Professional Documents

Culture Documents

Yamaha

Uploaded by

bonker508Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Yamaha

Uploaded by

bonker508Copyright:

Available Formats

How Organizations Handle Change – Yamaha Motors India

TABLE OF CONTENETS

TOPIC PAGE NO.

Acknowledgement 2

Yamaha Motors India 3

Industry Situation 4

What Triggered Change 6

Changes Outlined 7

Broad Cultural Change 8

The Productions Aspect 10

The Quality Control Aspect 12

The Human Resource Aspect 14

The Finance Aspect 16

Conclusion 17

Annexures 18

Prof . Nomita Kapoor Page 1

How Organizations Handle Change – Yamaha Motors India

ACKNOWLEDGEMENT

Our Project on How Change is handled in Corporate was centered around Yamaha

Motors India Ltd . The project won’t have been possible without the help and guidance

of members of the aforementioned organization and we would like to take this

opportunity to thank all of them :

Mr. V . K Mishra , Manager – Manufacturing , for lending his valuable time and

explaining the impact of Yamaha’s new production policies on the organization .

Mr. Anil Nanda , Manager – Quality Assurance , for his detailed brief about the

Quality control department and changed that it underwent after Yamaha took over .

Mr M . K . Jaggi , Manager – Safety , for his valuable inputs regarding the Human

Resource aspect of change how was it embraced by employees .

Mr P . K . Khanna , Manager – Financial Accounting , for explaining what were the

financial implications of the split and how were financial matters handled durig the

change .

A special thanks to Mr A . K Ahuja , who made personal efforts to make our audience

with the management of Y.M.I possible .

Finally , a word of gratitude for Mr Nitin Kapoor who accompanied us during our visit

to the plant in Surajpur and took care of all bottlenecks .

Prof . Nomita Kapoor Page 2

How Organizations Handle Change – Yamaha Motors India

YAMAHA MOTORS INDIA

The first ever Press release made by Y.M.I was as follows :

“An agreement has recently been reached between Yamaha Motor Co., Ltd. (YMC) and

its joint venture partner in India, Escorts Limited (Chairman and Managing Director:

Mr. Rajan Nanda. Location: Faridabad, suburbs of New Delhi) under which YMC will

acquire all of the 26% of the stock presently held by Escorts Limited in the two

companies' motorcycle manufacturing and marketing joint venture, Yamaha Motor

Escorts Ltd. (YMEL).

The aims of this move to make Yamaha Motor Escorts a 100% YMC subsidiary are to

increase the overall speed of managerial and business decisions, to improve product

development capabilities and production efficiency, while also strengthening the

marketing organization. Plans call for the change in the company's name and other

procedures to be completed by the end of June.

In addition to YMC acquiring Escorts' 26% of YMEL stock, the company's name will be

changed to Yamaha Motor India Private Limited (YMI) and concerted efforts will be

made to heighten its competitiveness in the Indian market and promote the spread of the

Yamaha brand with target themes of developing products with greater appeal and a

distribution network that can respond more quickly to user needs.”

As a company , YMI is only 3 years old in the Indian Motorcycle market . However

Yamaha has had a presence in this sector for over 18 years ever since it entered into a

technical collaboration with Escorts motors in 1985 .

Ever since the establishment of the first technical assistance agreement between the two

companies in 1985, YMC and Escorts Limited have built a cooperative relationship

dedicated to the manufacture and sales of Yamaha brand motorcycles in an environment

of growing motorcycle demand in the Indian market. In November of 1995, the two

companies established the joint venture company Escorts Yamaha Motor Limited, based

on a 50-50 capital investment. In June of 2000, that investment ratio was changed to 74%

for YMC and 26% for Escorts Limited and YMC assumed managerial control of the

company with the name being changed to YMEL and undertook numerous measures to

build the company's motorcycle manufacturing and marketing operations.

The next logical progression for Yamaha was obviously assuming full control of

Indian operations . This is precisely the change which we are going to study in this

research . We shall try to understand the phases which an organization goes through

during the process of change . How employees at all levels react to a Multi National

Corporation taking control of their jobs ? How change is viewed by various

departments and divisions in the organization and the role played by them in

successful implementation of change.

Prof . Nomita Kapoor Page 3

How Organizations Handle Change – Yamaha Motors India

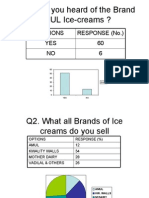

INDUSTRY SITUATION

Forget the four-wheeler revolution everybody's talking about in India. The real action is

taking place not on the freeways but on the country's side roads, alleys and dusty streets.

That is where the nearly half a dozen motorbike manufacturers are introducing one glitzy

product after the other, toting up sales and bringing excitement into a market that has lain

dormant for quite some time.

The sector is bristling with brands, colors and engine sizes. Over the next six months, 12

new bike models are scheduled to hit the Indian roads. During the last financial year

(April 1, 2002 to March 31, 2003), the Indian motorbike industry posted sales growth of

28 percent, according to data compiled by the Society of Indian Automobile

Manufacturers. This is considered a significant achievement, all the more since many

sectors of the Indian economy are still struggling to come out of the recession that crept

in two years ago.

The local subsidiary of Japan's Yamaha Motor Company introduced a new model,

Enticer. The company recorded a 21.4 percent rise in sales. Sales of LML and Kinetic

Engineering went up by 16.7 percent and 29.4 percent respectively. Royal Enfield

Motors, whose rugged 250cc and 500cc Bullet bike are sold on the strength of the catchy

ad line "Let the boys have their toys", recorded 16.6 percent growth.

Unlike the four-wheeler segment, where only one Japanese manufacturer, Suzuki, has

been able to make a significant dent, in motorbikes it is the Japanese all the way. Honda

has a 26 percent stake in market leader Hero Honda. Yamaha broke away some years ago

from Escorts, a major Indian manufacturer of tractors. Even Bajaj Auto has a technical

collaboration with Kawasaki of Japan.

On average, the purchase of a brand new bike will set back an interested soul by about Rs

40,000 (US$845) - a big amount by Indian standards. But buyers don't blink an eyelid

thanks to the attractive finance options offered by banks and financial institutions, as well

as the motorbike manufacturers themselves. Then there are the goodies thrown in: a free

three-day, two-night, holiday; a gold pendant and in the case of TVS Motor, whose brand

ambassador is Sachin Tendulkar, a dinner with the cricketing maestro for the winner of a

lucky draw.

