Professional Documents

Culture Documents

Ts-2 Characterization of Associated Proteins and Phospholipids in Natural Rubber Latex

Uploaded by

Steven LauCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ts-2 Characterization of Associated Proteins and Phospholipids in Natural Rubber Latex

Uploaded by

Steven LauCopyright:

Available Formats

Journal of Bioscience and Bioengineering VOL. 111 No. 6, 628 634, 2011 www.elsevier.

com/locate/jbiosc

Characterization of associated proteins and phospholipids in natural rubber latex

Jitlada Sansatsadeekul,1 Jitladda Sakdapipanich,1,2, and Porntip Rojruthai1

Department of Chemistry and Center of Excellence for Innovation in Chemistry, Faculty of Science, Mahidol University, Rama VI Rd., Phayathai, Bangkok 10400, Thailand 1 and Institute of Molecular Bioscience, Mahidol University, Salaya Campus, Putthamonthon, Nakhonpathom 73170, Thailand 2 Received 20 April 2010; accepted 22 January 2011 Available online 26 February 2011

Non-rubber components present in natural rubber (NR) latex, such as proteins and phospholipids, are presumed to be distributed in the serum fraction as well as surrounding the rubber particle surface. The phospholipidprotein layers covering the rubber particle surface are especially interesting due to their ability to enhance the colloidal stability of NR latex. In this study, we have characterized the components surrounding the NR particle surface and investigated their role in the colloidal stability of NR particles. Proteins from the cream fraction were proteolytically removed from the NR latex and compare to those from the serum fractions using SDSpolyacrylamide gel electrophoresis revealing that both fractions contained similar proteins in certain molecular weights such as 14.5, 25 and 27 kDa. Phospholipids removed from latex by treatment with NaOH were analyzed using 1H-NMR spectroscopy and several major signals were assignable to (CH2)n, CH2OP, CH2OC=O and OCH2CH2NH. These signals are important evidence that indicates phospholipids associate with the rubber chain. The colloidal behavior of rubber lattices before and after removal of proteinlipid membrane was evaluated by zeta potential analysis and scanning electron microscope (SEM). The lowest zeta potential value of NR particles was observed at pH 10, consequently leading to the highest stability of rubber particles. Additionally, SEM micrographs clearly displayed a gray ring near the particle surface corresponding to the proteinlipid membrane layer. 2011, The Society for Biotechnology, Japan. All rights reserved.

[Key words: Natural rubber latex; Proteins; Phospholipids; Colloidal stability]

The latex from Hevea brasiliensis, the commercial source of natural rubber, is composed of about 36% of rubber fraction, 5% of nonrubbers components such as protein, lipid and sugar, with water accounting for the remaining 59%. The rubber particles are generally spherical, although medium-sized and larger ones in latex from certain mature trees may be pear shaped (1). Previously, it was proposed that natural rubber particles are protected by a complex film containing proteins and lipids (2), and that these lipids and proteins layers were the inner and outer layers of rubber particle, respectively (3). It has been proposed that proteins contaminating natural rubber products, such as gloves and condoms, may be responsible for allergic reactions in some people exposed to NR latex. The total protein content of fresh latex is approximately 11.5%, of which about 20% is adsorbed on the rubber particles and the similar proportion is associated with the bottom fraction (4), with the remainder dissolved in the serum phase. The major component of the adsorbed proteins is most likely -globulin, that has a molecular weight of approximately 200 kDa and it is insoluble in pure water (5,6). Hevein, the second major protein in latex has a molecular weight of 5 kDa and is a water-soluble protein generally present in the bottom fraction of latex (7). These proteins adsorbed on NR particle are composed of many types of amino acids, including neutral amino

Corresponding author. Tel./fax: +66 2 889 3116. E-mail address: scjtp@mahidol.ac.th (J. Sakdapipanich).

acid, acidic amino acid and basic amino acid, resulting in electrophoretic. The amino acid composition of each protein is also distinct leading to different isoelectric points. Proteins from latex can be separated and identified based on its electrophoresis mobility. The proteins adsorbed on the rubber particles have not been studied in much detail due to the difficulties in removing them unchanged from the particle surface. However, proteins from fresh latex particles have isoelectric points ranging from pH 4.0 to 4.6, depending on the rubber clonals (8), indicating that more than one kind of proteins is adsorbed on the rubber particle and that the relative proportions of the adsorbed proteins on the rubber particle is a characteristics of the clone. Lipids associated with NR are comprised mainly of neutral lipids and phospholipids (9). The principle phospholipids of the rubber particles are -lecithin. Other lipids are sterol esters, fats, which are a subgroup of lipids called triglycerides, and waxes (Tangpakdee, J., Ph.D. thesis, Tokyo University of Agriculture and Technology, Tokyo, 1998). The presence of the phosphatidylcholine and small amounts of phosphatidylethanolamine associated with the rubber particles has also been reported (10). Recently, NR was described to contain phospholipid molecules at the -termini of the rubber chain associated via mono- and diphosphate groups at the chain-end (11). Moreover, it also appears that phosphate groups of phospholipids originate the branching formation in DPNR (12). For clarity, the proteins and phospholipids associated to the rubber chain-end were referred to as associated proteins and phospholipids, respectively.

1389-1723/$ - see front matter 2011, The Society for Biotechnology, Japan. All rights reserved. doi:10.1016/j.jbiosc.2011.01.013

VOL. 111, 2011 The surface surrounding the rubber particles has been investigated by many techniques such as phase transfer, which follows the migration of a reactant in heterogeneous reaction mixtures from one phase to another using a counter ion (Baimark, Y., Master thesis, Mahidol University, Thailand, 1998), scanning electron microscopic (SEM) (13), and transmission electron microscopic (TEM) techniques. It was affirmed that the particles are surrounded by a film of phospholipid protein layer with 100 in thickness (14). The surface surrounding the rubber particles contains both positive and negative charges and has been investigated by using the electrophoresis mobility technique. The negative charges were attributed to ionization of adsorbed carboxylic group on phospholipid molecules, and the positive charges are generated from certain amino groups of the adsorbed proteins. The isoelectric point of Hevea latex is reported to be within the pH range of 3.05.0, corresponding to the characteristics of adsorbed proteins (15). Above the isoelectric point, NR particles are stabilized by the negative charge of the adsorbed long-chain fatty acid and hydrolysis products of phospholipids (16). However, the proteins and lipids adsorbed on the rubber particles have not been studied in much detail due to the difficulties in removing them unchanged from the particle surface. Therefore, this study analyzed the phospholipids and proteins associated to the rubber surface and other components in serum. These properties were compared with those of cream rubber particles before and after removal of proteins and ester components by centrifugation, deproteinization and saponification reaction.

