Professional Documents

Culture Documents

Buffer Tank Hesabı PDF

Uploaded by

Devrim GürselOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Buffer Tank Hesabı PDF

Uploaded by

Devrim GürselCopyright:

Available Formats

CWB Series

C hille d Wa te r Buffe r Ta nks

CWB Series

C EM LINE C O RPO RATIO N

P.O. BOX 55 CHESWICK, PENNSYLVANIA 15024

Phone: (724) 274-5430 FAX (724) 274-5448

www.cemline.com

N

O

W

A

V

A

I

L

A

B

L

E

G

r

o

o

v

e

d

-

e

n

d

P

i

p

e

C

o

n

n

e

c

t

i

o

n

s

CWB Sizing

Step 1

Standard Equipment

Selecting a Chilled Water Buffer Tank

Cemline Chilled Water Buffer Tanks (CWB) are designed to be used with chillers

which do not have water volumes of sufficient size in relation to the chiller. The

insufficiently sized systems do not have enough buffer capacity for the chilled

water causing poor temperature control, erratic system operation, and

excessive compressor cycling. The CWB solves this problem by adding

volume to buffer the system. The CWB reduces the rate of change of the

return water temperature.

Chillers are designed to be used in

systems with a minimum water

volume. The minimum water volume is

based upon the chiller manufacturer

requirements, typically 3 to 6 gallons

per ton for typical air conditioning

applications or 6 to 10 gallons per ton

when temperature accuracy is criti-

cal. When chiller systems are

2

Step 2

Tank - ASME (125 psi @ 400 F)

1

2 flexible, elastomeric thermal

insulation black in color

(Thicknesses of

3

4, 1, 1

1

2, 2 available)

Legs for vertical installation

Internal Baffle

Air Vent

Chiller manufacturers recommend the system volume should be between 3 to 6

gallons per ton of nominal cooling for typical air conditioning applications.

When temperature accuracy is critical, they recommend 6 to 10 gallons

per ton of nominal cooling.

Calculate the system volume

required by the manufacturer. Please

check with the manufacturer specific

recommendations for gallons per ton

of nominal cooling required and use

in the below equation.

Required system volume (RSV) =

Chiller tons x Recommended

system volume/ton

Calculate the existing water

volume of the system. The system

includes piping and terminal equip-

ment. The table below shows how many

gallons per foot are in schedule 40 steel

pipe. Add to the pipe volume to the vol-

ume of the terminal equipment.

Actual system volume (ASV) =

piping volume (PV) + terminal equip-

ment volume (TEV)

Pipe Size Schedule

40 Steel Pipe

1

1.5

2

2.5

3

4

5

6

Gallons Per Foot

0.04

0.1

0.17

0.25

0.38

0.66

1.04

1.5

Pipe Size Schedule

40 Steel Pipe

8

Gallons Per Foot

10

12

14

16

18

20

2.59

4.09

5.82

7.02

9.18

11.67

14.45

properly sized, the chiller compressor

will not short cycle. Without the prop-

er amount of system water, the source

temperature will be reached quickly

and the compressor will shut off. Many

chiller compressors can only start 3

times per hour. If the compressor is

off and there is a demand for chilled

water, the demand can not be

met because the compressor cannot

turn back on. This causes very unsatis-

fied people within the building who

cannot have the required cooling.

Insufficiently sized system problems

can cause excessive compressor

cycling, poor temperature control

and erratic system operations.

Available Options

Seismic zone 4 angle legs (4 qty)

Outdoor exterior coating.

White in color and weather

resistant to UV and ozone.

Outdoor stucco-embossed

aluminum jacket (0.016 thick,

26 GA)

Example

3

The table at

right shows the

tank volume

sizes available

to select.

Chilled water tanks

can be supplied

with inlet/outlet

openings selected

from the chart

at right.

A building has a 100 Ton Chiller with a flow rate of 240 g.p.m. through 300 feet

of 4 pipe. The unit to be located indoors with a tank temperature of 45 F.

Unit to have standard leg stands.

