Professional Documents

Culture Documents

Product Overview To Road Layer Works Material

Uploaded by

anon_b186Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Overview To Road Layer Works Material

Uploaded by

anon_b186Copyright:

Available Formats

Build with Confidence

Road layer works material

Aggregate - product brochure

Road layer works material

Road layer works material

Product overview Base and subbase materials are those materials that provide the supporting structure in any pavement design. Material specifications Aggregate for crushed - stone base or subbase shall be derived from hard, sound and durable rock. AfriSam aggregates comply to specifications as listed in the following tables.* Material overview table.

Use

Base and subbase

curve is then classified as the approved target grading for a specific project. All future gradings are evaluated against the target grading in accordance with specified tolerances. Aggregate for G1 to G3 materials

Property Grading limits, % (m/m) passing sieve sizes, mm 53,0 37,5 26,5 100 84 - 94 71 - 84 59 - 75 36 - 53 23 - 40 11 - 24 4 - 12 100 85 - 95 71 - 84 42 - 60 27 - 45 13 - 27 5 - 12 from COLTO table 3602/1 COLTO requirements 37,5 mm G1 - G3 26,5 mm G3

Material

G1 G2 G3

Nominal maximum size, mm

37,5

Additional fines allowed

Only from parent rock Up to 10% natural fines*

19,0 13,2 4,75 2,00 0,425 0,075

37,5 or 26,5

Crushed: 37,5 and 26,5 Uncrushed: 53

Up to 15% natural fines* Natural materials

Pavement G4 layers

G5 G6

Crushed: 53 Uncrushed: 63 Crushed: 53 Uncrushed: 2/3 of compacted layer thickness

G7

Crushed: 75 Uncrushed: 2/3 of compacted layer thickness

N/A

The aggregates used for crushed stone base shall comply with the requirements reflected on the crushing value tables below. 10% Fines aggregate crushing values

Rock type Matrix Dry min 140 kN Wet min Wet/dry relationship min 75%

from COLTO tables 3602/1 and 3402/1

Grading requirements for approved target grading, tolerances and coarse sand ratio For base and subbase, the mean grading (a minimum of six results) of the trial section (prior to compaction) meeting the grading limits and the requirements for approved target grading is determined. A smooth grading

Arenaceous rocks

Non-siliceous cementing material Siliceous cementing material

110 kN

75%

Diamictites (tillite) Argillaceous rocks Other rock types

200 kN

70%

180 kN

125 kN

110 kN

75%

from COLTO table 3602/2

Aggregate crushing value

Rock type Arenaceous rocks: without siliceous cementing matrix Arenaceous rocks: with siliceous cementing matrix Diamictites (tillite) Argillaceous rocks Other rock types ACV, max 27% 29% 21% 24% 29% from COLTO table 3602/3

Note: To ascertain where the various types of AfriSam aggregate would fall within the above table, please contact the technical services department.

Road layer works material

Aggregate flakiness index

Property Flakiness index, % maximum (-26,5 + 19,0) and (-19 + 13,2) mm fractions COLTO requirements 35 (All faces fractured for G1; at least one fractured face on half of stone particles for G2 and G3) from COLTO table 3602/1

Aggregate for G5 - G7 Gradings on these materials are mainly determined by a grading modulus as prescibed by COLTO. Atterberg limits G1 - G7 Atterberg limits are in accordance with the SABS/ THM1 test methods. Test results are conducted using - 0.425 mm fraction. The arithmetic mean of the PIs for a lot (a minimum of six tests) shall be used to determine the result. Note: All SABS specifications will be replaced by SANS specifications, but the data contained therein will remain constant. Note: All typical gradings and water demands may be obtained, on request, from the product technical department. *Note: As members of ASPASA (Aggregate & Sand Producers Association of South Africa) we comply with COLTO specifications except where amended by ASPASA.

Grading requirements on approved target for G4 material Aggregate for G4 materials

% Passing through sieve by map Crushed materials Grading limits, % (m/m) passing sieve sizes, mm 53,0 37,5 26,5 19,0 13,2 4,75 2,00 0,425 0,075 100 84 - 94 71 - 84 59 - 75 36 - 53 23 - 40 11 - 24 4 - 12 100 85 - 95 71 - 84 42 - 60 27 - 45 13 - 27 5 - 12 30 - 65 20 - 50 10 - 30 5 - 15 from COLTO table 3402/1 60 - 90 Nominal maximum size 37,5 mm Nominal maximum size 26,5 mm Uncrushed materials 53,0 mm

100 85 - 100

Road layer works material

Road layer works material

Aggregate Quarry Locations Gauteng KwaZulu-Natal Eikenhof Coedmore Ferro Ladysmith Jukskei Newcastle Olifantsfontein Pietermaritzburg Roodekrans Umlaas Rooikraal Verulam Vogels Zeekoewater Western Cape Peninsula Philippi (Depot) Rheebok

