Professional Documents

Culture Documents

Welding Procedure Specification Structural-3G

Uploaded by

dndudcCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Procedure Specification Structural-3G

Uploaded by

dndudcCopyright:

Available Formats

Doc No.

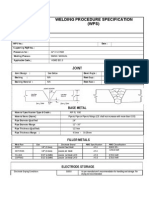

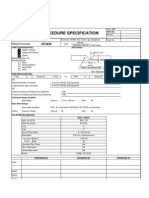

WELDING PROCEDURE SPECIFICATION(WPS) STRUCTURAL 3G

Revision :

Page 1 of 3

WELDING PROCESS: SMAW

WPS No.: Rev No.: Date: JOINT(QW-402) Joint Design: See sketch Backing: (Yes)__ (No) X Applicable code/Spec: ASME IX/AWS D1.1. Backing material (type): N/A.

TYPES: Manual

Supporting PQR No: PREQUALIFIED

60

2mm

3mm

STANDARD VEE BEVEL BUTT JOINT

4 3 1 2

SEQUENCE OF BEAD

BASE METALS (QW-403): P No 1 Group No 1 To P No 1 Group No 1 Material specification: ASTMA36TO A 1011

To Specification Type and Grade: Same or in Combination Thickness Range: Base Metal Groove 7.5mm to 37.5mm Pipe Dia. 12 OD 24 Others: Fillet 1/8 to Unlimited Fillet N/A

FILLER METALS (QW-404) Spec No. (SFA) AWS- No. F- No. A- No. Size of Filler Metals Deposited Weld Metal Thickness Welding Progression

WPS IN ACCORDANCE WITH ASME IX/AWS D1.1.

ROOT A5.1 E-7018 4 1 3.2mm 9mm MAX Uphill

FILL/CAP A5.1 E-7018 4 1 3.2 & 4.0mm 12mm MAX Uphill

WPS STRUCTURAL 3G

Doc No. :

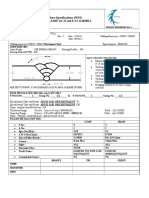

WELDING PROCEDURE SPECIFICATION(WPS) STRUCTURAL 3G

Revision :

Page 2 of 3

WELDING PROCESS: SMAW

Groove Position Fillet Electrode Flux (class) Flux trade name

TYPES: Manual

3G ALL N/A Lincoln Electric Jetweld 5P 3G ALL N/A Lincoln Electric Jetweld 7018 N/A

Consumable insert POSITIONS (QW-405) Position of Groove: 3G Positions of Fillet: ALL Welding Progression: UP: X Down:_ PREHEAT (QW-406) Preheat temperature Min: AWS TABLE 3.2 Interpass temperature: 250C MAX Preheat Maintenance: None Shielding

N/A POST WELD HEAT TREATMENT Temperature Range: N/A Time Range: N/A

GAS (QW-408) Percent composition Gas(es) N/A N/A N/A Mixture N/A N/A N/A Flow Rate N/A

Trailing N/A (Continuous or special heating where applicable should be recorded) Backing N/A

ELECTRICAL CHARACTERISTICS (QW-409) Current AC or DC: DC Polarity: Reverse Amps (Range): 70-190 Volts (Range) 24-30

Tungsten Electrode size and type; N/A Electrode Wire feed Speed Range: N/A

TECHNIQUE (QW-410) String or Weave Bead: BOTH Orifice or Gas cup size: N/A Initial & interpass cleaning: (Grinding & Brushing) Method of back Gouging: N/A

WPS IN ACCORDANCE WITH ASME IX/AWS D1.1. WPS STRUCTURAL 3G

Removal of line up clamp: After At Least 60% Of Root Pass Has Been Deposited Electrode: (single or multiple) Single

Doc No. :

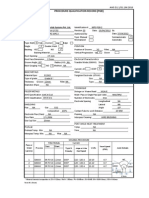

WELDING PROCEDURE SPECIFICATION(WPS) STRUCTURAL 3G

Revision :

Page 3 of 3

WELDING PROCESS: SMAW

Type of line up clamp: External (where applicable) Travel Speed Range 3- 15 inches per minute

TYPES: Manual

Travel speed (see table) Weld layers Process Filler Metal Class Dia (mm) Current Type of polarity Amp. Range Volt Range Travel Speed Range (mm/min) 1 2 3 SMAW SMAW SMAW E7018 E7018 E7018 3.2 3.2 4.0 DCEP DCEP DCEP 60-130 60-130 100-180 20-40 20-40 20-40 66-198 66-198 72-192 Stringer Weave Weave Others

Time laps between completion of root pass and commencement of second pass: 5 minutes Time laps between completion of second pass and commencement of other pass: 5 minutes Welding to be a continuous operation. Weld to completion (one heat cycle)

WPS IN ACCORDANCE WITH ASME IX/AWS D1.1.

