Professional Documents

Culture Documents

Ee 123 Handouts Machines

Uploaded by

Ricardo VelozCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ee 123 Handouts Machines

Uploaded by

Ricardo VelozCopyright:

Available Formats

EE 123 HANDOUTS : ELECTRICAL MACHINES

Generators converts mechanical energy to electrical energy Motor converts electrical energy to mechanical energy Transformers converts electrical energy of one form to electrical energy of another form. NOTES ON DC Machines PARTS OF A DC MACHINE: a. Two Main Parts: 1. Stationary part designed mainly for producing magnetic flux 2. Rotating part called armature, where mechanical energy is converted into electrical energy (generator) or electrical energy converted into mechanical energy (motor). b. Various parts 1. Frame 4. Field poles 7. Commutator poles 2. Armature 5. Brush Gear 8. Armature windings 3. Commutator 6. Armature shaft bearings Two types of Armature Windings according to the degree of closure 1. Open Coil Winding 2. Closed Coil Winding Two Types of Closed Armature Winding 1. Ring Winding 2. Drum Winding Two Types of Drum Winding 1. Lap winding suitable for comparatively low voltage but high current generators. The finish of each coil is connected to the start of the next coil so that winding or commutator pitch is unity. 2. Wave winding suitable for comparatively low current but high voltage generators. The finish of coil is connected to the start of another coil electrical degrees away from the first coil. Types of DC Generators: 1. According to method of Excitation: a. Separately excited generators generators whose field magnets are energized from an independent external source of DC current. b. Self excited generators whose field magnets are energized by the current produced by the generators themselves. 2. According to how the field windings are connected: (Refer to Figure) a. Shunt wound generators b. Series woung generators c. Compound wound generators 1. Short Shunt 2. Long SHUNT Losses in a DC generator: 1. Copper Losses a. Armature Copper Loss Ia2Ra b. Shunt Copper Loss Ish2Rsh or VtRsh c. Series Copper Loss Ise2Rse d. Loss due to brush contact resistance

Ia - armature current Ra armature resistance Ish Shunt field current Rsh shunt field resistance

Vt - terminal voltage 2. Iron Loss (Core Loss) Rse Series Field Resistance 1.6 a. Hysteresis loss Ph = Kh (Bmax) N watts Ise - series field current b. Eddy Current Loss Pe = Ke(BmaxNt)2 watts Pe Eddy Current loss c. Mechanical Loss Friction and Windage Ph Hyteresis Loss Kh , Ke proportionality constant 3. Mechanical Loss Friction & Windage Bmax maximum flux density N speed of armature rotation t thickness of armature core lamination Requirements for the parallel operation of DC generator: 1. the same external characteristics or behaviors when loaded 2. terminal voltage of each machine must be numerically equal 3. terminal polarity must be the same Advantages of operating in parallel over single operation 1. no generator will be overloaded 2. good maintenance procedure 3. continuity of service Alternator also called as synchronous generators. An alternating current generator. Requirements for parallel operation of alternator 1. operating frequency must be equal 2. line to line voltage must be equal 3. phase sequence must be the same TRANSFORMERS: Characteristics: a. According to the core used 1. Core type transformer 2. Shell type transformer b. According to method of cooling the windings 1. Self-cooled transformer 2. Oil-self cooled transformer 3. Forced-oil cooled transformer 4. Force-air cooled transformer c. According to purpose of applications 1. Distribution type transformer 2. Instrument type transformer 3. Power transformer 4. Welding transformer 5. Rectifier transformer 6. Regulating transformer 7. Lighting transformer d. According to voltage transformation 1. Step-up transformer (low to high) 2. Step-down transformer (high to low)

Parallel operation of transformers Requirements: 1. voltage ratio must be the same 2. transformers must be properly connected as to polarity 3. the ratio of the equivalent resistance to reactance of all transformers should be the same Autotransformer a transformer with only one winding common to both primary and secondary windings. Instruments transformers used in conjunction with an ammeter or a voltmeter to measure relatively large values of current or voltage. a. Current transformer (CT) the primary terminals is connected in series to line in which the current flowing through it is to be measured while an ammeter of suitable range is connected across the secondary terminals. b. Potential transformer (PT) the primary terminals is connected across the high voltage line in which the voltage across it is to be measured while a voltmeter of suitable range is connected across the secondary terminals.

