Professional Documents

Culture Documents

2205GB Complete Pit

Uploaded by

vikas_ojha54706Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2205GB Complete Pit

Uploaded by

vikas_ojha54706Copyright:

Available Formats

Landia Dry Installed Pump MPTK

Mounting instructions for installation in dry pit for efficient slurry evacuation and pumping from channels to storage tank.

Ask us for professional advice for packaged pumping systems that are friendly to the environment, free of bad odours, easy and quick to install.

Quality in every detail

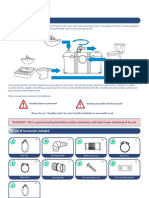

Mounting instruction for dry installed Landia pump

Install the pit. The upper edge of the pit must be at least 150 mm above ground in order to prevent surface water from running into the pit. Drill a hole in the pit in the level of the pump inlet (340 mm) Drill a hole for a 160 mm pipe discharge, either left or right. Thread the pipe from the shed with an 8 gradient. Mount the T-piece for the venting in front of the pit. Place the venting 5001500 mm above ground to prevent the slurry from pouring out through it, when the slurry flows back in case the pump is stopped. Mount the sluice valve after the T-piece, and thread a pipe from this part to the pump. Place the sluice valve and venting as close to the pit as possible. Mount a stainless steel sluice valve 160 mm on the piping towards the storage tank outside the pit; any 90 bends must be the large PN6 (pressure pipes) and not the small ones that are typically used as sewer pipes. Every joint (cast) is to be tight to prevent water from flowing into the pit and flood the motor. Pipe dimension 250, 315 mm ultra pipe or 250, 315 mm N-pipe (smooth pipe). Dimension and type are to be announced when placing order. The channels must be free from contaminants (pieces of cable, plastic, rope, boards and the like). Before the stable is put into use, one can with advantage fill approx. 10 cm of water into the channels, thus preventing the dry concrete from absorbing the thin part of the slurry. Check that the motor is operating with the correct direction of rotation (see arrow).

Start-up:

Operation:

If necessary, open two plugs to ensure an adequate flow towards the pump.

Maintenance:

Before service, close the gate valves on inlet and outlet. In that way, as little slurry as possible will run into the pit when removing the pump. Control the seals Control performance by measuring the ampere consumption during operation. If the performance declines, change the impeller.

Security:

During maintenance or repair, please observe relevant health and safety regulations (gas risk).

We reserve the rights to alterations of technical specification. This text and its technical data cannot be copied entirely or partially without Landias permission.

2205GB0250907

Please contact:

e-mail: info@landia.dk www.landia.dk

Landia A/S Industrivej 2 DK- 6940 Lem St. Tel.: + 45 97 34 12 44 Fax: + 45 97 34 16 98

You might also like

- Specification of Multipurpose Fire TenderDocument8 pagesSpecification of Multipurpose Fire TenderMd SaddamNo ratings yet

- Twist N' Lock Manual Toilets 29090 & 29120: FeaturesDocument9 pagesTwist N' Lock Manual Toilets 29090 & 29120: FeaturesCarl WhitworthNo ratings yet

- Pump Piping and Valve InstallationDocument8 pagesPump Piping and Valve InstallationSinghNo ratings yet

- OPVC Pipes of Class 500 Orientation IS 16477:2017 1. GeneralDocument3 pagesOPVC Pipes of Class 500 Orientation IS 16477:2017 1. GeneralShirish BhavsarNo ratings yet

- Jointing Instructions Dec 20123Document2 pagesJointing Instructions Dec 20123Gabi CristacheNo ratings yet

- A Few Things About PumpDocument2 pagesA Few Things About Pumpabhilibra14No ratings yet

- Pump & Compressor PipingDocument24 pagesPump & Compressor PipingDeven SutharNo ratings yet

- Pantera Sand ManualDocument21 pagesPantera Sand Manualisme78No ratings yet

- Wickes Underground DrainageDocument6 pagesWickes Underground DrainageMohammed Asimuddin FarooquiNo ratings yet

- Instalatii Complete de DrenajDocument6 pagesInstalatii Complete de DrenajCatalinaLixandruNo ratings yet

- Ball Valve BrochureDocument6 pagesBall Valve BrochureRohith GrandhiNo ratings yet

- Pump PipingDocument88 pagesPump Pipingmohamed abd eldayem100% (1)

- Stainless Steel Vertical Pump Installation and MaintenanceDocument6 pagesStainless Steel Vertical Pump Installation and Maintenancejoshua gomezNo ratings yet