Contact the regional office in your area for Sales or Technical Services or any other information. Gauteng: 0860 141 141 KwaZulu-Natal: 0800 313 151 Western Cape: 0860 009 114 customer.service@za.afrisam.com www.afrisam.com (011) 670 5666 (031) 460 9000 (021) 659 3100

May 2008 AfriSam South Africa

17358

You might also like

- Smart Logger 3000 ADocument1 pageSmart Logger 3000 Aanon_b186No ratings yet

- TDP - 2019 - Public - Forum - Presentation - 30 - Oct2019 - Final1Document223 pagesTDP - 2019 - Public - Forum - Presentation - 30 - Oct2019 - Final1anon_b186No ratings yet

- Tender Notice and Invitation To TenderDocument1 pageTender Notice and Invitation To Tenderanon_b186No ratings yet

- Suffering From Hypertension?: Get The Covid-19 Vaccine As Soon As You QualifyDocument1 pageSuffering From Hypertension?: Get The Covid-19 Vaccine As Soon As You Qualifyanon_b186No ratings yet

- Doubts Raised On The Validity of Construction and Payment GuaranteesDocument26 pagesDoubts Raised On The Validity of Construction and Payment Guaranteesanon_b186No ratings yet

- Smart Logger 3000 ADocument1 pageSmart Logger 3000 Aanon_b186No ratings yet

- Industry Circular: Page 1 of 2Document2 pagesIndustry Circular: Page 1 of 2anon_b186No ratings yet

- Doubts Raised On The Validity of Construction and Payment GuaranteesDocument26 pagesDoubts Raised On The Validity of Construction and Payment Guaranteesanon_b186No ratings yet

- Tender Notice and Invitation To TenderDocument1 pageTender Notice and Invitation To Tenderanon_b186No ratings yet

- Industry Circular: Page 1 of 2Document2 pagesIndustry Circular: Page 1 of 2anon_b186No ratings yet

- SolarQuarter December Issue 2018 Final Print-CompressedDocument44 pagesSolarQuarter December Issue 2018 Final Print-Compressedanon_b186No ratings yet

- ANSI Codes PDFDocument3 pagesANSI Codes PDFelectrical_1012000100% (2)

- Tender Notice - Renewable Engineering Services - NDT0013-19Document1 pageTender Notice - Renewable Engineering Services - NDT0013-19anon_b186No ratings yet

- TECHNO SUN Solar Photovoltaic Price List ENDocument73 pagesTECHNO SUN Solar Photovoltaic Price List ENanon_b186No ratings yet

- Ford Ecosport ManualDocument199 pagesFord Ecosport ManualMUHAMMAD TAUSEEF SABIR0% (1)

- From 2340 To 7200 kVA: Medium Voltage Inverter Station, Customized Up To 7.2 MvaDocument2 pagesFrom 2340 To 7200 kVA: Medium Voltage Inverter Station, Customized Up To 7.2 Mvaanon_b186No ratings yet

- Paling BillDocument5 pagesPaling Billanon_b186No ratings yet

- GuidelineDocument15 pagesGuidelineanon_b186No ratings yet

- Design, Construction and Commissioning of A Tank Farm Facility in Zone 10 of The Coega SezDocument1 pageDesign, Construction and Commissioning of A Tank Farm Facility in Zone 10 of The Coega Sezanon_b186No ratings yet

- The Art & Science of Protective Relaying - C. Russell Mason - GEDocument357 pagesThe Art & Science of Protective Relaying - C. Russell Mason - GEAasim MallickNo ratings yet

- Condensed Installation & Operating Procedures: Technical BulletinDocument5 pagesCondensed Installation & Operating Procedures: Technical Bulletinanon_b186No ratings yet

- Electrical Products - FinalDocument8 pagesElectrical Products - Finalanon_b186No ratings yet

- Electrical Products - FinalDocument8 pagesElectrical Products - Finalanon_b186No ratings yet

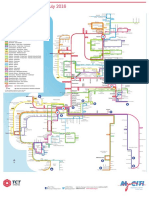

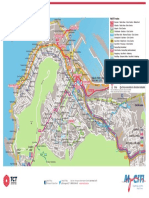

- 697 System MapDocument1 page697 System Mapanon_b186No ratings yet

- Central City Routes - 2 July 2016Document1 pageCentral City Routes - 2 July 2016anon_b186No ratings yet

- Arcade Machines - Arcade Ga...Document5 pagesArcade Machines - Arcade Ga...anon_b186No ratings yet

- Travel Logbook: South African Revenue ServiceDocument27 pagesTravel Logbook: South African Revenue Serviceanon_b186No ratings yet

- Arcade Machines - Arcade Ga...Document5 pagesArcade Machines - Arcade Ga...anon_b186No ratings yet