1. Required system volume = (chiller tons) x (recommended system

volume/ton)

100 ton x 5 gallons/ton = 500 gallon volume required

2. Actual system volume = (piping volume) + (terminal equipment volume)

Piping volume: 300 ft x 0.66 gallons/ft = 198 gallon

Terminal equipment = 35 gallon

Actual system volume = 198 + 35 = 233 gallon

3. Tank size required = (required system volume) - (actual system volume)

500 gallon - 233 gallon = 267 gallon

4. Insulation required = 1/2

Therefore, choose a V300CWB with 4 flanges or grooved-end pipe

with 1/2 thick insulation Model No. V300CWB4F-C-05-I

Tank

Volume

Diameter

120 200 300 680 850 1040

24"

60" Length

30"

72"

48"

96"

54"

96"

36"

72"

60"

96"

500

42"

90"

Openings 'F'

1" NPT

1.5" NPT

2" NPT or Grooved-end Pipe

2.5" NPT or Grooved-end Pipe

3" FLANGE or Grooved-end Pipe

4" FLANGE or Grooved-end Pipe

6" FLANGE or Grooved-end Pipe

8" FLANGE or Grooved-end Pipe

10" FLANGE or Grooved-end Pipe

12" FLANGE or Grooved-end Pipe

16" FLANGE or Grooved-end Pipe

18" FLANGE or Grooved-end Pipe

20" FLANGE or Grooved-end Pipe

14" FLANGE or Grooved-end Pipe

Step 3

Calculate the tank size required.

Buffer tank size required is calculated

by subtracting the actual system

volume from the required system

volume.

Tank size required (TSR) = Required

system volume (RSV) -Actual system

volume (ASV)

Cemline CWBs are now available

with grooved-end pipe.

Grooved-end Pipe

6 and below Schedule 40 pipe

8 and above Schedule 30 pipe

Step 4

Select insulation

thickness based upon tank

temperature and

maximum ambient

temperature + humidity.

Tank

Temperature

Max. Ambient

Temperature

Recommended

Insulation Thickness

50 F

35 F

0 F

Max. Ambient

Humidity

50 F

35 F

0 F

85 F

85 F

85 F

90 F

90 F

90 F

70% RH

70% RH

70% RH

80% RH

80% RH

80% RH

1

2"

1

1

2"

1"

1

1

2"

2"

3

4"

D

L

Divider Plate

3-Leg Stands (36" diameter and below)

4-Leg Stands (42" diameter and above)

B

Air Vent

E

36"

C

12"x16"

Manhole in

42" Dia.

or greater

Tanks

A

Drain

F

Inlet

F

Outlet

1/2" Thermal

Insulation

G

Submittal Drawing

CEMLINE CORPORATION

P.O. BOX 55 CHESWICK, PENNSYLVANIA 15024

Phone: (724) 274-5430 FAX (724) 274-5448

www.cemline.com

CWB Series

CWB Series

Chilled Water Buffer Tanks

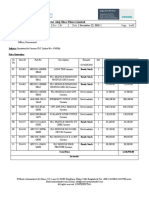

Tank

Volume

Diameter

"D"

Distance of

Center of

Opening

"C" "E"

120

200

300

500

850

1040

24"

30"

36"

42"

54"

60"

Length

"L"

60"

72"

72"

90"

96"

96"

12"

14"

16"

18"

22"

24"

20"

24"

24"

30"

32"

32"

Drain

"A"

1"

1"

1"

1

1

2"

1

1

2"

1

1

2"

Vent

"B"

3

4"

3

4"

3

4"

3

4"

3

4"

3

4"

"G"*

34"*

40"*

46"*

52"*

64"*

70"*

680 48" 96" 20" 32" 1

1

2"

3

4" 58"*

Openings 'F'

1" NPT

1.5" NPT

2" NPT or Grooved-end Pipe

2.5" NPT or Grooved-end Pipe

3" FLANGE or Grooved-end Pipe

4" FLANGE or Grooved-end Pipe

6" FLANGE or Grooved-end Pipe

8" FLANGE or Grooved-end Pipe

10" FLANGE or Grooved-end Pipe

12" FLANGE or Grooved-end Pipe

16" FLANGE or Grooved-end Pipe

18" FLANGE or Grooved-end Pipe

20" FLANGE or Grooved-end Pipe

14" FLANGE or Grooved-end Pipe

Model Number Code

V CWB

GALLON CAPACITY OPENING SIZE OPENING TYPE SUPPORT INSULATION THICKNESS LOCATION

F = Flange C = Leg Stands None = 0 I = Indoor

N = NPT SL = Siesmic Legs 1/2 = 05 O = Outdoor Coating

G= Groove End Pipe 3/4 = 075 A = Stucco Embossed Aluminum Jacket

1 = 10 N = No Insulation

1 1/2 = 15

2 = 20

*G dimension for Flanged and Grooved-end pipe only.

