Professional Documents

Culture Documents

How To Control The Color of Surimi

Uploaded by

Konica Minolta Sensing Singapore Pte LtdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Control The Color of Surimi

Uploaded by

Konica Minolta Sensing Singapore Pte LtdCopyright:

Available Formats

What is Surimi?

The word sir-ree-mee is a Japanese loanword that refers to food products that have been processed by mincing lean meat into a paste to resemble seafood like crabs, shrimps, lobsters and other shellfish. It is a typical fish-based food product that is made from fish meat that includes the Alaska Pollock, Atlantic Cod, Pacific Hake and Swordfish. Many Asian food use surimi as its primary ingredient and is a much-enjoyed food product which is very popular in Asian cultures. Surimi attains a rubbery and springy texture when they are cooked and served. Common Surimi product in the market comes in different shapes, forms and textures which are also known as crab sticks and seafood sticks. History and Popularity of Surimi Originated in Japan several centuries ago, surimi is one of Asias diet. Common usage of surimi is to make california rolls, sushi and fish sausages also known as Komoboko. These Japanese food crafts have made surimi products well known worldwide. It is widely accepted in America around 1970 and in Europe around 1980. The popularity and demand escalated sharply in 1983. Since then, surimi could be found in almost any supermarket and consumed worldwide because of its low fat content and high nutritional value. Currently, 2 to 3 tons of fish harvested around the world is used in the production of surimi. The United States of America and Japan are the two major producers of surimi products. Surimi Processing Surimi is made by washing minced flesh with water and mixed with sugar and other additives and then frozen into blocks. Food processing companies use surimi blocks and shape it to look like imitation crab meat, fish ball and so on. Surimi is popular in many Japanese restaurants, widely consumed, and is available in many supermarkets because of its long shelf life. Firstly, raw fish is skinned and deboned. The fillets are minced, washed and then strained to get a concentrated fish paste. The final refinement is to separate into different grades and then dehydrated. The frozen process is called cryoprotectants, which will flash freeze the surimi blocks in order to keep its freshness and quality.

Color Perception of Surimi In the food processing industry, color indicates the freshness and superiority of the product and is often at times a quality indicator. For example, fresh, chilled, and frozen packages of surimi products today are more eye appealing than the nose appeal. Surimi producers know this well as the quality of surimi is determined by its color and they are increasingly adopting instrumental color assessment technologies to control the quality. Color Assessment Instrumental color measurements are used in a number of ways when it comes to the production of surimi. Most of the time, they are used during the initial grading of raw material at the incoming quality checks. The colorimeter can, for example, be used to check the color of lean meat of the fish to determine whether it falls within the limits of its specification for color. These colorimeters allow color analysis that can be carried out in various processing stages such as: Research and Development To determine the amount of additives used in surimi to enhance its whiteness (eg. by removing yellowish pigment). To determine the effect of storage period and method on the quality of surimi (eg. whiteness) Process Control Monitoring of washing process (reduction b* yellowness value) and ingredient mixing (whiteness enhance) Monitoring of post-pasteurization color of surimi. Grading of final product (usually based on its whiteness value). Colorimeter for Surimi Assessment Colorimeter measures a food sample as it appears under daylight by using a lamp to provide a consistent lighting for each measurement. The lamp illuminates a sample and the reflected light is analysed to give a color space data like CIE L*a*b*. It is designed for color difference measurement and is very useful to help food producers and technologists to determine whether a product is within the color specification. The data given is valuable as it provides a guide in color consistency.

