Professional Documents

Culture Documents

Protoype Composite Slab

Uploaded by

enatagoeOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Protoype Composite Slab

Uploaded by

enatagoeCopyright:

Available Formats

REPORT OF FULL SCALE TEST ON PROTOYPE COMPOSITE SLAB OF PRECAST PRESTRESSED T-BEAMS AND HOLLOW CONCRETE BLOCKS

CLIENT :

M/SITAL PRESTRESS AND CONSTRUCTION COMPANY

INVESTIGATOR:

PROF. C.K. KANKAM CIVIL ENGINEERING DEPARTMENT KNUST

October 2001

EXECUTIVE SUMMARY At the request of M/S ITAL PRESTRESS CONSTRUCTION COMPANY of Accra, Professor C.K. Kankam of the Civil Engineering Department of the Kwame Nkrumah University of Science and Technology, Kumasi assessed the service behaviour of a model composite floor slab on site. The composite structure consisted of prestressed concrete joist, hollow concrete blocks and mass concrete topping. The investigation took the form of uniform loads of bagged sand arranged in layers on the structure and measurement of central span deflection by means of a mechanical dial gauge. Theoretical analysis indicates that, the composite slab flexural capacity if allowed to develop cracks (ie. Class three type of prestressed member) at service conditions is 106.85k Nm. For it to behave as a class two member where tension in the slab is limited to the allowable stress, but no cracking takes place the service moment capacity is 46.73k Nm. The experimental loading was stopped and sustained at 192 tons or 192Kn. This is equivalent to a moment of 546.8kNm. Ther deflection corresponding to this load after nine days of sustained loading when creep had taken place was 14.81mm. Ten fine cracks of average width 0.05mm developed.

REPORT OF FULL SCALE TEST ON PROTOTYPE COMPOSITE SLAB OF PRECAST PRESTRESSED T- BEAMS AND HOLLOW CONCRETE BLOCKS CLIENT : M/S ITAL PRESTRESS AND CONSTRUCTION COMPANY.

INVESTIGATION: PROF. C.K. KAMKAM CIVIL ENGINERING DEPARTMENT K.N.U.S.T. ERECTION OF TEST SPECIMEN The test specimen consisted of a concrete slab. Which was a composite construction of five inverted precast prestressed T- beams (joists) that were laid at 500mm centers (see fig 1) )Each joist was prestressed with 6 stands to a stress of 1500 N/mm2). The space between the beams were filled with the precast hollow cement blocks manufactured from cement and quarry dust. The composite beams- hollow blocks assembly was the topped with 50mm mass concrete. The slab spanned one 0way on simple support of beams with nominal point reinforcement between the end beams and the slab. TEST PROCEDURE The composite floor slab spanned one way was simply supported at its ends on a reinforced concrete portal frame. The span was 6.47m. The composite slab was loaded 2.16. The test loads consisted of 100kg bags of sand. The composite slab was loaded symmetrically from the ends towards the centre until the entire top surface was covered with a total of 48 bags. This set of lads was considered as one complete layer. The layer comprised four bags along the shorter dimension and twelve bags along the span. The central deflection of the slab was recorded by means of a mechanical dial gauge after the full layer of loads was put on.

This procedure of loading was repeated and again the deflection was recorded. (no cracks developed at this stage of the test). The test slab was left for six days under the action of two layers (i.e 96 bags of 100kg) each of loads to assess the effect of creep on the floor, particularly on the main structural members, namely prestressed joists. Loading of the slab resumed the 7th day with an initial deflection recording and followed by 2 layers. (i.e 96 bags of 100kg) of loads. Again the central deflection was recorded after each layer. The results in terms of loads and deflection were presented in Table 1. At the service state, ten structural cracks developed within the central span of 109. 1cm. The maximum average crack width was 0.1mm, which is within allowable limits for partially prestressed beams Appendix 2 presents a calculation of the ser vice moment of the composite floor structure. Computation of the moment due to applied external loads and self-weight dead loads is summarized in appendix 1. The loaded structure was kept for 41 days and exposed to the vagaries of weather sicne1/9/2001. Rain water absorbed by the loading sand bags increased external loads on the structure. This state of affairs leading to wetting and drying of the sand constituted some form of cyclic loading, and combined with the effect of creep, widened extended cracks. The maximum and average crack sizes were 0.4 and 0.2mm, respectively. The deflection of the floor slab was 29.8mm.