ASSOCIATED PROTEINS AND PHOSPHOLIPIDS IN NR LATEX

629

MATERIALS AND METHODS Plant materials and chemicals Fresh latex was provided by Thai Rubber Latex Co., Ltd., Chonburi, Thailand. Sodium dodecylsulfate (SDS), TritonX-100 and sodium hydroxide (NaOH) were purchased from BDH Company. Proteolytic enzyme (KP 3939) from KaO Corporation was used in deproteinization reaction. The proteins obtained from the deproteinization process were precipitated with acetone, trichoroacetic acid (TCA) and 2-mercaptoethanol from Lab scan, Sigma-Aldrich Chemical and Amersham Company, respectively. The pellet proteins were dissolved in the mixture solution of urea, CHAP, dithiothreitol (DTT) and PharmalyteTM, purchased from Amersham Company. All other reagents were of analytical grade. Preparation of large and small rubber particles for proteins extraction Freshly tapped natural rubber latex of the RRIM 600 clone of Hevea brasiliensis stabilized with 0.2% (w/v) of Triton X-100 was centrifuged at 19,000 rpm for 1 h at 20C (17). The top creamy fraction of rubber particles was collected and resuspended in 0.2% (w/v) TritonX-100 solution. The serum fraction was then recentrifuged at 19,000 rpm for 1 h at 20C to collect small rubber particles (SRP). Preparation of rubber samples for phospholipids extraction Fresh NR latex in 0.5% (w/v) SDS solution was centrifuged, and cream fraction was dried at 60C for at least 3 days. Dry cream NR was extracted with acetone in a Soxhlet apparatus for 16 h under a nitrogen atmosphere and dried in a vacuum oven at 40C for 3 days. Dry acetone-extracted natural rubber (AENR) was extracted with a chloroformmethanol (2:1) mixture in a Soxhlet apparatus under the same conditions. The CHCl3MeOH extract from AENR was dried in a vacuum oven at 40C for 3 days. Extraction of proteins from rubber particles by SDS solution, enzymatic deproteinization and saponification reaction The large and small rubber particles obtained from centrifugation were dispersed in 2% (w/v) SDS and stirred overnight at 4C. Each mixture was then centrifuged at 19,000 rpm for 1 h at 20C to remove rubber particles from the aqueous phase which contained soluble proteins. The 30% dry rubber content (DRC) of large rubber particles in 0.2% (w/v) TritonX-100 solution was incubated with 0.04% (w/v) proteolytic enzyme (KP 3939) at 37C for 16 h followed by centrifugation at 14,000 rpm for 1 h (11). The cream fraction was redispersed in 0.2% (w/v) TritonX-100 solution and recentrifuged under the same conditions. The deproteinized natural rubber (DPNR) latex was obtained from the dispersion of the cream fraction in a 0.2% (w/v) TritonX-100 aqueous solution. To decompose phospholipids deproteinized natural rubber latex was treated with 1% (w/v) NaOH at 70C for 3 h in a saponification reaction (18) and then centrifuged at 19,000 rpm for 1 h at 20C to separate the serum fraction. Proteins precipitation with TCA in acetone The serum fraction was prepared in the presence of 10% (w/v) trichoroacetic acid (TCA) in acetone with 0.07% (v/v) 2mercaptoethanol. Proteins were subjected to precipitate for 45 min at 20C. Pellet proteins were collected by centrifugation and were further washed with cold acetone containing 0.07% (v/v) 2-mercaptoethanol. Residual acetone was removed by airdrying and the proteins were redissolved in lysis buffer, 8 M urea, 4% (v/v) CHAP, 60 mM DTT and 2% (v/v) PharmalyteTM.

Proteins analysis and nitrogen content measurement Proteins were separated by sodium dodecylsulfatepolyacrylamide gel electrophoresis (SDSPAGE) on a 15% acrylamide separating gel and a 3% acrylamide stacking gel at 25 mA for 1 h (19), and 4 g of protein sample was loaded onto each lane of the SDSPAGE gel (17) and after electrophoresis the gel was subsequently stained with a solution of Coomassie Blue R-250 for 20 min and de-stained for several times with the mixture solution of 125 ml of methanol, 37.5 ml of acetic acid and 337.5 of distilled water. A nitrogen analyzer (LECO FP-258) was used for nitrogen analysis based on the combustion by oxygen gas. The rubber sample (0.25 g) was weighed and subjected to the nitrogen analysis. The combustion of rubber sample converts the nitrogen in compounds to nitrogen gas, which can then be detected as nitrogen content (% w/w). In this experiment, EDTA was used as a standard with an accuracy of 0.02% (w/w). The results were obtained from triplicate analysis. Particle size and zeta potential analysis Particle size distribution was determined using a Malvern 2000 laser particle analyzer. About 510% (v/v) of rubber latex was dispersed in distilled water before the analysis. The stock buffer solution was freshly prepared in the pH range of 412 for dispersing the natural rubber latex, as given in Table 1. Samples were prepared by adding one drop of latex to 20 ml of buffer solution. Zeta-potential values for natural rubber particles were determined using zeta potential analyzer (MALVERN S4700 version 1.27). The rubber latex was dropped into de-ionized water and then injected into the sample handling for reflush and measurement, respectively. Zeta potential was observed using the conversion of the frequency and scattering intensity function. Fourier transform infrared (FT-IR) analysis Natural rubber latex samples were dried in an oven overnight at 50C and then further prepared for FT-IR analysis by dissolving in chloroform (1% w/v) and casting on a KBr disk under a stream of nitrogen. The rubber film was scanned with an FT-IR spectrophotometer (JASCO: FT-IR SA 450 plus) at a resolution of 2 cm1 with 100 scans. The content of long-chain fatty acid ester group was obtained using the intensity ratio of carbonyl groups at 1739 cm1 (C=O) and unsaturated carbon absorbance at 1664 cm1 (C=C) according to the calibration curve obtained from a mixture of methyl stearate and synthetic cis -1,4polypolyisoprene. Scanning electron microscopy (SEM) The morphology of natural rubber surface was analyzed using a scanning electron microscope (SEM S-2500). Samples were secured onto an aluminum stubs and coated with platinum/paradium in a Polaron high-resolution sputter coat to obtain enough contrast in the SEM micrographs, and the energy of electron beam was 20 kV. Associated phospholipids extraction Saponification of CHCl3MeOH extracted from AENR (5 g) was carried out in 500 ml toluene solution by reacting with 1% (w/v) potassium hydroxide at 70C for 2 h. The toluene fraction containing rubber solution and phospholipids cleaved from the rubber was neutralized with 6% (v/v) acetic acid and the water fraction removed using a separatory funnel. The rubber fraction in toluene was precipitated with excess methanol. The toluene methanol mixture solution containing associated phospholipids was evaporated, and the obtained product was characterized using NMR spectroscopy. Furthermore, acyl chains of phospholipids cleaved from the rubber were converted to fatty acid methyl esters before it was subjected to GCMS analysis. Fatty acid methyl esters preparation Fatty acid methyl esters were prepared as follows: 2 ml of 1% solution of sodium methylate in methanol was added to 10 mg of total lipids (20). The mixture was kept at 65C for 2 h, at with point 2 ml of 5% solution of HCl in methanol was added and the mixture was incubated at 60C for an additional 0.5 h. After cooling at room temperature, fatty acid methyl esters were stored at 18C. Nuclear magnetic resonance (NMR) and gas chromatographymass spectroscopy (GCMS) measurement The 1H-NMR analyses of extracted lipid in CDCl3 solution were performed at 300 MHz and 50C. Chemical shifts were determined using tetramethylsilane (TMS) as an internal standard. The volatile components of fatty acid methyl esters were collected and analyzed by GCMS instrument equipped with an InnowaxTM column (30 m 0.25 mm i.d.). The carrier gas was helium at a constant pressure of 10.7 psi with an injection split of 1:60. Fatty acid methyl esters were analyzed with the column temperature at 210C, and the injector temperature of 250C. The oven temperature was maintained at 150C for 1 min, raised at 15C min1 to 200C, raised at 2C min1 to 250C and then kept at the final temperature of 5 min. The mass spectrometer was operated in electron impact

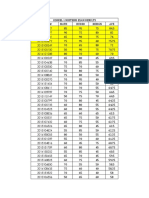

TABLE 1. Preparation of the buffer solution in pH range 412. pH 4 5 6 7 8 9 10 11 12 0.1 M Citric acid (ml) 61.45 48.50 36.85 0.2 M Na2HPO4 0.2 M NaH2PO4 0.2 M Glycine (ml) (ml) (ml) 38.55 51.50 63.15 30.50 47.35 19.50 2.65 25.00 25.00 25.00 25.00 0.2 M NaOH (ml) 4.40 16.00 28.00 40.00

Volume was then made to 100.00 ml with de-ionized water.

