Professional Documents

Culture Documents

Solar Installation Manual

Uploaded by

Shubham ArvikarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Solar Installation Manual

Uploaded by

Shubham ArvikarCopyright:

Available Formats

Installation & User Manual

for 8.33 Solar Photovoltaic (PV) Modules

Date: January 2013 Version: IUM-013-01

Overview Thank you very much for using 8.33 Solar PV modules. This manual contains information regarding the safe installation and handling of photovoltaic module produced by Pangea Systems S.A. (8.33 Solar). In order to enable the PV module to be installed correctly and to generate electric power properly, please read the following operation instructions carefully before installing and using the modules. If there are any questions, please contact 8.33 Solar Customer Service. Please remember that you are operating a product that generates electricity, and therefore certain safety measures need to be implemented in order to avoid accidents. Installers must follow all safety precautions as described in this guide as well as local requirements and regulations by law or authorized organizations. Disclaimer of Liability Because the use of this manual and the conditions or methods of installation, operation, use and maintenance of PV product are beyond 8.33 Solars control, 8.33 Solar will not accept any responsibility and expressly disclaims any liability for loss, damage, or expense arising out of or in any way connected with such installation, operation, use or maintenance. No responsibility will be assumed by 8.33 Solar for any infringement of patents or other right of third parties, which may result from use of the PV module. No license is granted by implication or otherwise under any patent or patent right. The information in this manual is based on 8.33 Solars knowledge and experience and it is believed to be reliable. Nevertheless such information, including product specication (without limitations) and suggestions do not constitute a warranty, expressed or implied. 8.33 Solar reserves the right to change the manual, the PV module, the specications or product information sheets without prior notice. Product Identication Each module can be identied by means of the following embedded information: Nameplate: located on the module backside. According to EN 50380 Directives it is giving information about the main parameters of the module: Product Type, Maximum Power, Current at Maximum Power, Voltage at Maximum power, Open Circuit Voltage, Short Circuit Current, all as measured under Standard Test Conditions, weight, dimensions, Maximum System Voltage, Maximum series fuse etc. Serial number: each individual module is identied by a unique serial number accompanied with a barcode. They are permanently inserted inside the laminate, under the front glass of the module, visible when viewing from the front of the module. There are only one serial number accompanied with one barcode on the module.

Safety General You must understand and follow all applicable local, state, and federal regulations and standards for building construction, electrical design, re, and safety, and much check with local authorities to determine applicable permitting requirements to install or maintain PV modules. Rooftop PV systems should only be installed on dwellings that have been formally analyzed for structural integrity, and conrmed to be capable of handling the additional weighted load of PV system components, including PV modules, by certied building specialist or engineer.

www.833solar.com!

8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 1 of 12

For your safety, do not attempt to work on a rooftop until safety precessions have been identied and taken, including without limitation fall protection measures, ladders or stairways, and personal protective equipment (PPE). Installers should assume the risk of all injury that might occur during installation including, without limitation, the risk of electrical shock. For your safety, do not install or handle PV modules under adverse conditions, including without limitations strong or gusty winds, and wet or frosted roof surfaces. Do not attempt to disassemble the modules, and do not remove any attached nameplates or components form the modules. Do not apply paint or adhesive to module top surface. Do not use mirrors or other magniers to articially concentrate sunlight on the modules. Do not expose back sheet foils directly to sunlight. Transport and Handling 8.33 Solar PV modules must be transported in the supplied packaging only and kept in the packaging until they are ready to be installed. Protect pallets against movement and exposure to damage during transportation. Secure pallets from falling over. Do not exceed the maximum height of pallets to be stacked as indicated on the pallet packaging. Store pallets in a cool and dry location until the PV modules are ready to be unpackaged. 8.33 Solar PV modules are heavy and should be handled with care. PV modules shall be handled at the frame; never use the junction box or cables as a grip. Do not exert mechanical stress on the cables. Do not scratch surface of PV modules. Never step on PV modules or drop or place heavy objects on them. Be careful when placing PV modules on hard surface, and secure them from falling. Broken glass can result in personal injury. PV modules with broken glass cannot be repaired and must not be used. Broken or damaged PV modules must be handled carefully and disposed of properly. Unpacking Once the PV module has been shipped to the installation site all of the parts should be unpacked properly with care. For unpacking PV modules from the 8.33 Solar supplied packaging, rst remove the pallet lid (after removing securing straps, if provided). Remove PV modules one at a time by lifting them up the channel in the package. You may need to secure the remaining PV modules in the pallet packaging to prevent them from falling/sliding over. Check PV modules for damage due to transportation before they are installed; do not install damaged modules. Contact the company you purchased the 8.33 Solar PV modules from in order to obtain information on making claims for defective PV modules. PV modules surfaces are susceptible to damage that could affect the performance or safety of the PV module; do not damage or scratch the PV module surfaces, and do not apply paint or adhesive to any of the surfaces, including the frame. For you safety, do not disassemble or modify 8.33 Solar PV modules in any way. Doing so may degrade performance or cause irreparable damage and will void any applicable warranties. If it is necessary to store PV modules prior to installation, the PV modules should remain inside the packaging and protected from exposure that could compromise the durability of the packaging. www.833solar.com! 8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 2 of 12

