Professional Documents

Culture Documents

Glen - Dhu.wind - Farm VolumeII AppendixB-Section4DesignBasis

Uploaded by

segunoyesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Glen - Dhu.wind - Farm VolumeII AppendixB-Section4DesignBasis

Uploaded by

segunoyesCopyright:

Available Formats

Design Basis E-82

Page 1 of 3

All ENERCON wind energy converters are designed and certified according to the latest international standards. Currently the basis for design are the internationally acknowledged IEC standards of the IEC-61400 series. This implies several assumptions and conditions that are used to define the load cases which the wind turbine has to survive. In the following, the main design conditions are listed. For details it is hereby referred to the original IEC standards. The safety system of the ENERCON wind turbines features various control sensors that protect the turbine and its components from damage. This includes - among other things - high and low temperatures, vibrations and oscillations, strain etc. In the case that one or more of these sensors detect conditions outside the design limits, the main control of the turbine will take the appropriate measures which range from small power limitations to complete stop of the turbine. In case it is planned to install the turbines in complex terrain (included but not limited to steep hills, mountains, ridges, sites at more than 1000m above sea level, etc.), it is highly recommended to consult with ENERCON at an early stage of the project in order to carry out a detailed assessment of the site. For sites with environmental conditions outside of the design conditions, ENERCON cannot be held responsible for any defects, including but not limited to damages and/or loss of energy yield.

IEC Design conditions: Wind classes Wind turbine classes are defined in terms of wind speed and turbulence parameters. In case of the standard wind turbine classes, the mean value of the wind speed over a time period of 10 min is assumed to be Rayleigh distributed for the purposes of design load calculations. The E-82 (turbine and all available towers) are designed for sites with IEC class IIA wind characteristics: 1. Extreme wind speed (3 sec-average) in hub height 2. Extreme wind speed (10-min average) in hub height 3. Annual average wind speed and turbulence intensity The operational loads of wind energy converters depend on the combination of annual average wind speed and average turbulence intensity at the site. The E-82 has been designed for vm = 8.5 m/s (annual average wind speed in hub height) with constant turbulence intensity of 18% at v = 15 m/s (according to IEC turbulence class A) vE = 59.5 m/s v = 42.5 m/s

Document information: Author / date: Department: Approved / date: Revision / date:

ENERCON reserves the right to technical modifications MK / 20.09.05 WRD Translator / date: - Revisor / date: WRD-04-Design Basis E-82-Rev2_1-eng-eng 2.1 / 27.07.07 Reference:

Design Basis E-82

Page 2 of 3

For the load calculations the following has been assumed: safety factor on the loads of SF = 1.35 (normal and extreme loads) inclination of mean flow with respect to the horizontal plane of up to 8 (invariant with height) symmetrical icing on all blades (see below)

IEC Design conditions: Other environmental conditions According to IEC among others the following environmental conditions are taken into account for the design of the wind turbines: normal system operation ambient temperature range of extreme temperature range of relative humidity of up to atmospheric content equivalent to that of a solar radiation intensity of air density of

10C to +40C 20C to +50C 95% non-polluted inland atmosphere 1000 W/m2 1.225 kg/m3

Other Design conditions In order to protect the wind turbine from damages, it will operate according to the following scheme, not taking into account power losses due to changes of aerodynamic behavior when icing occurs on the blades: T = ambient temperature T > -15C -15C > T > -20C -20C > T > -25C T < -25C normal operation Pmax = 100% Prated linear decrease with temperature of Pmax from 100% Prated at -15C down to 25% Prated at -20C linear decrease with temperature of Pmax from 25% Prated at -20C down to 5% Prated at -25C operation with maximum 5% rated power

Below -25C the turbine continues to operate with maximum 5% rated power in order to keep the rotating components moving and the turbine at a moderate temperature level. Given this operational characteristics, the survival temperature for a standard E-82 is 40C. For sites with lower temperature characteristics special material can be used for certain decisive turbine components which then will allow normal operation down to -30C. A similar operational scheme as shown above will then be used for temperatures below -30C.

