Professional Documents

Culture Documents

Typ 5 Eng

Uploaded by

sasan490 ratings0% found this document useful (0 votes)

51 views4 pagesThe access floor type 5 can be offered in different variants / systems. Depending on the requirements of the user, systems are suitable for: standard office areas offices requiring increased static load bearing capacity, e.g. Lecture rooms, training and performance rooms, therapy rooms and construction offices. Systems reinforced by additional equipment can be delivered for: Floors with fork-lift traffic, for industrial plants and laboratories.

Original Description:

Original Title

Typ_5_eng

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe access floor type 5 can be offered in different variants / systems. Depending on the requirements of the user, systems are suitable for: standard office areas offices requiring increased static load bearing capacity, e.g. Lecture rooms, training and performance rooms, therapy rooms and construction offices. Systems reinforced by additional equipment can be delivered for: Floors with fork-lift traffic, for industrial plants and laboratories.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

51 views4 pagesTyp 5 Eng

Uploaded by

sasan49The access floor type 5 can be offered in different variants / systems. Depending on the requirements of the user, systems are suitable for: standard office areas offices requiring increased static load bearing capacity, e.g. Lecture rooms, training and performance rooms, therapy rooms and construction offices. Systems reinforced by additional equipment can be delivered for: Floors with fork-lift traffic, for industrial plants and laboratories.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Floor Systems

MERO Access Floor Typ 5 / Wood

Innovative solution out of one hand

Development Access oor

Consultation Hollow oor

Project management Loose covering tiles and

Production Laying

Installation Change of applied coverings

2

The access oor type 5 can be

offered in different variants/

systems. Depending on the re-

quirements of the user, systems

are suitable for:

Standard ofce areas

Ofces requiring increased

static load bearing capacity,

e.g. lecture rooms, training

and performance rooms, the-

rapy rooms and construction

ofces

Industrial buildings with

light operations (e.g. storage

rooms, laboratories with light

operations, libraries)

Computer centres

Electric switching station rooms

On request, systems reinforced

by additional equipment can be

delivered for:

Floors with fork-lift trafc, for

industrial plants and laborato-

ries

MERO-TSK access oor sy-

stems are tested acc. to DIN EN

12825 and certied by indepen-

dent laboratories.

High exibility

Easy processing of panel

material for installation

Low panel and system weight

Easy handling of later additio-

nal installations

Achieves plenum as standard

High preventive re protection

properties

High sound protection proper-

ties

Variable construction heights,

heights of more than 1.000

mm on request

Large variety of oor co-

verings can be applied

Floor panel:

The oor panel type 5 consists

of high density wooden mate-

rial of emission class E1. The

panel edges are chamfered and

protected all round by synthetic

trim. On request, panel surface

and/or panel underside can be

provided with galvanized steel

sheet or aluminium foil. Panel

can be produced in different

thickness, density and dimensi-

on acc. to requirements.

MERO-TSK uses only environ-

ment friendly material. There-

fore, waste disposal or recycling

is not a problem.

Fields of application Advantages: Construction principle:

3

Understructure:

The understructure can be used

for all panel types. It consists

of steel pedestals adjustable in

height to t with precision. All

Flexibility:

The use of panels with oor

coverings applied in factory

guarantees high exibility. This

variant allows to change panels

with mounting units like sockets

etc. against standard panels.

Partition walls:

For an unlimited use of the ac-

cess oor cavity partition walls

should always be installed on

the access oor system. Only

re section walls respectively

walls between different building

sections should be installed

directly on the suboor. Parti-

tion walls with re resistance

requirements can be installed

on the access oor system and

supplemented with re fascias

below the access oor on re-

quest.

Floor coverings:

The access oor systems

MERO-TSK type 5 can be provi-

ded with different types of oor

coverings.

Elastic oor coverings suitable

for access oor like PVC, lino-

leum, rubber as well as laminate

can only be applied in the fac-

tory.

Textile oor coverings can be

glued or loosely laid on the oor

panels. Glued oor coverings

must be suitable for access

oor. MERO-TSK has a lot of

experience in this eld and can

even test the suitability of new

oor coverings in own labora-

tories.