KONICA MINOLTA SENSING SINGAPORE PTE LTD 10 TEBAN GARDENS CRESCENT SINGAPORE 608923 sensing.konicaminolta.asia

Type of Color Analysis Whiteness variance is normally indicated by whiteness indices, such as: Whiteness (Hunter): WHU = L 3b Whiteness (Hunter): WH = 100 - [(100 L) + a + b]1/2

Type of Color Instrument Accessories Colorimeters are generally portable instruments that are suitable for any kind of food samples. Using a granular material attachment, surimi paste can be placed into this accessory holder for easy access to non-solid food samples for quick and accurate color measurement. For measurement of wet surfaces or to ensure that the food samples are flat during measurement, a light projection tube which has a glass plate at the tip can be useful. This prevents any external substances like liquid to enter the sensor. Lastly, measurement data transfer is straight forward with the SpectraMagic NX software for color data processing, indices calculation and spreadsheet export. These features are comprehensive yet easy to use even for the non-experts.

The unwanted yellowness in surimi is determined by the *b value, or Yellowness Index. Redness value, which is indicated by the a* value, is normally used by some food producers to determine the freshness of raw material. To confirm the color when colorant is used in the final products (eg. imitation crab meat), all L*a*b* values will be used.

KONICA MINOLTA SENSING SINGAPORE PTE LTD 10 TEBAN GARDENS CRESCENT SINGAPORE 608923 sensing.konicaminolta.asia

You might also like

- Is Chapter 2Document10 pagesIs Chapter 2Xarbie RebadomiaNo ratings yet

- SurimiDocument12 pagesSurimikekenNo ratings yet

- 66731whitepaper FoodcolourDocument3 pages66731whitepaper FoodcolourEbadur Rahman BarbhuiyaNo ratings yet

- 6 Minced Fish and Surimi ProcessingDocument3 pages6 Minced Fish and Surimi ProcessingAngelBeatZNo ratings yet

- Konica Minolta Food Color MeasurementDocument0 pagesKonica Minolta Food Color MeasurementManish ParulNo ratings yet

- Post Harvest Units 4 To 6Document65 pagesPost Harvest Units 4 To 6finis704No ratings yet

- Tle Reviewer Module 1 2Document2 pagesTle Reviewer Module 1 2Margie B. OroNo ratings yet

- Measuring The Color of Milk - Objective Color Measurement and ControlDocument2 pagesMeasuring The Color of Milk - Objective Color Measurement and ControlKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- ThesisDocument28 pagesThesisBellaImperial56% (9)

- Monitoring and Measuring Techniques For Quality and Safety: © 2006 by Taylor & Francis Group, LLCDocument14 pagesMonitoring and Measuring Techniques For Quality and Safety: © 2006 by Taylor & Francis Group, LLCSyed Ali Akbar BokhariNo ratings yet

- Gastronomical JourneyDocument4 pagesGastronomical JourneyLucky Allan ValleNo ratings yet

- Sorting and Grading of Raw Materials in Salting, Curing and SmokingDocument26 pagesSorting and Grading of Raw Materials in Salting, Curing and SmokingOmar Palma Gil MangolayonNo ratings yet

- Presentation by DilpreetDocument20 pagesPresentation by DilpreetYukti GargNo ratings yet

- Fish Industries Brochure GBDocument7 pagesFish Industries Brochure GBMikeNo ratings yet

- SurimiDocument24 pagesSurimiDewi SetiyowatiNo ratings yet

- 8.0 FinancialDocument6 pages8.0 FinancialFatinFarhanaAzmiNo ratings yet

- Fish Industries Sales Guide - FOSS - GB PDFDocument7 pagesFish Industries Sales Guide - FOSS - GB PDFDiaconu DragosNo ratings yet

- Surimi, Salting and Fermentation TechnologiesDocument5 pagesSurimi, Salting and Fermentation TechnologiesAngelBeatZNo ratings yet

- Chapter 4 Surimi and Fish Protein Concentrate IsolateDocument46 pagesChapter 4 Surimi and Fish Protein Concentrate IsolateFETRITCIA OMPOK -No ratings yet

- Aqph310 Case StudyDocument11 pagesAqph310 Case StudyLenz Ayuste100% (1)

- By: Eirene Eunike Meidiana Gaghauna & Rifa'Atul MahmudahDocument30 pagesBy: Eirene Eunike Meidiana Gaghauna & Rifa'Atul MahmudahRifa'atul MahmudahNo ratings yet