WPS STRUCTURAL 3G

You might also like

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- WPS (AsmeDocument8 pagesWPS (AsmeMohammad Elhedaby100% (6)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (1)

- PT - Bumi Laut Perkasa: AWS D1.1 Welding Procedure Specification (WPS)Document2 pagesPT - Bumi Laut Perkasa: AWS D1.1 Welding Procedure Specification (WPS)Wahyu Lailil FaisNo ratings yet

- Joint Detail (Qw-402)Document2 pagesJoint Detail (Qw-402)Nitesh Patel100% (3)

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- Welding Procedure Specification Structural 3G PDFDocument3 pagesWelding Procedure Specification Structural 3G PDFsebincherianNo ratings yet

- Contoh WPS: Pengelasan Austenitik Stainless Steel Tipe 304: Dr. Ir. Winaarto, M.SCDocument14 pagesContoh WPS: Pengelasan Austenitik Stainless Steel Tipe 304: Dr. Ir. Winaarto, M.SCDessy Ayu Lestari100% (3)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- WpsDocument6 pagesWpsabhishek198327No ratings yet

- Wps SawDocument2 pagesWps Sawdevendrasingh2021100% (6)

- Smaw PQR FinalDocument3 pagesSmaw PQR Finalsheikmoin100% (1)

- WPS PQR Smaw + Fcaw D1.1Document8 pagesWPS PQR Smaw + Fcaw D1.1Yhuto W. Putra100% (3)

- WPS For Smaw06-001 (Pipe 6G CS)Document10 pagesWPS For Smaw06-001 (Pipe 6G CS)walitedison100% (1)

- WPS Fcaw PDFDocument1 pageWPS Fcaw PDFErik Huang100% (3)

- 2G +5GDocument1 page2G +5GRahul Moottolikandy0% (1)

- WPS Gtaw 2GDocument1 pageWPS Gtaw 2GSachin S. Salunkhe100% (2)

- Wps 316L SMAW+GTAW R00Document2 pagesWps 316L SMAW+GTAW R00Richard Periyanayagam86% (14)

- Procedure Qualification Record (PQR)Document3 pagesProcedure Qualification Record (PQR)Senthil KumaranNo ratings yet

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- WPS 2014-002 002 - 1G & 2G S 275 JRDocument2 pagesWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- Welding Procedure SpecificationDocument101 pagesWelding Procedure SpecificationOsman Gone Rana63% (8)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Wps SmawDocument1 pageWps SmawFedericoC67% (3)

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- WPS 304L &316LDocument2 pagesWPS 304L &316LShakeel Memon100% (1)

- How To Write A Welding Procedure SpecificationDocument14 pagesHow To Write A Welding Procedure Specificationnizam1372100% (2)

- Welding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Document2 pagesWelding Procedure Specification Krishna Steel Industries: Electrical Characterstics (Qw-409)Harshit AdwaniNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Ramadhan AdityaNo ratings yet

- Wps - PQR Traslape A-36 E-6013Document2 pagesWps - PQR Traslape A-36 E-6013Larc99No ratings yet

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 pageWelder Qualification Test Certificate: Weld Test Details Range of ApprovalPeter Johnston100% (3)

- Positive Material Identification (Pmi) ReportDocument2 pagesPositive Material Identification (Pmi) Reportchim_downloadNo ratings yet

- Fit-Up & Welding Visual Inspection ReportDocument11 pagesFit-Up & Welding Visual Inspection ReportRachel Flores71% (7)

- Qualified Welders ListDocument3 pagesQualified Welders ListdavNo ratings yet

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- WPS Flow Proceess Chart PDFDocument1 pageWPS Flow Proceess Chart PDFSatish KeskarNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- PQR Gmaw3gDocument4 pagesPQR Gmaw3gdevendrasingh2021100% (3)

- Sembcorp Marine Integrated Yard PteDocument3 pagesSembcorp Marine Integrated Yard PteMd. Mizanur Rahaman100% (1)