Finally, another reason for the surge in motorbike sales is the targeting of most marketing

and sales efforts towards the youth segment. The motorbike, which earlier stood for a

secondary mode of transportation for the guy who could not afford a car, is now being

promoted as a symbol of freedom, of exuberance, of convenience. Surf through the 120-

odd Indian TV channels and you can't help noticing a recurring theme - the beautiful girl

rides pillion with the guy having the smartest looking motorbike.

Prof . Nomita Kapoor Page 4

How Organizations Handle Change – Yamaha Motors India

At the entry level (below Rs 35,000), it is Bajaj Auto which rules the roost with a 46.5

percent market share. TVS Motor follows with 23.6 percent. The third place is taken

up by Hero Honda (19 percent). In the executive segment (Rs 35,000 to Rs 45,000) of

the Indian motorbike market, the top three slots are held by Hero Honda, TVS Motor

and Bajaj Auto at 68.2, 22.1 and 6.2 percent, respectively. But with a 42 percent market

share, Bajaj Auto is a clear winner in the premium segment, followed by Hero Honda

(27.8 percent) and Yamaha (24.02 percent).

Even though Indian motorbike manufacturers are now gung-ho about the market and are

planning new launches, barely six months ago they were worried about the threat of

cheap Chinese imports. But the Chinese threat fizzled out before it could materialize.

Take the case of Bajaj Auto's turnaround. For a long time it was the undisputed king of

the Indian two-wheeler market, mainly on the strength of its dominance in the scooters

category. But Bajaj Auto made a fundamental mistake - for a long time it made

consumers stick to scooters long after they had started romancing the motorbike. When

Bajaj Auto realized its mistake, it was too late, and new entrants like Hero Honda had

stolen the march.

But a bigger consolidation seems to be taking place in south India where last month TVS

Motor announced that its turnover will leap by 52 percent to Rs 29 billion this financial

year, riding on the back of rising motorbike sales. The company plans to overtake Bajaj

Auto to become India's second largest two-wheeler maker next fiscal. In 2003-04, it

expects a turnover of Rs 35 billion.

Much of TVS Motor's good fortunes have come via the launch of its runaway hit, the

Victor. Even though the Victor was launched 18 months ago with a stress on style and a

contemporary look, it is still setting the cash registers ringing. TVS is planning to push

volumes of the Victor from 40,000 to 50,000 units a month by June. The company is

launching two variants of the Victor in August 2003 - one will have a sleeker and more

stylish look while the other will be a rugged version targeted at the semi-urban market.

TVS Motor is also thinking of manufacturing new models at surplus land that it has near

Mysore in Karnataka state.

The market has opened up and now every manufacturer wants to be a national player. But

simultaneously, competition too has become stiffer. Who grabs a bigger share of the pie,

therefore, will depend not on where they are located, but how smartly they can read the

market, re-jig their strategies and how quickly they can introduce a new model - or

upgrade a best-seller.

Prof . Nomita Kapoor Page 5

How Organizations Handle Change – Yamaha Motors India

WHAT TRIGGERED CHANGE

The change cannot be said to have happened overnight . The gradual process had begun

ever since Yamaha progressed from being a technical collaborator to a stakeholder in the

organization . The fact that the transformation was bloodless bears proves that interests of

both the parties were served by this change . The macro cause for the change was

Escorts Yamaha’s sliding share in the Motorcycle Market . In the light of growing

competition , both parties deemed it fit to part ways . How it was seen as beneficial

for both parties can be explained in detail :

(New M.D of Yamaha Motors India Mr Masihoka Shiboya taking over from Mr S .K

Taneja , the outgoing General Manager of Yamaha Motors Escorts Ltd)

1.Yamaha : Yamaha believed that operating on an individual basis would help in

building it’s separate Brand Name . A strategy was formulated in order to facilitate new

product launches and the entire Marketing policy was overhauled . As part of the

strategy, Yamaha Motors also planned to convert its India operations into a sourcing base

for parts and fully-built two-wheelers . The company was hoping to manufacture as many

as 5.5 lakh vehicles in the country by 2003-04, which will be sold both in the domestic

and export markets.

2.Escorts : After Escorts' hugely successful motorcycle brand, Rajdoot, the group had

not been able to replicate the success with the offerings under the Yamaha brand. While

the Yamaha RX 100 model, which before being withdrawn due to new emission norms,

seemed to achieve considerable success, the other models including the Yamaha YBX, its

first four-stroke bike, have only received lukewarm response from the market. The

Escorts group Chairman, Mr. Rajan Nanda, had also often emphasized the group's

intentions to focus on core activity and on enhancing shareholder value. The latest

proposal to divest partly in EYML would signal a furtherance of these objectives .

Escorts was quick to realize that it’s core competence lied in commercial transport

vehicles rather than passenger transport .

In essence the decision to separate was on grounds of mutual consent by both parties . It

made business sense to part ways now and the timing could not have been better in the

light of prevailing competitive environment .

Prof . Nomita Kapoor Page 6

How Organizations Handle Change – Yamaha Motors India

CHANGE OUTLINED

YAMAHA Motor Company of Japan renamed its wholly-owned Indian subsidiary

Yamaha Motor India Pvt Ltd, after buying out the entire equity holding of the Escorts

group in the erstwhile joint venture Yamaha Motor Escorts Ltd.

The world's second largest manufacturer of motorcycles also planned to restructure its

sales channels, product development department and its human resources policies at the

Indian subsidiary.

At the two plants on the suburbs of Delhi , wholesale changes were made in

Administration staff . Each department now has a Japanese representative called Deputy

General Manager . As far as hierarchy in the top brass is concerned , the C.E.O ,

President , Vice President and Associate Vice President were all now Japanese . The first

Indian involvement in the top management begins at General Manager level of individual

departments .

Along with the rechristening, the Yamaha Motor India also initiated a `Challenge 21'

project to restructure its businesses in the country. According to the company, the project

is a time-bound initiative that will reorient and revitalize the entire operations and

provide sustainable competitive advantage. Yamaha Motor India is hoping to corner a

market share of 21 per cent by the year 2003 after the restructuring is fully in place.

As part of its revival plans, Yamaha is also proposing to launch at least one new model

every year for the next four years. The company is also expected to gradually increase its

manufacturing capacity from the present three lakhs units per annum at its two plants

near the capital to about 5.5 lakh units per annum by the year 2003.

While the initial emphasis is expected to be on motorcycles, Yamaha is not ruling out the

possibility of getting into the scooter and scooterette segments.