630

SANSATSADEEKUL ET AL.

J. BIOSCI. BIOENG.,

ionization mode (70 eV). The temperature of transfer line and ion source was 280C. The structure of fatty acid adducts was elucidated from their mass spectra.

RESULTS AND DISCUSSION Study of basic properties of NR latex Hevea latex is originally composed of spherical particles. Some of these particles become attached to each other to form groups or chains. Table 2 demonstrates that the particle size of rubber particles from whole fresh NR latex is relatively smaller than that from centrifuged latex, deproteinized latex and saponified latex. The size of the small rubber particles from the serum phase is smallest as 189 nm. As expected, the NR particles obtained from centrifuged, deproteinized and saponified latex rapidly combined together due to the removal of the protein and phospholipid layers. The protein contents of small rubber particles and fresh latex were found to be high, while those of centrifuged latex, deproteinized latex and saponified latex were less than the former. This indicates that the centrifugation of natural rubber latex in the presence of TritonX-100 could remove only soluble proteins and that some proteins are still tightly bound to the rubber particles. Therefore, the most effective method to remove proteins is through deproteinization of natural rubber latex with a proteolytic enzyme. Additionally, almost all proteins associated to rubber particles were also reduced by strong alkali hydrolysis known as the saponification reaction. As expected, the natural rubber particles became unstable after removal of the associated protein. The fatty acid ester content is a measure of both free and associated phospholipid as well as fatty acid esters present in the natural rubber. Table 2 exhibits fatty acid ester content value in dry rubber samples, which display abnormal groups such as hydroxyl, aldehyde and lactone groups as detected by FT-IR spectroscopy. It was clarified that the deproteinized latex was composed of low associated fatty acid ester content compared to centrifuged latex, while the associated fatty acid ester value of the saponified latex was reduced to zero because of the removal of phospholipid groups. In addition, natural rubber was accounted to contain saturated and unsaturated fatty acids (21). Therefore, the signal overlapping of unsaturated fatty acids and polyisoprenoid could have an effect on the determination of fatty acid ester content in natural rubber. Characterization of extracted proteins in natural rubber latex Proteins from natural rubber latex were distributed into two fractions, the rubber and serum fractions. To characterize these proteins they were extracted after processing using several chemical reactions and washing with surfactant solution. Removal of protein from rubber particles was confirmed by monitoring the decrease in protein content of treated latex. The proteins removed from latex were analyzed using SDSPAGE technique, as shown in Fig. 1. SDSPAGE gel image presents the standard proteins (lane A), soluble proteins (lane B), decomposed proteins after deproteinization reaction (lane C), decomposed proteins after saponification reaction (lane D), SDS-extracted proteins from large rubber particles (lane E) and SDS-extracted proteins from small rubber particles (lane F).

FIG. 1. SDSPAGE images (15% gel) of proteins from the rubber and serum fractions: (A) standard protein, (B) soluble protein, (C) decomposed protein after deproteinization, (D) serum protein after saponification, (E) SDS-extracted proteins from large rubber particles and (F) SDS-extracted proteins from small rubber particles.

TABLE 2. The mean diameter, protein content and linked fatty acid ester content of fresh natural rubber latex, centrifuged latex, deproteinized latex, saponified latex and small rubber. Sample Fresh latex Centrifuged latex Deproteinized latex Saponified latex Small rubber particles Mean diameter (nm) 636 2 655 1 664 3 678 1 189 2 Protein content (%w/w of dry rubber) 4.30 0.02 0.96 0.03 0.07 0.02 0.05 0.02 1.95 0.03 Ester content (mmol/kg rubber) 28.1 0.2 38.5 0.5 30.9 0.7 ~0 ~0

The SDSPAGE analysis of the soluble proteins (lane B) revealed the presence of protein bands in the region of 6 to more than 200 kDa. The major bands observed in the soluble protein fraction appeared to be derived from B- and C-sera of fresh latex, as well as rubber particles. The B-serum was incidentally released from the lutoids, in which it can be burst by addition of ammonia. Molecular weights of proteins above 30 kDa were originated primarily from the serum fraction, while the 33 kDa proteins and the proteins with lower molecular weights were generated from the rubber fraction. Therefore, it can be assumed that these proteins are polar proteins because they can reside in the water phase (17). It was observed that lanes C and D contain low molecular weight proteins, which were decomposed by proteolytic enzyme and strong alkali treatment. Lanes E and F contain proteins removed from large and small rubber particles by SDS extraction. It was explicated that SDS could extract proteins associated with the rubber particles after the isolation of serum fraction. Although the obtained protein solution was contaminated with some SDS molecules, this surfactant could be removed using dialysis (18). SDSPAGE of lane D revealed a prominent protein band at about 14.5 kDa and two less prominent bands at 25 and 27 kDa. In the case of small rubber particles (lane E), the protein bands at 14 and 27 kDa were also discovered, but the intensity band at 27 kDa was higher than that of 14 kDa. It was pointed that the molecular weights of some proteins were similar to rubber elongation factor or REF (14.5 kDa) and Hevamines (29 kDa), which were to cause allergic reactions (22,23). Based on the study of natural rubber biosynthesis, it was believed that proteins present in natural rubber are the important factor concerning the initiation of natural rubber molecule (24). Thus, the distinct proteins band intensity indicates that proteins at the initiating end of small and large rubber particles are different and these differences may contribute to large rubber particles ability to extend their chains more than that of small rubber particles. During the chain extension process, the initiating end may also be modified however such modified proteins have yet to be identified. Characterization of extracted associated phospholipids in natural rubber This study focuses on the extraction of phospholipids associated to the natural rubber particle from dry rubber. As described previously, free phospholipids in natural rubber were