- Fluid Lines FittingsDocument61 pagesFluid Lines FittingsVy ThoaiNo ratings yet

- Manhole: Manhole Is The Most Important Structure Used in Sewerage System. It Is Made Either ofDocument11 pagesManhole: Manhole Is The Most Important Structure Used in Sewerage System. It Is Made Either ofSandeepNo ratings yet

- Penguin - Magnetic Drive Pump M SeiresDocument4 pagesPenguin - Magnetic Drive Pump M SeiresMiguel Angel LòpezNo ratings yet

- Direct Plumbing R58 and Evoluzione Installation Check ListDocument2 pagesDirect Plumbing R58 and Evoluzione Installation Check ListAnAn EspressoNo ratings yet

- 4-Sewer AppurtenancesDocument11 pages4-Sewer AppurtenancesMuhammad AmirNo ratings yet

- KBR T407-3 Manual PDFDocument12 pagesKBR T407-3 Manual PDFgiulian2009No ratings yet

- Drain Pipe Work of Indoor UnitDocument24 pagesDrain Pipe Work of Indoor UnitMiguel AbuegNo ratings yet

- Technical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Document11 pagesTechnical Specifications OF Water Bouser (16 TON 150-180 HP CHASSIS)Naushad WadiaNo ratings yet

- Spe62752 Viscous Pill InfoDocument1 pageSpe62752 Viscous Pill InfoAkkassin AbdullayevNo ratings yet

- Water Dist. Sys, Stand Pipe, Drainage Pipe & Sys.Document22 pagesWater Dist. Sys, Stand Pipe, Drainage Pipe & Sys.KevinNavidad100% (3)

- Pompa MusholaDocument21 pagesPompa Musholaerofik72No ratings yet

- Plug and Abandonment - Producing WellDocument32 pagesPlug and Abandonment - Producing Welldriller22No ratings yet

- Technical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Document11 pagesTechnical Specifications OF Multi Purpose Tender (16 Ton 150 HP Chassis)Naushad WadiaNo ratings yet

- M-VF Series: Safety Excess Flow ValveDocument5 pagesM-VF Series: Safety Excess Flow ValvebiomenggNo ratings yet

- AbstractDocument10 pagesAbstractGagan H P100% (1)

- Polaris 280 Repair ManualDocument42 pagesPolaris 280 Repair ManualPool Supply Sales100% (3)

- Conventional Pumping System GuidelinesDocument20 pagesConventional Pumping System GuidelinesT.N. Ramnauth Co LtdNo ratings yet

- Sewer Appurtenances and Pumping Station: Dr. Hansa Jeswani Associate Professor CEDDocument56 pagesSewer Appurtenances and Pumping Station: Dr. Hansa Jeswani Associate Professor CEDSahil WadhwaniNo ratings yet

- 623英文厄瓜多尔 液气分离器说明书Document5 pages623英文厄瓜多尔 液气分离器说明书Eric TianNo ratings yet

- 622英文厄瓜多尔 液气分离器说明书Document5 pages622英文厄瓜多尔 液气分离器说明书Eric TianNo ratings yet

- Dosing PumpDocument10 pagesDosing PumpniceseshaNo ratings yet

- Piping Layout - Piping Guide - 2Document10 pagesPiping Layout - Piping Guide - 2s_baishyaNo ratings yet

- So If: Recommendations For The Installation, Fabrication, Testing and Cleaning of Air, Gas or Steam PipingDocument1 pageSo If: Recommendations For The Installation, Fabrication, Testing and Cleaning of Air, Gas or Steam PipingKarim MohamedNo ratings yet

- PVC-O Tecnical Spesification MolecorDocument11 pagesPVC-O Tecnical Spesification MolecorRusdy NugrahaNo ratings yet

- Technical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Document23 pagesTechnical Specifications OF Multi Purpose Tender (LCV 100 HP Chassis)Naushad WadiaNo ratings yet

- 6 SWR Drainage SystemDocument4 pages6 SWR Drainage SystemDhananjay Subhash DamleNo ratings yet

- Liner Running, Setting & Cementing ProceduresDocument43 pagesLiner Running, Setting & Cementing Proceduresarez muhammedNo ratings yet

- Erie 541-008 Manual2Document16 pagesErie 541-008 Manual2John KoNo ratings yet

- Handling Precautions: Butterfly Valves (Common To All Models)Document9 pagesHandling Precautions: Butterfly Valves (Common To All Models)xaaabbb_550464353No ratings yet

- Duplex Filter Model 50Document2 pagesDuplex Filter Model 50abcdefNo ratings yet

- Procedure - Hot TappingDocument6 pagesProcedure - Hot Tappingmanimaran_ratnam100% (4)