Announcing the new name and the restructuring plans of the company, Mr Masahiko

Shibuya, the new Managing Director of Yamaha Motor India said the company's

realignment plans have been necessitated due to the growing importance of the Indian

two-wheeler industry and the increasing expectations of the consumers here.

Mr Shibuya said the restructuring programme is expected to speed up product

development, quality and design. The plans include improving product quality and

reduction of costs. The sales channel reorientation is also expected to help the company

add new distributors and infuse a customer-oriented policy amongst the existing channel

partners.

Prof . Nomita Kapoor Page 7

How Organizations Handle Change – Yamaha Motors India

BROAD CULTURAL CHANGE

Put yourselves into the shoes of an employee who is used to walking in at 9:15 for a shift

which starts at 9:00. an employee who wants leaves at will and runs to his union at the

slightest mention of conflict with management. Now imagine being asked to get your act

together or else find a different job. That’s exactly what happened at Yamaha Motors

India. As long as Escorts had a say in the organization, atypical Indian Culture prevailed.

With Yamaha taking over the entire operation, Japanese Culture become dominant.

Of course, the takeover didn’t happen overnight. Employees saw the change coming and

were conditioned to handle it. From a mere technical collaborators for Escort’s

indigenous motorcycle- Rajdoot, Yamaha’s stake in the organization had grown over the

period of time. For reasons mentioned before, Yamaha decided to have complete

ownership in India. While the financial benefits of such a move were known, Yamaha

also realized the perils of an Indian Work Force being managed by Japanese leadership.

Strangely, there was limited or almost no resistance from employees at any level. We

shall better understand the cause of that when we take up the Human Resource

perspective later.

Japanese work ethos are built around a single minded devotion to discipline. No

employee is offered preferential treatment and some rules apply for everybody. If your

Japanese manager walks in at 8:45 for a 9’o clock shift, imagine the example it sets for

subordinates. That’s exactly what happened at Yamaha Motors India strict financial

penalties were put in place for those who re[ported late at work. Moreover, continuing the

policy of unbiased treatment, every employee was given the same uniform. Regardless of

the fact that whether you are a Foreman or Chief general manager, everyone is expected

to turn up in the same uniform. The obvious benefits are an increased sense of

camaraderie and team spirit.

The lunch hours were also streamlined. During the reign of Escorts, separate departments

had their own lunch timings. With Yamaha, lunch hours were divided into two categories.

One for the operation level workers and other for managers. The upside of such a

bifurcation is stronger and more open channels of informal communication among

employees working in different departments but at similar level in the organization.

Above mentioned examples amply demonstrate the typical Japanese attention to details.

Japanese Companies believe in life time involvement with it’s employees. In return, they

expect their employees to treat the organization as their own family. When visiting their

plant in Surajpur, close in Noida, you can notice posters like these.

Have you remembered to :

1. Switch off A.Cs , fans and lights .

2. Keep the gangway clear of any hindrances .

3. Put yours tools in appropriate closet .

4. Keep your work surroundings clean and hygienic .

Prof . Nomita Kapoor Page 8

How Organizations Handle Change – Yamaha Motors India

Such reminders can be found all over the place – H.R. Department, Finance Division,

Shop Floor etc. A concept introduced by all the Japanese but gladly embraced by all

employees.

While management expects employees to carry out their duties, it does not turns a blind

eye towards it’s own obligations. The standards for employees safety and general

sanitation are same in India as in Japan. After Yamaha took over, an entire new

department was created, just to look after general cleanliness of the plant and employees

health and well being. Expenditure in such areas is looked upon as investment rather than

cost. The Japanese work on the premise- “ A happy Employee is a productive employee”

The acid test of any cultural change is the degree to which it is embraced by the people

who are affected by it. During any interview at any level, we didn’t detect any tone of

remorse or dissatisfaction with Japanese way of work life. “ A little bit of discipline does

no work life anybody” – as one of the workers remarked. Clearly, the general perception

which prevailed was that the benefits of changed culture have for outweighed the

bottlenecks and costs involved in the process of change.

Prof . Nomita Kapoor Page 9

How Organizations Handle Change – Yamaha Motors India

THE PRODUCTION ASPECT

When your core product is as technical a as motorbike, the first department you look to

upgrade is production. Japanese are a quality conscious breed who have traditionally

believed that a technologically superior product will sell itself against any competition.

After Yamaha took over, increased attention was paid to streamlining the entire

production process. Every change whether big or small, had a common objective of

improving employee productivity. Changes in Production Department are summarized

below :

1. Introduction of Public announcement system on the shop floor : Yamaha

placed loud speakers on the shop floor across the entire plant. They come in hardy

to communicate any instruction to the worker or to locate any worker on the shop

floor. Workers are also continuously reminded to conserve electricity wherever

possible and to keep the gangway empty. Soft instrumental music is played to

soothe the workers.

2. Training of production employees in Japan : Every six months, a batch of 4-5

employees is selected to be trained at the Yamaha production plant in Japan.

Stress is on selecting employees from areas as varied as possible so that all

aspects of production are benefited. Employees receive salary for their work in

the Japanese plant. The objective of such n exercise is that employees get to learn

the latest production techniques as employed in Japan. They also get a first hand

experience of Japanese work culture and discipline.

3. Stress on planning and involvement : Instead of communicating the production

instructions downwards, shop floor workers are encouraged to plan out their work

schedule. The schedule and resources required to complete the job is finalized

through direct interaction of workers and management. Workers are also expected

to state a minimum level of productivity- per day or per week. Any deviation from

this standard is analysed and corrected jointly by the workers and the

management.

4. Quality Circles : A concept, originally pioneered by the Japanese, was

successfully implemented at Yamaha Motors India. Employees in 5the production

department were divided into groups of 8 to 10. These groups, called quality

circles, are expected to meet after work hours to discuss common production

related issues faced by the plant. Any group coming up with the solution or a cost

reduction idea is financially rewarded. Names of the members of the quality circle

whose idea has been selected are put up on the notice board.

Prof . Nomita Kapoor Page 10

How Organizations Handle Change – Yamaha Motors India

Although employee empowerment is a central theme running through above mentioned

changes. Japanese still kept certain key powers to themselves. Product designing and

assembly layout decisions were confined to the top management in Japan. Similarly,

budget allocation for different areas of production was done directly by the Yamaha,

Japan’s finance professionals. Despite this, production still developed as a function more

integrated with employee’s needs and individual objectives. The fact that there was

almost no resistance bears testimony to the goodwill of the top management and their

commitment to employee participation and empowerment.