Document information: Author / date: Department: Approved / date: Revision / date: ENERCON reserves the right to technical modifications MK / 20.09.05 WRD Translator / date: - Revisor / date: WRD-04-Design Basis E-82-Rev2_1-eng-eng 2.1 / 27.07.07 Reference:

Design Basis E-82

Page 3 of 3

According to the GL standard a cold climate site which will call for special requirements for the wind turbines is defined as follows: Minimum temperatures of below -20C have been observed during long term measurements (preferably ten years or more) on an average of more than nine days a year. The nine-day criteria is fulfilled, if the temperature at the site remains below -20C for one hour or more on the respective days. For sites with lower extreme temperatures, different materials will have to be used for various turbine components including but not limited to lubrication and steel material. Icing on the blades: The IEC standard requires that symmetrical icing (i.e. the same amount on each blade) has to be taken into account, but does not say how. Therefore ENERCON is calculating the ice loads as described in the GL standard: The ice accumulates on the leading edge of the blades. There is zero ice at the blade root, the ice thickness increases linearly up to a value of at the middle of the blade and then remains constant up to the blade tip. Unsymmetrical icing (different ice mass on the three blades) does not have to be taken into account, because the ENERCON turbines have a sensor for imbalance that will prevent the turbine from operation with unsymmetrical ice (imbalance of the rotor).

Wind farm layout (Micrositing) Loading of wind turbines in a wind farm is determined by the above mentioned external wind conditions and additionally by the influence of neighboring wind turbines (so-called wake effects). Behind the turbines the incoming wind speed is being reduced, while the turbulence is increased. The effects of this on the operating loads have been assessed in so-called wake expertises and the allowed minimum distances of the turbines are defined accordingly, depending on the annual average wind speed and turbulence intensity at the site. These expertises are available on request. In general ENERCON wind turbines can be placed in distances of 5 rotor diameters in prevailing wind direction and in distances of down to 3 rotor diameters in directions of less distinct wind without further calculations. If smaller distances are planned, ENERCON has to approve the park layout. If this approval is not given or not being asked for, ENERCON cannot be held responsible for any defects, including but not limited to damages and/or loss of energy yield. Smaller distances can be allowed if the site and layout conditions comply with the data mentioned in the wake expertises. If for any reason the conditions do not fit, there is the option to carry out a site specific calculation at the expense of the customer. In this case please contact your ENERCON sales representative at an early stage of the project.

Document information: Author / date: Department: Approved / date: Revision / date:

ENERCON reserves the right to technical modifications MK / 20.09.05 WRD Translator / date: - Revisor / date: WRD-04-Design Basis E-82-Rev2_1-eng-eng 2.1 / 27.07.07 Reference:

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Weighted Criteria Matrix: Value Option 1 Score Option 2 Score Option 3 Score Option 4 Score Prioritization CriteriaDocument3 pagesWeighted Criteria Matrix: Value Option 1 Score Option 2 Score Option 3 Score Option 4 Score Prioritization CriteriasegunoyesNo ratings yet

- Overview of Pipeline Engineering PDFDocument605 pagesOverview of Pipeline Engineering PDFsegunoyesNo ratings yet

- Comparative Analysis of Joint Venture and Production Sharing New Contractual System in NigeriaDocument7 pagesComparative Analysis of Joint Venture and Production Sharing New Contractual System in NigeriasegunoyesNo ratings yet

- Gas Flaring NigeriaDocument36 pagesGas Flaring NigeriaSahar SohailNo ratings yet

- Economic EvaluationDocument12 pagesEconomic EvaluationsegunoyesNo ratings yet

- E & P November 2019 PDFDocument100 pagesE & P November 2019 PDFsegunoyesNo ratings yet

- Economic EvaluationDocument12 pagesEconomic EvaluationsegunoyesNo ratings yet

- Appraisal of Flexible Pipe Systems: Guidance Notes ForDocument27 pagesAppraisal of Flexible Pipe Systems: Guidance Notes ForsegunoyesNo ratings yet