Grooved-end Pipe

Connection Available

2009 Cemline Corporation All Rights Reserved.

All trademarks on this brochure are the property of Cemline Corporation, unless otherwise

noted or in any other way set forth as a third party rights. Unauthorized use of these trade-

marks, as well as the materials presented on this site, is expressly prohibited and constitutes

a violation of the intellectual property rights of Cemline Corporation.

You might also like

- Rockwool ThicknessDocument36 pagesRockwool ThicknessDevrim Gürsel100% (1)

- TAB 2005 PS - 7th Edition - Second Printing - March 2009 FINALDocument118 pagesTAB 2005 PS - 7th Edition - Second Printing - March 2009 FINALDevrim GürselNo ratings yet

- Tango Fake BookDocument127 pagesTango Fake BookDevrim GürselNo ratings yet

- 0-91899-The Psychrometric Charts PDFDocument43 pages0-91899-The Psychrometric Charts PDFKardos ZoltanNo ratings yet

- Fakebook DjangoDocument242 pagesFakebook DjangoDevrim GürselNo ratings yet

- HVAC Handbook Commissioning GuidelineDocument145 pagesHVAC Handbook Commissioning Guidelinebabmech600795% (21)

- Adhesive Compounds'2 Component For Sealing Wire and Light in PavementDocument4 pagesAdhesive Compounds'2 Component For Sealing Wire and Light in PavementDevrim GürselNo ratings yet

- Compression Joint Seals For Concrete PavementsDocument10 pagesCompression Joint Seals For Concrete PavementsDevrim GürselNo ratings yet

- Part X - Turfing: Item T-901 SeedingDocument6 pagesPart X - Turfing: Item T-901 SeedingDevrim GürselNo ratings yet

- Bituminous Prime CoatDocument4 pagesBituminous Prime CoatDevrim Gürsel100% (2)

- Item P-603 Bituminous Tack CoatDocument4 pagesItem P-603 Bituminous Tack CoatMunarwand AhmadNo ratings yet

- Plant Mix Bituminous Pavements (Base, Leveling or Surface Course)Document27 pagesPlant Mix Bituminous Pavements (Base, Leveling or Surface Course)Devrim GürselNo ratings yet

- MulchingDocument4 pagesMulchingDevrim GürselNo ratings yet

- Bituminous Pavement RejuvenationDocument12 pagesBituminous Pavement RejuvenationDevrim GürselNo ratings yet

- Airport 8-Foot and 12-Foot Wind ConesDocument5 pagesAirport 8-Foot and 12-Foot Wind ConesDevrim GürselNo ratings yet

- Hazard BeaconDocument6 pagesHazard BeaconDevrim GürselNo ratings yet

- Underground Power Cable For AirportsDocument12 pagesUnderground Power Cable For AirportsDevrim GürselNo ratings yet

- Airport Obstruction LightsDocument4 pagesAirport Obstruction LightsDevrim GürselNo ratings yet

- Airport Transformer Vault and Vault EquipmentDocument9 pagesAirport Transformer Vault and Vault EquipmentDevrim GürselNo ratings yet

- Airport Underground Electrical Duct Banks and ConduitsDocument8 pagesAirport Underground Electrical Duct Banks and ConduitsDevrim Gürsel0% (1)

- Porous Friction CourseDocument10 pagesPorous Friction CourseDevrim GürselNo ratings yet

- Plant Mix Bituminous PavementsDocument33 pagesPlant Mix Bituminous PavementsDevrim GürselNo ratings yet

- Airport Beacon TowersDocument4 pagesAirport Beacon TowersDevrim GürselNo ratings yet

- Electrical Manholes and Junction StructuresDocument8 pagesElectrical Manholes and Junction StructuresDevrim GürselNo ratings yet

- Sand-Clay Base CourseDocument4 pagesSand-Clay Base CourseDevrim GürselNo ratings yet

- 150 5370 10e p209Document6 pages150 5370 10e p209Munarwand AhmadNo ratings yet

- Caliche Base CourseDocument4 pagesCaliche Base CourseDevrim GürselNo ratings yet

- Wildlife Deterrent FencesDocument6 pagesWildlife Deterrent FencesDevrim GürselNo ratings yet