Prof . Nomita Kapoor Page 11

How Organizations Handle Change – Yamaha Motors India

THE QUALITY CONTROL ASPECT

Quality control, or quality assurance as they like to call it, is something Japanese are

obsessed with. Quality assurance became a key performance area only after Yamaha took

over. During the era of Escorts when Yamaha was just a technical collaborator,

professionals from Japan visited only to collect date regarding rejection rate, efficiency,

volumes per hour etc. Now, realizing that profit levels, quality assurance is given it’s due

share of importance. Changes that Yamaha introduced after taking over are summarized

below :

1. Quality Control Process Control sheet : Earlier, quality inspection used to be

carried out only when the final product was manufactured. Yamaha realized that

this caused a lot of motorbikes to be rejected as scrap just because one or two

components had problems. Now quality control was conducted at each and every

level of production. Through QCPC sheets, workers were asked to record their

total quality produced and categorized them as “ good” and “ Not good”. Self

maintenance is the underlying thought and workers are given gauges to check

quality by themselves.

2. Rejection Rate : During the reign of Escorts a 1% rejection rate of components

was deemed satisfactory. Now, with Yamaha, this standard was lowered to 0.5%.

Infact, during recent checks, this number was found closer to 0.25%. A low

rejection rate of components transforms into lower cost of production and better

quality of final product.

3. Direct on line : DOL is the Yamaha version of just in time. A team of 4-5

production professionals is created to stay in touch with the vendors of parts and

components. The team ensures that there are no hitches on the vendors side during

order processing. If a particular vendor is facing certain problems in delivering on

time, the team communicates the same to top level management. Alternate

sources or vendors are also suggested. The benefits of DOL is reduced inventory

levels which in turn leads to lower costs of material handling.

4. Y.M.I Infotech : This is a network software developed to handle the production

process in Yamaha Motors India. This software links up three departments-

Purchases, stores and production department requires a certain component, the

physical flow of information follows the route :

Production Stores Purchases.

Once the vendor has supplied the component the flow of material follows the

route :

Purchases Stores Production

Earlier, with no networking software, the flow had to be physically verified at

each level by the employees. With this new system, employees are only required

to enter the status from heir respective work stations. It saves time and also

eliminates chances of leakage of goods.

Prof . Nomita Kapoor Page 12

How Organizations Handle Change – Yamaha Motors India

The gains from all these changes were very visible. The average productivity of an

eight hour shift increased from 450units to 650 units. Gains were also noticed in

components production .for e.g, number of produced in a day went up from 175 to

225.yamana is continuously looking to automate the whole plant C.N.C or computerized

numerically controlled machines are being installed to reduce the chances of human error.

The fact that the quality standards for production in India is same as in Japan

demonstrates the commitment on the part of Yamaha to never let their guard down.

Prof . Nomita Kapoor Page 13

How Organizations Handle Change – Yamaha Motors India

THE HUMAN RESOURCE ASPECT

Change, in any organization is routed through it’s Human Resource Department. There

are always disgruntled employees who complain that change has adversely affected them.

There are employees who believe in status Quo and believe that if a system is working,

there is no point in changing it.

Escorts going out and Yamaha coming in was a change that influenced each other and

every employee working on all levels. Strangely though, the resistance to this major

change and to all subsequent decisions taken to enforce the change was minimized,. It

only depicts the success of the H.R. department in educating all employees. Change was

viewed as mandatory rather than optional. Employees were made to believe that their

future bread and butter depended upon the success of this change. Almost every

employee understood the need for this broad change. There were some voices of

discontent regarding small details which had to be worked out. The H.R. department’s

role in handling the entire process of change is summarized below :

1. Agreement with the Union : Escorts left behind a strong labour union which was

known to use aggressive tactics to get it’s demand met. Yamaha suspended the old

agreement with the union and entered into a new one after taking over. The

agreement covered various aspects like pay packages, increments, working hours,

leaves schedule etc. Yamaha also offered V.R.S. ( Voluntary retirement schemes)

to those who did not wanted to continue with the organization. However, the

attraction rate of labour and managers was very low. What Yamaha ensured

through was there are no dissatisfied employees in the organization. Yamaha knew

that workers will be facing a cultural change soon and only wanted those

employees who were ready and willing to accept change in it’s true spirit.

2. Training of employees in Japan : Not every employee looks upon training in

Japan as an opportunity or value addition. Certain employees are reluctant to

leave their families back in India for a period of 6 months. People used to the

social and cultural environment of India find it difficult to adjust to a foreign

country. The challenge for the H.R. Department was to motivate such employees.

These employees were assured that their families will be taken care of. While

trainees will receive salary for their work in Japan, their families will be a paid a

fixed amount periodically by the company during the [period of training. Secure

wit the knowledge that their families are taken care of, employees were motivated

to undergo training in Japan.

3. Networking with dealers : Yamaha is currently in process of networking all it’s

dealer all over India. Dealers are seen as valuable channel partners and not mere

supply chain members. The purpose of this online network queries on a perpetual

basis. Dealers are encouraged to report all complaints, suggestions, ideas through

this network. The network will also be used for online order processing.

Prof . Nomita Kapoor Page 14

How Organizations Handle Change – Yamaha Motors India

4. Routing bills through Tedfel : Dealers were not happy with Yamaha routing it’s

bills through Tedfel. Earlier, dealers were not asked to pay until the motor cycles

were actually sold. Now Tedfel only offered a 15 days credit period to the dealers.

Presently, may dealers have already approached Yamaha and have asked to revert

back to the old system. At the time of our research, the dialogue between the

dealers and the company was still on. Yamaha still believes in the company

validity of hiring an outside agency for bill payments and wants to bring around

the dealers to its way of thinking.

Yamaha has also followed the policy that Indian managers are best equipped to handle

Indian work force. The Japanese presence in the H.R. department is bare minimum.

Language barrier is a significant constraint in this regard. So, while the company boasts

of presence of Japanese professionals in production, quality assurance and finance

department, the H.R. department is still completely handled by their Indian counterparts.

Prof . Nomita Kapoor Page 15

How Organizations Handle Change – Yamaha Motors India

THE FINANCE ASPECT

Yamaha joined Escorts Motors as a technical Collaborator . It then became a 24%

stakeholder in the Company. It’s stake gradually increased and at the time of separation

the stake was 74% . Today, Yamaha Motors India is Yamaha’s only wholly owned

subsidiary outside Japan. A major reason why Escorts and Yamaha decided to part ways

was the continuously falling market share in the Motorcycle segment. When Yamaha took

over the reigns, the mandate was simple. While marketing will look to improve the top

line, Finance Department should focus on improving the bottom line. The measures

undertaken to achieve cost reduction are summarized below :

1. Cost Reduction Department : Under the finance division, a whole new

department was created just to look after cost reduction. All quality circles report

to this department. The department scans technological economic and political

environment to unearth possible methods of cost reduction. By using DOI

techniques, the department has been successful in reducing procurement costs of

components by around 8-10%.