Caution: the environment for unpacking the modules and all other apparatus should be proofed against dampness and rainfall. Electrical PV modules can produce current and voltage when exposed to light of any intensity. Electrical current increases with higher light intensity. DC voltage of 30 Volts or higher is potentially lethal. contracting the live circuitry of a PV system operating under light can result in lethal electric shock. De-energize PV modules by removing them entirely from light or by covering their front surface with an opaque material. Regard the safety regulations for live electrical equipment when working with modules that are exposed to any light. Use insulated tools and do not wear metallic jewelry working with PV modules. In order to avoid arching or electrical shock, do not disconnect electrical connectors under load. Faulty connectors can also result in arcing and electrical shock. Keep connectors dry and clean, and ensure that hey are in proper working condition. Never insert metallic objects into the connectors, or modify them in any way in order to secure an electrical connection. Do not touch or handle PV modules with broken glass, separated frames or a damaged back-sheet unless the PV modules are rst disconnected and you are wearing proper PPE. Do not wear metallic rings watchbands, ear, nose or lip rings or other metallic devices while installing or troubleshooting photovoltaic systems in order to keep safe from electric shock. Avoid handling PV modules when they are wet unless cleaning the PV modules as directed in this manual. Never touch electrical connectors that are wet without protecting yourself with insulated gloves. Fire 8.33 Solar PV modules have a Class C re resistance rating in accordance with the IEC 61730-2 certication. When PV modules are mounted on rooftops, the roof must have a re resistant covering suitable for this application. PV modules are electrical generating devices that may affect the re safety of a building. The use of improper installation methods and/or defective parts may result in the unexpected occurrence of an electrical arc during operation. In order to mitigate the risk of re in the event, PV modules should not be installed near ammable liquids, gases, or locations with hazardous materials. In the event of re, PV modules may continue to produce a dangerous voltage, even if they have been disconnected from the inverter, have been partly or entirely destroyed, or the system wiring have been compromised or destroyed. In the event of re, inform the re crew about the particular hazards from the PV system, and stay away from all elements of the PV system during and after a re until the necessary steps have been taken to make the PV safe. Warning Solar modules have a protective glass front. Broken solar module glass is an electrical safety hazard (electric shock and re). These modules cannot be repaired and should be replaced immediately. Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current and/or voltage than reported at standard test conditions. Accordingly, the value of Isc and Voc marked on this module should be multiplied by 1.56 when determining component voltage ratings, conductor current ratings, fuse sizes, and size of controls connected to the PV module. The installation work of the PV array can only be done under the protection of sun-sheltering covers or sunshades and only qualied person can install or perform maintenance work on this module. Follow the battery manufacturers recommendations if batteries are used with module. Do not install this module to substitute - even partially - a roof or wall of a habitable structure. Do not touch live terminal with bare hands. Use insulated tools for electrical connections. 8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 3 of 12

www.833solar.com!

All instructions should be read and understood before attempting to install, wire, operate and maintain this module.

Application Information Application Restrictions 8.33 Solar PV modules must be mounted on appropriate mounting structure positioned on suitable buildings, the ground, or other structures suitable for PV modules (e.g. carports, building facades or PV trackers). PV modules must not be mounted on moving vehicles of any kind. 8.33 Solar PV modules most not be installed in locations where they could be submerged in water. 8.33 Solar PV modules must not be sited in locations where aggressive substances such as salt or saltwater, or any other type of corrosive agent could affect the safety and/or performance of the PV modules. Although some typed of 8.33 Solar PV modules have passed IEC 61701 salt-mist corrosion test with a salt concentration of 5% by weight, galvanic corrosion can occur between the aluminum frame of the PV module and mounting or grounding hardware if such hardware is comprised of dissimilar metals. Articially concentrated light must not be directed on 8.33 Solar PV modules. Do not install modules where ammable gas may be present. Design Recommendations 8.33 Solar recommend that PV modules be mounted at a minimum tilt angle of 10 degrees to allow for proper self-cleaning from normal rain showers. Partial or complete shading of a PV module or modules can signicantly reduce system performance. 8.33 Solar recommends minimizing the amount of shade throughout the year to increase the amount of energy produced by the PV modules. Lightning protection is recommended for PV modules that are to be installed in locations with high probability of lightning strike. High system voltages could be induced in the event of an indirect lightning strike, which could cause damage to PV system components. The open area of wire loops should be minimized in order to reduce the risk of lightning induced voltage surge.