Standard kVA ratings of SINGLE PHASE TRANSFORMERS 1, 1 , 2, 3, 5, 7 , 15, 20, 25, 30, 37 , 50, 75, 100, 150, 167, 200, 250, 333 and 500

Standard kVA ratings of THREE PHASE TRANSFORMERS 3, 6, 9, 15, 20, 25, 30, 37 , 45, 50, 60, 75, 100, 112 , 150, 200, 225, 300, 400, 500, 750, 1000, 1500 and 2000

You might also like

- EE 2802 - Transformers - Concise NoteDocument10 pagesEE 2802 - Transformers - Concise NoteLasal RNo ratings yet

- Electrical Machine 7-26-2016Document94 pagesElectrical Machine 7-26-2016Engr. Raheel khanNo ratings yet

- AC Generator Regulation: How Load and Power Factor Affect VoltageDocument71 pagesAC Generator Regulation: How Load and Power Factor Affect Voltagenoveas u. eroisaNo ratings yet

- Summary of DC GeneratorDocument10 pagesSummary of DC GeneratorChristopher YsitNo ratings yet

- Electrical Machines 2 AC MachinesDocument654 pagesElectrical Machines 2 AC Machinesgokulchandru89% (19)

- Electric Motors and Generators: Jitendra Kumar 1103107Document40 pagesElectric Motors and Generators: Jitendra Kumar 1103107bhuvanaNo ratings yet

- Bab 1-DC GeneratorDocument52 pagesBab 1-DC GeneratorKhairul AnnuarNo ratings yet

- Pablo Borbon Main II, Alangilan Batangas CityDocument9 pagesPablo Borbon Main II, Alangilan Batangas CityJoseph JeremyNo ratings yet

- Electrical SystemDocument42 pagesElectrical SystemSamiha Maysoon NooriaNo ratings yet

- BASIC ELECTRICAL AND ELECTRONICS ENGINEERINGDocument80 pagesBASIC ELECTRICAL AND ELECTRONICS ENGINEERINGSIVAPRASAD KOLLATI GIEREEE100% (1)

- Types of Welding Power SourcesDocument12 pagesTypes of Welding Power SourcesRyanM.PradelNo ratings yet

- PROJECT WORK SubstationDocument91 pagesPROJECT WORK SubstationSai Royals100% (1)

- DC motor speed control experimentDocument5 pagesDC motor speed control experimenttahiaNo ratings yet

- DC Machines GuideDocument54 pagesDC Machines GuideAshutosh KushwahaNo ratings yet

- DC MachinesDocument52 pagesDC MachinesArun Kumar100% (1)

- Unit-2 ANS KEYDocument13 pagesUnit-2 ANS KEYRajaNo ratings yet

- DC Machines: Principles and PartsDocument10 pagesDC Machines: Principles and PartsFrances GalangNo ratings yet

- Chapter 4 & 5Document55 pagesChapter 4 & 5Balamurugan SMNo ratings yet

- Electrical MachinesDocument38 pagesElectrical Machineshephzi28No ratings yet

- EM I Unit IIDocument87 pagesEM I Unit IIPrakashNo ratings yet

- PART 1 Review QuestionsDocument11 pagesPART 1 Review QuestionsStefan RediuNo ratings yet

- Presented By:-Borse RishikeshDocument15 pagesPresented By:-Borse Rishikeshjitu borgohainNo ratings yet

- AC Generators or Alternators ExplainedDocument43 pagesAC Generators or Alternators ExplainedPauline SilvaNo ratings yet

- ALTERNATOR TITLEDocument23 pagesALTERNATOR TITLEpremameNo ratings yet

- Operate & Maintain X-ray Machine ComponentsDocument62 pagesOperate & Maintain X-ray Machine Componentshailemicael mesfin100% (2)

- Unit 3Document88 pagesUnit 3thamizhan4341No ratings yet

- Long Examination 214Document4 pagesLong Examination 214Kobe Alcantara ReyesNo ratings yet