2. Credit Control Department : This department was created to mainly deal with

the dealers. Earlier, dealers were allowed credit until Motorcycles were actually

sold and cash was realized. Such a system lengthened the working capital cycle

and exerted added pressure on liquidity requirements of the company. After

Yamaha took over, an external agency called Tedfel was hired for this purpose.

Tedfel made prompt payment to Yamaha and then collected the respective

amounts from individual dealers. Yamaha is saved from the hassle of monitoring

every dealer and possibility of bad debts.

3. No centralized Financing Company. Escorts require it’s dealers to offer it’s

customers only one finance option which was pre decided by the company.

Dealers all over India were communicated the decision of the company regarding

which financing company is to be associated with Escorts Yamaha. After Yamaha

took over, all dealers were allowed individual discretion to tie up with any

financing company of their choice.

IN a bid to become a dominant player in the Indian motorcycles market, Yamaha India

plans to invest Rs 35-60 crore on capacity expansion and upgradation every year for the

next three years. Anticipating greater demand for its newly launched models, the 125-cc

Enticer and the 106-cc Libero, Yamaha India will increase the capacity of both the

models to 10,000 units per month each from January 2003 onwards. Yamaha will think of

going for an IPO when the need for a third plant arises. This will happen when the

combined capacity at two plants hits 6,00,000 units.

Yamaha is expecting a 30-40 per cent increase in sales. In volume terms, Yamaha are

targeting sales of about 4,00,000 units next year.

Prof . Nomita Kapoor Page 16

How Organizations Handle Change – Yamaha Motors India

CONCLUSION

“ Change” is often viewed negatively by the people who are influenced by it. Nobody

likes to be forced to change and if it happens, resistance is a natural reaction which is

bound to show up. During our interviews at the plant, we tried to dig deep and locate any

hint of resistance or discontent on the part of employees. However, the general perception

was that change has been for the benefit of all those involved.

Lack of resistance also signifies the gravity of the situation when Yamaha took over. In

the light of continuously sliding market share, Yamaha was seen as the saviour of 2000

employees working with Escorts Yamaha motors India. The fact that there was no in

fighting signified goodwill on the part of both Yamaha and Escorts.

Yamaha is still to turn the corner in the highly competitive motorcycle market. However,

Yamaha has recognized the enormous potential of the market and it’s penchant to switch

brands according to latest trends and technology. The profits are showing an upward

trend recently. The progress made is painstakingly slow but sure. Employees at all levels

showcase a deep rooted belief that their company can once again repeat the success

stories of mid 1990s.

The culture change which came as a shock two years ago has now become a norm.

discipline has become a way of life. The professional approach which Yamaha introduced

is no more imposed on the workers. It has become a part of their social conditioning at

the workplace. Yamaha Motors India is a perfect case study for understanding how

change can be successfully implemented in organization.

Prof . Nomita Kapoor Page 17

How Organizations Handle Change – Yamaha Motors India

ANNEXURES

Checklist For In-Depth Interview With Human Resource Department :

1. Under what circumstances did the company require to separate from Escorts?

2. What according to you was the main driver for change in this process?

3. What triggered the change?

4. Who initiated the change from the organization’s perspective –

i. Role of top management

ii. Communicating the decision to all employees

iii. What all was told and how?

5. Did the change process require a major change in the employee’s behavioral

aspect?

6. Was there any culture change, as now the company is a wholly owned subsidiary

of YAHAHA (Japan)?

7. What sort of action plan or strategy did the HR department design?

8. Was there any resistance to this change?

9. If yes, then how was it tackled by the HR department?

10. Were there any changes done to the organizational structure as such, which would

have an effect on the power, responsibility, and authority equation of YAHAMA?

Checklist for In – Depth Interview at Productions Department :

1. Were there any major reshuffles in the Productions Dept after Yamaha took over ?

2. What were the visible changes in methods of Production after change was

implemented ?

3. Were there any changes in measures followed for worker’s safety ?

4. Is the Product designing done indigenously or in Japan ?

5. Was any new Technology introduced after Yamaha took over ?

6. Was there any resistance to new technology or work practice introduced ?

7. How was this resistance tackled ?

Prof . Nomita Kapoor Page 18

How Organizations Handle Change – Yamaha Motors India

Checklist for In-depth Interview at Finance Department :

1. How was the finance division affected by the change ?

2. What was the shareholding pattern before Yamaha assumed total control ?

3. What was the market share at the time of separation and what is it’s status now ?

4. Were the dealings with the Dealers influenced in any way by the change ?

5. How were Escort’s share prices in India and Yamaha’s in Japan affected by the

change ?

6. What are the future expansion plans of the company ?

Checklist for In-depth Interview at Quality Control Department :

1. Were there any reshuffles in the Quality Control Dept. after the change ?

2. Are quality standards in India any different from those in Japan ?

3. Were the quality standards made more stringent after Yamaha took over ?

4. What is the Standard rate of output of Motorcycles per day/week/month ? Is it

higher or lower than what it was during the time of Escorts ?

5. What are standards followed in the Components division of manufacturing ?

6. What is the frequency of revision of Quality standards ?

7. Are there any rewards associated with achieving quality norms ?

Prof . Nomita Kapoor Page 19

You might also like

- It’s Not What You Sell—It’s How You Sell It: Outshine Your Competition & Create Loyal CustomersFrom EverandIt’s Not What You Sell—It’s How You Sell It: Outshine Your Competition & Create Loyal CustomersNo ratings yet

- Customer Profiling & Purchase Parameters - Cars IndiaDocument116 pagesCustomer Profiling & Purchase Parameters - Cars Indianishutha3340No ratings yet

- BRANDING Thesis VineetmalaniDocument77 pagesBRANDING Thesis Vineetmalanibonker508100% (3)

- Suresh v. Uma Tvs 5Document43 pagesSuresh v. Uma Tvs 5Solomon RajuNo ratings yet

- Piaggio CsiDocument44 pagesPiaggio Csisameermahajan100% (3)

