Professional Documents

Culture Documents

Flow Visualization

Uploaded by

Muralikrishnan GMCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flow Visualization

Uploaded by

Muralikrishnan GMCopyright:

Available Formats

Module IV

Compressible Fluid Flow

Semester VIII

FLOW VISUALIZATION Flow visualization is the art of making flow patterns visible. Most fluids (air, water, etc.) are transparent, thus their flow patterns are invisible to us without some special methods to make them visible. Moving fluids often form patterns so complicated that intuition fails when we try to imagine them. Some flows are so complicated that we cannot analyse all their details from the governing equations, even with the biggest computers now available. 1. Tracers Tracers are fluid additives that permit the observation of flow patterns. An effective tracer does not alter the flow pattern but is transported with the flow and is readily observable. It is important that tracers are not affected by gravitational or centrifugal forces resulting from density differences. 2. Streamers Flow visualization along a surface can be accomplished by attaching tufts of wool, silk or cotton to the surface, or if flow away from the surface is to be observed, they may be supported on wires. Surface tufts may be used to observe the transition from laminar to turbulent motion. They may also be used to study flow separation qualitatively, where the violent motion of the tufts or their tendency to point in the upstream direction identifies that separation is taking place. 3. Liquid films This method makes use of contrast obtained on account of the unequal rates of evaporation of a liquid film in the laminar and turbulent regions. A film of some volatile oil is applied on the surface of the model prior to starting the flow. When the air flow takes place over this surface the evaporation of the oil film in the turbulent region is faster than in the laminar region. A clearer contrast is obtained by using black paint on the surface. This method can be used for aerofoil blade surfaces in wind tunnels. 4. Smokes Smoke has been used successfully to study the detailed structure of complex flow phenomena. It is the most popular agent used for flow visualization in wind tunnels. One injection technique is the so-called smoke-wire method, where the smoke is generated by vaporizing oil from a fine electrically heated wire. The method can be applied to flows where the Reynolds number based on the wire diameter is less than 20. Smoke can

[Dept. of Mech. Engg.]

[College of Engineering Adoor]

[VENKITARAJ K P]

Page

Module IV

Compressible Fluid Flow

Semester VIII

also be released from a small-diameter tube or rake to create one or more streaklines. 5. Optical Flow Visualization Methods Flow patterns in gas streams can be observed by means of optical techniques which are sensitive to variation in gas density. At high velocity, changes in density can be sufficiently large to cause comparable changes in the refractive index of the gas. The velocity of light in a medium increases as the density of the medium decreases. Also, the change in density of a gas produce changes in the refractive index of the gas, which in turn changes the direction of the light rays that passes through the gas. When these rays are projected on a screen, the intensity of illumination becomes sensitive to the direction of the light rays. The optical index of refraction n of a medium is defined as ratio of the speed of light in a vacuum (a0) to the speed of light in that medium (a).

The refractive index is related to the fluid density by Snells law as

where is a constant characteristic of the gas, is the local density and s is the standard density ( at 0C and atm pressure) The refractive index n is related to the fluid density also through the ClausiusMosotti equation, which for a gas reduces to the simpler form of the GladstoneDale equation

with being the gas density and K the GladstoneDale constant, which has the dimension of 1/, is specific for a gas, and depends weakly on the wavelength of light used. In compressible flow of an ideal gas the density is a function of the Mach number, and, for these flows, the information obtainable with the methods is therefore a measure of the Mach number or flow velocity.

[Dept. of Mech. Engg.]

