Professional Documents

Culture Documents

Brochure FullMissionSimulator

Uploaded by

glitterintheairCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Brochure FullMissionSimulator

Uploaded by

glitterintheairCopyright:

Available Formats

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk/comm

PC Maritime

Full Mission Engine Room Simulator

MED3DH with ERC 4.5 XL 1. Overview

The package comprises the supply and implementation of two types of full mission engine room simulator: 1. MED3DH Full Mission Engine Room Simulator with medium speed main engine with CPP (MAK type) and a hardware switchboard, modelling a computer-controlled engine room, typical of a modern container ship 2. ERC4.5XL Low Speed Engine Room Simulator with main engine with FPP (Man Diesel LMC type) with one hardware console only, incorporated in MED3DH consoles

2. MED3DH description

The MED3DH virtual reality simulator enables much more than a passive 3D walk through an engine room space; it gives quick and easy access to different elements of the system such as valve opening/closing, setting position of switches, push-buttons etc using state-of-the art 3D visualisation with zooming. The latest development includes a combination of 3D and 2D diagrams, which enables students to follow how a certain device functions and gives a complete picture of its structure. Due to the innovative 3D visualization, it has been possible to eliminate hardware mimic panels and consoles. In MED3DH, mimic panels and local hardware consoles are incorporated into virtual reality. The purpose of MED3DH is to prepare the trainee for engine room operation including: - basic engine room installation (compressed air system, fresh and sea water cooling system, lubricating, fuel oil system etc.) - main engine and auxiliary equipment procedures - propulsion system manoeuvring (main engine reduction gear CPP) The simulator has been developed in compliance with: - STCW Code: Section A-1/12 and Section B-1/12. - ISM Code: Section 6 and Section 8. MED3DH simulator is equipped with hardware consoles and panels to operate and control main engines, gear, CPP, auxiliary machinery and electric systems. It consists of three main parts (Fig. 1): 1. Engine Control Room (ECR) with main engine control console and main electric switchboard 2. Engine Room with two PC projectors and control console for 3D visualization combined with diagram presentation 3. Instructors Room.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

Fig. 1 General view of MED3DH

Fig. 2 MED3DH Switchboard panels

Fig. 3 MED3DH - Engine control room consoles On the PC screens (Fig. 3) are diagrams of specific installations like fuel oil, compressed air system, cooling system, lubricating system, steam system etc.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

-2-

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

For security reasons the Engine Control Room is equipped with two identical PCs with monitors. In case of one PC failure, the second one takes over automatically.

Fig. 4 MED3DH - Example of compressed air diagram (remote control from PC screen) All operating procedures (outside the Engine Control Room) are carried out in a separate room equipped with two projector screens. One screen presents engine room elements in 3D. The second screen presents a diagram of specific compartments or systems, for example auxiliary generators room, emergency generators room, compressed system room etc. See Fig. 5.

Fig. 5 MED3DH - Two screen presentation in engine room Selecting engine room elements is performed simply by zooming. The software simulates opening/closing of valves and auxiliary equipment operation and generates the main engine room sound. The diagrams contain all the sub-systems included in a specific part of engine room. For example, the auxiliary diesel generators diagram includes fuel system, compressed air and cooling systems. The relevant section of the engine room can be selected from the menu

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk -3-

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

Room Selection shown on the left in Fig 6. The selected Auxiliary Diesel Generators is shown in Fig. 7. There is also an Info feature which describes the selected part name and its status (eg: valve open or closed). See Fig. 8.

Fig. 6 MED3DH - Auxiliary Diesel Generators - diagram

Fig. 7 MED3DH - Auxiliary Diesel Generators - 3D view

Fig. 8 MED3DH - Auxiliary Diesel generator No. 1 cooling system valves, zoomed with Info feature

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk -4-

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

Figs. 9 onwards show selected parts of engine room machinery in 3D

Fig. 9 MED3DH- Hydrophore installation

Fig. 10 MED3DH Fresh water generator installation

Fig. 11 MED3DH fuel separator module

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

-5-

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

Fig. 12 MED3DH Rotary vane steering gear installation

3. ERC 4.5 XL description

ERC 4.5 XL is a low speed diesel power plant simulator. It consists of a desktop console and Virtual Engine Room software with actual controls on the console and virtual controls on screen. The ME remote control system does not include manoeuvring from bridge, because this is outside the scope of the simulator unless the instructor station is operational.