- Supply Chain Management in The Automotive Industry: Present by Narendra Singh Rathore Guide Name Miss. Mona Ma'amDocument15 pagesSupply Chain Management in The Automotive Industry: Present by Narendra Singh Rathore Guide Name Miss. Mona Ma'amNarendra Singh RathoreNo ratings yet

- BBA Project - ForD.Document58 pagesBBA Project - ForD.Sushant Singh100% (1)

- Project 123Document55 pagesProject 123abhi_sek20050% (2)

- Chapter - 1 A Study On Customer Satisfaction Towards Maruti Suzuki Swift in VelacheryDocument14 pagesChapter - 1 A Study On Customer Satisfaction Towards Maruti Suzuki Swift in VelacherypradeepNo ratings yet

- Profile of The CompanyDocument8 pagesProfile of The Companyaryaa_stat0% (1)

- Project Vespa in IndiaDocument27 pagesProject Vespa in IndiaRama Ravikanth VijapurapuNo ratings yet

- A Study On Dealer's SatisfactionDocument44 pagesA Study On Dealer's SatisfactionSandeep GandepallyNo ratings yet

- Brand Awareness-1Document5 pagesBrand Awareness-1aarthiNo ratings yet

- Sale Management Keys Kotler Mcq'sDocument14 pagesSale Management Keys Kotler Mcq'sRaman Kulkarni100% (1)

- Consumer Behaviour 2 PDFDocument24 pagesConsumer Behaviour 2 PDFBalaji GajendranNo ratings yet

- Consumer Behavior On Maruti Suzuki SwiftDocument7 pagesConsumer Behavior On Maruti Suzuki SwiftKushal SahuNo ratings yet

- A Study On Customer Satisfaction in Indus MotorsDocument5 pagesA Study On Customer Satisfaction in Indus MotorsKali Pandi100% (1)

- King NARZARY BBA PROJECT 6Document80 pagesKing NARZARY BBA PROJECT 6Sunny SinghNo ratings yet

- hYUNDAI ProjectDocument20 pageshYUNDAI ProjectShradha PereiraNo ratings yet

- A Study On Customer Perception Towards Sales and Service of Suzuki MotorsDocument70 pagesA Study On Customer Perception Towards Sales and Service of Suzuki Motorsviswajith RNo ratings yet

- Literature Review of Automobile Industry in IndianDocument8 pagesLiterature Review of Automobile Industry in Indiankikufevoboj2No ratings yet

- Consumer PerceptionDocument43 pagesConsumer PerceptionKunal Rajput100% (1)

- My ReportDocument81 pagesMy ReportNeeraj JoshiNo ratings yet

- A Study On Customer Satisfaction Towards YamahaDocument77 pagesA Study On Customer Satisfaction Towards YamahaSachin Kumar SakriNo ratings yet

- DFHILDocument15 pagesDFHILraj dhumalNo ratings yet

- The Webster and Wind ModelDocument1 pageThe Webster and Wind ModelKushagra VarmaNo ratings yet

- BBA III Internal AssignmentDocument32 pagesBBA III Internal AssignmentMamtaSharmaNo ratings yet

- Sharad Mishra Project ReportDocument117 pagesSharad Mishra Project ReportGarima PatelNo ratings yet

- "A Study On Customer Expectation From On-Line Marketing WithDocument89 pages"A Study On Customer Expectation From On-Line Marketing Withprathamesh kaduNo ratings yet

- Aswathi Honda Analysis New-1Document56 pagesAswathi Honda Analysis New-1Aŋoop KrīşħŋặNo ratings yet

- Porter'S Five Forces Model: - Barriers To EntryDocument5 pagesPorter'S Five Forces Model: - Barriers To Entryhimanshu agrawalNo ratings yet

- A9 - Marketing Management - Project Part 1Document11 pagesA9 - Marketing Management - Project Part 1malvika_varma100% (1)

- Two-Wheeler Industry in IndiaDocument13 pagesTwo-Wheeler Industry in IndiaTYAGI PROJECTSNo ratings yet

- Mahindra and Mahindra Financial Limited SHIVANK DANTREDocument9 pagesMahindra and Mahindra Financial Limited SHIVANK DANTREmadhu sudhanNo ratings yet

- Indus Motor Report BBA-35Document23 pagesIndus Motor Report BBA-35Zeeshan MazharNo ratings yet

- Dream Company ITCDocument9 pagesDream Company ITCamandeep152No ratings yet

- Product Services Feasibility Analysis Marketing EssayDocument4 pagesProduct Services Feasibility Analysis Marketing Essayvikram100% (1)

- Hero MotorDocument50 pagesHero MotorVignesh SNo ratings yet

- Project Report FinalDocument48 pagesProject Report Finalnilratan86100% (1)

- Inplant Training ReportDocument48 pagesInplant Training ReportyogeshNo ratings yet

- Sip Report NehalDocument21 pagesSip Report NehalNehal DarvadeNo ratings yet

- Part 2 ProjectDocument50 pagesPart 2 Projectramakrishnad reddyNo ratings yet

- LG TVDocument63 pagesLG TVshobhitNo ratings yet

- Swot AnalysisDocument8 pagesSwot AnalysisShahidaNo ratings yet

- Customer Satisfaction in Big BazaarDocument76 pagesCustomer Satisfaction in Big BazaarAditya VermaNo ratings yet

- Marketing ProjectDocument15 pagesMarketing ProjectShretha lakshmi rNo ratings yet

- Marketing - COMPARATIVE STUDY OF CUSTOMERS PERCEPTION FOR HONDA & YAMAHA BIKESDocument56 pagesMarketing - COMPARATIVE STUDY OF CUSTOMERS PERCEPTION FOR HONDA & YAMAHA BIKESShailabh KhandelwalNo ratings yet

- A Dissertation ReportDocument73 pagesA Dissertation ReportRanjan Kumar RamNo ratings yet

- Sales and Distribution Channel of Tata Motors LTD FinalDocument76 pagesSales and Distribution Channel of Tata Motors LTD Finaljasmine chowdharyNo ratings yet

- Best Buy AssignmentDocument13 pagesBest Buy Assignmentamandeep singhNo ratings yet

- User Brand Preference of Two BikesDocument106 pagesUser Brand Preference of Two BikesShahzad SaifNo ratings yet

- Customer Relationship ManagementDocument8 pagesCustomer Relationship ManagementdibeeshNo ratings yet

- Customer Perception of Maruthi SuzukiDocument9 pagesCustomer Perception of Maruthi SuzukiOm Prakash100% (1)