[College of Engineering Adoor]

[VENKITARAJ K P]

Page

Module IV

Compressible Fluid Flow

Semester VIII

The optical methods in common use ( interferometer, schlieren and shadowgraph) depends on one of the two physical phenomena: (i) the speed of light depends on the index of refraction of the medium through which it passes, and the index of refraction of a gas in turn depends upon its density; and as a consequence of this first phenomenon, (ii) light passing through a density gradient in a gas (and therefore through a gradient of index of refraction) is deflected in the same manner as though it were passing through a prism. In high speed gas flow the density changes are sufficiently large to make these phenomena sizable enough for optical observation. The interferometer, based on phenomenon (i), measures directly changes of density, and is primarily suited for quantitative determination of density field. The schlieren method based on phenomenon (ii), measures density gradients. Although it is theoretically adaptable to quantitative use, it is inferior to the interferometer in this respect, and its greatest utility is in giving an easily interpretable picture of the flow field together with a rough picture of the density variations in the flow. The shadow graph method, also based on phenomenon (ii), measures the second derivative of the density (i.e., first derivative of density gradient). Therefore it makes visible only those parts of the flow where density gradients changes rapidly, and it has found it greatest utility in the study of shock waves. Of the three methods mentioned, the interferometer yields the most information and the shadowgraph the least. On the other hand the interferometer is the most costly and the most difficult to operate, whereas the shadowgraph is the least costly and the easiest to operate. Interferometer In this technique the variation of density in the flow field is directly determined from the pattern obtained on the screen or a photographic plate. The Mach-Zehnder interferometer shown in figure is extensively used in wind tunnel experimentation. It consists of two fully reflecting mirrors M1 & M2, and two half silvered mirrors (splitters) M1 & M2. Light from the source first passes througha collimating lense which renders light parallel, and then passes through a monochromatic filter. It then reaches the first splitter M1, which passes half the light and reflects the other half. The light which is reflected is changed back to its original direction by the mirror M2 and then passes through the test section.

[Dept. of Mech. Engg.]

[College of Engineering Adoor]

[VENKITARAJ K P]

Page

Module IV

Compressible Fluid Flow

Semester VIII

The light which passes the first splitter M1 passes through the reference section (where the density is known) and reaches mirror M1. The mirror M1 reflects the light towards splitter M2 where the two beams now get combined into a single coherent beam. The combined beam is now focused by a lens system on to a photographic plate. When there is no flow through the test section (i.e, no density gradient), the two beams joined at the splitter M2 will be in phase and the pattern of illumination obtained on the screen will be uniform. When flow is established in the test section the beam of light passing through its varying density field will be out of phase with the beam coming through the reference section. This results in an interference pattern on the screen. the pattern obtained don the screen consists a series of light and dark fringes. Each fringe represents a region of consatnt density. The differences in density between in gas in the test section and the gas in the reference section are obtained by analysing the fringe pattern. Schlieren Method The schlieren system is used for the flow visualisation and is based on the principle of refraction of light as being proportional to the density gradient. It has a wide range of applications, including the visualisation of boundary layers, combustion, shock waves, and convection currents within fluids during heating or cooling, and air flow over models in wind tunnel testing.

Page

A beam of light is sent through the test section from the light source by the properly oriented concave mirror M1. The beam coming out from the test

[Dept. of Mech. Engg.]

[College of Engineering Adoor]

[VENKITARAJ K P]

Module IV

Compressible Fluid Flow

Semester VIII

section is reflected on to a screen by the suitable located concave mirrors M2 & M3.

A sharp knife-edge is inserted at the focal point of the mirror M2 so that it intercepts about half the light. When there is no flow through the test section the screen is uniformly illuminated by the portion of the light that escapes the knife edge. When the flow is established in the test section the light rays passing through regions with density gradient will get deflected as though it had passed through a prism. Depending on the orientation of the knife edge with respect to the density gradients, more or less amount of light escapes the knife edge and illuminates the screen. Thus the Schlieren system makes density gradients visible in terms of illumination. A photographic plate at the viewing screen records these density gradients as different shades of gray. Shadowgraph method The shadow graph method is particularly suitable where there are large density gradients, such as in the flow across a shock wave. This method is simpler, less expensive and easy to operate compared to other two methods explained above. But it does not provide any fine details of the density field, and therefore is used for qualitative analysis. A shadow system comprises a light source, a collimating lens, and a viewing screen or photographic plate. If the source is far from the test section, then the collimating lens is not required.

