Professional Documents

Culture Documents

Keanu Husein Material Testing

Uploaded by

Keanu MitchellCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Keanu Husein Material Testing

Uploaded by

Keanu MitchellCopyright:

Available Formats

Keanu Mitchell Hoerip Tatetdagat 1206292023 Metallurgy and Material Engineering Material Testing Assignment 1

Muhammad Husein Firdaus 1206229396 Metallurgy and Material Engineering

The differences output of mechanical properties in tensile test for HCP, BCC, and FCC are occurs because of their natural crystal structure. Crystal structures define the movement of dislocation along the plane. Easier movement in the plane causing a material to deformed easier. So in this case, if we use different crystal structure in the tensile test, the result will be different for each kind of crystal structure. The deformation in tensile test is closely related with slip. The mechanism by which plastic yielding takes place in metals is called slip. Essentially, all slip processes can be related to dislocation motion in the crystal structure. These linear imperfections in the crystal structure determine the plastic deformation characteristics of a Tensile Test material. Under elastic loading, dislocations remain motionless, and deformation occurs at the interatomic level only. When loading is sufficient to "move" dislocations, slip is said to have taken place and plastic deformation begins. As slip begins, dislocations will start to move in certain favorably oriented crystal planes in polycrystalline metals. The dislocations will eventually begin to pile-up at the grain boundaries and, in order for slip to continue, dislocations must move in less favorably oriented slip planes in neighboring crystals. A greater stress is required for this to happen, and so the material is said to become harder, or to strain-harden. In HCP crystals, which include zinc and magnesium, the planes of closest packing are those containing the hexagons, and the slip directions in those planes are parallel to the diagonals. Hexagonal close-packed crystals therefore have three primary slip systems, although at higher temperatures other, secondary, slip systems may become operative. Face-centered cubic crystals, by contrast, have twelve primary slip systems: the closepacked planes are the four octahedral planes, and each contains three face diagonals as the closest-packed lines. As a result, FCC metals, such as aluminum, copper, and gold, exhibit considerably more ductility than do HCP metals. In body-centered cubic crystals there are six planes of closest packing and two slip directions in each, for a total of twelve primary slip systems. However, the difference in packing density between the closest-packed planes and certain other planes is not great, so that additional slip systems become available even at ordinary temperatures. Consequently, metals having a bcc structure, such as -iron (the form of iron found at ordinary temperatures), tungsten, and molybdenum, has ductility similar to that of FCC metal. Why HCP crystals are more brittle than FCC and BCC crystal? They tend to be more brittle because they have fewer slip system than other structure. Because of this, fewer planes of crystals can glide past each other under stress. Instead, the metal breaks. Why FCC metals are more ductile than BCC metals? FCC has a higher packing efficiency and the slip planes are more closely packed than BCC. In fact, BCC has more slip

systems than FCC. But they are not as closely packed as FCC. For plastic deformation, we need at least 5 independent slip systems. Both FCC and BCC have those. But the previously mentioned factor makes FCC [7] more ductile than BCC. Flat test specimen

All values in inches

Plate type (1.5 in. wide)

Sheet type (0.5 in. wide)

Sub-size specimen (0.25 in. wide)

Gauge length

8.000.01

2.000.005

1.0000.003

Width

1.5 +0.125 -0.25 0.5000.010

0.2500.005

Specimen standard for tensile testing ASTM E8:

Thickness

0.25 < T < 316

0.005 T 0.25

0.005 T 0.25

Fillet radius (min.)

0.25

0.25

Overall length (min.) 18

Length of reduced section (min.)

2.25

1.25

Length of grip section (min.)

1.25

Width of grip section 2 (approx.)

0.75

Specimen standard for tensile testing JIS 2201: W (Widt) 25 L (gauge length) 50 P (Parallel Length) 60 approx R (Radius of Fillet) 15 min T (Thickness) Thickness of material

According to the table that I have research, the difference between the specimen ASTM E8 and JIS 2201 list of the size the result is all of the number in the table are different. There are no similarities in each table. So I can conclude that ASTM and JIS has is not the same, since the results are different.