- Motor, Electric Traction and Electrical Control Trainer YL-195Document41 pagesMotor, Electric Traction and Electrical Control Trainer YL-195jhgffdfdffNo ratings yet

- Temperature, Eddy Current & Stray Field Errors in DC MachinesDocument20 pagesTemperature, Eddy Current & Stray Field Errors in DC MachinesELON MUSKNo ratings yet

- Autotransformer Connection ExplaineDocument6 pagesAutotransformer Connection ExplaineNepoliyanNo ratings yet

- Ass 2 Wind0.02Document25 pagesAss 2 Wind0.02Šämęh ËšśämNo ratings yet

- EE6352 Electrical Engineering and InstruDocument27 pagesEE6352 Electrical Engineering and InstruSaravanan ArulmaniNo ratings yet

- LECTURE 4 Transformers 02Document156 pagesLECTURE 4 Transformers 02MINH Nguyễn TuấnNo ratings yet

- Types of AlternatorsDocument12 pagesTypes of AlternatorsHamoudRazaMazherNo ratings yet

- Chapter2-1 - Overview of DC MachinesDocument40 pagesChapter2-1 - Overview of DC MachinesTabi4every175% (4)

- Electrical Machines BookDocument222 pagesElectrical Machines BookSUNILNo ratings yet

- ECE Electrical Engineering 2 Marks PDFDocument22 pagesECE Electrical Engineering 2 Marks PDFsivagamiNo ratings yet

- Alternator Part I Eac ReviewDocument15 pagesAlternator Part I Eac ReviewKevin MaramagNo ratings yet

- Alternators PDFDocument57 pagesAlternators PDFChanning Tatum100% (5)

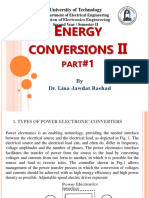

- Nergy Conversions: University of TechnologyDocument9 pagesNergy Conversions: University of TechnologyFadhil A. HasanNo ratings yet

- of DC MachineDocument45 pagesof DC MachinePrabhjotNo ratings yet

- AC Generators ExplainedDocument14 pagesAC Generators ExplainedJay EyNo ratings yet

- Lecture No 5Document41 pagesLecture No 5sami ul haqNo ratings yet

- Robotics AnswersDocument3 pagesRobotics Answersshinde.siddharthNo ratings yet

- DC Generator and Motor FundamentalsDocument234 pagesDC Generator and Motor Fundamentals413 YASH MANE100% (1)

- Automotive Charging System: Chapter FourDocument23 pagesAutomotive Charging System: Chapter FourIsaac TesfayeNo ratings yet

- Electric Machines Basics and TypesDocument32 pagesElectric Machines Basics and TypesDeke Elektronik IndustriNo ratings yet

- Abigail EE 330 Assignment 7Document12 pagesAbigail EE 330 Assignment 7Jay EyNo ratings yet

- Pe Unit 5 PDFDocument8 pagesPe Unit 5 PDFmjrsudhakarNo ratings yet

- DCAC ModuleDocument19 pagesDCAC ModuleDHEMI ALAWINo ratings yet

- 220kv Sustation ChinhutDocument33 pages220kv Sustation ChinhutRaj VermaNo ratings yet

- DC MachineDocument35 pagesDC Machinehs637717No ratings yet

- Alternators PDFDocument57 pagesAlternators PDFHoo Waijian100% (1)

- InvertersDocument29 pagesInvertersMelecio Jesus Leano Jr.No ratings yet

- Transformers: Embedded: Designing & Programming Using ArduinoDocument7 pagesTransformers: Embedded: Designing & Programming Using ArduinoShrdha Nimse100% (1)

- EEOM AssignmentDocument4 pagesEEOM Assignmentjoseph5689No ratings yet

- Answer For WorksheetDocument4 pagesAnswer For Worksheetabene danNo ratings yet

- An Ordinary TransformerDocument4 pagesAn Ordinary Transformersopan saNo ratings yet

- Interview Questions Electrical EnggDocument21 pagesInterview Questions Electrical Enggwelcome2twinkle_2272100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- ShareDocument1 pageShareRicardo VelozNo ratings yet