- Industrial and General Purpose: Owners ManualDocument22 pagesIndustrial and General Purpose: Owners ManualoscarpabaNo ratings yet

- Sewer AppurtenancesDocument16 pagesSewer AppurtenancesAjay JainNo ratings yet

- And Dosage Pumps - Installation GuideDocument6 pagesAnd Dosage Pumps - Installation GuideJose R C FernandesNo ratings yet

- ManholesDocument6 pagesManholesarfaatNo ratings yet

- PRFD - Design ManualDocument2 pagesPRFD - Design ManualSreepathy RangarajanNo ratings yet

- Water Pump STN StandardDocument5 pagesWater Pump STN StandardTeguh SetionoNo ratings yet

- SanibestDocument8 pagesSanibesth8banksNo ratings yet

- Plunger Pump Service Manual: Installation and Start-Up InformationDocument6 pagesPlunger Pump Service Manual: Installation and Start-Up InformationSubhendu KarNo ratings yet

- Piping Recommendations For Pump PipingDocument3 pagesPiping Recommendations For Pump Pipingkapoorkunal26No ratings yet

- 42 80 - 4280 Motor Mounted Pump - IOI PDFDocument4 pages42 80 - 4280 Motor Mounted Pump - IOI PDFLokesh ModemzNo ratings yet

- Polaris 380 Repair ManualDocument46 pagesPolaris 380 Repair ManualPool Supply Sales100% (5)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Business Tax Account Update: Step 1Document2 pagesBusiness Tax Account Update: Step 1vikas_ojha54706No ratings yet

- Little Champs PMS: An Investment Strategy For Indian Small Caps From Marcellus Investment ManagersDocument18 pagesLittle Champs PMS: An Investment Strategy For Indian Small Caps From Marcellus Investment Managerssubham mohantyNo ratings yet

- Dtf275 Fill inDocument1 pageDtf275 Fill invikas_ojha54706No ratings yet

- DTF 950Document1 pageDTF 950vikas_ojha54706No ratings yet

- Certificate of Indian Exemption For Certain Property or Services Delivered On A ReservationDocument2 pagesCertificate of Indian Exemption For Certain Property or Services Delivered On A Reservationvikas_ojha54706No ratings yet

- q3 13 Efh Inv Call Deck FinalDocument26 pagesq3 13 Efh Inv Call Deck Finalvikas_ojha54706No ratings yet

- S16R - S16R MPTK PDFDocument1 pageS16R - S16R MPTK PDFvikas_ojha54706No ratings yet

- SDT Connector Quick StartDocument4 pagesSDT Connector Quick Startvikas_ojha54706No ratings yet

- Statement of Financial Condition and Other InformationDocument8 pagesStatement of Financial Condition and Other Informationvikas_ojha54706No ratings yet

- SDT Connector Quick StartDocument4 pagesSDT Connector Quick Startvikas_ojha54706No ratings yet

- 386609004Document24 pages386609004vikas_ojha54706No ratings yet

- S12A2MPTKDocument3 pagesS12A2MPTKvikas_ojha5470650% (2)

- 1717949Document2 pages1717949vikas_ojha54706No ratings yet

- Summary of Dev DiscourseDocument5 pagesSummary of Dev Discoursevikas_ojha54706No ratings yet

- MPTK Source Installation With Win32Document13 pagesMPTK Source Installation With Win32vikas_ojha54706No ratings yet

- Abr 2012 3 4 1712 1718Document7 pagesAbr 2012 3 4 1712 1718vikas_ojha54706No ratings yet

- EnzzDocument7 pagesEnzzshine141No ratings yet

- Landia MPTK-I MediumDocument2 pagesLandia MPTK-I Mediumvikas_ojha54706No ratings yet

- S12A2MPTKDocument3 pagesS12A2MPTKvikas_ojha5470650% (2)

- MBN003 MitsubishiMarineGasEngineRangeDocument2 pagesMBN003 MitsubishiMarineGasEngineRangevikas_ojha54706No ratings yet

- S6A3MPTKDocument3 pagesS6A3MPTKvikas_ojha54706100% (6)

- S6R2MPTKDocument3 pagesS6R2MPTKvikas_ojha54706100% (4)

- Landia MPTK-I MediumDocument2 pagesLandia MPTK-I Mediumvikas_ojha54706No ratings yet

- Abr 2012 3 4 1712 1718Document7 pagesAbr 2012 3 4 1712 1718vikas_ojha54706No ratings yet

- Ts KLM-KLP DKLM-DKLP EngDocument5 pagesTs KLM-KLP DKLM-DKLP Engvikas_ojha54706No ratings yet