Preparation Before Installation Visual check before installation, to make sure there is no defect in the packaging and junction box as well as the surface of module. Check the series number Check the solar cell modules with irradiance of more than 600W/m2 and get the voltage. In case the voltage is ZERO, it should not be installed and please contact the supplier. The users should design and build metallic bracket for installing and bearing the weight of the PV modules. The brackets are specially designed for users installation places such as open land or on roof of houses.

Caution: It is recommended to place the module in a gradient angle facing the sun, in order to insure maximum irradiance and also to avoid damage from ooding and other unpredictable events, such as heavy impacts. www.833solar.com! 8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 4 of 12

Installation and Operation System should be installed by qualied personnel only as at least by two persons. The system involves electricity, and can be dangerous if the operators are not familiar with the appropriate safety procedures. Although modules are quite rugged, the glass can be broken (and the modules will no longer work properly) if it is dropped or hit by tools or other objects. Modules should not be shaded at any time. If a module is shaded or even partially shaded, it will fail to perform at idea conditions and results in lower power output. A permanent shade on the modules may void the standard warranty. Do not immerse the module in liquid. The installation of the modules to sea water lakes and seas should be about 500 meters. Protect solar modules from over-voltage, e.g. voltage peaks of battery charges, generators, etc. If the modules is connected to a storage battery all precautions of the battery manufacturer should be adhered. While designing the nal layout of the modules in the photovoltaic system (on the ground or on a roof), we recommend the designed to keep suitable access space to allow easy maintenance and inspection works. 8.33 Solar PV modules must be stored and installed in the following conditions: Operating ambient temperature: from -40 C to +85 C. Storage temperature: from -40 C to +60 C. Humidity: below 85 RH%.

When installing a module on a roof or building, ensure that it is securely fastened and prevented from falling because of wind, snow or other mechanical loads. The modules should not be exposed to unusual chemical loads. Electrical Conguration Under normal conditions, a photovoltaic module is likely to experience conditions that produce more current and/or voltage than reported at Standard Test Conditions (STC: 1000 W/m2, AM 1.5, and 25 C cell temperature). The short-circuit current (Isc) should be multiplied by a factor of 1.56 and the open-circuit voltage (Voc) should be multiplied by a factor of up to 1.56 based on the lowest ambient temperature recorded for the installation location when determining component voltage ratings, conductor current ratings, fuse sizes, and size of controls connected to the PV output. Voltages are additive when PV modules are connected directly in series, and module current are additive when PV modules are connected directly in parallel. PV modules with different electrical characteristics must not be connected directly in series. The use of suitable third-party electronic devices connected to PV modules may enable different electrical connections and must be installed according to the manufacturers specied instructions. The maximum number of PV modules that can be connected in series string must be calculated in accordance with applicable regulations in such a way that the specied maximum system voltage of the PV module and all other electrical DC components will not be exceeded in open-circuit operation at the lowest temperature expected at the PV system location. www.833solar.com! 8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 5 of 12

An appropriately rated over-current protection device must be used when the reserve current could exceed the value of the maximum fuse rating of the module. An over-current protection device is required for each series string if more than two series strings are connected in parallel. Cables and Wiring 8.33 Solar PV modules are provided with two (2) standard, sunlight resistant output cables that are terminated with PV connectors ready for most installations. The positive (+) terminal has a female connector while the negative (-) terminal has a male connector. The module wiring is intended for series connectors [i.e. female (+) to make male (-) interconnections], but can also be used to connect suitable third-party electrical devices that may have alternative wiring congurations so long as the manufacturers instructions are followed. Use eld wiring with suitable cross-section areas that are approved for use at the maximum short-circuit current of the PV module. 8.33 Solar recommend installers use only sunlight resistant cables qualied for direct current (DC) wiring in the PV system. The minimum wire size should be 4mm2 in accordance with TUV 2PfG 1169 testing standard. Cables should be xed to the mounting structure in such a way that mechanical damage of the cable and/or the module is avoided. Do not apply stress to the cables. For xing, use appropriate means, such as sunlight resistant cables ties and/or wire management clips specically designed to attach to the PV module frame. While the cables are not sunlight resistant and waterproof, where possible, avoid direct sunlight exposure and water immersion of the cables. When selecting the size of the cables that connect the module stings to the solar inverter, ti is recommended to refer to the nameplate electrical parameters of the related module type. Also, consult rated local wiring regulations to determine system wire size, type, and temperature allowed for your installation. Connectors Keep connectors dry and clean, and ensure that connector caps are hand tight before connecting the modules. Do not attempt making an electrical connection with wet, soiled, or otherwise faulty connectors. Avoid sunlight exposure and water immersion of the connectors. Avoid connectors resting on the ground or roof surface. Faulty connectors can result in arcs and electrical shock. Check that all electrical connectors are securely fastened. Make sure that all locking connectors are fully engaged and locked. Do not insert electrically conductive parts into the connectors. Bypass Diodes The junction boxes used with 8.33 Solar PV modules contain bypass diodes wired in parallel with the PV cell strings. In the case of partial shading, the diodes bypass the current generated by the non-shaded cells, thereby limiting module heating and performance losses. Bypass diodes are not over-current protection devices. Bypass diodes diver current from the cell strings in the event of partial shading. In the event of known or suspected diode failure, installers or maintenance providers should contact the company the PV modules were purchased from. never attempt to open the junction box of a 8.33 Solar PV module yourself. Equipment Grounding www.833solar.com! 8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 6 of 12