Imposed Load Total Load on structure = 19200 kg = 19200 x 10 = 192 KN Over an area of slab of 6.47m span (support to support) width 2.16m (intensity of load = 13.7 KN m2 imposed; compare this to code load) Assuming whole slab is of the same stiffness, this is equivalent to 192 = 88.9 KN 2.16 OOOOOOOOOOOOOOOOOO 6.47(imposed) OOOOOOOOOOOOOOOO 6.47m(dead) 4 x 48 x 100 kg

Dead Load Again assuming the stiffness of the slab i.e. composite structure of precastprestressed beams, hollow concrete blocks and concrete overlay as a single unit. (a) depth of slab = 0.3m dead load = 2.16 x 0.3 x 24 = 15.6 KN/m

Total load = imposed + dead = 88.9 + 15.6Kn/M Maximum moment at midspan = 12 = 104.5 x 6.472 = 546.8 KN 8 8 For a simply supported one-way slab, M = 546.8 KN

Appendix 2 Service Moment Capacity of Transformed Section Equivalent area, Aeq = 64.3 x 103 mm2 Second moment of area, Ieq =348.75 x106 mm4 Distance of bottom fiber from centroid = 157.4 mm Distance of top joist fiber from centroid = 157.4 55 35 = 67.4 mm For elastic behavior, the general engineers equation M = f. I y Two cases to consider Case 1: Based on allowable service tensile stress at base of joist: Initial allowable stress due to Prestress at base of joist is compressive and equal to 15.54 N/mm2 At service load of the joist, as a component of the floor slab this compressive stress should be overcome first before the joist is transformed into tension. For class 2 members in which tension is allowed but no cracking occurs, let allowable tension be 3.35 N/mm2, the total stress is f = 15.54 + 3.5 = 18.89 N/mm2 From the general engineers equation M = f I 18.89 = 348.75 y 157.4 = 41.85 KNm

For class 2 members, where cracking takes place, Let limiting tensile stress = 1/10 x fcu = 55.N/mm Then total Stress f = 15.54 + 5.5 = 21.09 N/mm M = 21.09 x 348.75 157.4 = 46.73 KNm Case 2: Based on allowable concrete compressive stress of top of joist when Cracks have develop and stabilize, corresponding to Class 3 type of prestressing. Initial stress at top of joist is tensile = 2.5 N/mm Allowable concrete stress fe = 0.33fcu = 18.15N/mm Total stress = 20.65 N/mm2 Y top M = 67.4mm =f. I y = 20.65 x 348.75 67.4 = 106.85 KNm

APPENDIX 2: ELASTIC ANALYSIS OF FLOOR SLAB In-situ concrete fcu = 25N/mm Joist concrete fcu = 55N/mm

In-situ concrete Ecu = 25N/mm Esteel = 200kN/mm2 Diameter = 3.9mm Conversion of steel into equivalent concrete section using depth of 3.9mm (corresponding to its diameter) Base Steel Es x 5 x 11. 93 = 200 x 5 x 11.93 = 477. 2mm2

For rectangular equivalent section of depth 3.9mm 477.2 = 122.4 3.9 Top Steel 122.4 3.9

Es x 11.93 = 200 x 11.93 = 95.44mm2 Ec 25

95.44 = 24.5mm 3.9

92.6mm C 157.4 D 18

A B

72mm 160mm 39mm 39.mm 39mm 180mm 55mm 250mm

Portion A B C D

Centroid from base Ay y 500 x 70 = 35 x 103 215 752.5 x 104 160 x 180 = 28.8 x103 90 259.2 x 104 0.507 x 104 2 x 12.25 x 3.9 = 0.955 53.05 x 103 2 x 61.2x 3.9 = 447.36 16.05 0.722 x 104 = 0.45 x 103 Area (mm2) 64.35 x 103

=

1012.93 x 104

y = 1012.93 x 10 = 157.4mm 64.35 x 103 Part Distance of CG from centroid (mm) 57.6 67.4 102.4 139.4 1mm Ay mm IG = mm4 + Ay2

A B C D

14.3 x 10 77.76 x 10 121.1 604.05

11.12 x 10 130.83 x 10 1.00 x 10 8.74 x 10

130.42 x 106 208.59x 106 1 x 106 8.74 x 106 =

348.75x106

I of equivalent section = 348.75 x 106

Table 1: Results of Load Test

LOAD KN 4800 8000 8000 9600 14400 19200 19200 19200 19200 48 80 80 96 144 192 192 192 192 DEFLECTION(mm) 0 1.65 3.68 4.10 4.50 6.97 10.70 11.28 No Cracking 14.81 Effect of creep after 1 hour 40min 29.81 Effect of creep after 3 days. Appearance of 10 fine cracks Sand bags exposed to changing Weather for a period of 41 days. Rainwater absorbed by sand Increased external loads on structure. Cracks extended in length and widened. Maximum crack Width = 0.4mm Average crack = 0.2mm Loading left for 6 days. Increase in deflection due to creep Instantaneous cracking loading, no REMARKS

