagesEliminator™ FiltertstkupdhNo ratings yet

- Caterpillar 3412 Marine Engine Details, Specs, Features & ExtrasDocument5 pagesCaterpillar 3412 Marine Engine Details, Specs, Features & ExtrasTobias Bengtsen100% (1)

- Marine Diesel Generators 6 W126S Technical SpecificationsDocument2 pagesMarine Diesel Generators 6 W126S Technical SpecificationsirdawanNo ratings yet

- Service Drawings: KTA38 Engine PlatformDocument19 pagesService Drawings: KTA38 Engine PlatformMehdi Chakroune100% (1)

- 3606&3608 Mar PRJ Guide - LEBM0600Document124 pages3606&3608 Mar PRJ Guide - LEBM0600della alNo ratings yet

- L100N5 Getm3 PDFDocument17 pagesL100N5 Getm3 PDFkarol1177No ratings yet

- Manual DDFPDocument92 pagesManual DDFPCarlos VegaNo ratings yet

- Pressure Test D16F Cylinder HeadDocument4 pagesPressure Test D16F Cylinder HeadbabyNo ratings yet

- 6ha2m WHTWDTDocument2 pages6ha2m WHTWDTdha100% (1)

- Overhead Set (OBC)Document19 pagesOverhead Set (OBC)MohamedNo ratings yet

- Marine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMDocument2 pagesMarine Generator Set: 30.0 Ekw (60 HZ) at 1800 RPM 24.5 Ekw (50 HZ) at 1500 RPMByron CheleNo ratings yet

- Parts Catalogue 6CTAA-8.3-G4Document125 pagesParts Catalogue 6CTAA-8.3-G4Joko Irawanto100% (2)

- D2842 Heavy DutyDocument4 pagesD2842 Heavy Dutym_najman100% (2)

- Crankshaft Form MeasurementDocument1 pageCrankshaft Form MeasurementHendriHendrianto100% (2)

- N855 CCEC: Marine Propulsion and Auxiliary Engines For Commercial ApplicationsDocument2 pagesN855 CCEC: Marine Propulsion and Auxiliary Engines For Commercial ApplicationsTRVL TRFNo ratings yet

- SS815Document24 pagesSS815Adel Ahmed100% (1)

- Lampiran 2 Lampiran Penawaran Harga: Pengadaan Filter Untuk Kebutuhan Motor Induk Dan Motor Bantu Kapal Perintis 2021Document10 pagesLampiran 2 Lampiran Penawaran Harga: Pengadaan Filter Untuk Kebutuhan Motor Induk Dan Motor Bantu Kapal Perintis 2021Deni prastiyoNo ratings yet

- Cummins n855 Engine Specs PDF FreeDocument6 pagesCummins n855 Engine Specs PDF Freema.powersourceNo ratings yet

- Caterpillar 3408C, 3412C and 3412D High Performance Marine Engine GuideDocument6 pagesCaterpillar 3408C, 3412C and 3412D High Performance Marine Engine GuideYudha GaganNo ratings yet

- Kta38 DM1Document2 pagesKta38 DM1samir badriNo ratings yet

- Crankshaft As 3849907 - Caterpillar d10tDocument1 pageCrankshaft As 3849907 - Caterpillar d10tgraha networkNo ratings yet

- 3512B SD Engines Maintenance IntervalsDocument4 pages3512B SD Engines Maintenance Intervalsharikrishnanpd3327No ratings yet

- Cummins 6BTA5.9 parts catalog and service recommendationsDocument129 pagesCummins 6BTA5.9 parts catalog and service recommendationsinggavNo ratings yet

- Manual de Partes QSK45Document173 pagesManual de Partes QSK45ChristianM.Carrasco100% (1)

- Caterpillar Marine InformationDocument58 pagesCaterpillar Marine InformationTrunk DangNo ratings yet

- Motor Caterpillar 3516BDocument5 pagesMotor Caterpillar 3516BCesar Calle JimenezNo ratings yet