The frame of the PV module, as well as any exposed non-current-carrying metal parts of xed equipment that are able to become energized by the PV system, must be connected to the equipment grounding conductor (EGC) in order to prevent electrical shock. Even when applicable regulations, code requirements, and standards do not require safety-related grounding, 8.33 Solar recommends grounding all PV module frames in order to ensure the voltage between electrical conductive equipment and earth ground is zero in all circumstances. Proper equipment grounding is achieved by bonding all exposed non-current-carrying metal equipment continuously to one another using an appropriately sized EGC or ranking system that can be used for integrated grounding. In case of executing the grounding of the module frames, 8.33 Solar recommends taking into account the following considerations: The long sides of PV module frame are equipped with pre-drilled grounding holes in their center. These holes shall be used only for grounding purposes and must not be used for mounting purposes. Proper grounding is achieved by connecting the module frame(s) and structural members continuously using suitable grounding conductor. The grounding wire must be properly fastened by the module frame to assure good electrical contact. Use copper, copper alloy or any other conductive material accepted by the applicable National Electrical Regulation. Make electrical contact be penetrating the anodized coating of the aluminium frame. To break the anodized layer, 8.33 Solar recommend a stainless steel toothed washer to be inserted between the nut and the frame. When carrying out the grounding of the modules, the aluminium frame must not enter in permanent direct contact with dissimilar metals, which could result in a galvanic corrosion. Stainless steel at washers can be inserted between frame and grounding lug. 8.33 Solar recommend the use of stainless steel grounding bolts or grounding lugs specically designed for photovoltaic applications.

Figure 1: Grounding Bolt

Mechanical Installation General 8.33 Solar PV modules should be installed in a location where they will receive maximum amount of sunlight throughout the year. In the Northern Hemisphere modules should face South, while in the Southern hemisphere modules should face North. www.833solar.com! 8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 7 of 12

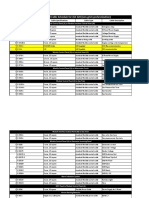

Always use structures and materials specically developed and certied for installations of photovoltaic modules. 8.33 Solar PV modules connected in series should be installed at the same orientation and title angle. Different orientations and angles may cause a loss of power output due to the change in sunlight exposure. 8.33 Solar PV Modules have been certied for a maximum static load on the back of the module of up to 2400Pa (i.e. wind load) and maximum static load on the front of the module of up to 5400Pa (i.e. wind and snow load). Mounting structure and other mechanical parts must be designed and approved to withstand the design wind and snow loads applicable for a particular site. 8.33 Solar PV module must not be subjected to forces from the substructure, including forces caused by thermal expansion. The mounting method must not result in the direct contact of dissimilar metals with the aluminium frame of the PV module that will result in galvanic corrosion. 8.33 Solar PV modules can be mounted in portrait or landscape orientation, provided that the mounting method follows one of the acceptable methods listed below. in choosing the orientation, please keep in mind the internal PV module by-pass diode conguration to ensure the optimum electrical behavior from any potential shading over the modules. In order to maintain the re class rating, the distance between the PV module front surface (glass) and the roof surface shall be at least 10 cm. This spacing also allows air ow to cool the PV module, Install PV modules with a minimum spacing of 10 mm between neighboring frames to allow for thermal expansion. 8.33 Solar recommend distance between two solar modules of 20 mm to allow wind circulation, in order to reduce pressure loads and improve module ventilation. The PV module should not be mounted in such a way that the drain holes of PV module can incur blockage. Galvanic corrosion can occur between the aluminium frame of the PV module and mounting hardware if such hardware is composed of dissimilar metals, especially in harsh environments such as high humidity. In those cases, to prevent corrosion neoprene tape, PVC washers or stainless steel washers are recommended to be placed between PV module frame and the support structure. Al module support structures used to support PV modules at correct tilt angles should be wind and snow load rated by appropriate local and civil Directives prior to installation. It is not allowed to dismount, drill or modify the frame or any other part of the PV modules. This may cause the loss of warranty. Please contact 8.33 Solar Technical Service Contact if module mounting procedure is not clear. Mounting methods The following mounting methods are available: Installation using the frame mounting holes Modules must be securely xed to the mounting structure using the four pre-drilled mounting holes (14mm * 9mm) placed in the long frame rails at 400 mm from the middle. Use M8 stainless steel hardware, spring washers and at washers with a torque of approximately 10 newton meter [Nm] for normal installation. Galvanized or hot dipped zinc plated hardware is also acceptable. 8.33 Solar recommends to use all eight mounting holes, if excessive wind or snow loads are expected for the PV installation.

www.833solar.com!