Instantaneous loading - do Loading left for 2 hours, Increase in deflection due to creep

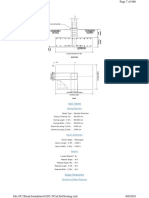

Section through composite slab

topping 30,40 or 50

joist centers=500mm

block wall thickness=20mm

fig 1

Section of prestressed concrete joist

35mm

15mm

18mm

120m m

fig 2

35mm

40mm

You might also like

- FPSO Kwame Nkrumah MV21Document1 pageFPSO Kwame Nkrumah MV21enatagoeNo ratings yet

- Double Scaffold Tubes 01Document1 pageDouble Scaffold Tubes 01enatagoeNo ratings yet

- Narcissistic Personality DisorderDocument10 pagesNarcissistic Personality DisorderenatagoeNo ratings yet

- Dzorwulu Primary and Junior High School Accident Site Visit Report ReviewedDocument2 pagesDzorwulu Primary and Junior High School Accident Site Visit Report ReviewedenatagoeNo ratings yet

- Joint Venture Agreement SummaryDocument6 pagesJoint Venture Agreement SummaryRohit BawaNo ratings yet

- BoG Revokes Licenses of 23 Savings and Loans CompaniesDocument27 pagesBoG Revokes Licenses of 23 Savings and Loans CompaniesThe Independent GhanaNo ratings yet

- WIND LOAD AND STRUCTURAL DESIGN PARAMETERSDocument4 pagesWIND LOAD AND STRUCTURAL DESIGN PARAMETERSenatagoeNo ratings yet

- Steel Ladder PDFDocument1 pageSteel Ladder PDFenatagoeNo ratings yet

- The New Companies Act 2019: Key changesDocument12 pagesThe New Companies Act 2019: Key changesenatagoe67% (3)

- BS 5975 Temporary Works CategoriesDocument2 pagesBS 5975 Temporary Works CategoriesenatagoeNo ratings yet

- Corrosion of Embedded MaterialsDocument6 pagesCorrosion of Embedded MaterialsenatagoeNo ratings yet

- Itinerary For Group 2Document5 pagesItinerary For Group 2enatagoeNo ratings yet

- STANLIB Ghana ProfileDocument16 pagesSTANLIB Ghana ProfileenatagoeNo ratings yet

- Steel Ladder PDFDocument1 pageSteel Ladder PDFenatagoeNo ratings yet

- TG20-13 Supplement PDFDocument4 pagesTG20-13 Supplement PDFenatagoeNo ratings yet

- Paradise Temple 01a Beams 37 & 38Document28 pagesParadise Temple 01a Beams 37 & 38enatagoeNo ratings yet

- BS 5975 Temporary Works CategoriesDocument2 pagesBS 5975 Temporary Works CategoriesenatagoeNo ratings yet

- Permission Letter - August 2018Document1 pagePermission Letter - August 2018enatagoeNo ratings yet

- Technical Specification of Midas Gen PDFDocument2 pagesTechnical Specification of Midas Gen PDFbryamdv23No ratings yet

- The Construction Stages of The Six-Storey Residential Building in Saint-PetersburgDocument49 pagesThe Construction Stages of The Six-Storey Residential Building in Saint-PetersburgAkshay SharmaNo ratings yet

- Load Dev Silo DesignDocument0 pagesLoad Dev Silo Designuser 54No ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Steel Loading Bays 01a DesignDocument91 pagesSteel Loading Bays 01a DesignenatagoeNo ratings yet

- Pages From FootingDocument4 pagesPages From FootingenatagoeNo ratings yet

- Requirements for Engineers in RwandaDocument1 pageRequirements for Engineers in RwandaenatagoeNo ratings yet

- Lecture Theatre Remedial Beam On Gridline 3Document6 pagesLecture Theatre Remedial Beam On Gridline 3enatagoe100% (1)

- 21 - Eigenvalue Mode Using RitzDocument5 pages21 - Eigenvalue Mode Using RitzenatagoeNo ratings yet

- Ghana News - Abu Ramadan III - Clarification Ruling & Orders & The ECDocument22 pagesGhana News - Abu Ramadan III - Clarification Ruling & Orders & The ECenatagoeNo ratings yet

- Scan Doc by CamScannerDocument1 pageScan Doc by CamScannerenatagoeNo ratings yet