- Seminar Report On Bajaj Auto LimitedDocument15 pagesSeminar Report On Bajaj Auto LimitedVikasNo ratings yet

- Honda - CSR-2014 PDFDocument82 pagesHonda - CSR-2014 PDFluqmanNo ratings yet

- Customer Satisfaction and Expectation Towards After Sales Service of TVS MotorsDocument27 pagesCustomer Satisfaction and Expectation Towards After Sales Service of TVS MotorsDaniel Siddharth100% (1)

- A Synopsis Report ON: "A Business Process Design in Tata Motors, Lucknow"Document7 pagesA Synopsis Report ON: "A Business Process Design in Tata Motors, Lucknow"Vikram Pratap SinghNo ratings yet

- Employ SatisfactionDocument41 pagesEmploy SatisfactionVidhi Sethi100% (1)

- Strategic Management Project Report: Yamaha MotorsDocument22 pagesStrategic Management Project Report: Yamaha Motorsmahtaabk67% (6)

- Strategic Management Project Report Yamaha MotorsDocument24 pagesStrategic Management Project Report Yamaha MotorsShrinivas PrabhuneNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Rural Marketing LifebouyDocument21 pagesRural Marketing LifebouyPriyanka ChikaneNo ratings yet

- Export of Agricultural and Processed Food ProductsDocument51 pagesExport of Agricultural and Processed Food Productsbonker508No ratings yet

- Fruit Juice Concentrate PlantDocument25 pagesFruit Juice Concentrate Plantbonker508100% (15)

- AmulDocument6 pagesAmulbonker508100% (9)

- Rural NirmaDocument15 pagesRural Nirmabonker508100% (13)

- Hutch ProjectDocument2 pagesHutch Projectbonker508No ratings yet

- Store Visit ChartDocument6 pagesStore Visit Chartbonker508100% (1)

- Material Shortage FormatDocument1 pageMaterial Shortage Formatbonker508No ratings yet

- Duke 390 Repair Manual (Full Version - 204pages)Document229 pagesDuke 390 Repair Manual (Full Version - 204pages)Aaron EranackalNo ratings yet

- Simply Sport Bikes Case StudyDocument11 pagesSimply Sport Bikes Case StudySalsyaNo ratings yet

- Owners Manual-Continental GTDocument108 pagesOwners Manual-Continental GTUmar ShamsudinNo ratings yet

- MT03 2011 en AccesoriesDocument6 pagesMT03 2011 en AccesorieskrasiooNo ratings yet

- Kawasaki W800 Owner's Manual PDFDocument148 pagesKawasaki W800 Owner's Manual PDFMarius BabosNo ratings yet

- Kartik ChauhanDocument7 pagesKartik ChauhanarupNo ratings yet

- Safe Operating Procedure of Motor BikeDocument4 pagesSafe Operating Procedure of Motor BikeTafadzwaNo ratings yet

- FW06-User's ManualDocument72 pagesFW06-User's ManualJuan Camilo EchavarríaNo ratings yet

- Electrek - EV and Tesla News, Green Energy, EbikesDocument1 pageElectrek - EV and Tesla News, Green Energy, EbikesI'm Number 23No ratings yet

- HUB Center SteeringDocument64 pagesHUB Center SteeringMukesh ReddyNo ratings yet

- Honda Two WheelersDocument37 pagesHonda Two WheelersJagadish SahuNo ratings yet

- Status Report 2009Document16 pagesStatus Report 2009Aman VermaNo ratings yet

- 2014 CvoDocument21 pages2014 CvoSamDJD42No ratings yet

- Comparitive Study On Consumer Buying Behaviour of Hero Honda and PulsarDocument23 pagesComparitive Study On Consumer Buying Behaviour of Hero Honda and Pulsarvipin5678100% (1)

- Chapter 1Document14 pagesChapter 1sathishprabu89No ratings yet

- (English WS) (Advertisement)Document19 pages(English WS) (Advertisement)Aditya Chaudhary0% (1)

- Tvs Motors ProjectDocument77 pagesTvs Motors ProjectAshish Sinha72% (65)

- E GDKTZ Lbcne 3 Si N0 K1 Hqab LG W3 IDocument6 pagesE GDKTZ Lbcne 3 Si N0 K1 Hqab LG W3 IRonaldo AlvesNo ratings yet

- Platina 110 - 100Document48 pagesPlatina 110 - 100Hector Jose Murillo CordobaNo ratings yet

- E-Boda Project ProposalDocument11 pagesE-Boda Project ProposalSita GVNo ratings yet

- Yamaha XT 225Document2 pagesYamaha XT 225Pablo ArevaloNo ratings yet

- Customer Satisfaction - YAMAHA MOTORSDocument74 pagesCustomer Satisfaction - YAMAHA MOTORSservicenagarjuna67% (9)

- Customer Satisfaction of Two Wheelers Industries Customer Satisfaction of Two Wheelers IndustriesDocument74 pagesCustomer Satisfaction of Two Wheelers Industries Customer Satisfaction of Two Wheelers IndustriesAlok kumarNo ratings yet

- Manual Rusi Classic 250iDocument40 pagesManual Rusi Classic 250iJun Baldemor100% (1)

- Strategic Management On Harley DavidsonDocument20 pagesStrategic Management On Harley DavidsonNariman H. B.100% (1)

- Marketing Strategy in Hero Moto Corp1Document42 pagesMarketing Strategy in Hero Moto Corp1j_sachin09No ratings yet

- A Mini ProjectDocument52 pagesA Mini ProjectVishi Prajapati100% (3)

- Marketing Project in TVSDocument31 pagesMarketing Project in TVSRoyal Projects73% (11)

- Automobile IndustryDocument88 pagesAutomobile IndustryAmit MishraNo ratings yet

- Viewresource BimotaDocument2 pagesViewresource BimotarasgeetsinghNo ratings yet

- Summary of The Anxious Generation by Jonathan Haidt: How the Great Rewiring of Childhood Is Causing an Epidemic of Mental IllnessFrom EverandSummary of The Anxious Generation by Jonathan Haidt: How the Great Rewiring of Childhood Is Causing an Epidemic of Mental IllnessNo ratings yet

- The Compound Effect by Darren Hardy - Book Summary: Jumpstart Your Income, Your Life, Your SuccessFrom EverandThe Compound Effect by Darren Hardy - Book Summary: Jumpstart Your Income, Your Life, Your SuccessRating: 5 out of 5 stars5/5 (456)