Fig. 20 ERC 4.5 XL Main Engine Control Panel.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

-6-

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

Fig. 21 ERC 4.5 XL Main Engine Software Panel.

Fig. 22 ERC 4.5 XL Main Engine Control Console upper part.

Fig. 23 ERC 4.5 XL Main Engine Control Console lower part. The remaining ME Controls are at the Control Panel tab onscreen as virtual controls.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

-7-

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

3.1 Model description ERC 4.5 XL simulates the main engine which drives a fixed pitch propeller and has a remote control system. The ME can run on DO or HFO during manoeuvring. Technical data is: Type: 2 stroke, low speed, reversible No of cylinders: 7 No of turbochargers: 2 Nominal output: 19670 kW Nominal speed: 91 rpm Diameter of cylinder: 700 mm Length of stroke: 2674 mm 3.2 Modelled Engine Room 3.2.1 Main Engine The ME Control Panel provides all controls and gauges for ME remote control. The ME can be also controlled remotely from bridge when using Bridge Panel.

Fig. 24 ME General View and Turbocharging, Emergency Control, VIT and Combustion.

3.2.2

Fuel System

The fuel system stores and delivers DO and HFO to the main engine, diesel generators and the auxiliary steam boiler.

Fig. 15 Fuel Supply, Storage and Separator Diagram

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

-8-

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

3.2.3

Cooling System

The cooling system is divided into 2 sub-systems: fresh water cooling and sea water cooling. Sea water is responsible for central coolers and TG condenser cooling. The fresh water system cooling includes low and high temperature cooling installations.

Fig. 26 Cooling System control panel, SW and FW System Diagram 3.2.4 Lubricating System

The lubricating system stores and delivers lubricating oil for the main engine and diesel generators and cylinder oil for the ME. The lubricating system includes one LO separator, designated for continuous operation.

Fig. 27 LO Storage, Circulation, Separator and Stern Tube Diagram 3.2.5 Compressed Air System

The compressed air system includes two water-cooled piston compressors, two main starting air receivers and one separate DG starting air receiver. The control air installation is also included.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

-9-

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

Fig. 28 Compressed Air, Domestic Water, Sewage Treatment Plant and Incinerator Diagram 3.2.6 Steam System

Saturated steam produced by the auxiliary boiler is used for HFO heating and water heating. The exhaust boiler produces a superheated steam which is used for turbo generator operation.

Fig. 29 Steam system control panel and diagram 3.2.7 Bilge and Ballast System

The bilge system includes four hold bilges and three engine room bilges. Each bilge has a well and a related alarm controlled by bilge level. Three bilge pumps can be used: two (#1 and #2) are centrifugal pumps. The engine room bilge pump is a displacement type. The bilge system includes an oily water separator. The ballast system includes sixteen example ballast tanks with valves, piping system and ballast pumps. The ballast pumps are connected to the two separate mains, one on each board. This arrangement enables not only filling and emptying of the ballast tanks, but also quick correction of large stability changes (for example when bunkering a fuel). 3.2.8 Refrigerating and Air Conditioning System

The refrigerating system consists of the screw compressor, its lubricating system, the condenser cooled by LT cooling water and two refrigerated. This direct expansion system uses R22 as a refrigerant. The air conditioning system is designed to provide full thermal comfort for the crew.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk - 10 -

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

3.2.9

Power Plant

The power plant includes 2 medium speed diesel generators with the following specification: Type: 4 stroke, medium speed, non-reversible Number of cyl.: 6 Nominal output: 600 kW Nominal speed: 1000 rpm The diesel generators can be operated remotely from the control panel and locally from the mimic panel. The power plant includes a shaft generator (600 kW) with a static frequency converter. The generator is mounted at the front part of the main engine and is driven directly by the crankshaft. The emergency diesel generator (300 kW) is powered by a four-stroke diesel engine running on DO. The emergency generator can be started automatically or manually. Another possible source of electric power is a turbo generator (600 kW) which can be used in full navigation conditions.