8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 8 of 12

Figure 2: Mounting using frame holes Installation using pressure clamps Installation using pressure clamps may be executed along both side of the module frame. The obligatory position of the clamp along the frame depends on which side of the module is used for the installation: Fixing on the long side, the clamps must be mounted along the frame at the position of the mounting hole, with a tolerance of 10% of the module total length to the edge of the frame. Fixing on the short side, the clamps must be mounted along the frame at the edges of the module with a tolerance of 25% of the module total width to the middle of the frame.

Note that on both sides of the module the pressure clamps should be mounted always in a symmetric position with respect to the middle line for a proper load distribution. Clamps must be installed according to the manufacturers specic instructions. Do not apply excessive pressure on the frame such that the frame deforms. 8.33 Solar recommends a torque of approximately 10 newton meter [Nm] force. Please refer to the clamp manufacturer for specic hardware and torque requirements. The clamps must only x the modules though the contact with just the frame. Do not allow contact between clamp and glass and avoid shading effect from the module clamps. Do not install the modules with pressure clamps mounted outside of the specied areas, otherwise the module mechanical resistance can be affected.

Figure 3: Mounting using pressure clamps Insertions system Insertion system on the short sides of the module are allowed with a limitation on the maximum load resistance of 2400 Pa. Insertion system on the long side of the module are not affected by any limitation and are allowed with a maximum of 5400 Pa snow load.

www.833solar.com!

8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 9 of 12

Figure 4: Mounting using insertion method Note: When using insetion systems where the modules are installed sliding though the inner side of the rails, 8.33 Solar recommends to use PVC tape in order to prevent damage in the anodized layer of the frame.

Figure 5: Mounting using insertion method Module Load Resistance Wind load: 2400 Pa Snow load: 5400 Pa According to IEC 61215 clause 10.16, 2400 Pa corresponds to a wind pressure of 130 km/h (approximately +/- 800 Pa) with a safety factor of 3 for gust winds. Note: Information provided above could vary according to the mounting system and conguration.

Electrical Installation Modules electrically connected together in a series/parallel conguration generate DC electrical energy which may be converted to AC by means of a solar inverter. the resulting PV system may be therefore connected to the local utility grid system. As local utilities policies and technical rules on connecting a renewable energy system to their power grids vary from region to region, consult a qualied system designer or integrator to design such a system to comply with the Directives. Permits are normally required for installing a PV system and the utility must formally approve and inspect the system before its connection to the grid can be accepted. The PV system electrical installation must be executed in accordance with the respective National Electrical Code or applicable National Regulations.

www.833solar.com!

8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 10 of 12

Use only insulated tools that are approved for working on electrical installations. Abide with the safety regulations for all the components used in the system, including wiring and cables, connectors, charge regulators, inverters, storage batteries, etc. To avoid conductor loops the strings (+) and (-) should laid together. The cable groove on the cross prole can hereby be used. If possible roof penetration should only be at one point.

Figure 6: Wire loop design recommendation

Maintenance General 8.33 Solar recommends that PV systems be inspected by the installer, or other qualied person, every six months. The purpose of the PV system inspection is to ensure that all system components are functioning properly. At a minimum, this inspection should conrm the following: All electrical and mechanical connections are clean, secure and undamaged The mounting hardware, terminal screws and grounding components are tightly secured with no corrosion. No sharp objects are in contact with the PV module surface PV modules are not shaded by unwanted obstacles and/or foreign material Mounting and grounding components are tightly secured with no corrosion

Do not touch live parts of cables and connectors. Use appropriate safety equipment (insulated tools, insulating gloves, etc) when handling modules. Defects should be addressed immediately. Cleaning Over time, dirt and dust can accumulate on the glass surface of the module, reducing its power output. 8.33 Solar recommends periodic cleaning of PV modules to ensure maximum power output, especially in regions with low precipitation. In order to reduce the potential for electrical and thermal shock, 8.33 Solar recommends cleaning PV modules during early morning or late afternoon hours when solar radiation is low and the modules are cooler, especially in regions with hotter temperatures. Never attempt to clean a PV modules with broken glass or other signs of exposed wiring, as this presents a shock hazard.

www.833solar.com!

8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 11 of 12

Clean the glass surface of the PV module with a soft brush using soft, clean water with a recommended pressure less than 690 kPa, which is typical of most municipal water systems. Water with high mineral content may leave deposits on the glass surface and is not recommended. 8.33 Solar PV modules may contain a hydrophobic anti-reective coating on the glass surface to enhance power output and reduce dirt and dust buildup. In order to avoid module damage, do not clean PV modules with a power washer or pressure washer. Do not use steam or corrosive chemicals to facilitate the cleaning of modules. Do not use aggressive tools or abrasive materials that could scratch or damage the glass surface. Failure to comply with these requirements may adversely affect the PV module performance. 8.33 Solar PV modules are designed to withstand high snow loads. However, if removing snow is desired to enhance production, use a brush to gently remove snow. Do not try to remove frozen snow or ice from PV modules. Do not clean the modules that have broken glass or exposed wiring. This can cause a general electrical failure of the module or electrical shock hazard. Decommissioning The dismantling of PV systems must be performed with the same care and safety precautions used during the initial installation. The PV system can generate hazardous voltage even after the system has ben disconnected. Follow safety regulations for working with live electrical equipment. Recycling 8.33 Solar is a member of CERES, the European association for voluntary take back and recycling of PV modules. Please contact CERES at www.ceres-recycling.org for details regarding the recycling process.