- The One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsFrom EverandThe One Thing: The Surprisingly Simple Truth Behind Extraordinary ResultsRating: 4.5 out of 5 stars4.5/5 (709)

- Can't Hurt Me by David Goggins - Book Summary: Master Your Mind and Defy the OddsFrom EverandCan't Hurt Me by David Goggins - Book Summary: Master Your Mind and Defy the OddsRating: 4.5 out of 5 stars4.5/5 (383)

- The Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaFrom EverandThe Body Keeps the Score by Bessel Van der Kolk, M.D. - Book Summary: Brain, Mind, and Body in the Healing of TraumaRating: 4.5 out of 5 stars4.5/5 (266)

- Summary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesFrom EverandSummary: Atomic Habits by James Clear: An Easy & Proven Way to Build Good Habits & Break Bad OnesRating: 5 out of 5 stars5/5 (1635)

- How To Win Friends and Influence People by Dale Carnegie - Book SummaryFrom EverandHow To Win Friends and Influence People by Dale Carnegie - Book SummaryRating: 5 out of 5 stars5/5 (556)

- The Whole-Brain Child by Daniel J. Siegel, M.D., and Tina Payne Bryson, PhD. - Book Summary: 12 Revolutionary Strategies to Nurture Your Child’s Developing MindFrom EverandThe Whole-Brain Child by Daniel J. Siegel, M.D., and Tina Payne Bryson, PhD. - Book Summary: 12 Revolutionary Strategies to Nurture Your Child’s Developing MindRating: 4.5 out of 5 stars4.5/5 (57)

- Summary of 12 Rules for Life: An Antidote to ChaosFrom EverandSummary of 12 Rules for Life: An Antidote to ChaosRating: 4.5 out of 5 stars4.5/5 (294)

- The War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesFrom EverandThe War of Art by Steven Pressfield - Book Summary: Break Through The Blocks And Win Your Inner Creative BattlesRating: 4.5 out of 5 stars4.5/5 (273)

- Summary of The Algebra of Wealth by Scott Galloway: A Simple Formula for Financial SecurityFrom EverandSummary of The Algebra of Wealth by Scott Galloway: A Simple Formula for Financial SecurityNo ratings yet

- Summary of Atomic Habits by James ClearFrom EverandSummary of Atomic Habits by James ClearRating: 5 out of 5 stars5/5 (169)

- Book Summary of Ego Is The Enemy by Ryan HolidayFrom EverandBook Summary of Ego Is The Enemy by Ryan HolidayRating: 4.5 out of 5 stars4.5/5 (387)

- Mindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessFrom EverandMindset by Carol S. Dweck - Book Summary: The New Psychology of SuccessRating: 4.5 out of 5 stars4.5/5 (328)

- Summary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsFrom EverandSummary of The Galveston Diet by Mary Claire Haver MD: The Doctor-Developed, Patient-Proven Plan to Burn Fat and Tame Your Hormonal SymptomsNo ratings yet

- Steal Like an Artist by Austin Kleon - Book Summary: 10 Things Nobody Told You About Being CreativeFrom EverandSteal Like an Artist by Austin Kleon - Book Summary: 10 Things Nobody Told You About Being CreativeRating: 4.5 out of 5 stars4.5/5 (128)

- Essentialism by Greg McKeown - Book Summary: The Disciplined Pursuit of LessFrom EverandEssentialism by Greg McKeown - Book Summary: The Disciplined Pursuit of LessRating: 4.5 out of 5 stars4.5/5 (187)

- Make It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningFrom EverandMake It Stick by Peter C. Brown, Henry L. Roediger III, Mark A. McDaniel - Book Summary: The Science of Successful LearningRating: 4.5 out of 5 stars4.5/5 (55)

- Designing Your Life by Bill Burnett, Dave Evans - Book Summary: How to Build a Well-Lived, Joyful LifeFrom EverandDesigning Your Life by Bill Burnett, Dave Evans - Book Summary: How to Build a Well-Lived, Joyful LifeRating: 4.5 out of 5 stars4.5/5 (62)

- We Were the Lucky Ones: by Georgia Hunter | Conversation StartersFrom EverandWe Were the Lucky Ones: by Georgia Hunter | Conversation StartersNo ratings yet

- Sell or Be Sold by Grant Cardone - Book Summary: How to Get Your Way in Business and in LifeFrom EverandSell or Be Sold by Grant Cardone - Book Summary: How to Get Your Way in Business and in LifeRating: 4.5 out of 5 stars4.5/5 (86)

- How Not to Die by Michael Greger MD, Gene Stone - Book Summary: Discover the Foods Scientifically Proven to Prevent and Reverse DiseaseFrom EverandHow Not to Die by Michael Greger MD, Gene Stone - Book Summary: Discover the Foods Scientifically Proven to Prevent and Reverse DiseaseRating: 4.5 out of 5 stars4.5/5 (84)

- Summary of When Things Fall Apart: Heart Advice for Difficult Times by Pema ChödrönFrom EverandSummary of When Things Fall Apart: Heart Advice for Difficult Times by Pema ChödrönRating: 4.5 out of 5 stars4.5/5 (22)

- Summary of Million Dollar Weekend by Noah Kagan and Tahl Raz: The Surprisingly Simple Way to Launch a 7-Figure Business in 48 HoursFrom EverandSummary of Million Dollar Weekend by Noah Kagan and Tahl Raz: The Surprisingly Simple Way to Launch a 7-Figure Business in 48 HoursNo ratings yet

- The 5 Second Rule by Mel Robbins - Book Summary: Transform Your Life, Work, and Confidence with Everyday CourageFrom EverandThe 5 Second Rule by Mel Robbins - Book Summary: Transform Your Life, Work, and Confidence with Everyday CourageRating: 4.5 out of 5 stars4.5/5 (329)

- Summary, Analysis, and Review of Daniel Kahneman's Thinking, Fast and SlowFrom EverandSummary, Analysis, and Review of Daniel Kahneman's Thinking, Fast and SlowRating: 3.5 out of 5 stars3.5/5 (2)

- Blink by Malcolm Gladwell - Book Summary: The Power of Thinking Without ThinkingFrom EverandBlink by Malcolm Gladwell - Book Summary: The Power of Thinking Without ThinkingRating: 4.5 out of 5 stars4.5/5 (114)

- Tiny Habits by BJ Fogg - Book Summary: The Small Changes That Change EverythingFrom EverandTiny Habits by BJ Fogg - Book Summary: The Small Changes That Change EverythingRating: 4.5 out of 5 stars4.5/5 (111)