Fig. 30 Power plant control panel and main switchboard.

Fig. 31 Diesel Generators and Consumers Diagram 3.2.10 Steering Gear and Fire Fighting System

The steering gear is an electrohydraulic device i.e. the rudder movement is driven by a hydraulic system controlled by an electrohydraulic system. The steering gear is ready for operation when one of the two pumps, driven by an electric motor, is running.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

- 11 -

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

The fire fighting system includes two fire pumps driven by electric motors and one independent emergency fire pump driven by an independent diesel engine. The emergency fire pump is connected to a separate sea water chest and located outside the engine room. 3.3 Additional Functions

Additional functions allow simulation control, general system communication, introducing faults, setting/changing of operational and ambient conditions and evaluating training. 3.3.1 Simulator Control Functions Simulator start up Simulator shut down Simulator freezing Sound mixer Scenario Handling Scenario selection Scenario load, start and stop Scenario editing Engine Room Status Manipulation Quick info about the engine room status Input of environment data Introduction of faults Engine room resources manipulation Monitoring Functions Event log. Alarm information from the total system Operation parameters inspection. Assessment Functions

3.3.2

3.3.3

3.3.4

3.3.5

ERC 4.5 XL has a unique integrated assessment system which includes following tests: START TEST - static test of the engine room prepared for immediate main engine start (for example when leaving harbour). STANDBY TEST - static test of the engine room prepared for a short break in operation with the ability to be operational in a very short time (for example when waiting at anchor for the pilot). STOP TEST - static test of the engine room prepared for a longer break in operation (for example when lying alongside for several days).

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk

- 12 -

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

Fig. 32 Assessment window Test results are based on a state-of-the-art faults classification and scoring system. 3.3.6 Bridge Control Functions Sending Engine Telegraph commands Remote control of steering gear pumps Rudder control. Bow thrusters control. Checklist Support

3.4

The checklist concept has been implemented in ERC 4.5 XL in such a way that the whole engine room operation has been divided into many smaller, typical tasks and a specific checklist covers each of these tasks. Checklists are based on the following principles: Each checklist begins with a certain engine room setup, typical for that checklist. This setup is loaded automatically each time the checklist is opened by the user. For example, with the checklist name "ME start', the setup loaded will guarantee that engine start is possible. A checklist properly completed should lead to another engine room setup, which is the aim of this procedure. Clear instructions on what to do and how to do it, will be given in every checklist step. Thus, a user who follows precisely all the instructions given will be able to reach the target setup The checklists have been linked so that the target setup of one checklist is an entry setup for the next one in almost every case. This means that learning all checklists results in learning the whole engine room operation. 3.5 Synthesized Speech

Synthesised speech has been widely implemented in ERC 4.5XL, as follows: On-line advice called Ask Chief offers verbal information about the most important problems in the current engine room configuration and is based on an integrated expert system. The aim is to determine if the engine room is ready for main engine start. Because many problems may be present, only the most important one will be reported. For example, if there is no steam and no voltage on the bus bars, only the missing voltage will be reported. This is the so-called top of the heap strategy.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk - 13 -