You might also like

- EBT211 - Lecture 6 - Slip PDFDocument36 pagesEBT211 - Lecture 6 - Slip PDFSollehah SuhaimiNo ratings yet

- 2 - Need For Ductility in SteelDocument16 pages2 - Need For Ductility in SteelTANZIM AHMAD HAZARI TANZIM AHMAD HAZARINo ratings yet

- 06 - Uet FM LecDocument48 pages06 - Uet FM LecAbcNo ratings yet

- ScientificDocument12 pagesScientificbalajiNo ratings yet

- Structure of Engineering MaterialsDocument12 pagesStructure of Engineering Materialsjust_killing_pplNo ratings yet

- Ch-27.1 Basic Concepts On Structure of SolidsDocument39 pagesCh-27.1 Basic Concepts On Structure of SolidsJyotilal SahuNo ratings yet

- Crystal Structure in Metals: Critical Resolved Shear StressDocument1 pageCrystal Structure in Metals: Critical Resolved Shear StressPeyman GrdNo ratings yet

- Ch-27.1 Basic Concepts On Structure of SolidsDocument45 pagesCh-27.1 Basic Concepts On Structure of SolidsdSGDASUDNo ratings yet

- Manufacturing Science and MetallurgyDocument47 pagesManufacturing Science and MetallurgyAppu bjNo ratings yet

- Wear of CeramicDocument3 pagesWear of CeramicGhaith MdljNo ratings yet

- 1.physical and Mechanical Properties of Wrought AlloysDocument83 pages1.physical and Mechanical Properties of Wrought AlloysDhanush kumarNo ratings yet

- Closed-Book Practice-Ch 07 (2016!12!24)Document8 pagesClosed-Book Practice-Ch 07 (2016!12!24)JuanNo ratings yet

- Unit IV Pilling Bedworth RatioDocument7 pagesUnit IV Pilling Bedworth RatioManikandan MuthuvijayanNo ratings yet

- Lec3-Dislocation, Slip Systems and TwiningDocument32 pagesLec3-Dislocation, Slip Systems and Twiningsamurai7_77No ratings yet

- Factors Affecting Fatigue Life: Shot PeeningDocument5 pagesFactors Affecting Fatigue Life: Shot PeeningDeliaChiaNo ratings yet

- Materials Technology Elastic and Plastic BehaviourDocument90 pagesMaterials Technology Elastic and Plastic BehaviourkaranmarwahaNo ratings yet

- Ch-27.1 Basic Concepts On Structure of SolidsDocument39 pagesCh-27.1 Basic Concepts On Structure of SolidsManojNo ratings yet

- Review of Mechanical EngineeringDocument13 pagesReview of Mechanical EngineeringSyedFahadNo ratings yet

- Chap5 FinalDocument49 pagesChap5 Finalamanuelfitsum589No ratings yet

- Schmid's law and factors affecting plastic deformationDocument3 pagesSchmid's law and factors affecting plastic deformationyashvantNo ratings yet

- Chapter 5-Fracture of MetalsDocument18 pagesChapter 5-Fracture of MetalsAsemota OghoghoNo ratings yet

- Lecture Notes CEE474 Spring 2007Document89 pagesLecture Notes CEE474 Spring 2007RajanNo ratings yet

- MM207 Group 11Document52 pagesMM207 Group 11nitharsunNo ratings yet

- Plastic Deformation of Metals and Related PropertiesDocument23 pagesPlastic Deformation of Metals and Related PropertiesVinayak Bhustalimath50% (2)

- Crystal Structure and Plastic Deformation BasicsDocument22 pagesCrystal Structure and Plastic Deformation BasicsME011Mohsin BilalNo ratings yet

- Metallic Crystal Structures (BCC, FCC, HCPDocument10 pagesMetallic Crystal Structures (BCC, FCC, HCPRaniya Nur NNo ratings yet

- Viva Mech Que AnsDocument48 pagesViva Mech Que AnsTejasvi AnantNo ratings yet

- Elastic and Plastic Deformation in MetalsDocument24 pagesElastic and Plastic Deformation in MetalsHarris DarNo ratings yet

- Understanding Common Fracture MechanismsDocument9 pagesUnderstanding Common Fracture Mechanismsabid aliNo ratings yet

- Atomic Bonding: Classic Model: Ionic Lattice, Conduction Electrons Gas" (Fermi)Document8 pagesAtomic Bonding: Classic Model: Ionic Lattice, Conduction Electrons Gas" (Fermi)goron_antonNo ratings yet

- Ductile Fracture WhitepaperDocument9 pagesDuctile Fracture WhitepaperaoliabemestreNo ratings yet

- Defects in The Crystal Structure of MetalsDocument10 pagesDefects in The Crystal Structure of MetalsSahin KerimliNo ratings yet