[Dept. of Mech. Engg.]

[College of Engineering Adoor]

[VENKITARAJ K P]

Page

Module IV

Compressible Fluid Flow

Semester VIII

When the gas is not flowing through the test section, there is no density gradient and the screen is illuminated uniformly. When the flow is established in the test section the light beam will be refracted wherever there is a density gradient. However, if the density gradient were constant each ray will be deflected by the same amount, and there would be no change in the illumination on the screen. If the density gradient varies there will be tendency for the light rays to get diverge or converge. Bright regions appear where the light rays converge, dark regions where light rays diverge. The resulting image on the screen is thus a series of light and dark regions. Thus it is evident that the variations in the illumination of the screen are proportional to the second derivative of density. The shadow graph is particularly useful for viewing shock waves. In the region of shock wave, the derivative of density gradient is positive on the upstream side of the shock and negative on the downstream side. Hence the shock wave appears as a dark region on the screen followed by a bright region. The upstream and downstream of the shock the screen is uniformly illuminated.

[Dept. of Mech. Engg.]

[College of Engineering Adoor]

[VENKITARAJ K P]

Page

You might also like

- Centrifugal Pump Piping Design LayoutDocument19 pagesCentrifugal Pump Piping Design Layoutvijayakumar2015No ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- Voluntary Specification For Self Adhering Flashing Used For Installation of Exterior Wall Fenestration Products (AAMA711-05)Document17 pagesVoluntary Specification For Self Adhering Flashing Used For Installation of Exterior Wall Fenestration Products (AAMA711-05)Mauricio Riquelme100% (2)

- Flow Visualization Techniques and Their use-RH5001A53 - Atish Kumar-CIV 208Document16 pagesFlow Visualization Techniques and Their use-RH5001A53 - Atish Kumar-CIV 208Atish Kumar100% (1)

- Fundamentals of Flow VisualizationDocument10 pagesFundamentals of Flow Visualizationnsa10124100% (1)

- Gas Turbine Power PlantDocument42 pagesGas Turbine Power PlantMuralikrishnan GM100% (3)

- SO 13320, Particle Size Analysis - Laser Diffraction Methods - Part 1: General PrinciplesDocument5 pagesSO 13320, Particle Size Analysis - Laser Diffraction Methods - Part 1: General PrincipleslouispriceNo ratings yet

- Äkta Pilot 600: Operating InstructionsDocument226 pagesÄkta Pilot 600: Operating InstructionsKatie MickoNo ratings yet

- Article J Agalloco L Mestrandrea Pharmaceutical Technology and Biopharm Ebook Vaccine 2017Document9 pagesArticle J Agalloco L Mestrandrea Pharmaceutical Technology and Biopharm Ebook Vaccine 2017Salut PhuengpraNo ratings yet

- Fiitjee: Talent Reward Exam - 2018Document19 pagesFiitjee: Talent Reward Exam - 2018DSNo ratings yet

- Manufacturing ProcessesDocument477 pagesManufacturing ProcessesVinod89% (19)

- MU Calculation: The ESTRO Formalism: Maria Rosa MalisanDocument41 pagesMU Calculation: The ESTRO Formalism: Maria Rosa Malisanmaryam yaftianNo ratings yet

- Blast Injury ManagementDocument16 pagesBlast Injury Managementheart wisdomNo ratings yet

- Container Closure IntegrityDocument19 pagesContainer Closure IntegrityYessieNo ratings yet

- Sand CastingDocument45 pagesSand CastingwinasharNo ratings yet

- Gear LecturDocument50 pagesGear LecturMuralikrishnan GM100% (1)

- Treatment Planniinc IDocument6 pagesTreatment Planniinc IAbdul Al-FattahNo ratings yet

- Installation / Operational Qualification Protocol Insert Incubator Name & I.DDocument32 pagesInstallation / Operational Qualification Protocol Insert Incubator Name & I.DMuhammad AzeemNo ratings yet