- ShareDocument1 pageShareRicardo VelozNo ratings yet

- Engineering EconomyDocument4 pagesEngineering EconomyRicardo VelozNo ratings yet

- The Apollo HoaxDocument15 pagesThe Apollo HoaxknowledgefirstNo ratings yet

- How To Create Your Constitution and By-LawsDocument4 pagesHow To Create Your Constitution and By-LawsRicardo VelozNo ratings yet

- Interest: Future Worth: EffectiveDocument5 pagesInterest: Future Worth: EffectiveRicardo VelozNo ratings yet

- The Corporation Code of The PhilippinesDocument7 pagesThe Corporation Code of The PhilippinesRicardo VelozNo ratings yet

- TABLE 2-351 Saturated Water Substance-Temperature (Fps Units)Document6 pagesTABLE 2-351 Saturated Water Substance-Temperature (Fps Units)Ricardo VelozNo ratings yet

- Engineering EconomyDocument4 pagesEngineering EconomyRicardo VelozNo ratings yet

- Unit 2: Learning From ApolloDocument2 pagesUnit 2: Learning From ApolloRicardo VelozNo ratings yet

- Diffusion Through A Stagnant Gas FilmDocument16 pagesDiffusion Through A Stagnant Gas FilmSuleman Tariq100% (3)

- Business ContractDocument5 pagesBusiness ContractRicardo Veloz100% (1)

- A Key Engineer From David LaithDocument3 pagesA Key Engineer From David LaithRicardo VelozNo ratings yet

- Interest: Future Worth: EffectiveDocument5 pagesInterest: Future Worth: EffectiveRicardo VelozNo ratings yet

- Corporate ConstitutionDocument2 pagesCorporate ConstitutionRicardo VelozNo ratings yet

- Scandal in Bohemia: Adventure 1Document32 pagesScandal in Bohemia: Adventure 1Ricardo VelozNo ratings yet

- Day 1Document60 pagesDay 1Ricardo VelozNo ratings yet

- TomorrowDocument2 pagesTomorrowRicardo VelozNo ratings yet

- Quadratic EquationDocument1 pageQuadratic EquationRicardo VelozNo ratings yet

- Schedule Weekly 24 HoursDocument1 pageSchedule Weekly 24 HourschandranegaraNo ratings yet

- Schedule Weekly 24 HoursDocument1 pageSchedule Weekly 24 HourschandranegaraNo ratings yet

- Evaluating Rate Expressions from Experimental DataDocument46 pagesEvaluating Rate Expressions from Experimental DataYassin RoslanNo ratings yet

- Lab Form 1Document1 pageLab Form 1Ricardo VelozNo ratings yet

- White Paper: Dispersing Powders in Liquid For Particle Size AnalysisDocument7 pagesWhite Paper: Dispersing Powders in Liquid For Particle Size AnalysisRicardo VelozNo ratings yet

- MsdsDocument5 pagesMsdsRicardo VelozNo ratings yet

- Weekly schedule template with time slotsDocument3 pagesWeekly schedule template with time slotsRicardo VelozNo ratings yet

- Hydroxy ApatiteDocument3 pagesHydroxy ApatiteRicardo VelozNo ratings yet

- Mineral SeparationDocument9 pagesMineral SeparationNamwangala Rashid NatinduNo ratings yet

- DIY Knifemaker's Info Center - Heat Treatment Oven ProjectDocument34 pagesDIY Knifemaker's Info Center - Heat Treatment Oven ProjectRicardo VelozNo ratings yet

- (Dy - DX) (X 2+1) + (4 (Y 2) +1) + (8xy) +1 - Wolfram - AlphaDocument2 pages(Dy - DX) (X 2+1) + (4 (Y 2) +1) + (8xy) +1 - Wolfram - AlphaRicardo VelozNo ratings yet

- SynETechRefV4 (001 101)Document101 pagesSynETechRefV4 (001 101)Blanca E. CastillejosNo ratings yet

- 01 - Operators ManualDocument41 pages01 - Operators ManualSaad ElhemediNo ratings yet

- IEEE STD ANSI-IEEE STD 67-1972Document48 pagesIEEE STD ANSI-IEEE STD 67-1972abdou sami100% (1)