For loosely laid textile oor co-

vering tiles panels with alumi-

nium foil or steel sheet on top

should be used. Panels with

steel sheet on top offers utmost

protection during construction

period and enables additional-

ly the installation of magnetic

oor coverings like MERO-TSK

Magnetoor. During installation

of loosely laid oor covering

tiles please see that the neces-

sary release bond adhesive does

not inltrate the panel joints in

order to avoid that panels stick

together (not necessary with

MERO-TSK Magnetoor).

Furthermore, oor covering ti-

les should always be installed

middle over cross to the access

oor module.

Glueing of carpet rolls is only

possible by additional measu-

res. However, it should generally

be avoided as it stands against

the exibility of an access oor

system. Type 5 panels with steel

sheet on the underside can also

be used for parquet. However,

due to its swelling behaviour not

all parquet coverings are suitab-

le. For detailed information plea-

se contact MERO-TSK.

Delivery and installation of

oor coverings:

MERO-TSK stores standard

oor coverings being available

at short notice. If the oor co-

verings will not be applied in our

factory we recommend to have

application and delivery done

by/or under instruction of skilled

MERO-TSK installers. This avo-

ids problems between different

suppliers which could become

cost-intensive for the contractor

or afterwards the builder.

Mounting units

Cutouts for mounting units like

sockets, air outlets etc. can

either be done in factory or on

jobsite. However, step bores for

twist air outlets can be done in

the factory only.

Wall connections:

The access oor system con-

nected to walls or rising building

parts are done by a special self-

adhesive foam tape which avo-

ids sound conduction and seals

the connection joints. For rigid

installations (e.g. heating tubes)

a distance of 120 mm should

generally be kept from the wall

which enables the installation

of system pedestals and avoids

expensive and additional sound

absorbing wall supports. The

edges of cut panels have always

to be sealed.

Special advice for use:

With beginning of installation

the thermal conditions of nal

use should already been given.

Renovation:

MERO-TSK has the necessary

know how in the eld of access

oor renovation. We have a ma-

chinery for the removal of worn

oor coverings, application and

edging of new ones as well as its

execution by professionals.

For the renovation of old buil-

dings with very low nished ac-

cess oor heights (after removal

of the screed height) please see

our special brochure for type

5 systems.

Accessories:

(see brochure)

cutouts

special wall connections

sockets

air outlets

air conditioning panels

fascias (re, acoustic, air

conditioning)

front fascias

bridgings

expansion joints

stairs

ramps

additional foot fall sound

absorption

MERO-TSK underoor hea-

ting/cooling

MERO-TSK oor coverings

pedestals are galvanized and

passivated against corrosion

The base plate is designed to

be glued to the suboor. On re-

quest, pedestal base plate can

aditionally be dowelled.

For installation pedestal head is

provided with gasket for panel

xing and sound dampening.

The gasket is electrically con-

ductive and can be provided with

metal rivets if high frequency

shielding is required.

The use of stringers increases

the lateral stability of the whole

construction. Later installation of

stringers is not a problem. On re-

quest, stringers can be screwed

with pedestal had which avoids

high frequency disturbances.

Stringers are installed as U-type

stringers for lateral stability and

as C-type stringers for increase

of load bearing capacity and la-

teral stability.

Planning instructions

MERO-TSK

International GmbH & Co.KG

Floor System Division

Lauber Strae 7

D-97357 Prichsenstadt/

Germany

Phone: +49 (0) 9383/203-351

Fax: +49 (0) 0383/203-629

Email: bodenysteme@

mero-tsk.de

Internet: www.mero-tsk.de

2

3

1

0

e

0

6

/

S

u

b

j

e

c

t

t

o

t

e

c

h

n

i

c

a

l

c

h

a

n

g

e

s

w

i

t

h

o

u

t

f

u

r

t

h

e

r

n

TV certicate since 2005-01-20

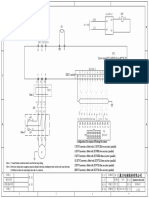

Technical Data*: Access Floor Type 5 / Wood

*For detailed technical data please see the data

sheets of the different type 5 systems or internet

page under www.mero-tsk.de.

1. Floor covering, steel or aluminium sheet

2. Floor panel

3. Steel sheet, aluminium nishing or without nishing

4. Gasket

5. Pedestal head

6. Hexagonal nut

7. Tube

8. Pedestal base plate glued to the suboor,

dowelled on request

l. 8odenbelag, Stahlblech oder

Alubeschichtung

2. 8odenplatte

3. Stahlblech, Alubeschichtung oder

ohne 8eschichtung

4. Stutzenkopfauflage

5. Stutzenkopf

6. Sechskantmutter

7. Pohr

8. Puplatte am Unterboden verklebt,

bei 8edarf verdubelt

0

8

.