- Material ScienceDocument16 pagesMaterial ScienceAnish BabuNo ratings yet

- El-Madhoun - Cyclic Stress Strain Response and Dislocation Strucutres in Polycrystaline AluminiumDocument8 pagesEl-Madhoun - Cyclic Stress Strain Response and Dislocation Strucutres in Polycrystaline AluminiumHajatNo ratings yet

- High Temperature MaterialsDocument120 pagesHigh Temperature MaterialsshakeelahmadjsrNo ratings yet

- AASTU Engineering Materials AssignmentDocument8 pagesAASTU Engineering Materials AssignmentAdam MekonnenNo ratings yet

- ESG 332 Test 1 Review SheetDocument12 pagesESG 332 Test 1 Review SheetAshish JohnsonNo ratings yet

- Materials and Processes For Agricultural and Biosystems EngineeringDocument11 pagesMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNo ratings yet

- Crystal DefectsDocument43 pagesCrystal Defectsmdashfakfaysal2003No ratings yet

- Auto 4sem MSEMDocument214 pagesAuto 4sem MSEMkhairnarsayali257No ratings yet

- Solid State StructureDocument12 pagesSolid State StructurezidaaanNo ratings yet

- Defects in Solids: Types, Control, and ImpactDocument25 pagesDefects in Solids: Types, Control, and Impactpramod_kNo ratings yet

- Hall-Petch Relationship: Use in Characterizing Properties of Aluminum and Aluminum AlloysDocument30 pagesHall-Petch Relationship: Use in Characterizing Properties of Aluminum and Aluminum Alloysmridzuan69No ratings yet

- CPUT - Phys Chem 4 Notes On Corrosion 2010Document40 pagesCPUT - Phys Chem 4 Notes On Corrosion 2010Justin JohnNo ratings yet

- The Delamination Theory of WearDocument14 pagesThe Delamination Theory of WearMatheus William CesarNo ratings yet

- ENGINEERING METALLURGY FUNDAMENTALSDocument87 pagesENGINEERING METALLURGY FUNDAMENTALSJay DedhiaNo ratings yet

- DraftDocument5 pagesDraftRicardo GabisNo ratings yet

- SCC NotesDocument4 pagesSCC NotesKhan AbdulNo ratings yet

- Fundametals of material science week 1Document6 pagesFundametals of material science week 1Hanin AqilahNo ratings yet

- Lecture 5 Chapter 4 Crystal StructureDocument41 pagesLecture 5 Chapter 4 Crystal StructureDhruv SahniNo ratings yet

- Ductility Explained: The Ability of Materials to Deform Without FracturingDocument4 pagesDuctility Explained: The Ability of Materials to Deform Without FracturingcelsolcruzNo ratings yet

- Lab 7 Fracture Ductile To Brittle TransitionDocument4 pagesLab 7 Fracture Ductile To Brittle TransitionTommy MilesNo ratings yet

- Material Science Conventional Question and AnswerDocument14 pagesMaterial Science Conventional Question and AnswerChitransh Agarwal100% (3)

- Ch-27.1 Basic Concepts On Structure of SolidsDocument39 pagesCh-27.1 Basic Concepts On Structure of SolidsVinit Khaiwal100% (1)

- Plastic Deformation and MicrostructureDocument10 pagesPlastic Deformation and MicrostructureJeevanantham KannanNo ratings yet

- Dislocations and strengthening mechanismsDocument8 pagesDislocations and strengthening mechanismsjulito paquitNo ratings yet

- Corrosion of HEADocument18 pagesCorrosion of HEAhydromaniaNo ratings yet

- Detailed Accident Investigation of Sunshine Mine DisasterDocument6 pagesDetailed Accident Investigation of Sunshine Mine DisasterKeanu MitchellNo ratings yet

- Flotation: M. Iqbal Kusumah 1206292042Document9 pagesFlotation: M. Iqbal Kusumah 1206292042Keanu MitchellNo ratings yet

- LTM Kimdas 1Document5 pagesLTM Kimdas 1Keanu MitchellNo ratings yet

- Act I Scene I PGDocument2 pagesAct I Scene I PGKeanu MitchellNo ratings yet

- List RDSO DrawingsDocument52 pagesList RDSO Drawingsprasagnihotri75% (4)

- MSCMS Issue 6 Rev-0-Pages-32Document1 pageMSCMS Issue 6 Rev-0-Pages-32Bilal JavaidNo ratings yet

- Radiant CityDocument14 pagesRadiant Citynightmare24No ratings yet

- Hex Head Bolt Din 933: Aa Az MXL Weight Kg/PieceDocument11 pagesHex Head Bolt Din 933: Aa Az MXL Weight Kg/PieceszystNo ratings yet

