Professional Documents

Culture Documents

Plywood Beam Design

Uploaded by

Nick RosatiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plywood Beam Design

Uploaded by

Nick RosatiCopyright:

Available Formats

D A T A F I L E

Nai led Structural-Use

Panel and Lumber Beams

A P A

T h e E n g i n e e r e d W o o d A s s o c i a t i o n

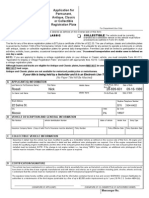

End stiffener

Upper flange

Lower flange

Panel joint

Panel web

Stiffener

Panel joint

Panel web

When roof load or span requirements

are too great to allow use of commonly

available dimension lumber or timbers, a

box beam constructed of lumber and

APA trademarked structural-use panels

can solve the problem. It offers an inex-

pensive alternative to steel or glued

laminated wood beams.

Nailed structural-use panel and lumber

beams have many other advantages, too.

Among them are:

Stiffness and strength

Light weight

No shrinkage, warping, or twisting

Ease of fabrication

Materials availability

Speedy, easy installation

Easily insulated, where necessary

Parts of a box beam are shown in the

diagram. The lumber flanges carry most

of the bending stresses and the struc-

tural panel webs transmit the shear

stresses. Vertical stiffeners between the

flanges act as shear splices at panel butt

joints, distribute concentrated loads and

end reactions, and resist web buckling.

The fasteners transfer the stresses

between the lumber and panel parts.

BASIC COMPONENTS

DF Z416 for pdf 4/18/00 4:26 PM Page 1

1999 APA - The Engineered Wood Association

2

The cross-sections A, B, and C refer

to the constructions shown in the

sketches. The loads in the tables are

given in pounds per linear foot. The

lumber and structural panel grades used

for calculating the tables are:

Lumber: 2x4 or 2x6 No. 1 Douglas-fir or

No. 1 southern pine (unless otherwise

noted, reduce allowable loads by 15%for

No. 2 Douglas-fir or No. 2 southern pine).

Structural Panels: APA RATED

SHEATHINGExposure 1, oriented

strand board (OSB), composite panels

(COM-PLY

), 4- or 5-ply plywood.

Three-ply plywood may be used if

regraded for core gap restrictions (see

item3 in the Fabrication section).

Substitution of higher grades or thick-

nesses may not result in higher allowable

loads, depending upon what limitation

controls the design. Also, the calculations

assume full-length flange lumber. For this

reason, beam length is usually limited to

that of available lumber.

CROSS SECTIONS

A

B

C

ALLOWABLE LOAD

(a)

FOR 12"-DEEP ROOF BEAM OR HEADER (lb/ lin ft)

Approx. Wt.

Structural Cross-

per Ft (lb)

Span (ft)

Wood Panel Section 2 x 4 2 x 6 10 12 14 16 18 20 22 24

15/32" 32/16 A 6 8 278* 232* 192 147 116 94 78 64

15/32" 32/16 B 9 12 339* 283* 242* 212 176 143 118 91

23/32" 48/24 B 11 14 408* 340 291 223 176 143 118 95

23/32" 48/24 C 13 17 234 198 160 133 105

ALLOWABLE LOAD

(a)

FOR 16"-DEEP ROOF BEAM OR HEADER (lb/ lin ft)

Approx. Wt.

Structural Cross-

per Ft (lb)

Span (ft)

Wood Panel Section 2 x 4 2 x 6 10 12 14 16 18 20 22 24

15/32" 32/16 A 8 10 393* 328* 274 210 166 134 111 93

15/32" 32/16 B 10 13 475* 396* 340* 297 264 219 181 152

23/32" 48/24 B 13 16 569* 474* 406 342 270 219 181 152

23/32" 48/24 C 15 19 295 266 219 184

ALLOWABLE LOAD

(a)

FOR 20"-DEEP ROOF BEAM OR HEADER (lb/ lin ft)

Approx. Wt.