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

Spoken checklists are the same as on-screen checklists but it is worth remembering that it takes more time to listen to spoken text than to read it. Some users may prefer the onscreen checklists therefore. Spoken text embedded in the scenarios. This is a very important benefit of synthesized speech, because voice comments can be added with the introduction of different faults. In the early stages of training this feature can be used for turning the trainees attention to symptoms which may not be visible at first glance. The scenario editor includes an additional field where text comments can be made and introduced with or without faults. Verbal warning and advice in critical situations. For example when main engine reaches critical speed, a spoken warning can be heard with visual information about heavy vibrations. 3.6 Instructor Software Instructor software allows: resources manipulation (the setting of the liquid levels in the tanks and pressure setting) simulator freezing fault introduction sending Engine Telegraph commands system alarms monitoring engine RPM monitoring event log monitoring

Fig. 33 Instructor workstation screen

6. Scope of delivery

6.1 Components Full Mission Engine Room Simulator Package consists of the following components: 1. One set of MED3DH Full mission version, including hardware consoles and software, simulating an engine room with medium speed main engine and controllable pitch propeller (including instructor software).

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk - 14 -

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

2. One set of ERC4.5XL Desktop version with one hardware console and software, simulating an engine room with low speed main engine and fixed propeller (including instructor software) 6.2 Facility layout

The environment in which the system is installed should be maintained at a max. temperature of 40C during the operation and a relative humidity level not exceeding 90% without condensation. The general atmosphere should be relatively dust free.

Fig. 1 Example of facility layout

Fig. 2 Example of facility layout A Engine control room B Engine room C PC class room D Instructors room 1. Engine control room hardware consoles MED3DH + ERC4.5XL (Medium and low speed engines) 2. Electrical switchboard 3. Console in engine room 4. Speakers

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk - 15 -

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

5. Projectors with screens 6. Students PC stations 7. Instructors PC station 6.3 Scope of delivery - hardware consoles

Fig. 4 Engine control room - Hardware consoles MED3DH + ERC4.5XL Console No. 1 - Oil fired boiler control - Fire pumps control - Sprinkler system - Steering gear pumps & alarms - Water for extinguishing warning system - Alarm panel Console No. 2 - Telegraph - Main engine control panel - Main engine gauges Console No. 3 - Safety system - Engine control - Printer - Telephone set Console No.4 - PC monitors - Keyboards - Track-balls Console No. 5 (Low Speed Engine Room Simulator ERC4.5XL) - Telegraph - Main engine control panel - Main engine gauges - Alarm and indications Engine control room Hardware consoles dimensions: Length 440 cm

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk - 16 -

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

High 130 cm Width 110 cm Electrical switchboard - Hardware panels:

Fig. 5 Engine control room - Electrical switchboard Panel No. 1,2 &3 Auxiliary machinery control Panel No. 4 - Generator No. 1 Panel No. 5 - Generator No. 2 Panel No. 6 - Synchronizing Panel No. 7 - Generator No. 3 Panel No. 8 - Shaft generator Panel No. 9 - 12 Auxiliary machinery control Electrical switchboard panel dimensions: Length 520 cm High 190 cm Width 30 cm 6. 4 Scope of delivery except hardware consoles

1. PCs with XP or Vista Operating System 4 pcs Each PC has a following minimum specification: CPU Intel Pentium Core 2 Duo, 2GHz 4 GB RAM Graphic card with 512 MB RAM HDD 300 GB CD/DVD-RW Network adapter Keyboard and mouse 2. PC monitors (resolution 1280x1024) 19 LCD. 3. PC projectors (resolution 1280x1024). 4. Colour Ink Jet printer 5. Sound System with high power speakers 1 set 6. Internal communication system (instructor engine control room engine room) 1 set 7. Network switch with cables 1 set

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk - 17 -

Full Mission Engine Room Simulator

http://www.pcmaritime.co.uk

PC Maritime

8. Spare parts for hardware consoles 1 set 6.5 Documentation

All documentation will be in English. The documentation will contain sufficient information to enable operators and instructors to operate and use the simulator, and to enable the maintenance personnel to operate, maintain and update the simulator. 1. User Manual for students 2. User Manual for instructor and technical staff 3. Technical Documentation All manuals will be also delivered in PDF format. 6.6 Acceptance