- Ismail Sulaiman Seminar5Document7 pagesIsmail Sulaiman Seminar5Wahyu.ramadaniNo ratings yet

- 1.SuperFrozen IntroductionDocument15 pages1.SuperFrozen IntroductionMichael McNicholasNo ratings yet

- Surimi Technology: Submitted To: Dr.A.K.Singh (Sr. Scientist) Submitted By: Rahul Kumar (M.Tech, DT, 1 Year)Document13 pagesSurimi Technology: Submitted To: Dr.A.K.Singh (Sr. Scientist) Submitted By: Rahul Kumar (M.Tech, DT, 1 Year)rahuldtc100% (2)

- Pengantar Sifat Bahan PanganDocument46 pagesPengantar Sifat Bahan PanganKurnia Perdana PangestikaNo ratings yet

- Fish ProcessingDocument8 pagesFish ProcessingIranga Liyanage100% (1)

- Value Added Fishery ProductsDocument21 pagesValue Added Fishery ProductsRam Kumar92% (12)

- Proposal BISNIS PLANDocument7 pagesProposal BISNIS PLANDODI ISKANDARNo ratings yet

- Kuliah 13,14-Fermented MeatDocument8 pagesKuliah 13,14-Fermented MeatyunitaNo ratings yet

- E.D.P Project: Manufacturing of Fish /prawn Pickle IntroductionDocument15 pagesE.D.P Project: Manufacturing of Fish /prawn Pickle IntroductionblackvenumNo ratings yet

- Quality Control of FishDocument9 pagesQuality Control of FishFath BondNo ratings yet

- Business PlanDocument19 pagesBusiness PlanJadzia SydneyNo ratings yet

- Food Pro. 9 PowerpointDocument33 pagesFood Pro. 9 PowerpointKrizel Legaspi67% (3)

- Food Fish Processing Module 1Document47 pagesFood Fish Processing Module 1Raneil Alvers100% (3)

- Surimi and Surimi ProductsDocument2 pagesSurimi and Surimi ProductsAsep SyafrudinNo ratings yet

- Title DefenseDocument23 pagesTitle DefenseRengie LaduaNo ratings yet

- Chapter1 ResearchDocument2 pagesChapter1 ResearchJonard Carace CardañoNo ratings yet

- Meat CuringDocument4 pagesMeat CuringBlair CarterNo ratings yet

- How To Measure Chocolate ColorsDocument2 pagesHow To Measure Chocolate ColorsKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- Group 1.MEAT AND MEAT PRODUCTS PDFDocument47 pagesGroup 1.MEAT AND MEAT PRODUCTS PDFGiselle LabaganNo ratings yet

- Fish Eye Image Identification in Order To Determine The Quality of The Fish Flesh With The Method of Fuzzy LogicDocument10 pagesFish Eye Image Identification in Order To Determine The Quality of The Fish Flesh With The Method of Fuzzy LogicTeguh Hari SantosoNo ratings yet

- Advance FisheriesDocument6 pagesAdvance FisheriesRaisul IslamNo ratings yet

- Food CharacteristicsDocument41 pagesFood CharacteristicsMonika KshetriNo ratings yet

- Business Plan: Alabang Campus #19 Ilaya ST., Alabang, Muntinlupa CityDocument8 pagesBusiness Plan: Alabang Campus #19 Ilaya ST., Alabang, Muntinlupa CityMarc BasamotNo ratings yet

- Genesis 1Document22 pagesGenesis 1MirajulIslamNo ratings yet

- Pickle 1Document5 pagesPickle 1Rohit Shendge100% (1)

- Week 3Document4 pagesWeek 3Prima LebananNo ratings yet

- Marketing PlanDocument15 pagesMarketing PlanvdchuongNo ratings yet

- Industrial Products: "If You're Still Cutting Onions, It's A Crying Shame!"Document2 pagesIndustrial Products: "If You're Still Cutting Onions, It's A Crying Shame!"Ahmad Syihab FahmiNo ratings yet