Structural Cross-

per Ft (lb)

Span (ft)

Wood Panel Section 2 x 4 2 x 6 10 12 14 16 18 20 22 24

15/32" 32/16 A 9 11 515* 429* 357 273 216 175 144 121

15/32" 32/16 B 12 15 610* 509* 436* 381* 339* 297 246 207

23/32" 48/24 B 15 18 728* 607* 520* 455* 367 297 246 207

23/32" 48/24 C 17 22 385* 346 312 262

ALLOWABLE LOAD

(a)

FOR 24"-DEEP ROOF BEAM OR HEADER (lb/ lin ft)

Approx. Wt.

Structural Cross-

per Ft (lb)

Span (ft)

Wood Panel Section 2 x 4 2 x 6 10 12 14 16 18 20 22 24

15/32" 32/16 A 11 13 643* 536* 439 336 266 215 178 149

15/32" 32/16 B 13 16 744* 620* 531* 465* 413 372 312 262

23/32" 48/24 B 16 20 885* 738* 632* 553 465 377 312 262

23/32" 48/24 C 18 24 474* 427 388 342

(a) Includes 15%snow loading increase.

*Lumber may be No. 2 Douglas-fir or No. 2 southern pine without reduction of tabulated capacity.

1

9

9

9

A

P

A

T

H

E

E

N

G

I

N

E

E

R

E

D

W

O

O

D

A

S

S

O

C

I

A

T

I

O

N

A

L

L

R

I

G

H

T

S

R

E

S

E

R

V

E

D

.

A

N

Y

C

O

P

Y

I

N

G

,

M

O

D

I

F

I

C

A

T

I

O

N

,

D

I

S

T

R

I

B

U

T

I

O

N

O

R

O

T

H

E

R

U

S

E

O

F

T

H

I

S

P

U

B

L

I

C

A

T

I

O

N

O

T

H

E

R

T

H

A

N

A

S

E

X

P

R

E

S

S

L

Y

A

U

T

H

O

R

I

Z

E

D

B

Y

A

P

A

I

S

P

R

O

H

I

B

I

T

E

D

B

Y

T

H

E

U

.

S

.

C

O

P

Y

R

I

G

H

T

L

A

W

S

.

These tables show allowable loading for

two typical thicknesses and Span Ratings

of structural panels. The Span Rating, a

set of two numbers separated by a slash

(for example, 32/16), is contained in the

APA trademark for structural panel

sheathing grades.

In the first column of each table, the

minimum nominal panel thickness is

given first, followed by the Span

Rating number.

DF Z416 for pdf 4/18/00 4:26 PM Page 2

3

Tables are also based on the following:

Deflection: Less than 1/240 of span under

total load.

N ailing: 8d common 1-1/2" o.c. each

flange member (spacing may be doubled

in middle half of beam).

Design

In order to build a box beam that will do

the job, you must first determine the

load requirements. Here is an example.

1. Figure the load on a beam.

Assume that a header using 2x4 lumber

is to span an 18-foot garage door open-

ing, where the roof is supported by

20-foot-long trusses, including a 1-foot

eave on each end.

The total roof load consists of 25psf

design snow load (check your local build-

ing code) plus 10psf dead load, which is

the weight of the materials in the roof.

This total load of 35psf is carried to the

garage-door header and to the back wall

of the garage. Thus, the design load on

the header is:

35 psf x

20 ft

= 350 plf

____

2

2. Find theappropriatebeamdesign.

Look in the 18-foot-span column of the

load-span tables and find a beam ade-

quate to support 350plf plus the weight

of the beam. Such a beam is 24inches

deep and consists of two 2x4 flange

members top and bottom (cross

sectionB), and 15/32" structural panel

webs. This beam has an allowable load of

413plf. The total load on this beam will

be 350plf plus 13plf, or 363plf.

Fabrication

There are just three simple steps in con-

structing a structural panel-and-lumber

box beam.

1. Determine the width of framing

lumber necessary to match wall

thickness and layout of stiffeners

and the panel butt joints.

The panel joint locations illustrated in

the sketches provide the required mini-

mum 2-foot stagger between panel butt

joints on opposite sides of the beam.

They also locate all butt joints within the

Garage door header

1

8

'

2

0

'

DESIGN EXAMPLE: GARAGE DOOR HEADER

DF Z416 for pdf 4/18/00 4:26 PM Page 3

1999 APA - The Engineered Wood Association

4

middle half of the beam. This technique

allows the stiffeners to act as web shear

splices. Vertical stiffeners should be

added in the layouts so that they are

no farther apart than 4 feet.