Contact Information 8.33 Solar Calle Central No 13 Tore Godoy 3B 30100 Espinardo Murcia, Spain Tel: +34 (0) 868 076 098 Email: info@833solar.com Web: www.833solar.com

www.833solar.com!

8.33 Solar Photovoltaic (PV) Module Installation and User Manual / Page 12 of 12

You might also like

- Sizing of Cable Tray Rev. D PDFDocument13 pagesSizing of Cable Tray Rev. D PDFAlvin SmithNo ratings yet

- Solar PV Installation Guidance DocumentDocument66 pagesSolar PV Installation Guidance Documentdexater007100% (2)

- DEWA Regulations For Elect Insatallations 1997 EditionDocument65 pagesDEWA Regulations For Elect Insatallations 1997 EditionGelo Almayda50% (2)

- Guideline For Solar PV System Installation For ServiceProvidersDocument66 pagesGuideline For Solar PV System Installation For ServiceProvidersdharmapriyaussNo ratings yet

- Solar PV Installation GuideDocument41 pagesSolar PV Installation GuideMichael OyiboNo ratings yet

- Design Guidelines For 30 100 KW SystemsDocument22 pagesDesign Guidelines For 30 100 KW SystemsMaan ENo ratings yet

- AmpacityDocument74 pagesAmpacityMoavviz Suhail100% (1)

- Solar PV Project Planing, Installation and Commissioning TechniquesDocument43 pagesSolar PV Project Planing, Installation and Commissioning TechniquesAnonymous EePp3z100% (1)

- 2.solar System Design and InspectionDocument69 pages2.solar System Design and InspectionHarshana PereraNo ratings yet

- Inspection of Solar SystemsDocument155 pagesInspection of Solar SystemsDiptiman GuhaNo ratings yet

- Standalone Photovoltaic (PV) Systems for Disaster Relief and Remote AreasFrom EverandStandalone Photovoltaic (PV) Systems for Disaster Relief and Remote AreasNo ratings yet

- Design and Sizing of Solar Photovoltaic Systems R2Document125 pagesDesign and Sizing of Solar Photovoltaic Systems R2Andrei TaranuNo ratings yet

- Guide for Installation of Solar PV SystemsDocument26 pagesGuide for Installation of Solar PV SystemsRobert Montoya100% (1)

- Best Practices in Solar PV Systems Operation and MaintenanceDocument99 pagesBest Practices in Solar PV Systems Operation and MaintenancesrichanderNo ratings yet

- Checklist Testing and Inspection Without Interconnection 2Document26 pagesChecklist Testing and Inspection Without Interconnection 2Hamid Rehman100% (1)

- Ground Mount PV SolarDocument6 pagesGround Mount PV SolarJohn Kamau Khalfani100% (1)

- Solar PV Installation - Training Handbook 2017Document124 pagesSolar PV Installation - Training Handbook 2017VIJAYARAGAVAN MOORTHY100% (1)

- Solar System Over Current ProtectionDocument10 pagesSolar System Over Current Protectiontriminhdang_phar6701No ratings yet

- Solar System Design Guide-1Document172 pagesSolar System Design Guide-1Ankit kumar100% (6)

- Scope of Work - Turnkey PV Project & AnnexesDocument13 pagesScope of Work - Turnkey PV Project & AnnexesChau DangNo ratings yet

- Lightning Protection For PV Farms - White PaperDocument10 pagesLightning Protection For PV Farms - White Papercristianc86100% (3)

- Guide - Pv.installation ChecklistDocument5 pagesGuide - Pv.installation ChecklistejoghenetaNo ratings yet

- Low VoltageDocument20 pagesLow VoltageFarhan ShahNo ratings yet

- Tese Grid Connected PV 2001Document124 pagesTese Grid Connected PV 2001chauhan303No ratings yet

- Renewable Energy Management Bureau (REMB) Guide to Net Metering and Solar Rooftops in the PhilippinesDocument22 pagesRenewable Energy Management Bureau (REMB) Guide to Net Metering and Solar Rooftops in the PhilippinesKim FernandezNo ratings yet

- Division 16 - Electrical WorkDocument326 pagesDivision 16 - Electrical WorknawajhaNo ratings yet

- Solar Labeling Requirements DatasheetDocument2 pagesSolar Labeling Requirements Datasheetguillermoanaya100% (1)