- Discov ErtDocument15 pagesDiscov ErtKitz Irish BelloNo ratings yet

- Studi Penerimaan Konsumen Terhadap Nugget Cumi-Cumi (Loligo SP.) Kering AsinDocument11 pagesStudi Penerimaan Konsumen Terhadap Nugget Cumi-Cumi (Loligo SP.) Kering AsinsidikNo ratings yet

- of Dry MeatDocument19 pagesof Dry Meatcarloseksaji1111No ratings yet

- Cap Report: Sensory Evaluation of Food ProductsDocument9 pagesCap Report: Sensory Evaluation of Food ProductsVeeraprasad CGNo ratings yet

- Project Report of Potato ChipsDocument5 pagesProject Report of Potato Chipsmitums100% (2)

- Mini Project 2017Document32 pagesMini Project 2017Lee KaiYangNo ratings yet

- Business PlanDocument22 pagesBusiness Planachmad musonifNo ratings yet

- Pemanfaatan Hasil Perikanan Sebagai Produk Bernilai Tambah (Value-Added) Dalam Upaya Penganekaragaman PanganDocument8 pagesPemanfaatan Hasil Perikanan Sebagai Produk Bernilai Tambah (Value-Added) Dalam Upaya Penganekaragaman PanganErlin Fitri YantiNo ratings yet

- PublicationDocument28 pagesPublicationFREDAKJNR20018569No ratings yet

- Salting PreservationDocument8 pagesSalting PreservationNaharia RangirisNo ratings yet

- Measuring The Color of Milk - Objective Color Measurement and ControlDocument2 pagesMeasuring The Color of Milk - Objective Color Measurement and ControlKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- How To Measure Chocolate ColorsDocument2 pagesHow To Measure Chocolate ColorsKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- The Color of Quality - Color Control and Measurement in Pharmaceutical IndustryDocument3 pagesThe Color of Quality - Color Control and Measurement in Pharmaceutical IndustryKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- Common Color IssuesDocument4 pagesCommon Color IssuesKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- SUS Colorimetry White PaperDocument3 pagesSUS Colorimetry White PaperKonica Minolta Sensing Singapore Pte LtdNo ratings yet

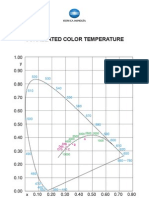

- CIE Yxy With Color Temperature - A1 SizeDocument1 pageCIE Yxy With Color Temperature - A1 SizeKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- Xy Chromaticity Chart With Isotemperature Lines A1 Size PosterDocument1 pageXy Chromaticity Chart With Isotemperature Lines A1 Size PosterKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- Visual Color Assessment FormDocument1 pageVisual Color Assessment FormKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- Lighting Technologies Principle and MeasurementDocument15 pagesLighting Technologies Principle and MeasurementKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- CIE 1931 Yxy Chromaticity Chart With Correlated Color Temperature A1 Size PosterDocument1 pageCIE 1931 Yxy Chromaticity Chart With Correlated Color Temperature A1 Size PosterKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- CIE 1931 Yxy Chromaticity Chart A1 Size PosterDocument1 pageCIE 1931 Yxy Chromaticity Chart A1 Size PosterKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- Correlated Color Temperature With Iso Temperature Curves - A1 SizeDocument1 pageCorrelated Color Temperature With Iso Temperature Curves - A1 SizeKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- 1 PB PDFDocument13 pages1 PB PDFAHMAD FATTAH ASMA'INo ratings yet

- TheSeafoodCompany Product+ListDocument33 pagesTheSeafoodCompany Product+ListJamil RozaqNo ratings yet

- FSSAI Microbiological StandardsDocument55 pagesFSSAI Microbiological StandardsKapil SinghNo ratings yet

- Fish Raw Material International Fish GroupsDocument40 pagesFish Raw Material International Fish GroupsjoshigautaNo ratings yet