- Travel Logbook: South African Revenue ServiceDocument27 pagesTravel Logbook: South African Revenue Serviceanon_b186No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Lecture-14 Sheet Metal Forming ProcessesDocument34 pagesLecture-14 Sheet Metal Forming ProcessesDida KhalingNo ratings yet

- Rigging Guide 2008Document222 pagesRigging Guide 2008Alex1No ratings yet

- ELEC 4170 1 Diode Rectifiers Fall 2022Document14 pagesELEC 4170 1 Diode Rectifiers Fall 2022Tafheem AlphaNo ratings yet

- Metal Q Clip System Brochure PDFDocument5 pagesMetal Q Clip System Brochure PDFSunil Dinanath JoshiNo ratings yet

- Viscous Fluid Flow Problem Set No. 3 Dr. A. Kebriaee Due Date: Sat.31 FarvardinDocument2 pagesViscous Fluid Flow Problem Set No. 3 Dr. A. Kebriaee Due Date: Sat.31 FarvardinmohammadtariNo ratings yet

- NEMA Enclosure TypeDocument6 pagesNEMA Enclosure TypeKumar MadhuNo ratings yet

- Waste TreatmentDocument8 pagesWaste TreatmentJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- January 2015 (IAL) MS - Unit 3 Edexcel Physics A-LevelDocument10 pagesJanuary 2015 (IAL) MS - Unit 3 Edexcel Physics A-LevelDaianna PeirisNo ratings yet

- Power Xpert Power Quality Meters: Product FocusDocument20 pagesPower Xpert Power Quality Meters: Product FocusMike MendozaNo ratings yet

- ROS Installation Guide: RequirementsDocument2 pagesROS Installation Guide: RequirementsLiz QuartzNo ratings yet

- Progressreport WritingDocument16 pagesProgressreport WritingSheraz AliNo ratings yet

- Assembly Language 8086 Exercise Solution (Marut) PDFDocument58 pagesAssembly Language 8086 Exercise Solution (Marut) PDFShaibal Ahmed56% (9)

- Microwave JunctionsDocument20 pagesMicrowave JunctionsSaraswathi Asirvatham100% (2)

- EXPERIMENT Heat BalanceDocument7 pagesEXPERIMENT Heat BalanceYogesh Shekhawat100% (2)

- JUMONG General (JMPS) Installation Manual - en - CMP200 - 20181129Document44 pagesJUMONG General (JMPS) Installation Manual - en - CMP200 - 20181129Juan Alberto RomeroNo ratings yet

- Digital Timer Modulator With Diagnostic Readout: Operating Instructions (701 10 Series)Document4 pagesDigital Timer Modulator With Diagnostic Readout: Operating Instructions (701 10 Series)Alex ConstantinescuNo ratings yet

- Extended Cell ConfigurationDocument31 pagesExtended Cell Configurationrfabre76No ratings yet

- Smore StoichiometryDocument4 pagesSmore Stoichiometry임민수No ratings yet

- Bottom Failure - Annex K - en 14015 - Rev 3Document3 pagesBottom Failure - Annex K - en 14015 - Rev 3KP SahuNo ratings yet

- حالات تحميل الرياح والزلازل للكود الجديد PDFDocument3 pagesحالات تحميل الرياح والزلازل للكود الجديد PDFmohamedmararNo ratings yet

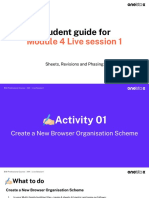

- M04 - L01 - Student GuideDocument9 pagesM04 - L01 - Student GuideShreyasNo ratings yet

- Valve Catalogue General Imsubs Pvt. Ltd.Document20 pagesValve Catalogue General Imsubs Pvt. Ltd.Spark MeditechNo ratings yet

- 014 A5.2 Floor FinishesDocument1 page014 A5.2 Floor FinishesqgfytzvqabzqrxyilmNo ratings yet

- M4700Document4 pagesM4700kylegazeNo ratings yet

- Joint and Combined Variation: Round Your Answer To Two Decimal PlacesDocument2 pagesJoint and Combined Variation: Round Your Answer To Two Decimal PlacesMarianne Peligro Marasigan0% (1)

- 1465914490CL June 2016 PDFDocument48 pages1465914490CL June 2016 PDFCoolerAdsNo ratings yet

- Non-Concurrent Space ForcesDocument2 pagesNon-Concurrent Space ForcesJessica De GuzmanNo ratings yet

- Dental Clinic - ResearchDocument10 pagesDental Clinic - ResearchAmorphus ViNo ratings yet

- Design Simulation Manufacture and Testingof A Free-Piston Stirling Engine - Ivan Niell Deetlefs PDFDocument138 pagesDesign Simulation Manufacture and Testingof A Free-Piston Stirling Engine - Ivan Niell Deetlefs PDFJorge ValianteNo ratings yet