- WPS For Structure Mild Steel Fillet WeldDocument2 pagesWPS For Structure Mild Steel Fillet WeldHarkesh Rajput76% (17)

- Welder Test Certificate - CSDocument1 pageWelder Test Certificate - CSPrathamesh Omtech100% (4)

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- WPS Format For ASME IX - WQTDocument1 pageWPS Format For ASME IX - WQTThe Welding Inspections CommunityNo ratings yet

- Welding Procedure Specification - Tie - inDocument3 pagesWelding Procedure Specification - Tie - indndudcNo ratings yet

- 1015 To Hastelloy VickoDocument14 pages1015 To Hastelloy Vickovgestantyo100% (1)

- Welding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Document2 pagesWelding Procedure Specification (W.P.S) According To ASME IX &ASME B31.3Erick HoganNo ratings yet

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- Welding Book Revised 2012 07 14Document15 pagesWelding Book Revised 2012 07 14surya1960No ratings yet

- Welding FormDocument4 pagesWelding FormAnand SomanNo ratings yet

- Welding Procedure Specification: Technip KT India LimitedDocument5 pagesWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocument6 pagesProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNo ratings yet

- Critical Path Method (CPM) in Project ManagementDocument11 pagesCritical Path Method (CPM) in Project ManagementdndudcNo ratings yet

- Rigging Safety in Cranes PDFDocument170 pagesRigging Safety in Cranes PDFLuis AcuaNo ratings yet

- Check List - Air Compressor InspectionDocument1 pageCheck List - Air Compressor Inspectiondndudc100% (4)

- Anchor Handling Tug Pre-Mob InspectionDocument8 pagesAnchor Handling Tug Pre-Mob Inspectiondndudc100% (1)

- Cathodic Protection 2007Document141 pagesCathodic Protection 2007arsssyNo ratings yet

- Offshore Book 2010Document117 pagesOffshore Book 2010Mos Woraphon100% (1)

- Plant Commissioning Start Up ProcedureDocument100 pagesPlant Commissioning Start Up Proceduremsaad292% (124)

- Primavera (P6)Document316 pagesPrimavera (P6)Abde Ali83% (6)

- Offshore Pipelaying Dynamic PDFDocument150 pagesOffshore Pipelaying Dynamic PDFdndudcNo ratings yet

- Construction Quality ManualDocument42 pagesConstruction Quality ManualBob Madlener100% (7)

- 5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepDocument21 pages5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepArup NathNo ratings yet

- Behaviour of Reinforced Earth Behind Quay Walls PDFDocument9 pagesBehaviour of Reinforced Earth Behind Quay Walls PDFdndudcNo ratings yet

- Construction Presentation - Container Terminal PDFDocument60 pagesConstruction Presentation - Container Terminal PDFdndudc100% (1)

- Study of Breakwaters Constructed With One Layer of Armor Stone PDFDocument58 pagesStudy of Breakwaters Constructed With One Layer of Armor Stone PDFdndudcNo ratings yet

- Quay Wall Construction PDFDocument8 pagesQuay Wall Construction PDFdndudcNo ratings yet

- Quay Construction With Concrete Caisson PDFDocument5 pagesQuay Construction With Concrete Caisson PDFdndudcNo ratings yet

- Metode Konstruksi Reklamasi PantaiDocument55 pagesMetode Konstruksi Reklamasi PantaiHosea Luahambowo100% (1)

- Quality Procedure Technical Queries PDFDocument7 pagesQuality Procedure Technical Queries PDFdndudc100% (2)

- Study of Reflection of New Low-Reflectivity Quay Wall Caisson PDFDocument11 pagesStudy of Reflection of New Low-Reflectivity Quay Wall Caisson PDFdndudcNo ratings yet

- Functional Specification Diesel Fuel System PDFDocument5 pagesFunctional Specification Diesel Fuel System PDFdndudcNo ratings yet

- Functional Specification Export Gas Compressor PDFDocument7 pagesFunctional Specification Export Gas Compressor PDFdndudcNo ratings yet

- DSR 2007 ExcelDocument277 pagesDSR 2007 ExcelProjjal GhoshNo ratings yet

- Bayou Concrete Weight Coating PDFDocument2 pagesBayou Concrete Weight Coating PDFTinuoye Folusho OmotayoNo ratings yet