- PV Installation ChecklistDocument6 pagesPV Installation Checklistvijayasiva86100% (1)

- Construction and Operation of Solar Farms CopDocument65 pagesConstruction and Operation of Solar Farms CoptammamshNo ratings yet

- 115kWp Rooftop Layout ReportDocument12 pages115kWp Rooftop Layout ReportvmramakrishnanNo ratings yet

- Maintenance and Inspection ChecklistDocument1 pageMaintenance and Inspection ChecklistRony NiksonNo ratings yet

- Technical Expert to Develop Grid Connection Guidelines and Standards for Distributed Solar PV Plants in BahrainDocument36 pagesTechnical Expert to Develop Grid Connection Guidelines and Standards for Distributed Solar PV Plants in BahrainSe SamnangNo ratings yet

- PV InstallationDocument40 pagesPV InstallationmatgarNo ratings yet

- Guide For Installation of Solar PV SystemsDocument26 pagesGuide For Installation of Solar PV SystemsChris ParkinsonNo ratings yet

- Design Aspect of Standalone Solar PV SystemDocument20 pagesDesign Aspect of Standalone Solar PV SystemMalik SameeullahNo ratings yet

- RFP Template For Grid-Tied PV ProjectDocument24 pagesRFP Template For Grid-Tied PV ProjectarunghandwalNo ratings yet

- Commissioning Procedure for Utility Scale Solar ProjectsDocument6 pagesCommissioning Procedure for Utility Scale Solar ProjectsnardoNo ratings yet

- Grid-Connected PV Systems Design and Installation 8Th EditionDocument1 pageGrid-Connected PV Systems Design and Installation 8Th Editionrajareski ekaputra0% (2)

- Grid-Tie Inverter - WikipediaDocument4 pagesGrid-Tie Inverter - WikipediaChandra Djaya EffendieNo ratings yet

- Testing Commissioning - Solar PV ProjectsDocument91 pagesTesting Commissioning - Solar PV ProjectsOm Saxena100% (2)

- Fault Codes MID249Document36 pagesFault Codes MID249Izz BaharNo ratings yet

- AuSES PV Installation Best Practice GuidelinesDocument31 pagesAuSES PV Installation Best Practice GuidelinesJames Webb100% (1)

- Inspector Training SLO 2012 4ppDocument41 pagesInspector Training SLO 2012 4ppAgung BayuNo ratings yet

- CCTV Mounting and PolesDocument112 pagesCCTV Mounting and Poleshusnikhalil100% (1)

- Questions and Answers - Photovoltaic Training Session 2Document4 pagesQuestions and Answers - Photovoltaic Training Session 2Fernando NunoNo ratings yet

- Electrical Engineer CV SampleDocument2 pagesElectrical Engineer CV SampleMehboob Alam67% (3)

- Model Inspection ChecklistDocument12 pagesModel Inspection ChecklistMahfuz HasanNo ratings yet

- Solar Photovoltaic (PV) System Installation: Guidance Notes ForDocument41 pagesSolar Photovoltaic (PV) System Installation: Guidance Notes Forsyu wai kinNo ratings yet

- Solar Modules Cleaning GuidelinesDocument2 pagesSolar Modules Cleaning GuidelinesCNP WEBNo ratings yet

- CEC Accredited Design Guidelines For GCPV PDFDocument20 pagesCEC Accredited Design Guidelines For GCPV PDFccwei713No ratings yet

- SOLAR SIZING OPTIMIZATIONDocument40 pagesSOLAR SIZING OPTIMIZATIONscada enggNo ratings yet

- Procedures For Solar Electric (Photovoltaic Abbreviated As PV) System Design and InstallationDocument5 pagesProcedures For Solar Electric (Photovoltaic Abbreviated As PV) System Design and InstallationVinit JhingronNo ratings yet

- PV System ChecklistDocument2 pagesPV System ChecklistzwerrNo ratings yet

- Deployment of Hybrid Renewable Energy Systems in MinigridsFrom EverandDeployment of Hybrid Renewable Energy Systems in MinigridsNo ratings yet

- Site Survey Check ListDocument20 pagesSite Survey Check ListYulius Sampe DatuNo ratings yet

- ZTT SOFC SubmaineCableDocument35 pagesZTT SOFC SubmaineCabletanto_deep_15No ratings yet

- Distributed PV System DesignDocument68 pagesDistributed PV System DesigntorinomgNo ratings yet

- SOLAR PV PLANT Commissioning Forms For PVDocument15 pagesSOLAR PV PLANT Commissioning Forms For PVElvert Dime RamosNo ratings yet

- 1MWp Solar Power Plant Technical ProposalDocument26 pages1MWp Solar Power Plant Technical Proposalashuluck2007100% (3)

- Solar Combiner Box TrainingDocument33 pagesSolar Combiner Box TrainingRavi Teja100% (1)