- Genset 2Document4 pagesGenset 2wiwitsetiyadiNo ratings yet

- Cat 3512 1280HP A RatingDocument4 pagesCat 3512 1280HP A RatingingjoseosunaNo ratings yet

- 3500B Industrial Engine Electrical System: Left Side View Rear ViewDocument2 pages3500B Industrial Engine Electrical System: Left Side View Rear ViewEd Calhe0% (1)

- Whitepaper Fuel SystemsDocument8 pagesWhitepaper Fuel SystemsQaiser Iqbal100% (4)

- Datasheet 2494Document1 pageDatasheet 2494Ed CalheNo ratings yet

- 3406Document2 pages3406Ed CalheNo ratings yet

- Calibrating Pressure GaugesDocument4 pagesCalibrating Pressure GaugesRonny AndalasNo ratings yet

- JCB JS EXCAVATOR HAMMERS GUIDEDocument1 pageJCB JS EXCAVATOR HAMMERS GUIDEEd CalheNo ratings yet

- Volvo Prosis 2013 VMDocument2 pagesVolvo Prosis 2013 VMEd CalheNo ratings yet

- WOMA Technical Data All Pumps en MedidasDocument11 pagesWOMA Technical Data All Pumps en MedidasEd CalheNo ratings yet

- Brant AgitatorDocument68 pagesBrant AgitatorEd CalheNo ratings yet

- WarrenCATDynoReport2 3508Document11 pagesWarrenCATDynoReport2 3508Ed CalheNo ratings yet

- CompetitorsDocument4 pagesCompetitorsEd CalheNo ratings yet

- CompetitorsDocument4 pagesCompetitorsEd CalheNo ratings yet

- !rex Roller To Part Book TableDocument1 page!rex Roller To Part Book TableEd Calhe0% (1)

- IADC Dull Bit Grading Chart GuideDocument1 pageIADC Dull Bit Grading Chart GuideanarkasisNo ratings yet

- 261 267Document7 pages261 267Ed CalheNo ratings yet

- Testing and Adjusting Cat 3412 SN 3fzDocument21 pagesTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- Grooy D9Awiñg'S: Cam LineDocument1 pageGrooy D9Awiñg'S: Cam LineEd CalheNo ratings yet

- System Operation Mechanical Cat 3306 SN EpsDocument37 pagesSystem Operation Mechanical Cat 3306 SN EpsEd Calhe94% (18)

- 3 Way Direct Acting Solenoid Valve SV83Document4 pages3 Way Direct Acting Solenoid Valve SV83Ed CalheNo ratings yet

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalheNo ratings yet

- Oteco Shear Pin Relief Pressure SettingsDocument1 pageOteco Shear Pin Relief Pressure SettingsEd Calhe100% (1)

- Request for Equipment Repair PartsDocument1 pageRequest for Equipment Repair PartsEd Calhe100% (1)

- KG Act 3121269Document24 pagesKG Act 3121269Gustavo KemeñyNo ratings yet

- Power Swivel Torque ReactionDocument6 pagesPower Swivel Torque ReactionEd CalheNo ratings yet

- Melco Type F and FC Manual Valve PartsDocument4 pagesMelco Type F and FC Manual Valve PartsEd CalheNo ratings yet

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalheNo ratings yet

- Top Driven Bowen BarcoDocument65 pagesTop Driven Bowen BarcoingcalderonNo ratings yet

- Westrom Cameron PartsDocument22 pagesWestrom Cameron PartsEd CalheNo ratings yet

- Cylinder Injector Readings ReportDocument9 pagesCylinder Injector Readings ReportEd CalheNo ratings yet

- Strippers JU y JU HDocument5 pagesStrippers JU y JU HEd CalheNo ratings yet

- Vicks Humidifier V745a ManualDocument5 pagesVicks Humidifier V745a ManualOrly Genoune HenkinNo ratings yet

- Engineering Management Painting SpecificationsDocument15 pagesEngineering Management Painting SpecificationsPaula MontalvoNo ratings yet