A detailed site acceptance procedure shall be prepared to demonstrate the functions and uses of the installed software and dedicated hardware. The final acceptance document will be signed and approved only after all necessary tests and checks have been verified to comply with t he agreed specification. The simulator software, dedicated hardware and PCs will be commissioned according to the final approved plan. 6. 7 Training

Training will be given to nominated instructors, operators and first line maintainers of the simulator and training courseware provided. Training shall be completed before commissioning. Appropriate certificates shall be issued to all participants that have undergone the training. The training will be in English language. 1. On-site instructor training 2. On-site maintenance training 6.8 Warranty 1 week 1 week

The Warranty period shall be two years from the site acceptance tests. Unitest will guarantee spare parts availability for all necessary spares, software and other components to operate the simulator for at least 15 years from date of acceptance. On expiry of warranty period, Unitest will propose an annual fee for a maintenance contract for a period of 5 years, renewable every year. The scope of maintenance will include software upgrade, technical support and trouble shooting, house-keeping of software and databases, testing of software and hardware and an hourly rate for repair services. Replacement of faulty hardware and software within warranty period will take place within max 30 days. The warranty scope does not include hardware and software faults caused by improper use. For further information, please contact PC Maritime.

PC Maritime, Brunswick House, Brunswick Road, Plymouth PL4 0NP, UK. Tel: +44 (0)1752 254205 Email: marketing@pcmaritime.co.uk http://www.pcmaritime.co.uk - 18 -

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Polaris Technical ManualDocument435 pagesPolaris Technical ManualRick Huey67% (6)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Basic Engine T4FDocument39 pagesBasic Engine T4FDragan100% (1)

- STCW Guide for SeafarersDocument78 pagesSTCW Guide for SeafarersANDREASBOUL100% (2)

- DETROIT - 6-71 - (Maintenance)Document204 pagesDETROIT - 6-71 - (Maintenance)Farlen Bulsoni100% (2)

- Piston Damage ReportDocument71 pagesPiston Damage ReportQamar Uz Zaman100% (2)

- CHAPTER 5 Internal Combustion EngineDocument49 pagesCHAPTER 5 Internal Combustion EngineYann YeuNo ratings yet

- STCW Amendments Guide For Seafarers PDFDocument6 pagesSTCW Amendments Guide For Seafarers PDFplur650% (1)

- Air Standard Cycles - BasicsDocument34 pagesAir Standard Cycles - Basicsrazvan66m100% (1)

- TM 5-5090 GENERATOR SET, BUDADocument363 pagesTM 5-5090 GENERATOR SET, BUDAAdvocate100% (1)

- QDB 15 PowerplantsDocument54 pagesQDB 15 PowerplantsKueh Chew Chai92% (12)

- Diesel Engine 16 V 956 TB 92 Description and Operation ManualDocument12 pagesDiesel Engine 16 V 956 TB 92 Description and Operation ManualAgus Qupink Luph AriaNo ratings yet

- VLX VT600 88-89 91-96 Service Manual 61MR107Document287 pagesVLX VT600 88-89 91-96 Service Manual 61MR107Gilang Dhikapati Abiwata0% (1)

- Adobe Illustrator CC 17.1 Final Multilanguage (ChingLiu)Document3 pagesAdobe Illustrator CC 17.1 Final Multilanguage (ChingLiu)glitterintheairNo ratings yet

- 01-7355-QHSE Procedures - Shore IntroductionDocument1 page01-7355-QHSE Procedures - Shore IntroductionglitterintheairNo ratings yet

- MLC Briefing Note July 2010Document2 pagesMLC Briefing Note July 2010glitterintheairNo ratings yet

- Policy Notes StatusDocument6 pagesPolicy Notes Statusglitterintheair0% (1)

- GMS Client Advisory 5-09 - EPA NPDES Vessel General Permit - Update 6 Feb 09Document2 pagesGMS Client Advisory 5-09 - EPA NPDES Vessel General Permit - Update 6 Feb 09glitterintheairNo ratings yet