0

7

/

T

y

p

e

5

/

S

u

b

j

e

c

t

t

o

c

h

a

n

g

e

w

i

t

h

o

u

t

f

u

r

t

h

e

r

n

o

t

i

c

e

Panel:

Dimension: 600 x 600 mm (special module on request)

Panel thickness: (without oor covering) ~ 23 - 39 mm

Panel surface: Aluminium foil, steel sheet or covering

Panel underside: Aluminium foil or steel sheet

System weight: ~ 23 - 36 kg/m

(without oor covering, oor height 250 mm)

Panel weight: ~ 7,5 - 12 kg/piece

Panel material: High density wood material panel

Understructure:

Module: 600 x 600 mm

Pedestal material: galvanized steel pedestals

Construction height: (without oor covering) ~ 55 2400 mm

Recommendation for use: we recommend to use stringers from a nished oor

height of 500 mm on, e.g. u-type stringers

Load values:

Concentrated load:

acc. to DIN EN 12825 class 1 - 5

Nominal load 2.000 5.000 N (increased load steps on request)

Ultimate load > 4.000 10.000 N

Electrostatic: > 10

5

Ohm (Depending on systems and oor covering)

Fire protection:

Building material class acc. to DIN 4102 T1: B2 or B1

Fire resistance class acc. to DIN 4102 T2: F30 (depending on system)

Thermal conductivity: (base material) ~ 0,13 W/mK

Acoustic values depending on system and oor covering:

New terms acc. to DIN EN

sound reduction index R

L,w,P

44 57 dB Standard ank level difference D

n,f,w,P

normalized impact sound pressure level L

n,w,P

71 45 dB Standard ank impact sound level L

n,f,w,P

improvement of sound pressure level

reduction L

w,P

15 32 dB Impact sound reduction L

w,P

You might also like

- Technical Data :: MERO Hollow Floor Combi T Hollow Floor Combi T DetailsDocument6 pagesTechnical Data :: MERO Hollow Floor Combi T Hollow Floor Combi T DetailsGiulio BosiNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Technical Data :: System Details Hollow Floor Combi T MERO Hollow Floor Combi TDocument6 pagesTechnical Data :: System Details Hollow Floor Combi T MERO Hollow Floor Combi Tadventure11111No ratings yet

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesFrom EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesRating: 3.5 out of 5 stars3.5/5 (3)

- PEB Requirment by ClientDocument4 pagesPEB Requirment by ClientViraj ModiNo ratings yet

- Airtight PanelDocument4 pagesAirtight PanelParth BhattNo ratings yet

- Wood-Aluminium Transom-Mullion Construction Batimet TM60 SE Formale Anforderungen An Die Konstruktionen Formal Requirements For ConstructionDocument4 pagesWood-Aluminium Transom-Mullion Construction Batimet TM60 SE Formale Anforderungen An Die Konstruktionen Formal Requirements For ConstructionLiew Yau WeiNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Iso Floor BergvikDocument8 pagesIso Floor BergvikcokiaaNo ratings yet

- Corus Panels Profiles SystemsDocument22 pagesCorus Panels Profiles SystemsMiruna MaziluNo ratings yet

- Sandwich Panels en Lo RUUKKIDocument8 pagesSandwich Panels en Lo RUUKKIszeestherNo ratings yet

- Beam and Block Floor Systems PDFDocument3 pagesBeam and Block Floor Systems PDFdamindaNo ratings yet

- Bu Sistema Ste en PDFDocument33 pagesBu Sistema Ste en PDFsebkahnNo ratings yet

- Terminal Boxes CatalogueDocument9 pagesTerminal Boxes Cataloguedeepthik27No ratings yet

- Metsec JoistsDocument40 pagesMetsec Joistsikirby7750% (2)

- Building Construction-V: Types of Metal CladdingDocument6 pagesBuilding Construction-V: Types of Metal CladdingShrish BaglaNo ratings yet

- Tehnologia Posi StrutDocument35 pagesTehnologia Posi Strutdanut_docNo ratings yet