- Design of Steel ISMC 300 Member for Axial and Bending LoadsDocument1 pageDesign of Steel ISMC 300 Member for Axial and Bending LoadsAnand.5No ratings yet

- Dvm+s+y+joint Mcu+port+twin Submittal 09192018Document3 pagesDvm+s+y+joint Mcu+port+twin Submittal 09192018Luis Fernado PaizNo ratings yet

- Week 2 Module - CHEMDocument13 pagesWeek 2 Module - CHEMMichael AustriaNo ratings yet

- Series: Standard Product CapabilitiesDocument4 pagesSeries: Standard Product Capabilitiespmfg847633No ratings yet

- Plastic ShredderDocument23 pagesPlastic ShredderJojimar JulianNo ratings yet

- PEB Specification and Standards With DetailsDocument15 pagesPEB Specification and Standards With DetailsMujjo SahbNo ratings yet

- Cat 03a en Compact Conductor System VKS10Document25 pagesCat 03a en Compact Conductor System VKS10quang.an185No ratings yet

- Production of Aniline by Hydrogenation of NitrobenzeneDocument15 pagesProduction of Aniline by Hydrogenation of Nitrobenzeneananya srivastavaNo ratings yet

- ProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Document1 pageProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Araujo Felipe AndrésNo ratings yet

- Ce133p 2 WSD NSCP 2015Document2 pagesCe133p 2 WSD NSCP 2015RapNo ratings yet

- Steel ConstructionDocument46 pagesSteel ConstructionKhadeeja AslamNo ratings yet

- An Accelerator Free Peroxide Vulcanization TechniqueDocument17 pagesAn Accelerator Free Peroxide Vulcanization TechniqueClinton ThomsonNo ratings yet

- Ten Points For Safe LiftDocument8 pagesTen Points For Safe LifthazopmanNo ratings yet

- Harduaganj Thermal Power Plant by Geetesh SharmaDocument66 pagesHarduaganj Thermal Power Plant by Geetesh Sharmageeteshaccurate100% (1)

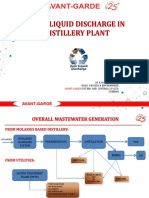

- Avant-Garde Mr. K Mohan KumarDocument46 pagesAvant-Garde Mr. K Mohan KumarSivakumar SelvarajNo ratings yet

- Ieee STD C57 100-1995Document4 pagesIeee STD C57 100-1995José Enrique García VillarrealNo ratings yet

- Beggs & Brill MethodDocument9 pagesBeggs & Brill Methodmatrix69No ratings yet

- Steam Reformer Pigtail Failures PDFDocument5 pagesSteam Reformer Pigtail Failures PDFHariharasudhanNo ratings yet

- Pcw-Ts-Pcs Design Process 2017Document89 pagesPcw-Ts-Pcs Design Process 2017Marlon ReonicoNo ratings yet

- 13 SH Cutting Tools R11Document65 pages13 SH Cutting Tools R11Richard ZawNo ratings yet

- NGK Spark Plug SchemeDocument1 pageNGK Spark Plug Schemeiskra vasileva100% (1)

- Pds-Cassida Rls GR 0Document3 pagesPds-Cassida Rls GR 0Milena GonzalezNo ratings yet

- Bullet Valve Series GuideDocument2 pagesBullet Valve Series GuideAnthony PecorinoNo ratings yet

- Application of FRC in Construction of The Underground Railway TrackDocument8 pagesApplication of FRC in Construction of The Underground Railway TrackClaudio PazNo ratings yet

- 1 s2.0 S0263822315001993 MainDocument10 pages1 s2.0 S0263822315001993 MainShree BiradarNo ratings yet

- AMMIE 2023 Conference on Advanced Materials and ManufacturingDocument9 pagesAMMIE 2023 Conference on Advanced Materials and ManufacturingrjNo ratings yet

- Glossery of Terms: AggregateDocument7 pagesGlossery of Terms: AggregateAssane RoqueNo ratings yet