- Phosphates & Non-Phosphates For SeafoodDocument4 pagesPhosphates & Non-Phosphates For Seafoodanhtuan_qnuNo ratings yet

- How To Control The Color of SurimiDocument2 pagesHow To Control The Color of SurimiKonica Minolta Sensing Singapore Pte LtdNo ratings yet

- Building Surimi OpportunitiesDocument8 pagesBuilding Surimi OpportunitiesAlanNo ratings yet

- SurimiDocument24 pagesSurimiDewi SetiyowatiNo ratings yet

- Gelling Properties and Lipid Oxidation of Kamaboko Gels From Grass Carp (Ctenopharyngodon Idellus) Influenced by ChitosanDocument7 pagesGelling Properties and Lipid Oxidation of Kamaboko Gels From Grass Carp (Ctenopharyngodon Idellus) Influenced by ChitosanAnisa TridiyaniNo ratings yet

- STKM 4612 Surimi IndustryDocument33 pagesSTKM 4612 Surimi IndustryCalvin Wyatt100% (1)

- Value Added Fishery ProductsDocument21 pagesValue Added Fishery ProductsRam Kumar92% (12)

- Perilaku Kewirausahaan Pelaku Usaha Pempek Skala Industri Kecil Dan Menengah Di Kota Palembang, Provinsi Sumatera SelatanDocument12 pagesPerilaku Kewirausahaan Pelaku Usaha Pempek Skala Industri Kecil Dan Menengah Di Kota Palembang, Provinsi Sumatera SelatanRyzki Nur PratamaNo ratings yet

- 1653 3071 1 SMDocument21 pages1653 3071 1 SMTau GakNo ratings yet

- Daft Ar Pro Duk HalalDocument703 pagesDaft Ar Pro Duk HalalSelamet YasinNo ratings yet

- Katalog Cedea 2018Document2 pagesKatalog Cedea 2018fenny talimNo ratings yet

- Oyster Meat F.S.Document25 pagesOyster Meat F.S.mxviolet50% (2)

- Iso Dis 23855Document9 pagesIso Dis 23855Huswatun HasanahNo ratings yet

- Ch19 Material For Apprenticeship FishDocument7 pagesCh19 Material For Apprenticeship FishS8 ValenciaNo ratings yet

- Effect of Different Starches On Colors and Textural Properties of Surimi Starch GelsDocument11 pagesEffect of Different Starches On Colors and Textural Properties of Surimi Starch GelsGheeaa 17No ratings yet

- 1 Crab Meat Analog PreparationDocument4 pages1 Crab Meat Analog PreparationKizzy RennieNo ratings yet

- Recent Advances in Surimi Technology: Uricml@uriacc - Uri.eduDocument7 pagesRecent Advances in Surimi Technology: Uricml@uriacc - Uri.eduNhi HoNo ratings yet

- 2 Crab Meat Analog ProcessingDocument4 pages2 Crab Meat Analog ProcessingKizzy RennieNo ratings yet

- Burger With A Bang "Taste Like Meat, Makes Your Body Fit"Document27 pagesBurger With A Bang "Taste Like Meat, Makes Your Body Fit"maeg07No ratings yet

- Make The Most Out of Our Natural Resources!: Flottweg Decanters For Surimi ProductionDocument4 pagesMake The Most Out of Our Natural Resources!: Flottweg Decanters For Surimi ProductionCésar MaravíNo ratings yet

- MethodologyDocument7 pagesMethodologyMuhamad Solleh Majid0% (1)

- Materi Sumber Daya SurimiDocument28 pagesMateri Sumber Daya SurimiSukti IlhamNo ratings yet

- Laporan p5 Selesai Kel 3Document10 pagesLaporan p5 Selesai Kel 3Sukirjo SukirjoNo ratings yet

- Crab Stick EquipmentDocument5 pagesCrab Stick EquipmentchromeNo ratings yet

- Market Insight For Seafood Products - Brenntag APACDocument28 pagesMarket Insight For Seafood Products - Brenntag APACboy andrianoNo ratings yet