- MLC Briefing Note July 2010Document2 pagesMLC Briefing Note July 2010glitterintheairNo ratings yet

- MCA Masters Guide Inc ReferencesDocument366 pagesMCA Masters Guide Inc ReferencesglitterintheairNo ratings yet

- ABS Survey - ItalyDocument38 pagesABS Survey - ItalyglitterintheairNo ratings yet

- Factsheet ILO MLC 2006Document2 pagesFactsheet ILO MLC 2006glitterintheairNo ratings yet

- Electro Teh NicaDocument162 pagesElectro Teh NicaglitterintheairNo ratings yet

- ABBSmart Grid - Presentation (Model PT Power Point)Document20 pagesABBSmart Grid - Presentation (Model PT Power Point)glitterintheairNo ratings yet

- MB2-3-Halstensen - Improving Total Efficiency and Safety During DP-OpeDocument7 pagesMB2-3-Halstensen - Improving Total Efficiency and Safety During DP-OpeglitterintheairNo ratings yet

- Cruise: in Support of ExcellenceDocument20 pagesCruise: in Support of ExcellenceglitterintheairNo ratings yet

- All Electric Ship PresentDocument26 pagesAll Electric Ship PresentglitterintheairNo ratings yet

- Legislatie Maritima 1-300Document87 pagesLegislatie Maritima 1-300glitterintheairNo ratings yet

- ElectrotehnicaDocument162 pagesElectrotehnicaglitterintheair100% (1)

- Me205 L02Document21 pagesMe205 L02SojolNo ratings yet

- Despiece-Mototaxi Re4sDocument112 pagesDespiece-Mototaxi Re4sCristian HiguitaNo ratings yet

- Halderman AutoTec ch09Document29 pagesHalderman AutoTec ch09tornomanNo ratings yet

- Machine Design ManualDocument20 pagesMachine Design ManualSp PatelNo ratings yet

- Internal Combustion Engines - Saleel and Sivakumar PDFDocument86 pagesInternal Combustion Engines - Saleel and Sivakumar PDFRam NareshNo ratings yet

- Full Paper Template by KPI USUDocument5 pagesFull Paper Template by KPI USUHendrik V SihombingNo ratings yet

- What Is Clean DieselDocument3 pagesWhat Is Clean DieselMeleștean MihaiNo ratings yet

- EMM 4209 - Week - 2Document39 pagesEMM 4209 - Week - 2dausNo ratings yet

- INNOVA5568 SchematicsDocument10 pagesINNOVA5568 Schematicscork_ie100% (1)

- C490BDDocument1 pageC490BDMohamdNo ratings yet

- Lecture 2Document26 pagesLecture 2hatelNo ratings yet

- Mar Power Week 2Document10 pagesMar Power Week 2DarkxeiDNo ratings yet

- 10.machine Design - Lab Manual 12.08.2017 PDFDocument14 pages10.machine Design - Lab Manual 12.08.2017 PDFDhruvil PatelNo ratings yet

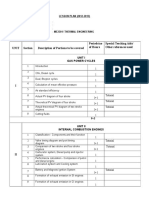

- THERMAL ENGINEERING LESSON PLANDocument3 pagesTHERMAL ENGINEERING LESSON PLANannaduraiNo ratings yet

- Aksum University Mechanical Engineering Course Explores IC Engines & Reciprocating MachinesDocument16 pagesAksum University Mechanical Engineering Course Explores IC Engines & Reciprocating MachinesratchagarajaNo ratings yet

- OQAPADocument5 pagesOQAPAYash RajNo ratings yet

- New Microsoft Word DocumentDocument3 pagesNew Microsoft Word DocumentSahil KalaNo ratings yet

- Basic Electro-Mechanics Lab Manual FinalDocument20 pagesBasic Electro-Mechanics Lab Manual FinalShabbir AhmadNo ratings yet

- Komatsu Pc35r 8Document6 pagesKomatsu Pc35r 8elminetorsystemNo ratings yet