- Technical and economic viability of water injection for marginal oil fieldsDocument20 pagesTechnical and economic viability of water injection for marginal oil fieldssegunoyesNo ratings yet

- Firs Tax Compendium PDFDocument686 pagesFirs Tax Compendium PDFsegunoyesNo ratings yet

- Investment Analysis of Marginal FieldsDocument39 pagesInvestment Analysis of Marginal FieldssegunoyesNo ratings yet

- Economic Model in Exploiting Stranded Natural Gas in Niger Delta Offshore FieldsDocument7 pagesEconomic Model in Exploiting Stranded Natural Gas in Niger Delta Offshore FieldsIJERDNo ratings yet

- 01 Microsoft Project Basics PDFDocument18 pages01 Microsoft Project Basics PDFMathias OnosemuodeNo ratings yet

- Offshore & Subsea Equipment ManufacturersDocument1 pageOffshore & Subsea Equipment ManufacturerssegunoyesNo ratings yet

- XSize Pump CALCDocument7 pagesXSize Pump CALCsegunoyesNo ratings yet

- Map of Nigeria Oil FieldDocument1 pageMap of Nigeria Oil Fieldriddi12350% (10)

- Basic Anti-Surge Control System ReferenceDocument6 pagesBasic Anti-Surge Control System ReferenceOlvis GuillenNo ratings yet

- Earthing and Lightning Protection, Gas Analysis System Nigeria, Onne - AOS OrwellDocument5 pagesEarthing and Lightning Protection, Gas Analysis System Nigeria, Onne - AOS OrwellsegunoyesNo ratings yet

- Teori Penting PDFDocument47 pagesTeori Penting PDFNaya Septri HanaNo ratings yet

- LNG Plant Cost Reduction 2014 18 NG137 PDFDocument49 pagesLNG Plant Cost Reduction 2014 18 NG137 PDFaakhyar_2100% (1)

- Nrel Cost ReportDocument106 pagesNrel Cost ReportRao PanidapuNo ratings yet

- Quick Guide Into The ISO 14692 Revision 2016 Edition 26 May 2016Document44 pagesQuick Guide Into The ISO 14692 Revision 2016 Edition 26 May 2016pmr80_2004100% (1)

- Fpso OverviewDocument2 pagesFpso OverviewsegunoyesNo ratings yet

- Nigeria - Algeria PipelineDocument11 pagesNigeria - Algeria PipelinesegunoyesNo ratings yet

- Offshore Safety Case TrainingDocument114 pagesOffshore Safety Case TrainingsegunoyesNo ratings yet

- Experienced Based Rules of Chemical EngineeringDocument33 pagesExperienced Based Rules of Chemical Engineeringintania66No ratings yet

- 2014 0224 Aspen Capital Cost Estimator Overview-AACE 25 Feb 2014 PDFDocument37 pages2014 0224 Aspen Capital Cost Estimator Overview-AACE 25 Feb 2014 PDFAbdul RBed IsaNo ratings yet

- Africa AOW A3 FinalDocument1 pageAfrica AOW A3 FinalsegunoyesNo ratings yet

- Siemensoilandgas2016 LactunitDocument35 pagesSiemensoilandgas2016 LactunitsegunoyesNo ratings yet

- DesignbasisdevelopmentDocument21 pagesDesignbasisdevelopmentsegunoyesNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Bryant AnalysisSiphonDocument12 pagesBryant AnalysisSiphonAshlee HiltonNo ratings yet

- AQA Physics Unit 6 Waves Student Progress SheetDocument7 pagesAQA Physics Unit 6 Waves Student Progress SheetGabriel HoNo ratings yet

- Astm D3418 2012Document7 pagesAstm D3418 2012Rodrigo TomazNo ratings yet

- Buried Pipeline Freezing Analysis SimulationDocument6 pagesBuried Pipeline Freezing Analysis SimulationKelvin CruzNo ratings yet