- Lindner KatalogDocument64 pagesLindner KatalogAnonymous hISvHbfiB1No ratings yet

- 2013 Mason Ancon MDC BracketsDocument36 pages2013 Mason Ancon MDC BracketsalwezalokNo ratings yet

- 155 - Supalux Water Resistant Shaftwall PDFDocument0 pages155 - Supalux Water Resistant Shaftwall PDFodemircioglu2No ratings yet

- 09 - PEX20 Screed & Concrete FloorDocument4 pages09 - PEX20 Screed & Concrete FloorIbrahim SahinNo ratings yet

- 0421 Roofing - CombinedDocument6 pages0421 Roofing - CombinedRiski SuhardinataNo ratings yet

- Eternit PločeDocument28 pagesEternit PločedarkopavicNo ratings yet

- Obo Specification - Metal 1.5mm Raceways + JBM + Gesx + Service PoleDocument2 pagesObo Specification - Metal 1.5mm Raceways + JBM + Gesx + Service PolepmyilsamyNo ratings yet

- CGC Shaft ConstructionDocument40 pagesCGC Shaft ConstructionMartin LarinNo ratings yet

- Quellluft enDocument4 pagesQuellluft enadventure11111No ratings yet

- Lattice Beam Technical ManualDocument40 pagesLattice Beam Technical ManualmariovalentiNo ratings yet

- ModuSec-Secure Modular Construction SystemDocument49 pagesModuSec-Secure Modular Construction SystemBrendan LynchNo ratings yet

- Shed ProfileDocument16 pagesShed ProfilesuganthiNo ratings yet

- Ejot Solar Full enDocument24 pagesEjot Solar Full enJie RongNo ratings yet

- Cabling Standard - ANSI-TIA-EIA 569 A - Commercial Building Standard For Telecom Pathway and SpacesDocument55 pagesCabling Standard - ANSI-TIA-EIA 569 A - Commercial Building Standard For Telecom Pathway and Spacestrongdan15No ratings yet

- 10.00 Internal Walls and Partitions v19Document4 pages10.00 Internal Walls and Partitions v19Joseph Cloyd LamberteNo ratings yet

- Emerging Technologies For Housing & Building Construction: Shortlisted by BMPTCDocument14 pagesEmerging Technologies For Housing & Building Construction: Shortlisted by BMPTCHaider Abbas100% (1)

- Technical Specification Main WarehouseDocument4 pagesTechnical Specification Main Warehouseadr_kharisma100% (2)

- Argeton Technical InformationDocument41 pagesArgeton Technical InformationSandu CiprianNo ratings yet

- Comparison Exd Vs Exe Design EnclosuresDocument10 pagesComparison Exd Vs Exe Design EnclosuresHarpreet SutdharNo ratings yet

- Commercial Building Standard For Telecom Pathway & SpacesDocument58 pagesCommercial Building Standard For Telecom Pathway & Spacesamhosny64No ratings yet

- 12 Pitched RoofsDocument3 pages12 Pitched Roofshkalloli@gmail.comNo ratings yet

- Wall ConstructionDocument22 pagesWall ConstructionJohn Michael CastilloNo ratings yet

- Fireclad System BoralDocument8 pagesFireclad System BoralSuciul E ViuNo ratings yet

- Matrix III Louvre System For Supply and Extract: Recessed FrameDocument4 pagesMatrix III Louvre System For Supply and Extract: Recessed FrameMunawar AbdullatifNo ratings yet

- Systemline Guide 3Document62 pagesSystemline Guide 3Zamfira OctavianNo ratings yet

- Katalog E Vollversion - 07 PDFDocument15 pagesKatalog E Vollversion - 07 PDFChristian HinostrozaNo ratings yet

- Metal Operation TheatreDocument14 pagesMetal Operation TheatrePyrotech MetalSpace Solutions Pvt LtdNo ratings yet

- Facades and InterfacesDocument22 pagesFacades and InterfaceshkatniwalaNo ratings yet

- IKO BUFR Design Guide Feb 2012Document40 pagesIKO BUFR Design Guide Feb 2012Deana WhiteNo ratings yet

- Rittal Technical System Catalogue Compact Enclosures AE 5 2591 PDFDocument10 pagesRittal Technical System Catalogue Compact Enclosures AE 5 2591 PDFMaxi SchremmelNo ratings yet