- Subsidy Scheme For Grid Connected Solar Rooftop Project in RajasthanDocument8 pagesSubsidy Scheme For Grid Connected Solar Rooftop Project in RajasthanKapil Kothari0% (1)

- Solar Rooftop PresentationDocument50 pagesSolar Rooftop PresentationmichkohktNo ratings yet

- Photovoltaic System Commissioning and Testing PDFDocument24 pagesPhotovoltaic System Commissioning and Testing PDFLeonardo Rojas RapsoNo ratings yet

- Cara Servis Manual RX10KY1 Si - 05cDocument458 pagesCara Servis Manual RX10KY1 Si - 05cArif Tresno Amy100% (2)

- Solar Training at ONGC, DehradhunDocument54 pagesSolar Training at ONGC, DehradhunParveen ChoudharyNo ratings yet

- Gci-1.5k PV ManualDocument16 pagesGci-1.5k PV Manualfarchipmm580% (1)

- EU Solar PV Business ModelsDocument78 pagesEU Solar PV Business ModelsAdrian Fratean100% (1)

- Installation ManualDocument34 pagesInstallation Manualseel asefNo ratings yet

- Global Installation Guide For Suntech Power Standard Photovoltaic ModuleDocument26 pagesGlobal Installation Guide For Suntech Power Standard Photovoltaic ModuleMohammed almarhabiNo ratings yet

- Hwang 2015Document6 pagesHwang 2015Shubham ArvikarNo ratings yet

- 65 JMES 371 2013 Dwivedi PDFDocument14 pages65 JMES 371 2013 Dwivedi PDFvijay_345No ratings yet

- Axial 2Document19 pagesAxial 2Shubham ArvikarNo ratings yet

- GRE SyllabusDocument2 pagesGRE SyllabusSrinivas S ChauhanNo ratings yet

- TE Mech 2012-Syllabus1 June2014Document36 pagesTE Mech 2012-Syllabus1 June2014Girish ChandankarNo ratings yet

- Automobile EngineeringDocument29 pagesAutomobile EngineeringlonemubashirNo ratings yet

- Hariis TRuepoint 4000 - The Radio InstallationDocument118 pagesHariis TRuepoint 4000 - The Radio InstallationWashburn61100% (2)

- VahleDocument18 pagesVahleSyamsi Straw HatNo ratings yet

- AL - CU - Integration - Preso - v7 24 Jul 08 ZipDocument80 pagesAL - CU - Integration - Preso - v7 24 Jul 08 ZipFreddy CadenaNo ratings yet

- IT ReportDocument32 pagesIT ReportOgunsola Oluwatosin SamuelNo ratings yet

- Direct Operated Servo Solenoide Valve NG6Document10 pagesDirect Operated Servo Solenoide Valve NG6nagar_maheshNo ratings yet

- Retrofitting ECS Power SystemsDocument22 pagesRetrofitting ECS Power SystemsgbaetaNo ratings yet

- EX0101-H01 H02 Operating Instructions - Vision HDDocument15 pagesEX0101-H01 H02 Operating Instructions - Vision HDPaulson HuangNo ratings yet

- TK84 82594 - CDocument21 pagesTK84 82594 - Crodruren01No ratings yet

- Technicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015Document25 pagesTechnicall Specification of 630 KVA, 11-0.415 KV Dry Type Outdoor Transformers.......... Dated. 31.08.2015spidervinoNo ratings yet

- E1 Local+code+of+practice+on+photovoltatic+installationDocument100 pagesE1 Local+code+of+practice+on+photovoltatic+installationblah geeNo ratings yet

- Reference Cable Schedule - JGS 320 - Non-Grid SynchronizationDocument2 pagesReference Cable Schedule - JGS 320 - Non-Grid SynchronizationfaisalnadimNo ratings yet

- RZ1-K Power CableDocument5 pagesRZ1-K Power CablegarysNo ratings yet

- Polarity Checker English ManualDocument3 pagesPolarity Checker English ManualArturoMoreiraNo ratings yet

- Neutral Cable IECDocument1 pageNeutral Cable IECNghia Huynh NgocNo ratings yet

- Advance Power SystemsDocument88 pagesAdvance Power SystemsRachit KhannaNo ratings yet

- Propagation of Transients in Extruded MV and HV Cables Considering Typical Thickness and Resistivity Values of Commercial Semiconductive CompoundsDocument6 pagesPropagation of Transients in Extruded MV and HV Cables Considering Typical Thickness and Resistivity Values of Commercial Semiconductive CompoundssanibubaNo ratings yet

- User Manual RadWin 1000Document124 pagesUser Manual RadWin 1000Jairson Gomez BolañosNo ratings yet

- Manual Instalacion RTUDocument25 pagesManual Instalacion RTUlmbkn2013No ratings yet

- Duties of TM, Tta & SR Toa S - DutiesDocument9 pagesDuties of TM, Tta & SR Toa S - DutiesSuresh GunduNo ratings yet

- Installation PDFDocument182 pagesInstallation PDFluk@_sNo ratings yet