- CH 21 WL Photon Dosimetry Concepts and CalculationsDocument47 pagesCH 21 WL Photon Dosimetry Concepts and Calculationsoomganapathi100% (1)

- Rising To The Challenge of Small Flexible Filler URS September 2021Document16 pagesRising To The Challenge of Small Flexible Filler URS September 2021Bulent InanNo ratings yet

- Manufacturing Process of GlassDocument39 pagesManufacturing Process of GlassAida Suhanum100% (1)

- Wind Tunnels BasicsDocument4 pagesWind Tunnels BasicsRoshan KumarNo ratings yet

- Mathematical Modeling of An Aqueous Film Coating Process in A Bohle Lab-Coater, Part 1: Development of The ModelDocument8 pagesMathematical Modeling of An Aqueous Film Coating Process in A Bohle Lab-Coater, Part 1: Development of The Modelmido nasseNo ratings yet

- Pre-Use Post Sterilization Integrity Test - PUPSIT: What Is The Position of The Regulatory Authorities On PUPSIT?Document4 pagesPre-Use Post Sterilization Integrity Test - PUPSIT: What Is The Position of The Regulatory Authorities On PUPSIT?DAVI DE MATOS ALVES alu.ufc.brNo ratings yet

- GenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Document22 pagesGenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Junelle Ramos Aquino100% (1)

- EDTA Titration of Calcium and MagnesiumDocument3 pagesEDTA Titration of Calcium and MagnesiumAnonymous NxpnI6jC67% (3)

- Handbook of Fat ReplacersDocument295 pagesHandbook of Fat Replacersgoldennanuk100% (1)

- GWP White Paper - The Standard - enDocument16 pagesGWP White Paper - The Standard - enAhmad Atsari SujudNo ratings yet

- MTech Aerospace Structures Curriculum Syllabus 20130918Document6 pagesMTech Aerospace Structures Curriculum Syllabus 20130918Muralikrishnan GMNo ratings yet

- 2 SonicScope SchlumbergerDocument19 pages2 SonicScope SchlumbergersudiptodattaNo ratings yet

- 1725 UV-Vis GlossaryDocument16 pages1725 UV-Vis GlossaryEdi RismawanNo ratings yet

- Liquid SulfurDocument20 pagesLiquid SulfurMarcin MaruchaNo ratings yet

- Gamma IrradiationDocument27 pagesGamma Irradiationmuzammil21_adNo ratings yet

- 2.9.31. Particle Size Analysis by Laser Light DiffractionDocument5 pages2.9.31. Particle Size Analysis by Laser Light DiffractionPablo ParraNo ratings yet

- ISA PNID StandardsDocument14 pagesISA PNID StandardsHanif PayandehNo ratings yet

- Microbiological Commissioning and MonitoringDocument28 pagesMicrobiological Commissioning and MonitoringSungkakNo ratings yet

- V81.N01. Constant Humidity Salts Lewis Greenspan 1977 A06Document8 pagesV81.N01. Constant Humidity Salts Lewis Greenspan 1977 A06Don CameronNo ratings yet

- XII Continuity and Differentiablity AssignmentDocument1 pageXII Continuity and Differentiablity AssignmentCRPF SchoolNo ratings yet

- Data InterpretationDocument4 pagesData InterpretationwjawichNo ratings yet

- Dyspareunia A Difficult Symptom in Gynaecological Practice 2015 Obstetrics Gynaecology Reproductive MedicineDocument6 pagesDyspareunia A Difficult Symptom in Gynaecological Practice 2015 Obstetrics Gynaecology Reproductive MedicineNoraNo ratings yet

- Imaging MethodsDocument63 pagesImaging MethodsYlrebmik ArrabiNo ratings yet

- Booklet 1 Methods For in Vivo Dosimetry in External RadiotherapyDocument87 pagesBooklet 1 Methods For in Vivo Dosimetry in External RadiotherapyNesly M. MateoNo ratings yet

- Circularity ErrorDocument8 pagesCircularity Errorganesh_the_aviatorNo ratings yet