- HC Walls ManualDocument20 pagesHC Walls ManuallyeshiunNo ratings yet

- Catalogue Mp200Document33 pagesCatalogue Mp200Adrian TudorNo ratings yet

- Bid Doc (4) 2Document13 pagesBid Doc (4) 2Royal AirconNo ratings yet

- Solitile SL3500 September 2019Document4 pagesSolitile SL3500 September 2019MarlonNo ratings yet

- 381GB Dachsys2000 0907 PDFDocument16 pages381GB Dachsys2000 0907 PDFVas SteelNo ratings yet

- Rowan University Design Guide 2013Document10 pagesRowan University Design Guide 2013zeliteNo ratings yet

- Vicwest Metal Roof SystemsDocument24 pagesVicwest Metal Roof SystemsNelu TrandafirNo ratings yet

- Eng MmountDocument38 pagesEng MmountIbrahimElKelanyNo ratings yet

- CladdingDocument19 pagesCladdingTakudzwa MwashushaNo ratings yet

- Eurovent-6 1Document32 pagesEurovent-6 1sasan49No ratings yet

- Eurovent-6 6Document82 pagesEurovent-6 6sasan49No ratings yet

- Eurovent-6 1Document32 pagesEurovent-6 1sasan49No ratings yet

- Eurovent-2 2Document12 pagesEurovent-2 2Hugo MorandavidsonNo ratings yet

- Eurovent 2.3Document24 pagesEurovent 2.3pipipopo75100% (1)

- Eurovent-2 4 PDFDocument27 pagesEurovent-2 4 PDFKevin TsuiNo ratings yet

- Australia Network - Nexus - EpisodesDocument4 pagesAustralia Network - Nexus - Episodessasan49No ratings yet

- A 50RO BG Hydronic Heating and Plumbing Products BrochureDocument40 pagesA 50RO BG Hydronic Heating and Plumbing Products Brochuresasan49100% (1)

- MSS SP 80 1997 Bronze Gate, Globe, Angle, Check ValvesDocument28 pagesMSS SP 80 1997 Bronze Gate, Globe, Angle, Check Valvessasan49No ratings yet

- Amca 511Document59 pagesAmca 511tjaycruz2100% (1)

- Principles of Siphonic Roof Drainage SystemsDocument3 pagesPrinciples of Siphonic Roof Drainage Systemssasan49No ratings yet

- HighRise Building Construction ProfileDocument161 pagesHighRise Building Construction ProfileHamayet Rasel86% (7)

- NIOSH Interim Recommendations For The Cleaning and Remediation of Flood-Contaminated HVAC Systems: A Guide For Building Owners and ManagersDocument5 pagesNIOSH Interim Recommendations For The Cleaning and Remediation of Flood-Contaminated HVAC Systems: A Guide For Building Owners and Managerssasan49No ratings yet

- Measuring Thermal Mass of Sustainable Concrete Mixes: K0838912@kingston - Ac.ukDocument8 pagesMeasuring Thermal Mass of Sustainable Concrete Mixes: K0838912@kingston - Ac.ukMickey DalbeheraNo ratings yet

- Sika PDS - E - Icosit KC 340-65 PDFDocument2 pagesSika PDS - E - Icosit KC 340-65 PDFlwin_oo2435No ratings yet

- IDTF (International Database Transport For FEED)Document8 pagesIDTF (International Database Transport For FEED)ivogabrielNo ratings yet

- 2021-AP Price List-Fixed Flames Controllers - Issue 3V12 - 20201211 - FinalDocument156 pages2021-AP Price List-Fixed Flames Controllers - Issue 3V12 - 20201211 - FinalListyo HandriyantoNo ratings yet

- Samsung Compressor: Il-Free Centrifugal Air Compressor M/SM100/SME SeriesDocument11 pagesSamsung Compressor: Il-Free Centrifugal Air Compressor M/SM100/SME SeriesSharad KokateNo ratings yet

- Bifurcated Axial FansDocument2 pagesBifurcated Axial FansNagiahTNo ratings yet

- PM High Strength Magnetic Alloys PDFDocument13 pagesPM High Strength Magnetic Alloys PDFSAMIT JAINNo ratings yet

- MEMS Base Micro Heater DesignDocument25 pagesMEMS Base Micro Heater DesignGaurav SumanNo ratings yet