VOL. 111, 2011 concerned with non-rubber components, which may disturb the analysis of associated phospholipids structure. First, we have tried to reduce the side effect of free phospholipids from dry rubber. It was prepared from fresh natural rubber latex, which was subjected to centrifugation and drying. Secondly, the obtained dry rubber was washed by acetone extraction to remove free fatty acid, followed by the chloroformmethanol extraction to remove free phospholipids. Third, the obtained dry rubber was treated with KOH to decompose the associated phospholipids in saponification reaction and was neutralized with acetic acid. The samples were then precipitated with methanol to separate the coagulated rubber fraction from supernatant as well as obtained rubber fraction for characterization by FT-IR. The associated phospholipids presented in the supernatant were extracted with chloroform and analyzed by 1H-NMR. FT-IR spectra of natural rubber before and after removal of the associated phospholipids are presented in Fig. 2. It has been reported that a phospholipids shows a C=O stretching band for associated fatty acid ester in the range of 17381742 cm1 (11). Moreover the absorption peak at 1240 cm1 was assigned to OPO asymmetric stretching of phospholipids (25). This assignment of FT-IR spectrum corresponded to the structural analysis of phospholipids at the rubber chain-end by Tarachiwin et al. (12). In this study, the FT-IR spectra were utilized to confirm the presence of associated phospholipids in dry natural rubber. Although the dry natural rubber sample was prepared using ultracentrifugation, the transmittance peak of the carbonyl group in associated fatty acids at 1737 cm1 and that of phosphate group at 1243 cm1 were still observed in this FT-IR spectrum. These signals are from phospholipid molecules linked to the rubber chain, since free fatty acids and free phospholipids were removed by centrifugation. In the dry saponified NR sample, the transmittance peak of carbonyl group at 1737 cm1 in the dry saponified NR sample disappeared confirming that the associated phospholipids were removed. Therefore, it can be noted that the saponification reaction is highly efficient for removing associated phospholipids. Moreover, these associated phospholipids also allowed for the characterization and confirmation of the chemical structure using 1H-NMR spectroscopy. The 1H-NMR spectra of standard phospholipids of L--phosphatidylcholine (PC) and extracted associated phospholipids are given in Fig. 3a and b, respectively. It was revealed that all signal positions in the spectrum of extracted phospholipids were not significantly shifted when compared to that of standard phospholipids. Characteristic signals of methylene and long-chain methylene protons in fatty acid ester group were clearly observed at the chemical shift of 0.96 and 1.24 ppm, and the resonances around 2.05 and 2.82 ppm were assigned to the methylene protons next to the unsaturated (CH2CH=CH) and allylic (CH2(C=C)2) bonds of fatty acid ester group, respectively. Moreover, the vinyl protons were found at 5.48 ppm. Methylene protons near the carboxyl group, CH2OC=O, of PC gave rise to the signal at 5.18 ppm, while those of the extracted associated phospholipids also showed a singlet signal at

ASSOCIATED PROTEINS AND PHOSPHOLIPIDS IN NR LATEX

631

FIG. 3. 1H-NMR spectra of (A) L--phosphatidylcholine and (B) phospholipids extracted from natural rubber.

FIG. 2. FT-IR spectra of (A) NR and (B) phospholipid removed NR.

5.18 ppm. In addition, two methylene protons linked to the phosphate group of phospholipid, CH2OP, and the signal of the CHOC=O protons in glyceride backbone of the extracted phospholipids appeared at 4.29 and 5.89 ppm. The polar head group demonstrated a unique resonance characteristic in each phospholipid. The resonance at 4.40 ppm of PC was assigned to the CH2OP of choline group overlapping with CH2OC=O protons of glyceride backbone. The signal of CH2OP protons in 1HNMR spectrum of extracted associated phospholipids appeared at 4.39 ppm, and the resonance of N+(CH3)3 protons was clearly observed at 3.54 ppm. The appearance of these signals clearly indicates that this fraction contains phospholipids associated to the rubber chain. The assignment of phospholipids associated to rubber chain is in good agreement with that reported by Tarachiwin et al. (11). Characterization of fatty acid of associated phospholipids in natural rubber The natural rubber latex from H. brasiliensis (RRIM 600) is generally known to contain phospholipids. Owing to the large molecular structure of phospholipids, they are difficult to identify using gas chromatographymass spectrometry (GC/MS) which is often utilized for the detection of small molecules. To perform this analysis, the lipids from rubber particles were converted to fatty acid methyl esters by transesterification reaction. This enables the conversion of a complex lipid mixture to simple molecular species (26). The obtained fatty acid methyl esters were characterized by GCMS using reference databases of fatty acids to identify these fatty acid methyl esters. Therefore, the identification of phospholipids associated to rubber particles can be obtained using GCMS chromatogram. Fig. 4 reveals the GCMS chromatogram of the extracted phospholipids obtained after the saponification reaction of CHCl3MeOH extracted AENR. It was observed in the chromatogram that many kinds of fatty acids were liberated from this extract. It was predicted that these fatty acids were obtained from the fatty acids associated to phospholipids. In other words, these fatty acids were derived from hydrolysis of phospholipids during the saponification reaction. In addition, the peak at retention time at around 4.63 min was 2,6-di-tert-butyl-p-cresol (BHT), which was used as an antioxidant in the saponification reaction, indicating that BHT remained in the extracts. The results revealed that some components of the extract were fatty acids, which was reported as the associated fatty acids in

632

SANSATSADEEKUL ET AL.

J. BIOSCI. BIOENG.,

FIG. 4. Gas chromatogram of fatty acid methyl esters from the extracts. The chromatogram was obtained on InnowaxTM capillary column at 210C.

natural rubber latex. The data (Fig. 4) indicated that the fatty acid components of associated with phospholipids were composed of palmitic acid, stearic acid, lauric acid, myristic acid, linoleic acid and linolenic acid. These peaks corresponding to palmitic acid (RT 5.09), stearic acid (RT 6.84), lauric acid (RT 7.51), myristic acid (RT 10.41), linoleic acid (RT 21.17) and linolenic acid (RT 22.99), can be attributed to 16:0, 18:0, 12:0, 14:0, 18:2 and 18:3 esters, respectively and confirmed the presence of the associated fatty acids in phospholipids. High abundance of the fatty acids linoleic acid and linolenic acid were observed and these fatty acids may have been derived by hydrolysis of phospholipids during the saponification reaction. Effect of pH and ionic strength The latex from Hevea brasiliensis was stabilized by TritonX-100 and the zeta potential was measured as a function of pH. Fig. 5 presents the zeta potential values for colloidal natural rubber, which was evaluated in the medium with pH between 4 and 12 at a constant ionic strength of 0.015 M NaCl. The negative zeta potential value of rubber latex indicates a negative charge on rubber particle surface. An almost linear decrease of negative zeta potential values was found as the pH value of the solution decreases and then became constant above pH 10 in all samples. This behavior was similar to the previous study (27), which reported that negative zeta potential value would decrease with the decrease of pH until it reached the isoelectric point (IEP). The negative charges were attributed to ionization of carboxylic acid groups surrounding the rubber particle surface. It was observed that the negative zeta potential value of the small rubber particles is lower than that of the fresh NR latex sample in all pH values. As pointed out above, these results were revealed that the stability of fresh NR latex is higher than that of small rubber particles. The increased amount of

adsorbed long-chain fatty acids and proteins should lead to an increase in the charge on the rubber particle surface. The distinct chemical nature of the adsorbed layers was reflected in the difference in the stability of two lattices. The greater the content of long-chain fatty acids and proteins adsorbed on the rubber surface, the larger the observed negative zeta potential value for the NR particles. Table 3 demonstrates the analysis of zeta potential values for natural rubber latex at pH 9 with ionic strength of 0.015 M NaCl. It was observed that the zeta potential value of natural rubber latex is always negative due to the negative charge of proteins and carboxylic groups surrounding the rubber particles. The zeta potential of fresh latex and small rubber were found to higher than that of the centrifuge latex, deproteinized latex and saponified latex consistent with the negative charge on the rubber particle surface being decreased due to the removal of proteins and phospholipids in the processed latex samples. The fresh latex is composed of phospholipids, carbohydrates, proteins and metal ions of which can contribute charge to the species leading to the highest of zeta potential value in this form of latex. Removing the serum (water phase) by centrifugation can cause the loss of the soluble protein and metal ion resulting in a lower negative zeta potential value. Moreover, the removal of the phospholipids and proteins results in the alteration of the chemical composition of the rubberwater interface in NR latex. It was found that the zeta potential values of both deproteinized latex and saponified latex samples were both low. Deproteinization of fresh latex leads to a low nitrogen content, as seen in Table 2. It may be because the long peptide chain was decomposed by proteolytic enzyme in the presence of surfactant, which caused the negative zeta potential value to become lower. The residual phospholipids and short peptide chains on the rubber particle surface can be removed by saponification with NaOH/TritonX-100 in the solution. Accordingly, it is the reason that the decrease in the negative zeta potential value of deproteinized latex was lower than that of the saponified latex.