- EMT Conduit PDFDocument2 pagesEMT Conduit PDFbluesierNo ratings yet

- DIY Hobby Spray Booth Assembly Instructions Material Cut List by Vent WorksDocument5 pagesDIY Hobby Spray Booth Assembly Instructions Material Cut List by Vent WorksDiego Alex Gomez PerezNo ratings yet

- Master Presentation AcotecDocument24 pagesMaster Presentation AcotecWIDYANo ratings yet

- JBR DCP - P.Q Log PDFDocument1 pageJBR DCP - P.Q Log PDFAL BASTAKI CONTRACTING L.L.C.No ratings yet

- VFA FittingsCatalogueDocument138 pagesVFA FittingsCatalogueEdwinIriantoNo ratings yet

- Sheet and Coil: Product GuideDocument54 pagesSheet and Coil: Product GuidehbookNo ratings yet

- Material Datasheet Cuzn30Document2 pagesMaterial Datasheet Cuzn30alex94kgNo ratings yet

- Allowable Settlement of FoundationsDocument6 pagesAllowable Settlement of Foundationssb1966No ratings yet

- Du Pont KevlarDocument23 pagesDu Pont Kevlarniks2409100% (3)

- Aluminium Alloy - 6082 - T6 T651 Plate: Specifications Chemical CompositionDocument3 pagesAluminium Alloy - 6082 - T6 T651 Plate: Specifications Chemical Compositionhardik033No ratings yet

- PVC-PP-PVDF Swing Check Valve SpecificationsDocument4 pagesPVC-PP-PVDF Swing Check Valve SpecificationsthangNo ratings yet

- Section 02820 Ornamental Metal Fences and GatesDocument14 pagesSection 02820 Ornamental Metal Fences and GatesMØhãmmed ØwięsNo ratings yet

- Tarnish & CorrosionDocument11 pagesTarnish & CorrosionShahzadi SamanaNo ratings yet

- Schmidt Hammer TestDocument7 pagesSchmidt Hammer TestJas DhillonNo ratings yet

- Wood Frame House ConstructionDocument241 pagesWood Frame House Constructioneglyph100% (13)

- Curriculum Vitae: Jaydeep Patel Mob: 9033008448 Ahmedabad Gujarat Pin Code: 382421Document3 pagesCurriculum Vitae: Jaydeep Patel Mob: 9033008448 Ahmedabad Gujarat Pin Code: 382421Kamlesh Bule LonariNo ratings yet

- Fiber and PRC and Resin PlasticDocument25 pagesFiber and PRC and Resin PlasticCORONA EVENTNo ratings yet

- Lindberg Silicon Carbide Element Furnace SpecificationsDocument32 pagesLindberg Silicon Carbide Element Furnace Specificationsnathalie31No ratings yet

- 4 Effect of Drying Methods and Sand Additiveon Shrinkage Cracks of An Expansive Soil PDFDocument13 pages4 Effect of Drying Methods and Sand Additiveon Shrinkage Cracks of An Expansive Soil PDFYousif MawloodNo ratings yet

- List of Accredited BP (2015)Document9 pagesList of Accredited BP (2015)Jayson MalaaNo ratings yet

- Polyheed 997Document2 pagesPolyheed 997anumnedNo ratings yet

- Chemical AdmixtureDocument3 pagesChemical AdmixtureFayeTaylorNo ratings yet

- Hexply 8552: Mid-Toughened, High Strength, Damage-Resistant, Structural Epoxy MatrixDocument6 pagesHexply 8552: Mid-Toughened, High Strength, Damage-Resistant, Structural Epoxy MatrixshaxahNo ratings yet

- Two Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransDocument21 pagesTwo Storey Commercial Warehouse W Mezzanine (Semi-Concrete) - 17-024 - VeteransJohn Michael TalanNo ratings yet

- High Rise Buildings-Enclosures: Precast ConcreteDocument4 pagesHigh Rise Buildings-Enclosures: Precast Concreteruchira prathyushaNo ratings yet

- ECG Interpretation Made Incredibly Easy! (5th Edition)Document29 pagesECG Interpretation Made Incredibly Easy! (5th Edition)Freisan Chen0% (1)

- Ford Wa950Document2 pagesFord Wa950amanNo ratings yet

- Duplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojDocument7 pagesDuplex 2209 Weld Overlay by ESSC Process: Er. Manoj Kumar, Dr. Abhishek KambojAyyappanSubramanianNo ratings yet