- Fermi Dirac StatisticsDocument15 pagesFermi Dirac StatisticsRiya SalujaNo ratings yet

- Slide3 2017 - Quick StartDocument18 pagesSlide3 2017 - Quick StartJordana FurmanNo ratings yet

- A35 AnswersDocument15 pagesA35 AnswersSeanNo ratings yet

- 15NT101 Elements of Nanoscience and NanotechnologyDocument3 pages15NT101 Elements of Nanoscience and NanotechnologyAravind Chandar BNo ratings yet

- PB 99162869Document132 pagesPB 99162869Shritej nirmalNo ratings yet

- Spaghetti Bridge ReportDocument12 pagesSpaghetti Bridge ReportMuhd Syafiq Othman0% (2)

- Design of Concrete Structures 15th Edition Ebook PDFDocument61 pagesDesign of Concrete Structures 15th Edition Ebook PDFmario.becker25297% (37)

- MIT 2.004 Dynamics and Control II Problem Set 1 SolutionsDocument6 pagesMIT 2.004 Dynamics and Control II Problem Set 1 SolutionsFatih TokgözNo ratings yet

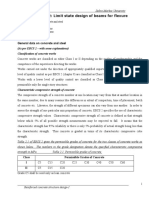

- Chapter 2: Limit State Design of Beams For Flexure: General Data On Concrete and SteelDocument27 pagesChapter 2: Limit State Design of Beams For Flexure: General Data On Concrete and SteelAntenehNo ratings yet

- Beam Is Code Crackwidth ValidationDocument1 pageBeam Is Code Crackwidth ValidationNirbhayNo ratings yet

- CFD ANALYSIS OF NACA 0012 AIRFOILDocument77 pagesCFD ANALYSIS OF NACA 0012 AIRFOILHassan Ayub KhanNo ratings yet

- Syllabus MSPHYS 2020-2021-1Document67 pagesSyllabus MSPHYS 2020-2021-1mithunNo ratings yet

- El-Moasser - Chemistry - Third Secondary - 2022 - Main BookDocument403 pagesEl-Moasser - Chemistry - Third Secondary - 2022 - Main BookMartria EhabNo ratings yet

- Fabrication of WC Micro-Shaft by Using Electrochemical EtchingDocument6 pagesFabrication of WC Micro-Shaft by Using Electrochemical EtchingGanesa BalamuruganNo ratings yet

- The TDC Device - Synopsis of Email CorrespondencesDocument7 pagesThe TDC Device - Synopsis of Email Correspondencestriple7incNo ratings yet

- Methods Used For Curing of ConcreteDocument3 pagesMethods Used For Curing of ConcreteAjayNo ratings yet

- API 5CT Coupling Stock2Document10 pagesAPI 5CT Coupling Stock2tarno12No ratings yet

- Distinguishing Between Ionic and Covalent Compounds LabDocument3 pagesDistinguishing Between Ionic and Covalent Compounds LabSamuelNo ratings yet

- Perma PipeDocument83 pagesPerma PipemohamadNo ratings yet

- Module-2 Fundamentals of SurveyingDocument2 pagesModule-2 Fundamentals of Surveyingnonononoway100% (1)

- Title: Tensile TestDocument5 pagesTitle: Tensile TestAbdulrahmanNo ratings yet

- Electrochemistry AssignmentDocument3 pagesElectrochemistry AssignmentSulekha SharmaNo ratings yet

- Q4 LP7 GenPysics2Document11 pagesQ4 LP7 GenPysics2ROMELYN GRACE BORBENo ratings yet

- Introducción WPS ISODocument41 pagesIntroducción WPS ISOCarlos Eduardo Castillo LanderosNo ratings yet

- Student's blood bromide results analyzedDocument11 pagesStudent's blood bromide results analyzedBio CeramicsNo ratings yet

- NMRDocument173 pagesNMRঋ ত্বিকNo ratings yet