TABLE 3. Zeta potential value of natural rubber latex at pH 9 with ionic strength of 0.015 M NaCl. Sample Fresh latex Centrifuged latex Deproteinized latex Saponified latex Small rubber particles Zeta potential (mV) 45.7 0.5 39.3 0.1 38.7 0.3 35.9 0.1 41.7 0.5

FIG. 5. Zeta potential value of sample with ionic strength of 0.015 M NaCl.

VOL. 111, 2011 Study of morphology of natural rubber particles by scanning electron microscope (SEM) Electron microscopic examination of rubber particles (28) has indicated that NR particles consist of hydrophobic rubber polymers enclosed by a monolayer membrane. This membrane consists of lipids, proteins and other components that are associated with the good mechanical properties of NR. Therefore, the physical and chemical characteristics of natural rubber particles were investigated to clarify the rubber particle membrane. The method, developed for determining the size and shape of rubber particles using SEM, involves air-drying of a particle suspension after fixation in osmium tetroxide. The scanning electron micrographs of fresh latex, centrifuged latex, deproteinized latex, saponified latex and small rubber are shown in Fig. 6. In the micrographic image, small features can be seen on the rubber particle surface. In comparison, air-dried preparation of particles from freshly tapped latex from mature Hevea trees remained their natural shape and size. Hevea rubber particles were spherical, occurring predominantly as discrete individual particles in a range of sizes. Size measurements for Hevea particles placed the particles in 0.100.75 m range, which agrees with previously reported values for particle size in this species (28,29). SEM analysis reveals that the features of rubber particle surface are most probably proteins and phospholipids. In the case of fresh latex (Fig. 6A), a continuous electron-rich membrane was clearly observed around the rubber particle surface. Inside the rubber particle, in most cases, a homogenous electron density distribution was observed: a less dense region (dark gray) and a denser region (light gray). The centrifuged rubber particles (Fig. 6B) contain a gray ring, which is probably the phospholipidprotein layer. In the case of deproteinized

ASSOCIATED PROTEINS AND PHOSPHOLIPIDS IN NR LATEX

633

(Fig. 6C) and saponified rubber particles of cream rubber (Fig. 6D), the gray rings were also observed. This is probably the surfactant layer. It is possible that surfactants could replace the phospholipid-protein layer for the stabilization of rubber particles after the removal of phospholipidprotein layer by deproteinization and saponification treatments. While the gray ring could not be observed in the small rubber particles (Fig. 6E), this may be due to the lower content of proteins and fatty acid esters, as given in Table 1. In this study, the serum phase of natural rubber latex was shown to contain proteins with molecular weight different from those of rubber particles. The proteins of serum phase were in regions of 6 to more than 200 kDa, while the major proteins of rubber particle were 14.5 and 29 kDa, which were similar to Rubber elongation factor and Hevamines, respectively. It was also found that enzymatic deproteinization could break down the protein linkages selectively and retained the oligopeptide groups associated to rubber molecules while saponification can remove both protein and phospholipid linkages. Characterization of the extracted associated phospholipids obtained from saponification treatment of dry AENR, were carried out by 1H-NMR spectroscopy and GC MS and compared with a database of known molecules. The 1H-NMR spectrum of the extracts revealed major signals, which are assignable to (CH2)n, CH2OP, CH2OC=O and OCH2CH2NH and the appearance of these signals indicates that the serum contains phospholipids associated with the rubber chain. GCMS analysis revealed that the composition of fatty acid ester groups associated with the NR molecule at the termini were saturated fatty acids including palmitic acid, stearic acid, lauric acid, myristic acid, and unsaturated fatty acids such as linoleic acid and linoleinic acid, which evidenced the presence of associated fatty acid in phospholipids. SEM and zeta

FIG. 6. Scanning electron micrograph of the rubber particles: (A) fresh latex, (B) centrifuged latex, (C) deproteinized latex, (D) saponified latex and (E) small rubber particles shown in closed circle.

634

SANSATSADEEKUL ET AL.

J. BIOSCI. BIOENG.,

branch-points by phospholipase and chemical treatments, Biomacromolecules, 6, 18581863 (2005). Singh, A. P., Wi, S. G., Chung, G. C., Kim, Y. S., and Kang, H.: Simple and rapid methods for SEM observation and TEM immunolabeling of rubber particles, J. Histochem. Cytochem., 51, 11051108 (2003). Gomez J. B., and Moir G. F. J: The ultracytology of latex vessels in Hevea brasiliensis, Monograph No. 4, p. 18. Malaysian Rubber Research and Development Board, Kuala Lumpur (1979). Ho, C. C., Subramaniam, A., and Yong, W. M.: Lipids associated with the particles in Hevea latex, Proc. Int. Rubb. Conf. Kuala Lumpur, 2, 441445 (1976). Southorn, W. A. and Yip, E.: Latex flow studies: III. Electrostatic considerations in the colloidal stability of fresh Hevea latex, J. Rubb. Res. Inst. Malaya, 20, 201215 (1968). Hasma, H.: Proteins of natural rubber latex concentrate, J. Nat. Rubb. Res., 7, 103107 (1992). Yunyongwattanakorn, J., Tanaka, Y., Sakdapipanich, J., and Wongsasutthikul, V.: Highly-purified natural rubber by saponification of latex: analysis of residual proteins in saponified natural rubber, Rubber Chem. Technol., 81, 121137 (2008). Bollag, D.M., Rozycki, M. D., and Edelstein, S. J.,: SDSpolyacrilamide gel electrophoresis, pp. 107154, in: Bollag, D. M., Rozycki, M. D., and Edelstein, S. J. (Eds.), Protein methods, 2nd ed. John Wiley & Sons, New York (1996). Carreau, J. P. and Dubacq, J. P.: Adaptation of macro-scale for fatty acid methyl transesterification of biological lipid extracts, J. Chromatogr., 151, 384390 (1978). Kawahara, S., Kakubo, T., Sakdapipanich, J. T., Isono, Y., and Tanaka, Y.: Characterization of fatty acids linked to natural rubber: role of linked fatty acids on crystallization of the rubber, Polymer, 41, 74837488 (2000). Chen, Z., Posch, A., Lohaus, C., Raulf-Heimsoth, M., Meyer, H. E., and Baur, X.: Isolation and identification of hevein as a major IgE-binding polypeptide in Hevea latex, J. Allergy Clin. Immunol., 99, 402409 (1997). Beezhold, D. H., Kostyal, D. A., and Sussman, G. L.: IgE epitope analysis of the hevein preprotein: a major latex allergen, Clin. Exp. Immunol., 108, 114121 (1997). Tanaka, Y., Kawahara, S., Eng, A. H., Shiba, K., and Ohya, N.: Initiation of biosynthesis in cis-polyisoprene, Phytochemistry, 39, 779784 (1995). Wong, P. T. T. and Mantsch, H. H.: High-pressure infrared spectroscopic evidence of water binding sites in 1, 2-diacylphospholipids, Chem. Phys. Lipids, 46, 213224 (1988). Tevini, M. and Schtainmuller, D.: Lipids, pp. 392424, in: Henschen, A., Hupe, K. P., Lottspeich, F., and Voelter, W. (Eds.), High performance liquid chromatography in biochemistry, Verlagsgesellschaft-VCH, Weinheim (1985). Ohshima, H. and Kondo, T.: Approximate analytic expression for the electrophoretic mobility of colloidal particles with surface-charge layers, J. Colloid Interface Sci., 130, 281282 (1989). Wood, D. F. and Cornish, K.: Microstructure of purified rubber particles, Int. J. Plant Sci., 161, 435445 (2000). Gomez, J. B. and Hamzah, S.: Particle size distribution in Hevea latex-some observations on the electron microscopic method, J. Nat. Rubb. Res., 4, 204211 (1989).