- Wire Fence With Wood Posts (Classes A and B Fences)Document6 pagesWire Fence With Wood Posts (Classes A and B Fences)Devrim GürselNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Digital Systems Project: IITB CPUDocument7 pagesDigital Systems Project: IITB CPUAnoushka DeyNo ratings yet

- Chakir Sara 2019Document25 pagesChakir Sara 2019hiba toubaliNo ratings yet

- Clustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaDocument18 pagesClustering Menggunakan Metode K-Means Untuk Menentukan Status Gizi BalitaAji LaksonoNo ratings yet

- Hyundai SL760Document203 pagesHyundai SL760Anonymous yjK3peI7100% (3)

- Source:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Document2 pagesSource:: APJMR-Socio-Economic-Impact-of-Business-Establishments - PDF (Lpubatangas - Edu.ph)Ian EncarnacionNo ratings yet

- Scrum Exam SampleDocument8 pagesScrum Exam SampleUdhayaNo ratings yet

- Michael Clapis Cylinder BlocksDocument5 pagesMichael Clapis Cylinder Blocksapi-734979884No ratings yet

- BIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Document32 pagesBIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Md TayfuzzamanNo ratings yet

- Modern Construction HandbookDocument498 pagesModern Construction HandbookRui Sousa100% (3)

- DLP English 10 AIRADocument8 pagesDLP English 10 AIRAMae Mallapre100% (1)

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Document2 pagesLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulNo ratings yet

- Chapter 11 AssignmentDocument2 pagesChapter 11 AssignmentsainothegamerNo ratings yet

- ABS Service Data SheetDocument32 pagesABS Service Data SheetMansur TruckingNo ratings yet

- Keeping Track of Your Time: Keep Track Challenge Welcome GuideDocument1 pageKeeping Track of Your Time: Keep Track Challenge Welcome GuideRizky NurdiansyahNo ratings yet

- National Interest Waiver Software EngineerDocument15 pagesNational Interest Waiver Software EngineerFaha JavedNo ratings yet

- Fundasurv 215 Plate 1mDocument3 pagesFundasurv 215 Plate 1mKeith AtencioNo ratings yet

- 2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - LibroDocument82 pages2010 - Howaldt y Schwarz - Social Innovation-Concepts, Research Fields and International - Librovallejo13No ratings yet

- Types of Chemical Reactions: Synthesis and DecompositionDocument3 pagesTypes of Chemical Reactions: Synthesis and DecompositionAlan MartínNo ratings yet

- 5steps To Finding Your Workflow: by Nathan LozeronDocument35 pages5steps To Finding Your Workflow: by Nathan Lozeronrehabbed100% (2)

- Rankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothDocument111 pagesRankine-Froude Model: Blade Element Momentum Theory Is A Theory That Combines BothphysicsNo ratings yet

- SM EFATEX Rev D2 3 1 2018 PDFDocument20 pagesSM EFATEX Rev D2 3 1 2018 PDFGuilhermePlacidoNo ratings yet

- 'Causative' English Quiz & Worksheet UsingEnglish ComDocument2 pages'Causative' English Quiz & Worksheet UsingEnglish ComINAWATI BINTI AMING MoeNo ratings yet

- Naval TV SystemDocument24 pagesNaval TV Systemsharmasandeep0010No ratings yet

- Banking Ombudsman 58Document4 pagesBanking Ombudsman 58Sahil GauravNo ratings yet

- Configuration Guide - Interface Management (V300R007C00 - 02)Document117 pagesConfiguration Guide - Interface Management (V300R007C00 - 02)Dikdik PribadiNo ratings yet

- FINAL SMAC Compressor Control Philosophy Rev4Document6 pagesFINAL SMAC Compressor Control Philosophy Rev4AhmedNo ratings yet

- WWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDocument8 pagesWWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDestiny EasonNo ratings yet

- Tomb of Archimedes (Sources)Document3 pagesTomb of Archimedes (Sources)Petro VourisNo ratings yet

- Analisis Kebutuhan Bahan Ajar Berbasis EDocument9 pagesAnalisis Kebutuhan Bahan Ajar Berbasis ENur Hanisah AiniNo ratings yet

- Quality Standards For ECCE INDIA PDFDocument41 pagesQuality Standards For ECCE INDIA PDFMaryam Ben100% (4)