- SBRT Lung Single LesionDocument21 pagesSBRT Lung Single Lesionapi-592938880No ratings yet

- 6 Total Body IrradiationDocument7 pages6 Total Body Irradiationfreemind_mxNo ratings yet

- Dosimetric Evaluation of Newly Developed Well-Type Ionization Chamber For Use inDocument11 pagesDosimetric Evaluation of Newly Developed Well-Type Ionization Chamber For Use inman gobinda chowdhuryNo ratings yet

- Guidlines On Environmental Monitoring For Aseptic Dispensing FacilitiesDocument10 pagesGuidlines On Environmental Monitoring For Aseptic Dispensing FacilitiesJai Prakash MauryaNo ratings yet

- Comparision of SCANRDI Vs Pharmacopiea MethodDocument10 pagesComparision of SCANRDI Vs Pharmacopiea MethodUmair ShekhaniNo ratings yet

- Times Series Analysis NotesDocument5 pagesTimes Series Analysis NotesDr Swati RajNo ratings yet

- PharmaDocument21 pagesPharmaThế KiệtNo ratings yet

- Unit - 4 Flow VisualizationDocument21 pagesUnit - 4 Flow VisualizationAkshay SNo ratings yet

- Experiment About Gas DymanicsDocument6 pagesExperiment About Gas DymanicsMohamed KadhimNo ratings yet

- Ryan Glover One PageDocument1 pageRyan Glover One PageJ GloverNo ratings yet

- Flow Visualization in Wind Tunnels: Muzafferuddin MahmoodDocument17 pagesFlow Visualization in Wind Tunnels: Muzafferuddin MahmoodsanjuNo ratings yet

- Smoke Flow Visualization Over A Delta WingDocument22 pagesSmoke Flow Visualization Over A Delta WingSharan Teja ElagandulaNo ratings yet

- Schlieren Image Velocimetry of Swirl SpraysDocument25 pagesSchlieren Image Velocimetry of Swirl Sprayslokesh14No ratings yet

- Schlieren Technique To Determine The Mach Number in Test SectionDocument10 pagesSchlieren Technique To Determine The Mach Number in Test SectionDr StrangeNo ratings yet

- Mach-Zehnder Interferometer - WikipediaDocument7 pagesMach-Zehnder Interferometer - WikipediaAndreiCabaNo ratings yet

- Ultrasonic Piezoelectric NebulizerDocument3 pagesUltrasonic Piezoelectric NebulizerVinodhanan RaviNo ratings yet

- FOL Unit 4Document7 pagesFOL Unit 4Sudhar SanNo ratings yet

- Moire Interferometria PDFDocument4 pagesMoire Interferometria PDFLuis RcNo ratings yet

- Photographic Investigations of Jet Disintegration in Airblast SpraysDocument13 pagesPhotographic Investigations of Jet Disintegration in Airblast SpraysZeSnexNo ratings yet

- Surface Plasmon Resonance: K. Scott Phillips and Quan Jason ChengDocument12 pagesSurface Plasmon Resonance: K. Scott Phillips and Quan Jason ChengTin Tức Mỗi NgàyNo ratings yet

- Flow Field MeasurementsDocument4 pagesFlow Field MeasurementsSurya prabha SNo ratings yet

- Measurement of 3D Pore-Scale Flow in Index-Matched Porous MediaDocument8 pagesMeasurement of 3D Pore-Scale Flow in Index-Matched Porous MediaBen MunroNo ratings yet

- 2000 Opt Lett - Prism Intereferometer For Fourier-Transform SpectroscopeDocument3 pages2000 Opt Lett - Prism Intereferometer For Fourier-Transform SpectroscopeMihaela OmutNo ratings yet

- FOL Unit 4 PDFDocument7 pagesFOL Unit 4 PDFShaik RoshanNo ratings yet

- 2 MarksDocument3 pages2 Marksmurjass85No ratings yet

- Lec 1 12122023 InterfernceDocument86 pagesLec 1 12122023 InterfernceUmair KhanNo ratings yet