potential analyses also showed that there are phospholipidprotein layers surrounding the surface of the rubber particles to stabilize colloidal of NR latex. After removal of the phospholipidprotein layers by deproteinization and saponification, a surfactant layer replaced the phospholipid-protein layers on the surface of rubber particles. ACKNOWLEDGEMENTS This work was supported by the Thailand Research Fund (RSA 5280009) and Thailand Graduate Institute of Science and Technology (TGIST), as well as the Center of Excellence for Innovation in Chemistry (PERCH-CIC), Commission on Higher Education, Ministry of Education. References

1. Bonner, J. and Galston, A. W.: The physiology and biochemistry of rubber formation in plants, Bot. Rev., 13, 543596 (1947). 2. Cereijidom M., and Rotunno, C. A.: Introduction to the study of biological membranes, p. 10. Gordon and Breach, New York (1970). 3. Tata, S. J.: Distribution of proteins between the fractions of Hevea Latex separated by ultracentrifugation, J. Rubb. Res. Inst. Malaya, 28, 7785 (1980). 4. Archer, B. L. and Sekhar, B. C.: The proteins of Hevea brasiliensis latex: 1. Protein constituents of fresh latex serum, J. Biochem., 61, 503508 (1955). 5. Blackley, D. C.: High polymer lattices, pp. 35. Maclaren and Sons, London (1996). 6. Archer, B. L. and Cockbain, E. G.: The proteins of Hevea brasiliensis latex: 2. Isolation of the -globulin of fresh latex serum, J. Biochem., 61, 508512 (1955). 7. Karunakaran, A., Moir, G. F. J., and Tata S. J., The proteins of Hevea latex: ion exchange chromatography and starch gel electrophoresis, p. 798808. Proc. Nat. Rubb. Res. Conf. Kuala Lumpur (1960). 8. Bowler, W. W.: Electrophoretic mobility study of fresh Hevea latex, Ind. Eng. Chem., 45, 17901794 (1953). 9. Hasma, H. and Subramaniam, A.: Composition of lipids in RRIM 501 latex, J. Nat. Rubb. Res., 1, 3040 (1986). 10. Dupont, J., Moreau, F., Lance, C., and Jacob, J. L.: Phospholipid composition of the membrane of lutoids from Hevea brasiliensis latex, Phytochemistry, 15, 12151217 (1976). 11. Tarachiwin, L., Sakdapipanich, J., Ute, K., Kitayama, T., Bamba, T., Fukusaki, E., Kobayashi, A., and Tanaka, Y.: Structural characterization of r-terminal group of natural rubber: 1. decomposition of branch-points by lipase and phosphatase treatments, Biomacromolecules, 6, 18511857 (2005). 12. Tarachiwin, L., Sakdapipanich, J., Ute, K., Kitayama, T., and Tanaka, Y.: Structural characterization of -terminal group of natural rubber: 2. decomposition of

13.

14.

15. 16.

17. 18.

19.

20. 21.

22.

23. 24. 25.

26.

27.

28. 29.

You might also like

- Handbook of Composites from Renewable Materials, Biodegradable MaterialsFrom EverandHandbook of Composites from Renewable Materials, Biodegradable MaterialsNo ratings yet

- Effect of Proteins and Phospholipids 2Document14 pagesEffect of Proteins and Phospholipids 2Thu Trang LêNo ratings yet

- Slow release materials from epoxidized natural rubber and rice husk compositesDocument8 pagesSlow release materials from epoxidized natural rubber and rice husk compositesAlexander Franco CastrillonNo ratings yet

- Sustainable Development of Natural Rubber and Its Environmentally Friendly CompositesDocument6 pagesSustainable Development of Natural Rubber and Its Environmentally Friendly CompositesyixuanstarNo ratings yet

- Determination of Residual Monomers Released From Soft Lining Materials With The Use of HPLCDocument10 pagesDetermination of Residual Monomers Released From Soft Lining Materials With The Use of HPLCSaravanan ThangarajanNo ratings yet

- 10 1016@j Ijbiomac 2016 01 041Document39 pages10 1016@j Ijbiomac 2016 01 041Kaye FabrosNo ratings yet

- Removal of Proteins and Its Effect On Molecular Structure and Properties of Natural RubberDocument8 pagesRemoval of Proteins and Its Effect On Molecular Structure and Properties of Natural RubberThu Trang LêNo ratings yet

- Sami 2Document7 pagesSami 2Marwa ChaariNo ratings yet

- A Polilactic PDFDocument10 pagesA Polilactic PDFAdrian ChivuNo ratings yet

- Manroshan 2009 Comparison Between SodiumDocument11 pagesManroshan 2009 Comparison Between Sodiumsimbua72No ratings yet

- 3 FactorsDocument11 pages3 FactorsNgoc Son NguyenNo ratings yet

- Synthesis of Poly (Lactic Acid) A ReviewDocument26 pagesSynthesis of Poly (Lactic Acid) A ReviewTOUFIKNo ratings yet

- Pineapple Peel Fiber Biocomposite Charac (1)Document6 pagesPineapple Peel Fiber Biocomposite Charac (1)pazziuaganmarkNo ratings yet

- Polymers: Novel Functionalized Polythiophene-Coated Fe O Nanoparticles For Magnetic Solid-Phase Extraction of PhthalatesDocument18 pagesPolymers: Novel Functionalized Polythiophene-Coated Fe O Nanoparticles For Magnetic Solid-Phase Extraction of Phthalatessharifah sakinah syed soffianNo ratings yet

- App 1985 070300510Document24 pagesApp 1985 070300510Thivagaran VeeraiyaNo ratings yet

- 1 Ijbtrjun20171Document10 pages1 Ijbtrjun20171TJPRC PublicationsNo ratings yet

- MPIC Paper Mohd Hafez.1Document11 pagesMPIC Paper Mohd Hafez.1mhafez1979No ratings yet

- Chemical, Morphological and Mechanical Analysis of Sisal Fiber-Reinforced Recycled High-Density Polyethylene CompositesDocument9 pagesChemical, Morphological and Mechanical Analysis of Sisal Fiber-Reinforced Recycled High-Density Polyethylene CompositesAnonymous Pt7NHkat9No ratings yet