The 6inches (0.5foot) added to the

clear spans shown in the load-span tables

represent the bearing length of both

double end stiffeners.

2. Build the framework of lumber

flanges and stiffeners.

Dry lumber should be used (not over

19%moisture content). Select full-length

flange lumber which is free of warp or

characteristics that would produce gaps

greater than 1/8" between lumber and

structural panel.

Lay out stiffeners and flanges accurately

in the pattern selected in Step1. Fasten

the flanges to the stiffeners with

8dcommon nails.

Double end stiffeners may be installed

between flanges. Frequently, however, it

is desirable to extend the end stiffeners

through the depth of the beam to allow

use of shorter-length flange lumber. On

other occasions, it may be desirable to

extend the top flange lamination beyond

the beam end to tie into the wall framing.

3. Fasten the panel webs to the

framework.

If 3-ply plywood is to be used, inspect

the plywood panels within 15% of each

end of the box beam to assure that no

core gap exceeds 1/4" width.

The flanges should be marked to show

location of stiffener centerlines. The panel

should be installed with its strength axis

in the same direction as the flanges, and

with the butt joints occurring over the

stiffeners, as determined in Step 1.

All beams in the load-span tables func-

tion with 8d common nails spaced

1-1/2" on center on each side of each

flange lamination. The spacing may be

doubled to 3" on center in the middle

half of the beam. Use corrosion-resistant

nails if the beam is exposed to moisture.

If staples, or nails of other sizes or types

are used, the spacing must be adjusted in

proportion to the allowable lateral load

for the fasteners selected. For instance,

fasteners allowed half the lateral load of

6' to 6-1/2'

1/2'

4' to 4-1/2'

4' to 4-1/2'

4' to 4-1/2'

6' to 6-1/2'

6' to 6-1/2'

6' to 6-1/2'

4'

10' to 10-1/ 2'

4'

8'

8'

12' to 12-1/ 2'

4'

8'

14' to 14-1/ 2'

4'

8'

16' to 16-1/ 2'

8' 8'

4'

5' to 5-1/2'

4' to 4-1/2'

4' to 4-1/2'

5' to 5-1/2'

5' to 5-1/2'

2'' to 2-1/2'

6' to 6-1/2'

6' to 6-1/2'

7' 8'

20' to 20-1/2'

7' 8'

6' 4' 8'

6' 4' 8'

24' to 24-1/2'

6' 4' 8'

6' 4' 8'

22' to 22-1/2'

8'

18' to 18-1/2'

5'

8' 8'

WEB JOINT LAYOUTS

DF Z416 for pdf 4/18/00 4:26 PM Page 4

1999 APA - The Engineered Wood Association

5

8d common nails would be spaced half

as far apart. For staples, the closer spac-

ing can be used because there is less

tendency to split the lumber.

Although the nailing shown is struc-

turally adequate for loads presented in

the tables, additional stiffness can be

developed by including glue at the inter-

faces. Any type of available wood adhe-

sive will contribute to performance, but

do not use it instead of any of the nails

required in the design.

RATED SHEATHING

EXPOSURE 1

SIZED FOR SPACING

32/16

15/32 INCH

000

PRP-108

THE ENGINEERED

WOOD ASSOCIATION

APA

Header

(web removed)

16d Nails

at 6" o.c.

Wall framing

Header

16d Nails

at 6" o.c.

Wall framing

HEADER ATTACHMENT DETAILS

ALTERNATE TOP FLANGE SUPPORT

Sheathing or siding over; or set beam out thickness of

sheathing and butt sheathing to web.

APA: the Mark of Quality

The trademarks of APA The Engineered

Wood Association appear only on products

manufactured by APA member mills. The

marks signify that the manufacturer is

committed to APAs rigorous quality

inspection and testing program and that

panel quality is subject to verification

through APA audit a procedure

designed to assure manufacture in confor-

mance with APA performance standards

or Voluntary Product Standard PS 1-95 for

Construction and Industrial Plywood. Always

insist on panels bearing the mark of

quality the APA trademark.