- Density Measurements Using Near-Field Background-Oriented SchlierenDocument12 pagesDensity Measurements Using Near-Field Background-Oriented SchlierenClaudioTRodriguesNo ratings yet

- O C S A S: Btaining Rosswind From A Ingle Perture CintillometerDocument4 pagesO C S A S: Btaining Rosswind From A Ingle Perture CintillometerresistanceisfutileNo ratings yet

- Shadograph and Schilireon Techniques PDFDocument24 pagesShadograph and Schilireon Techniques PDFYokesvaran KNo ratings yet

- Optical Nanofibers and SpectrosDocument13 pagesOptical Nanofibers and Spectrosprakush_prakushNo ratings yet

- PDF 1 PennDocument12 pagesPDF 1 PennAditya RaghunandanNo ratings yet

- New TechniquesDocument60 pagesNew Techniquesm a zargarNo ratings yet

- Michelson Interferometry: 1.1 The Moveable MirrorDocument8 pagesMichelson Interferometry: 1.1 The Moveable MirrorJustin SinghNo ratings yet

- Fl2014 DL Handbook Mechrev1028lrDocument64 pagesFl2014 DL Handbook Mechrev1028lrNidísh VashistháNo ratings yet

- Mechanical Engineering 2006 Sem VIIIDocument9 pagesMechanical Engineering 2006 Sem VIIIJerrin PaulNo ratings yet

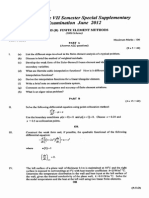

- Finite Element Methods 2012 June (2006 Ad)Document2 pagesFinite Element Methods 2012 June (2006 Ad)Muralikrishnan GMNo ratings yet

- Mahishasuramardhini StotramDocument7 pagesMahishasuramardhini Stotramsunil1958No ratings yet

- 2007 Jeep Compass Owners Manual PDFDocument408 pages2007 Jeep Compass Owners Manual PDFcarlos malvaciaNo ratings yet

- Joshy John (Joseph) & Alicia Jacob (Mary)Document1 pageJoshy John (Joseph) & Alicia Jacob (Mary)Muralikrishnan GMNo ratings yet

- Me Gate 2012Document22 pagesMe Gate 2012sauravkk245No ratings yet

- Finite Element Methods 2009 (02 Ad)Document2 pagesFinite Element Methods 2009 (02 Ad)Muralikrishnan GMNo ratings yet

- Gate 15 BrochDocument83 pagesGate 15 BrochViveen CharanNo ratings yet

- Finite Element Methods 2008 (02 Ad)Document1 pageFinite Element Methods 2008 (02 Ad)Muralikrishnan GMNo ratings yet

- Mahishasura Mardini Stotram - in Sanskrit With Meaning - Stotra On Devi DurgaDocument18 pagesMahishasura Mardini Stotram - in Sanskrit With Meaning - Stotra On Devi DurgaMuralikrishnan GMNo ratings yet

- Finite Element Methods 2006 (02 Ad) Qestion PaperDocument2 pagesFinite Element Methods 2006 (02 Ad) Qestion PaperMuralikrishnan GMNo ratings yet

- Mahishasura Mardini Stotram - in Sanskrit With Meaning - Stotra On Devi DurgaDocument18 pagesMahishasura Mardini Stotram - in Sanskrit With Meaning - Stotra On Devi DurgaMuralikrishnan GMNo ratings yet

- BTech ME Scheme & Syllabus 2012Document73 pagesBTech ME Scheme & Syllabus 2012Muralikrishnan GMNo ratings yet

- FDM Lecturenotes-4Document34 pagesFDM Lecturenotes-4Muralikrishnan GMNo ratings yet

- Otporni MomentDocument1 pageOtporni MomentRamiz HecimogluNo ratings yet

- A Hot Wire AnemometerDocument4 pagesA Hot Wire AnemometerMuralikrishnan GMNo ratings yet