- Inter-Urban Case StudyDocument3 pagesInter-Urban Case StudyenatagoeNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Tributary Area For 2ND FloorDocument7 pagesTributary Area For 2ND FloorDave Khyl Josol BosqueNo ratings yet

- Standard construction equipment performanceDocument34 pagesStandard construction equipment performanceTewodros TadesseNo ratings yet

- MS Formwork, Reinforcement & Concrete WorksDocument15 pagesMS Formwork, Reinforcement & Concrete Workstomj9104100% (1)

- Structural Design Systems Sixth SemesterDocument2 pagesStructural Design Systems Sixth SemesterShraddha 08No ratings yet

- 11 Flexure in Beams 03Document25 pages11 Flexure in Beams 03S. M. ZAHIDUR RAHMAN 1301129No ratings yet

- ST02 17 PDFDocument1 pageST02 17 PDFbilisuma sebokaNo ratings yet

- Kks 1 Addition (Rev)Document12 pagesKks 1 Addition (Rev)Syahir AhmadNo ratings yet

- EC5 Timber DesignDocument119 pagesEC5 Timber Designmargitorsi100% (2)

- DRCS Cover - To Author PDFDocument1 pageDRCS Cover - To Author PDFAJAY SHINDENo ratings yet

- IR 25-3 GypsumCeilingDocument3 pagesIR 25-3 GypsumCeilingmark.taylor2962No ratings yet

- Nucor Insulated Roof Panel Details ManualDocument35 pagesNucor Insulated Roof Panel Details ManualgvgbabuNo ratings yet

- TCM Brochure 2016Document2 pagesTCM Brochure 2016George YapNo ratings yet

- Day 1 Presentation PDFDocument55 pagesDay 1 Presentation PDFradhi_rads89No ratings yet

- M 170M-141 Standard Specification For Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Document24 pagesM 170M-141 Standard Specification For Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe (Metric)Thai Hai LyNo ratings yet

- ACI Concrete Design Mix ProcedureDocument4 pagesACI Concrete Design Mix ProcedureLan CorpuzNo ratings yet

- ConcreteDocument62 pagesConcreteMahmoud ShakerNo ratings yet

- ATC 20 Rapid Evaluation Safety Assessment FormDocument1 pageATC 20 Rapid Evaluation Safety Assessment FormKali Bahadur ShahiNo ratings yet

- Design Memorandum: WSDOT BDM Revisions: Bridge Design Manual Section 9.3.3 and Design-Build SectionDocument2 pagesDesign Memorandum: WSDOT BDM Revisions: Bridge Design Manual Section 9.3.3 and Design-Build SectionR_kabirNo ratings yet

- Post-tensioned Timber Walls for Earthquake Damage MitigationDocument8 pagesPost-tensioned Timber Walls for Earthquake Damage MitigationbintnNo ratings yet

- Concrete Masonry SpecificationsDocument4 pagesConcrete Masonry SpecificationsGlenda CambelNo ratings yet

- Proposed Marudi Bridge Over Batang Baram, Miri Division, SarawakDocument8 pagesProposed Marudi Bridge Over Batang Baram, Miri Division, SarawakKelvin LauNo ratings yet

- Max Fajardo Complete 2ndedDocument153 pagesMax Fajardo Complete 2ndedBenjamin Benicarlo Juanillo IIINo ratings yet

- BOQ For Customer Corridor WorkingDocument9 pagesBOQ For Customer Corridor Workingishmeet singhNo ratings yet

- Mahsr WH 03Document3 pagesMahsr WH 03kukadiya127_48673372No ratings yet

- Analysis Sem 1 (08-09) AnswerDocument23 pagesAnalysis Sem 1 (08-09) Answersyah123100% (1)

- Sehagic Medic - GNP2012Document8 pagesSehagic Medic - GNP2012senad medicNo ratings yet

- Concrete Durability Shrinkage: Jürg Schlumpf Sika Services Ag / Target Market ConcreteDocument29 pagesConcrete Durability Shrinkage: Jürg Schlumpf Sika Services Ag / Target Market ConcretehormilopezNo ratings yet

- GF - rt23m Tower Boq. (G.F)Document42 pagesGF - rt23m Tower Boq. (G.F)Nadira PervinNo ratings yet

- Composite Steel-Concrete Bridges With Double Composite ActionDocument7 pagesComposite Steel-Concrete Bridges With Double Composite ActionOanh PhanNo ratings yet

- SoP for Section designer of shear wall in ETABSDocument2 pagesSoP for Section designer of shear wall in ETABSMuhammad SafdarNo ratings yet