- Project On Partial Replacement of Cement With Marble PowderDocument11 pagesProject On Partial Replacement of Cement With Marble PowderSaurabh Pandey100% (2)

- Waste Heat Recovery at Compressor Stations: The Path Towards Novel and High-Impact Technologies and Their ImplementationDocument33 pagesWaste Heat Recovery at Compressor Stations: The Path Towards Novel and High-Impact Technologies and Their ImplementationraaaghaffarNo ratings yet

- TOR049 NovDec2020 WebDocument80 pagesTOR049 NovDec2020 WebVarun KumarNo ratings yet

- Line Index Table For Miano-18 Wellhead CompressionDocument2 pagesLine Index Table For Miano-18 Wellhead CompressionHafiz AkhtarNo ratings yet

- D10D632 Electrical Schematic diagram-ENDocument31 pagesD10D632 Electrical Schematic diagram-ENPrakashNo ratings yet

- Soot BlowersDocument279 pagesSoot BlowersLALCHAND RAWANI100% (2)

- Building EstimateDocument7 pagesBuilding EstimateRamesh rammiNo ratings yet

- Materials Final Project ReportDocument90 pagesMaterials Final Project Reportapi-302735992No ratings yet

- Industrial Environmental Chemistry - Waste MinimizDocument310 pagesIndustrial Environmental Chemistry - Waste MinimizAdisu ButaNo ratings yet

- Laboratory Equipment and Skills: Recognizing Lab EquipmentDocument2 pagesLaboratory Equipment and Skills: Recognizing Lab EquipmentDinesh ManikandanNo ratings yet

- Corrosion Damage Report (CDR)Document4 pagesCorrosion Damage Report (CDR)diaccessltd_17172961No ratings yet

- Dry TransformersDocument6 pagesDry TransformersJose Luius100% (1)

- Section 2: Insulation Materials and PropertiesDocument10 pagesSection 2: Insulation Materials and PropertiesJersey PerlasNo ratings yet

- Regenerated FibresDocument31 pagesRegenerated Fibreszxy_cbe100% (1)

- Armoured Unarmoured: Size (MM)Document3 pagesArmoured Unarmoured: Size (MM)Bonaventure NzeyimanaNo ratings yet

- Qa QC Welding Piping Inspector Resume An.Document6 pagesQa QC Welding Piping Inspector Resume An.nivasssvNo ratings yet

- The Study of Solar Absorption Air-Conditioning SystemsDocument8 pagesThe Study of Solar Absorption Air-Conditioning SystemsJaime Haro EstropNo ratings yet

- 05 Fuel SystemDocument109 pages05 Fuel SystemUtomo BudidarmoNo ratings yet

- DEAERATORDocument26 pagesDEAERATORSai Swaroop100% (2)

- Procurement & Distribution Logistics: Tutor: Mr. Michael KleinDocument14 pagesProcurement & Distribution Logistics: Tutor: Mr. Michael KleinRiya OberoiNo ratings yet

- Dow - Epoxy-Curing-Agents-Product-Overview NADocument12 pagesDow - Epoxy-Curing-Agents-Product-Overview NAfatemeh.ahmadkhaniNo ratings yet

- Aqualine SinglesoftenerDocument2 pagesAqualine Singlesoftenernermeen ahmedNo ratings yet

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesFrom EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (242)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationFrom EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettRating: 4 out of 5 stars4/5 (1)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyFrom EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyRating: 4 out of 5 stars4/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Estimating Construction Profitably: Developing a System for Residential EstimatingFrom EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNo ratings yet

- Civil Engineer's Handbook of Professional PracticeFrom EverandCivil Engineer's Handbook of Professional PracticeRating: 4.5 out of 5 stars4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsFrom EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsRating: 1 out of 5 stars1/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideFrom Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideRating: 3.5 out of 5 stars3.5/5 (7)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishFrom EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishRating: 4 out of 5 stars4/5 (3)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesFrom EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesNo ratings yet

- Essential Building Science: Understanding Energy and Moisture in High Performance House DesignFrom EverandEssential Building Science: Understanding Energy and Moisture in High Performance House DesignRating: 5 out of 5 stars5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Field Guide for Construction Management: Management by Walking AroundFrom EverandField Guide for Construction Management: Management by Walking AroundRating: 4.5 out of 5 stars4.5/5 (3)