- Colloids and Surfaces A: Physicochemical and Engineering AspectsDocument10 pagesColloids and Surfaces A: Physicochemical and Engineering AspectsAdonilson FreitasNo ratings yet

- Lappaceum.: Surface-Active Properties of Extracted Saponin From The Leaves of NepheliumDocument6 pagesLappaceum.: Surface-Active Properties of Extracted Saponin From The Leaves of NepheliumThuong Vu ThanhNo ratings yet

- Natural Rubber LatexDocument13 pagesNatural Rubber Latexadrianrdeitos100% (1)

- Synthesis and Analysis of Palm-Based Esterquats for Fabric SofteningDocument5 pagesSynthesis and Analysis of Palm-Based Esterquats for Fabric SofteningDjango BoyeeNo ratings yet

- Enterobacter SP, Basic Red 9 PDFDocument10 pagesEnterobacter SP, Basic Red 9 PDFANGELICA RAMOS RAMIREZNo ratings yet

- Ecotoxicology and Environmental Safety: R. Sathish Kumar, G. Arthanareeswaran, Diby Paul, Ji Hyang KweonDocument6 pagesEcotoxicology and Environmental Safety: R. Sathish Kumar, G. Arthanareeswaran, Diby Paul, Ji Hyang KweonLintang Noor FitriaNo ratings yet

- Preparation of Pure and Stable Chitosan Nanofibers by Electrospinning in The Presence of Poly (Ethylene Oxide)Document16 pagesPreparation of Pure and Stable Chitosan Nanofibers by Electrospinning in The Presence of Poly (Ethylene Oxide)يحيى بورغدةNo ratings yet

- The Synthesis and Characterisation of Retinol-Molecularly Imprinted Polymers As A Selective Sorbent in Solid-Phase ExtractionDocument13 pagesThe Synthesis and Characterisation of Retinol-Molecularly Imprinted Polymers As A Selective Sorbent in Solid-Phase ExtractionNadia Putri UtamiNo ratings yet

- SPE-188174-MS Green EOR Utilizing Well-Defined Nano-Cellulose Based Nano-Fluids From Flask To FieldDocument13 pagesSPE-188174-MS Green EOR Utilizing Well-Defined Nano-Cellulose Based Nano-Fluids From Flask To FieldJosé Manuel UsuriagaNo ratings yet

- Eco Friendly Extraction and Characterization of Cellulose From Oil Plam Empty Fruit BunchesDocument12 pagesEco Friendly Extraction and Characterization of Cellulose From Oil Plam Empty Fruit BunchesJair Fajrdo LopezNo ratings yet

- Chemical Engineering and Processing: Process Intensi FicationDocument7 pagesChemical Engineering and Processing: Process Intensi FicationrukwavuNo ratings yet

- NR by BacterialDocument4 pagesNR by BacterialSITI FARHANA ABDUL RAOFNo ratings yet

- PREPARATION AND Nanoparticle Characterization Ketoconazole of Chitosan and Sodium Trifolifosfat METHOD Ionic GelationDocument7 pagesPREPARATION AND Nanoparticle Characterization Ketoconazole of Chitosan and Sodium Trifolifosfat METHOD Ionic GelationDR AtmajaNo ratings yet

- Polysaccharide AnchoredDocument10 pagesPolysaccharide AnchoredValentina RoznovNo ratings yet

- Aqueous Two-Phase Extraction of Bromelain From Pineapple Peels ('Phu Lae' Cultv.) and Its Biochemical PropertiesDocument9 pagesAqueous Two-Phase Extraction of Bromelain From Pineapple Peels ('Phu Lae' Cultv.) and Its Biochemical PropertiesThamNo ratings yet

- Characterization of Chitosan/PVA Blended FilmsDocument9 pagesCharacterization of Chitosan/PVA Blended FilmsBarfphinxx NamNo ratings yet

- Reinforced PLA Composites for Improved PropertiesDocument18 pagesReinforced PLA Composites for Improved PropertiesBerlian SitorusNo ratings yet

- 10.1016@j.talanta.2018.01.004 2Document31 pages10.1016@j.talanta.2018.01.004 2AmirNo ratings yet

- Box-Behnken Design Formulation Optimization and in Vitro Characterization of Rutin - Loaded Pla Nanoparticles Using Design-Expert SoftwareDocument13 pagesBox-Behnken Design Formulation Optimization and in Vitro Characterization of Rutin - Loaded Pla Nanoparticles Using Design-Expert SoftwareRAPPORTS DE PHARMACIENo ratings yet

- The Preparation and Characterization of ChitosanDocument9 pagesThe Preparation and Characterization of ChitosanEndarto YudoNo ratings yet

- Efectos de Las Cargas Art.Document8 pagesEfectos de Las Cargas Art.Vivi AbelloNo ratings yet

- Production of Polyhydroxyalkanoates From Sludge Palm Oil Using Pseudomonas Putida S12Document5 pagesProduction of Polyhydroxyalkanoates From Sludge Palm Oil Using Pseudomonas Putida S12Shandyka YudhaNo ratings yet

- Graft Copolymerization of Soy Protein Isolate WithDocument15 pagesGraft Copolymerization of Soy Protein Isolate WithZahra MarjaniNo ratings yet

- Jurnal BiofisDocument8 pagesJurnal BiofisMega Juliyanti AlamsyahNo ratings yet

- Physicochemical and Micromeritics Properties of Ketoprofen-Tartaric Acid Binary SystemDocument8 pagesPhysicochemical and Micromeritics Properties of Ketoprofen-Tartaric Acid Binary SystemAziza Anggi MaiyantiNo ratings yet

- Zhang2013 Article DegradationOfParacetamolByPureDocument12 pagesZhang2013 Article DegradationOfParacetamolByPureahmed salahNo ratings yet

- Food Chemistry: Analytical MethodsDocument6 pagesFood Chemistry: Analytical MethodsFafa AlunksNo ratings yet

- Acido Citrico Dendrimeri PegDocument7 pagesAcido Citrico Dendrimeri PegSerena TorcasioNo ratings yet

- Jurnal 2 KoagulanDocument8 pagesJurnal 2 KoagulanfauzanNo ratings yet

- Par TechDocument6 pagesPar TechJAN JERICHO MENTOYNo ratings yet

- Novel Nanocomposites Based On gelatin/HPET/chitosan With High Performance Acid Red 150 Dye AdsorptionDocument8 pagesNovel Nanocomposites Based On gelatin/HPET/chitosan With High Performance Acid Red 150 Dye AdsorptionJefersonCorreiaNo ratings yet

- Nano Askorbil 1Document6 pagesNano Askorbil 1Agung PerkasaNo ratings yet

- ZZZZ PDFDocument4 pagesZZZZ PDFahmet375No ratings yet

- Optimization of Flotation EfficiencDocument17 pagesOptimization of Flotation Efficiencyang.xiaoNo ratings yet

- Preparation of NBR Polyol by Oxidative DegradationDocument10 pagesPreparation of NBR Polyol by Oxidative DegradationhamedNo ratings yet

- 1 s2.0 S0272884207001514 MainDocument5 pages1 s2.0 S0272884207001514 MainsivaNo ratings yet