1-1/2"Nail spacing*

1/2"Stagger

3"

1/2"Stagger

NAILING LAYOUT

*When end stiffeners extend through the

beam, nail spacing is the same as for

flanges, except space nails 1 in. on center

when double end stiffeners are used in

beams with three members per flange

(cross-section C). When end stiffeners are

inserted between flanges, nails may be

spaced 3 inches on center.

DF Z416 for pdf 4/18/00 4:26 PM Page 5

1999 APA - The Engineered Wood Association

A P A

T h e E n g i n e e r e d W o o d A s s o c i a t i o n

We have field representatives in most

major U.S. cities and in Canada who can

help answer questions involving APA

trademarked products. For additional

assistance in specifying APA engineered

wood products, get in touch with your

nearest APA regional office. Call or write:

WESTERN REGI ON

7011 So. 19th St.

I

P.O. Box 11700

Tacoma, Washington 98411-0700

(253) 565-6600

I

Fax: (253) 565-7265

EASTERN REGI ON

2130 Barrett Park Drive, Suite 102

Kennesaw, Georgia 30144-3681

(770) 427-9371

I

Fax: (770) 423-1703

U. S. HEADQUARTERS

AND I NTERNATI ONAL

MARKETI NG DI VI SI ON

7011 So. 19th St.

I

P.O. Box 11700

Tacoma, Washington 98411-0700

(253) 565-6600

I

Fax: (253) 565-7265

PRODUCT SUPPORT HELP DESK

(253) 620-7400

E-mail Address: help@apawood.org

(Offices: Antwerp, Belgium; Bournemouth,

United Kingdom; Hamburg, Germany;

Mexico City, Mexico; Tokyo, Japan.) For

Caribbean/Latin America, contact

headquarters in Tacoma.

The product use recommendations in this

publication are based on APA The

Engineered Wood Associations continuing

programs of laboratory testing, product

research, and comprehensive field experi-

ence. However, because the Association has

no control over quality of workmanship or

the conditions under which engineered wood

products are used, it cannot accept responsi-

bility for product performance or designs as

actually constructed. Because engineered

wood product performance requirements

vary geographically, consult your local archi-

tect, engineer or design professional to

assure compliance with code, construction,

and performance requirements.

Form No. Z416S

Revised May 1999/0050

www.apawood.org

@

W

e

b

Addre

s

s

:

DF Z416 for pdf 4/18/00 4:26 PM Page 6

1999 APA - The Engineered Wood Association

You might also like

- The U.S. Craft Distilling Market: 2015 UpdateDocument15 pagesThe U.S. Craft Distilling Market: 2015 UpdateNick RosatiNo ratings yet

- Bobcat 250 NTDocument80 pagesBobcat 250 NTNick RosatiNo ratings yet

- BizPlanningforNonProfits 0Document38 pagesBizPlanningforNonProfits 0warriorbride100% (1)

- Socket GuideDocument16 pagesSocket GuideNick RosatiNo ratings yet

- Pa Rev-72Document12 pagesPa Rev-72Nick Rosati0% (1)

- Standard For Design of Timber Frame Structures and CommentaryDocument49 pagesStandard For Design of Timber Frame Structures and CommentaryNick RosatiNo ratings yet

- Obtain PA Antique, Classic or Collectible PlateDocument2 pagesObtain PA Antique, Classic or Collectible PlateNick RosatiNo ratings yet

- Beretta AR70 Owner ManualDocument40 pagesBeretta AR70 Owner ManualNick RosatiNo ratings yet

- Maadi-Griffin 50 Cal. Rifle PlansDocument107 pagesMaadi-Griffin 50 Cal. Rifle PlansAride4ever88% (26)

- AirpowerDocument4 pagesAirpowerNick RosatiNo ratings yet

- AK47 Parts Blueprints in ARABICDocument256 pagesAK47 Parts Blueprints in ARABICNick Rosati90% (10)

- Newmanf PDFDocument62 pagesNewmanf PDFNick RosatiNo ratings yet

- Aquarail JetskiDocument6 pagesAquarail Jetskitony_williams_4No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Religion in Space Science FictionDocument23 pagesReligion in Space Science FictionjasonbattNo ratings yet