- 5sushruta KalpaDocument41 pages5sushruta KalpaYogesh ChavanNo ratings yet

- SRI June 2009 EngDocument40 pagesSRI June 2009 Engvikas_ojha54706No ratings yet

- KLP User DDocument84 pagesKLP User Dvikas_ojha54706No ratings yet

- KLP User DDocument84 pagesKLP User Dvikas_ojha54706No ratings yet

- W11 Normal and Higher Strength Hull Structural Steels W11Document45 pagesW11 Normal and Higher Strength Hull Structural Steels W11Fernando ReyesNo ratings yet

- Load Calculation For Stair CaseDocument2 pagesLoad Calculation For Stair CaseSantosh Bapu100% (1)

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- Orifice Flange Union Assembly and Orifice Run Installation and Operation ManualDocument8 pagesOrifice Flange Union Assembly and Orifice Run Installation and Operation ManualNithin CpNo ratings yet

- ACI 318-08, Appendix DDocument47 pagesACI 318-08, Appendix Dgelustan200691% (22)

- Fluid Mechanics PDFDocument73 pagesFluid Mechanics PDFSanjan KSNo ratings yet

- RFI 150 ResponseDocument3 pagesRFI 150 ResponseAmogh SwamyNo ratings yet

- Soil Structure Berbagai Macam Struktur TanahDocument17 pagesSoil Structure Berbagai Macam Struktur TanahFauziah AlmunawarohNo ratings yet

- Ac Dur Sba G PDFDocument2 pagesAc Dur Sba G PDFbhagwatpatilNo ratings yet

- Versatility & Durability: Engineered Liquid Level SolutionsDocument12 pagesVersatility & Durability: Engineered Liquid Level SolutionsnovriNo ratings yet

- Anderson Greenwood POPRV Catalog - Series 200, 400, 500, 700 & 800Document64 pagesAnderson Greenwood POPRV Catalog - Series 200, 400, 500, 700 & 800Federico MoranNo ratings yet

- On Base PlateDocument20 pagesOn Base PlateHemant SonawadekarNo ratings yet

- Welding Questions 1Document26 pagesWelding Questions 1dselvakuuNo ratings yet

- Lucky Cement - OPC & SRCDocument4 pagesLucky Cement - OPC & SRCAamirShabbirNo ratings yet

- Beam Column Joint IIT RoorkeeDocument109 pagesBeam Column Joint IIT RoorkeeMayank RajputNo ratings yet

- Sikagrout - 200Document3 pagesSikagrout - 200Tan TounNo ratings yet

- Sika Backing RodDocument2 pagesSika Backing Rodthe pilotNo ratings yet

- 5.deflections Using Energy Methods PDFDocument47 pages5.deflections Using Energy Methods PDFking burgosNo ratings yet

- Profiles For Ceramic TilesDocument6 pagesProfiles For Ceramic TilesnasuemilNo ratings yet

- Names of All Materials WRT ASTM No.Document6 pagesNames of All Materials WRT ASTM No.روشان فاطمة روشانNo ratings yet

- Monitoring Pekerjaan Dan MaterialDocument3 pagesMonitoring Pekerjaan Dan MaterialHarits Angga KusumaNo ratings yet

- 03 Welding Imperfections 29-11-03Document17 pages03 Welding Imperfections 29-11-03bizhanjNo ratings yet

- Ismb 600 Splice Design Calculation-R1Document1 pageIsmb 600 Splice Design Calculation-R1Anonymous sfkedkym100% (2)

- Failure of ToolDocument8 pagesFailure of ToolPROD DOPENo ratings yet

- 20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelDocument5 pages20NiCrMo2-2 Alloy Steel DIN 1.6523 AISI 8620 SteelzhenyupanNo ratings yet

- IS 2185-3 (1984) - Concrete Masonry Units, Part 3 - Autoclaved Cellular Aerated Concrete BlocksDocument21 pagesIS 2185-3 (1984) - Concrete Masonry Units, Part 3 - Autoclaved Cellular Aerated Concrete Blocksmanish_shashikantNo ratings yet

- DDM04 S310 16 SupplementDocument4 pagesDDM04 S310 16 SupplementmojeebmashalNo ratings yet

- Roofing SafetyDocument38 pagesRoofing SafetyDhârâñî KûmârNo ratings yet

- Deluxe Test Probe Kit Assembly Instruction by KK4HXJ - RevisedDocument6 pagesDeluxe Test Probe Kit Assembly Instruction by KK4HXJ - ReviseddonsterthemonsterNo ratings yet

- Tyco SprinklerDocument68 pagesTyco SprinklerLuka RadilNo ratings yet