- Aeolos-V 300 600W Brochure PDFDocument3 pagesAeolos-V 300 600W Brochure PDFAnonymous U7o8tht51KNo ratings yet

- AC 3 PhaseDocument46 pagesAC 3 PhaseSidratul NugrahaNo ratings yet

- 3D Printed PeltonDocument63 pages3D Printed PeltonRENZ JOHN AMPOSTANo ratings yet

- 130 TOP MOST D.C Generators PDFDocument38 pages130 TOP MOST D.C Generators PDFSIVAKAMI100% (2)

- TRIO-20.0-27.6-TL-OUTD-Product - ManualDocument131 pagesTRIO-20.0-27.6-TL-OUTD-Product - ManualEngr. Muhammad Arslan YousafNo ratings yet

- Electromagnetic Induction (196)Document74 pagesElectromagnetic Induction (196)caiogabrielNo ratings yet

- N.capability Curve (Ani.) MPPGCLDocument17 pagesN.capability Curve (Ani.) MPPGCLvikasoza100% (1)

- Module 5Document29 pagesModule 5डॉ. इन्द्रसेन सिंहNo ratings yet

- Modeling of an Electric Generator in 3DDocument28 pagesModeling of an Electric Generator in 3DAdnen GuedriaNo ratings yet

- Turbine Operation GuideDocument27 pagesTurbine Operation GuidebhaskarNo ratings yet

- Small Stability SMIB ExampleDocument8 pagesSmall Stability SMIB ExampleJaol1976No ratings yet

- Analysis of Two Area Power System With Battery Energy StorageDocument5 pagesAnalysis of Two Area Power System With Battery Energy StoragezahidNo ratings yet

- Peter Schäffert, Josef Thalhauser, Herbert Schaumberger, Uwe Liebscher Ge Jenbacher GMBH & Co OgDocument25 pagesPeter Schäffert, Josef Thalhauser, Herbert Schaumberger, Uwe Liebscher Ge Jenbacher GMBH & Co OgTayyab ZubairNo ratings yet

- Newage MX341 Automatic Voltage Regulator PDFDocument6 pagesNewage MX341 Automatic Voltage Regulator PDFosanebi100% (2)

- CAT Engine Specifications: G3516B Land Electric Drilling Package Generator SetDocument4 pagesCAT Engine Specifications: G3516B Land Electric Drilling Package Generator SetGabriel Paco LunaNo ratings yet

- Cummins Int Full Product Line PressDocument20 pagesCummins Int Full Product Line PressKhoi Nguyen100% (1)

- Electives - SA1 CompilationDocument4 pagesElectives - SA1 CompilationKYLE LEIGHZANDER VICENTENo ratings yet

- Electricity and Magnetism: Electric ChargeDocument21 pagesElectricity and Magnetism: Electric ChargeLencho Taye educationNo ratings yet

- Lec 4 & 5 - Power System ProtectionDocument35 pagesLec 4 & 5 - Power System ProtectionAwil MohamedNo ratings yet

- Spesifikasi Teknis Deutz 500kva SilentDocument7 pagesSpesifikasi Teknis Deutz 500kva Silenthafid CJSPNo ratings yet

- 1.4 1styr 1stsem ELECTRO 1 Basic ElectricityDocument29 pages1.4 1styr 1stsem ELECTRO 1 Basic ElectricityRYAN PILUETANo ratings yet

- Free energy generate by using magnetDocument5 pagesFree energy generate by using magnetAnil KatteNo ratings yet

- Control Loops 2Document22 pagesControl Loops 2Muntadher AbbasNo ratings yet

- Recent Trends in Power Electronics Technology - Vijaya BhaskarDocument67 pagesRecent Trends in Power Electronics Technology - Vijaya BhaskarMukundMikkilineniChowdaryNo ratings yet

- Piezoelectric ShoeDocument8 pagesPiezoelectric Shoearun kumarNo ratings yet

- 27 MDKDU New-EnDocument4 pages27 MDKDU New-Enabduallah muhammadNo ratings yet

- Digital Inverter Generator: Please Read This Manual Carefully Before UseDocument43 pagesDigital Inverter Generator: Please Read This Manual Carefully Before UseDavidNo ratings yet