- ML AiDocument2 pagesML AiSUYASH SHARTHINo ratings yet

- Xii Neet Chemistry Mcqs PDFDocument30 pagesXii Neet Chemistry Mcqs PDFMarcus Rashford100% (3)

- Fraktur Dentoalevolar (Yayun)Document22 pagesFraktur Dentoalevolar (Yayun)Gea RahmatNo ratings yet

- Revolutionizing Energy Harvesting Harnessing Ambient Solar Energy For Enhanced Electric Power GenerationDocument14 pagesRevolutionizing Energy Harvesting Harnessing Ambient Solar Energy For Enhanced Electric Power GenerationKIU PUBLICATION AND EXTENSIONNo ratings yet

- KoyoDocument4 pagesKoyovichitNo ratings yet

- ASA 2018 Catalog WebDocument48 pagesASA 2018 Catalog WebglmedinaNo ratings yet

- Maintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFDocument39 pagesMaintenance Handbook On Compressors (Of Under Slung AC Coaches) PDFSandeepNo ratings yet

- Lincoln Pulse On PulseDocument4 pagesLincoln Pulse On PulseEdison MalacaraNo ratings yet

- RPG-7 Rocket LauncherDocument3 pagesRPG-7 Rocket Launchersaledin1100% (3)

- Design of Fixed Column Base JointsDocument23 pagesDesign of Fixed Column Base JointsLanfranco CorniaNo ratings yet

- Product ListDocument4 pagesProduct ListyuvashreeNo ratings yet

- ProtectionDocument160 pagesProtectionSuthep NgamlertleeNo ratings yet

- Material and Energy Balance: PN Husna Binti ZulkiflyDocument108 pagesMaterial and Energy Balance: PN Husna Binti ZulkiflyFiras 01No ratings yet

- ROMUS 2012 Flooring CatalogueDocument20 pagesROMUS 2012 Flooring CatalogueDan George IIINo ratings yet

- IEEE T&D Insulators 101 Design CriteriaDocument84 pagesIEEE T&D Insulators 101 Design Criteriasachin HUNo ratings yet

- EP - EngineDocument4 pagesEP - EngineAkhmad HasimNo ratings yet

- Home Brewing Log Sheet PDFDocument2 pagesHome Brewing Log Sheet PDFStefanita0% (1)

- Math 202: Di Fferential Equations: Course DescriptionDocument2 pagesMath 202: Di Fferential Equations: Course DescriptionNyannue FlomoNo ratings yet

- DENSO COMMON RAIL INJECTOR REPAIR GUIDEDocument22 pagesDENSO COMMON RAIL INJECTOR REPAIR GUIDEMarcoNo ratings yet

- Chapter 16 - Energy Transfers: I) Answer The FollowingDocument3 pagesChapter 16 - Energy Transfers: I) Answer The FollowingPauline Kezia P Gr 6 B1No ratings yet

- Flowing Gas Material BalanceDocument4 pagesFlowing Gas Material BalanceVladimir PriescuNo ratings yet

- European GMP Annex 1 - 2008 Edition - 'Pmeasuring'Document3 pagesEuropean GMP Annex 1 - 2008 Edition - 'Pmeasuring'Khairul AnwarNo ratings yet

- Rotary Twin Scew Brochure UK HRDocument20 pagesRotary Twin Scew Brochure UK HRNguyễn Hữu DũngNo ratings yet

- Problem SolutionsDocument5 pagesProblem SolutionskkappaNo ratings yet

- VT6050 VT6010 QuickGuide ENDocument19 pagesVT6050 VT6010 QuickGuide ENPriyank KumarNo ratings yet

- Elements of ClimateDocument18 pagesElements of Climateእኔ እስጥፍNo ratings yet

- India - Wikipedia, The Free EncyclopediaDocument40 pagesIndia - Wikipedia, The Free EncyclopediaPrashanth KrishNo ratings yet

- Front Wheel Steering System With Movable Hedlights Ijariie5360Document6 pagesFront Wheel Steering System With Movable Hedlights Ijariie5360Ifra KhanNo ratings yet

- Plate-Load TestDocument20 pagesPlate-Load TestSalman LakhoNo ratings yet