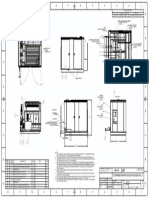

- Imw 50 Single Con CabinaDocument1 pageImw 50 Single Con CabinaIgnacio LopezNo ratings yet

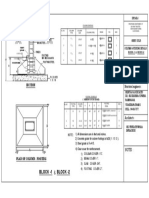

- Column & Footing Details Block-1 & Block-2Document1 pageColumn & Footing Details Block-1 & Block-2Sandeep VarmaNo ratings yet

- Aluminium - Specifications, Properties, Classifications and Classes, Supplier Data by AalcoDocument2 pagesAluminium - Specifications, Properties, Classifications and Classes, Supplier Data by Aalcowongtathong1987No ratings yet

- Clay BlanketDocument2 pagesClay BlanketAhmed Tarek100% (1)

- Cable 2Document12 pagesCable 2V Dhiraj DesaiNo ratings yet

- Foundation PresentationDocument34 pagesFoundation PresentationAbubakar Ashraf AnjumNo ratings yet

- Regleta 6700 Liquid Level IndicatorDocument4 pagesRegleta 6700 Liquid Level IndicatorJulio PCNo ratings yet

- Gravity Based Structure FoundationDocument8 pagesGravity Based Structure FoundationHa NgNo ratings yet

- Precast Concrete Girder BridgesDocument30 pagesPrecast Concrete Girder BridgesPacha Khan KhogyaniNo ratings yet

- TOS III B.ArchDocument213 pagesTOS III B.ArchSunny Varghese A KNo ratings yet

- Register of Significant Twentieth Century ArchitectureDocument8 pagesRegister of Significant Twentieth Century ArchitectureElsa SafriyaniNo ratings yet

- EN ASME RuryDocument3 pagesEN ASME RuryGentelmanOnlyNo ratings yet

- Proper Handling and Installation of Diaphragm Seal SystemsDocument0 pagesProper Handling and Installation of Diaphragm Seal Systemsyousaf_zai_khan81995No ratings yet

- 07Document32 pages07SERGIO CARDENAS CASTILLONo ratings yet

- MOS-002B Door Frame, Door Leaf & IronmongeriesDocument6 pagesMOS-002B Door Frame, Door Leaf & IronmongeriesChezy629No ratings yet

- V-STEEL J-TRACTION OFF-THE-ROAD TIRESDocument2 pagesV-STEEL J-TRACTION OFF-THE-ROAD TIRESJAVIER BERMUDEZNo ratings yet

- LIST OF QUALIFIED MANUFACTURERS SUPPLIERSS March 2019 PDFDocument47 pagesLIST OF QUALIFIED MANUFACTURERS SUPPLIERSS March 2019 PDFMaaz JunaidiNo ratings yet

- Analysis of Tension MembersDocument7 pagesAnalysis of Tension MembersAekJayNo ratings yet

- 00 Incident Investigation Report COMPLETEDocument56 pages00 Incident Investigation Report COMPLETEShannon MacDonald100% (5)

- ConcreteDesign PDFDocument64 pagesConcreteDesign PDFJuanAlfaroRodríguezNo ratings yet

- Introduction To History of Contemporary ArchitectureDocument2 pagesIntroduction To History of Contemporary ArchitectureSaumya ShuklaNo ratings yet

- Spit TEC DGU GB 1 PDFDocument216 pagesSpit TEC DGU GB 1 PDFabdelkader benabdallahNo ratings yet

- General Contract Construction SampleDocument6 pagesGeneral Contract Construction SampleKrizzy GayleNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- ACI 304R Guide For Meas., Mix., Transp., & Placing ConcDocument41 pagesACI 304R Guide For Meas., Mix., Transp., & Placing ConcVasanth KumarNo ratings yet

- Hansen PSV'S PDFDocument4 pagesHansen PSV'S PDF9082888lcNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Radium Girls: Women and Industrial Health Reform, 1910-1935From EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Rating: 4.5 out of 5 stars4.5/5 (4)

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849From EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Rating: 4 out of 5 stars4/5 (5)

- Establishing an occupational health & safety management system based on ISO 45001From EverandEstablishing an occupational health & safety management system based on ISO 45001Rating: 4 out of 5 stars4/5 (5)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)

- One Health: Integrated Approach to 21st Century Challenges to HealthFrom EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataNo ratings yet

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 4.5 out of 5 stars4.5/5 (2)

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceFrom EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceRating: 5 out of 5 stars5/5 (1)