- An Electrodeposited Terephthalic Acid-Layered Double Hydroxide (Cu-Cr) Nanosheet Coating For In-Tube Solid-Phase Microextraction of Phthalate EstersDocument10 pagesAn Electrodeposited Terephthalic Acid-Layered Double Hydroxide (Cu-Cr) Nanosheet Coating For In-Tube Solid-Phase Microextraction of Phthalate EstershanieNo ratings yet

- Caracterización de Fibras Electrohiladas Mezcladas Con Poliamida-6 PropóleoDocument10 pagesCaracterización de Fibras Electrohiladas Mezcladas Con Poliamida-6 PropóleoJuan Fernando Restrepo ZuluagaNo ratings yet

- J Biomedical Materials Res - 2011 - GhasabanDocument9 pagesJ Biomedical Materials Res - 2011 - Ghasaban발라드님No ratings yet

- Paracetamol GroundnutShellsDocument11 pagesParacetamol GroundnutShellsRajesh KannanNo ratings yet

- Starch-based biodegradable film properties with nano-SiO2Document6 pagesStarch-based biodegradable film properties with nano-SiO2sakshiNo ratings yet

- Mechanical, Color and Barrier, Properties of Biodegradable. 2018Document7 pagesMechanical, Color and Barrier, Properties of Biodegradable. 2018yurinnelNo ratings yet

- Jpa 2014118462Document17 pagesJpa 2014118462Steven LauNo ratings yet

- University College LondonDocument3 pagesUniversity College LondonSteven LauNo ratings yet

- Separation Process ExerciseDocument3 pagesSeparation Process ExerciseSteven LauNo ratings yet

- 2014 2015 CWK.4Document1 page2014 2015 CWK.4Steven LauNo ratings yet

- A GAMS Tutorial: by Richard E. RosenthalDocument21 pagesA GAMS Tutorial: by Richard E. RosenthalKaren Yuriko KatoNo ratings yet

- University College LondonDocument3 pagesUniversity College LondonSteven LauNo ratings yet

- Ceng3007 03Document4 pagesCeng3007 03Steven LauNo ratings yet

- Theoretical Insight Into Oxidative Decomposition of Propylene Carbonate in The Lithium Ion BatteryDocument7 pagesTheoretical Insight Into Oxidative Decomposition of Propylene Carbonate in The Lithium Ion BatterySteven LauNo ratings yet

- Theoretical Insight Into Oxidative Decomposition of Propylene Carbonate in The Lithium Ion BatteryDocument7 pagesTheoretical Insight Into Oxidative Decomposition of Propylene Carbonate in The Lithium Ion BatterySteven LauNo ratings yet

- 2009 Physics Paper 2Document18 pages2009 Physics Paper 2Steven LauNo ratings yet

- Us 20100119715 A 1Document4 pagesUs 20100119715 A 1Steven LauNo ratings yet

- 2009CEmock-Bio1 Q (Eng) RoyTseDocument24 pages2009CEmock-Bio1 Q (Eng) RoyTseSteven LauNo ratings yet

- 2009 Physics Paper 1Document20 pages2009 Physics Paper 1Steven LauNo ratings yet

- 2009CEmock-Maths2 Q&A OscarTamDocument38 pages2009CEmock-Maths2 Q&A OscarTamSteven LauNo ratings yet

- 0001981572-JAR Resources in JNLP File Are Not Signed by Same CertificateDocument13 pages0001981572-JAR Resources in JNLP File Are Not Signed by Same CertificateAnonymous AZGp1KNo ratings yet

- Kalayaan Elementary SchoolDocument3 pagesKalayaan Elementary SchoolEmmanuel MejiaNo ratings yet

- Introducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionDocument9 pagesIntroducing WESAD, A Multimodal Dataset For Wearable Stress and Affect DetectionJhónatan CarranzaNo ratings yet

- Ikan Di Kepualauan Indo-AustraliaDocument480 pagesIkan Di Kepualauan Indo-AustraliaDediNo ratings yet

- Epoxy Hardeners, Water-Reducible: ProductsDocument1 pageEpoxy Hardeners, Water-Reducible: ProductsDhruv SevakNo ratings yet

- Superalloy Brochure PDFDocument16 pagesSuperalloy Brochure PDFDaren NeradNo ratings yet

- Lab Manual MCSE 101Document35 pagesLab Manual MCSE 101Juan JacksonNo ratings yet

- Velocity profiles and incompressible flow field equationsDocument2 pagesVelocity profiles and incompressible flow field equationsAbdul ArifNo ratings yet

- Meeting 5: Data Warehouses and SQL Query OptimizationDocument4 pagesMeeting 5: Data Warehouses and SQL Query Optimizationzvipev1050% (2)

- 98 99 Anti Lock BrakesDocument101 pages98 99 Anti Lock BrakestrialnaqueraNo ratings yet

- Austenitic Stainless SteelsDocument10 pagesAustenitic Stainless SteelsbramNo ratings yet

- Service Manual: S&T Motors Co., LTDDocument94 pagesService Manual: S&T Motors Co., LTDJuliano PedrosoNo ratings yet

- A320 CBT Test 1 PDFDocument107 pagesA320 CBT Test 1 PDFCesarNo ratings yet

- Exam 1 Study Guide Bio 6C Ecology and EvolutionDocument2 pagesExam 1 Study Guide Bio 6C Ecology and EvolutionVyNguyễn0% (1)

- Winegard Sensar AntennasDocument8 pagesWinegard Sensar AntennasMichael ColeNo ratings yet

- Submittal Chiller COP 6.02Document3 pagesSubmittal Chiller COP 6.02juan yenqueNo ratings yet

- P2 Chp5 RadiansDocument28 pagesP2 Chp5 RadiansWaqas KhanNo ratings yet

- Smart Dustbin using ArduinoDocument22 pagesSmart Dustbin using ArduinoEr Dinesh TambeNo ratings yet

- Material Balance of Naphtha Hydrotreater and Reformer ReactorsDocument22 pagesMaterial Balance of Naphtha Hydrotreater and Reformer ReactorsSukirtha GaneshanNo ratings yet

- Spesifikasi ACER Travelmate P2-P245Document12 pagesSpesifikasi ACER Travelmate P2-P245Sebastian Fykri AlmuktiNo ratings yet

- Music GcseDocument45 pagesMusic GcseAimee DohertyNo ratings yet

- 02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0Document5 pages02-OceanStor Dorado 3 Highlights and 9 Must-Know Points 1.0QQNo ratings yet

- Biogen 2021Document12 pagesBiogen 2021taufiq hidNo ratings yet

- CI SetDocument18 pagesCI Setতন্ময় ঢালি Tanmay DhaliNo ratings yet

- Goniophotometer T1: OxytechDocument6 pagesGoniophotometer T1: OxytechGustavo CeccopieriNo ratings yet

- Pumps - IntroductionDocument31 pagesPumps - IntroductionSuresh Thangarajan100% (1)

- WPS Office 2016Document22 pagesWPS Office 2016Muhammad Aliff SyukriNo ratings yet

- Midterm Exam Result Ce199-1l 2Q1920Document3 pagesMidterm Exam Result Ce199-1l 2Q1920RA CarpioNo ratings yet

- Sample Question Paper Provides Practice for Class 9 Science ExamDocument5 pagesSample Question Paper Provides Practice for Class 9 Science ExamViswak BalajiNo ratings yet

- Solomons Organic Chemistry Solution Manual - Chapter 3Document12 pagesSolomons Organic Chemistry Solution Manual - Chapter 3Imanghh25% (4)