- Equipment Design Chapter 3Document30 pagesEquipment Design Chapter 3Miguel Magat JovesNo ratings yet

- Parts of A Centre LatheDocument21 pagesParts of A Centre LatheMuralikrishnan GMNo ratings yet

- Finite Element Methods 2006 (02 Ad) Qestion PaperDocument2 pagesFinite Element Methods 2006 (02 Ad) Qestion PaperMuralikrishnan GMNo ratings yet

- Heat Conduction EquationDocument26 pagesHeat Conduction EquationMuralikrishnan GMNo ratings yet

- Heat Conduction EquationDocument26 pagesHeat Conduction EquationMuralikrishnan GMNo ratings yet

- Electrical Resistance Strain Gage CircuitsDocument27 pagesElectrical Resistance Strain Gage CircuitsHareesha N GNo ratings yet

- Dielectric HeatingDocument4 pagesDielectric HeatingMuralikrishnan GMNo ratings yet

- CHM3201 Tutorial 1 Basic ConceptsDocument3 pagesCHM3201 Tutorial 1 Basic ConceptsAkmalZharifAbdullahNo ratings yet

- 3102 Shade Matching in Aesthetic Dentistry From Past To Recent Advances PDFDocument9 pages3102 Shade Matching in Aesthetic Dentistry From Past To Recent Advances PDFsapnaNo ratings yet

- Viva QuestionDocument4 pagesViva QuestionBarathkannan Lakshmi PalanichamyNo ratings yet

- Tutorial 5Document1 pageTutorial 5sakinah azizanNo ratings yet

- Lecture 2 - Origin of Elements, ClassificationDocument24 pagesLecture 2 - Origin of Elements, ClassificationMihatsu TakiNo ratings yet

- Hydrothermal Synthesis of Hydroxy Sodalite Zeolite Membrane SeparationDocument8 pagesHydrothermal Synthesis of Hydroxy Sodalite Zeolite Membrane Separationcelcenu100% (1)

- Homework-5 2Document3 pagesHomework-5 2Dorothy CastilloNo ratings yet

- Lab 3heatengine PhysicDocument3 pagesLab 3heatengine Physicapi-263500375No ratings yet

- Moisture Relations & TestingDocument21 pagesMoisture Relations & TestingRITIKNo ratings yet

- TDS T-Pro 000 EngDocument3 pagesTDS T-Pro 000 Engbhavinmehta9999No ratings yet

- 1968 Hypogene Texture and Mineral Zoning in A Copper Granodiorite Porphyry Stock NielsenDocument14 pages1968 Hypogene Texture and Mineral Zoning in A Copper Granodiorite Porphyry Stock NielsenKevin Hiram Torres Montana100% (1)

- Tle Report 3rd QuarterDocument5 pagesTle Report 3rd QuarterZaren MendozaNo ratings yet

- Unit1 Chapter 28 29Document27 pagesUnit1 Chapter 28 29teeradonpat.sNo ratings yet

- Interchar 963: Acrylic IntumescentDocument4 pagesInterchar 963: Acrylic IntumescentImran MulaniNo ratings yet

- Chem Is Try Lab 2019Document8 pagesChem Is Try Lab 2019leah phoNo ratings yet

- Isocop Rev 07-11-2012 - ENGLDocument15 pagesIsocop Rev 07-11-2012 - ENGLAlexandru RucareanuNo ratings yet

- Enen 619-03 Final Research ProjectDocument26 pagesEnen 619-03 Final Research ProjectSalman NoorNo ratings yet

- Ullmanns Encyclopedia of Industrial Chemistry Phosphoric Acid and Phosphates 58db177445fedDocument44 pagesUllmanns Encyclopedia of Industrial Chemistry Phosphoric Acid and Phosphates 58db177445fedMuhammad FirmansyahNo ratings yet

- Aderco Marine - Global Energy Sulphur Cap 2020 - v03Document24 pagesAderco Marine - Global Energy Sulphur Cap 2020 - v03Saw Win0% (1)