Professional Documents

Culture Documents

Uni en 15316-3-2 - 2008

Uploaded by

Stefano SquadraniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uni en 15316-3-2 - 2008

Uploaded by

Stefano SquadraniCopyright:

Available Formats

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008.

Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

Impianti di riscaldamento degli edifici

NORMA E U R OP E A

Metodo per il calcolo dei requisiti energetici e dei rendimenti dellimpianto

Parte 3-2: Impianti per la produzione di acqua calda sanitaria, distribuzione

UNI EN 15316-3-2

MAGGIO 2008 Heating systems in buildings

Method for calculation of system energy requirements and system efficiencies

Part 3-2: Domestic hot water systems, distribution La norma fa parte di una serie di norme sul metodo di calcolo dei requisiti energetici e dei rendimenti dellimpianto di riscaldamento degli edifici. La norma ha lo scopo di fornire i metodi di calcolo per: - le perdite termiche dellimpianto di distribuzione di acqua calda sanitaria; - le perdite termiche dellimpianto di distribuzione di acqua calda sanitaria recuperabili per il riscaldamento degli ambienti; - lenergia ausiliaria dellimpianto di distribuzione di acqua calda sanitaria.

TESTO INGLESE

La presente norma la versione ufficiale in lingua inglese della norma europea EN 15316-3-2 (edizione ottobre 2007) e tiene conto delle correzioni introdotte il 24 ottobre 2007.

ICS

UNI Ente Nazionale Italiano di Unificazione Via Sannio, 2 20137 Milano, Italia

91.140.10

UNI Riproduzione vietata. Tutti i diritti sono riservati. Nessuna parte del presente documento pu essere riprodotta o diffusa con un mezzo qualsiasi, fotocopie, microfilm o altro, senza il consenso scritto dellUNI. www.uni.com UNI EN 15316-3-2:2008 Pagina I

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

PREMESSA NAZIONALE

La presente norma costituisce il recepimento, in lingua inglese, della norma europea EN 15316-3-2 (edizione ottobre 2007 con correzioni del 24 ottobre 2007), che assume cos lo status di norma nazionale italiana. La presente norma stata elaborata sotto la competenza dellente federato allUNI CTI - Comitato Termotecnico Italiano La presente norma stata ratificata dal Presidente dellUNI ed entrata a far parte del corpo normativo nazionale il 22 maggio 2008.

Le norme UNI sono elaborate cercando di tenere conto dei punti di vista di tutte le parti interessate e di conciliare ogni aspetto conflittuale, per rappresentare il reale stato dellarte della materia ed il necessario grado di consenso. Chiunque ritenesse, a seguito dellapplicazione di questa norma, di poter fornire suggerimenti per un suo miglioramento o per un suo adeguamento ad uno stato dellarte in evoluzione pregato di inviare i propri contributi allUNI, Ente Nazionale Italiano di Unificazione, che li terr in considerazione per leventuale revisione della norma stessa. Le norme UNI sono revisionate, quando necessario, con la pubblicazione di nuove edizioni o di aggiornamenti. importante pertanto che gli utilizzatori delle stesse si accertino di essere in possesso dellultima edizione e degli eventuali aggiornamenti. Si invitano inoltre gli utilizzatori a verificare lesistenza di norme UNI corrispondenti alle norme EN o ISO ove citate nei riferimenti normativi. UNI EN 15316-3-2:2008 UNI Pagina II

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EUROPEAN STANDARD NORME EUROPENNE EUROPISCHE NORM

ICS 91.140.10

EN 15316-3-2

October 2007

English Version

Heating systems in buildings - Method for calculation of system energy requirements and system efficiencies - Part 3-2: Domestic hot water systems, distribution

Systmes de chauffage dans les btiments - Mthode de calcul des besoins nergtiques et des rendements des systmes - Partie 3-2 : Systmes de production d'eau chaude sanitaire, distribution Heizungsanlagen in Gebuden - Verfahren zur Berechnung der Energieanforderungen und Nutzungsgrade der Anlagen - Teil 3-2: Trinkwassererwrmung, Verteilung

This European Standard was approved by CEN on 18 August 2007. CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member. This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions. CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION COMIT EUROPEN DE NORMALISATION EUROPISCHES KOMITEE FR NORMUNG

Management Centre: rue de Stassart, 36

B-1050 Brussels

2007 CEN

All rights of exploitation in any form and by any means reserved worldwide for CEN national Members.

Ref. No. EN 15316-3-2:2007: E

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Contents

Page

Foreword..............................................................................................................................................................4 Introduction .........................................................................................................................................................6 1 2 3 4 5 5.1 5.2 5.3 5.4 6 6.1 6.2 6.2.1 6.2.2 6.2.3 6.2.4 6.2.5 6.2.6 6.2.7 6.2.8 6.3 6.3.1 6.3.2 6.3.3 6.3.4 6.3.5 6.4 6.5 7 7.1 7.2 7.3 7.3.1 7.3.2 7.3.3 8 Scope ......................................................................................................................................................7 Normative references ............................................................................................................................7 Terms and definitions ...........................................................................................................................7 Symbols, units and indices ................................................................................................................10 Domestic hot water system characteristics......................................................................................11 General..................................................................................................................................................11 Single zone and single system...........................................................................................................12 Single zone and multiple systems .....................................................................................................12 Multiple zones with single system .....................................................................................................13 Distribution thermal losses ................................................................................................................13 Total distribution thermal losses .......................................................................................................13 Thermal losses from individual distribution pipe section...............................................................14 General..................................................................................................................................................14 Thermal losses from pipes based on dwelling area ........................................................................14 Thermal losses from pipes based on pipe lengths and number of tappings per day..................15 Thermal losses from pipes based on pipe lengths and distribution efficiencies.........................15 Thermal losses from pipes based on pipe lengths and tapping profiles ......................................16 Thermal losses from pipes based on pipe lengths and average temperature..............................16 Heat energy lost due to wasted hot water.........................................................................................16 Time periods.........................................................................................................................................16 Thermal losses from circulation loop................................................................................................16 General..................................................................................................................................................16 Thermal losses from circulation loop based on pipe length and a fixed value of heat loss .......16 Thermal losses from circulation loop based on a physical approach ...........................................17 Additional thermal losses from circulation loop during periods of no circulation ......................17 Total thermal loss from circulation loop ...........................................................................................17 Thermal losses due to accessories ...................................................................................................18 User outlets ..........................................................................................................................................18 Auxiliary energy ...................................................................................................................................18 Total auxiliary energy consumption ..................................................................................................18 Auxiliary energy consumption for ribbon heating ...........................................................................18 Auxiliary energy consumption for pumps ........................................................................................19 General..................................................................................................................................................19 Simplified method................................................................................................................................19 Detailed calculation method ...............................................................................................................20 Recoverable, recovered and unrecoverable system losses ...........................................................20

Annex A (informative) Calculation of thermal losses from pipes based on pipe lengths and the number of tappings per day ...............................................................................................................22 Annex B (informative) Calculation of thermal losses from pipes based on pipe lengths and distribution efficiencies ......................................................................................................................24 Annex C (informative) Calculation of thermal losses from pipes based on pipe lengths and tapping profiles ....................................................................................................................................26 Annex D (informative) Calculation of thermal losses from circulation loop ...............................................28

2

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

D.1 D.2 D.2.1 D.2.2 D.2.3 D.2.4 D.2.5 D.2.6

Calculation of thermal losses based on pipe length .......................................................................28 Thermal losses based on a detailed calculation method................................................................28 General .................................................................................................................................................28 Determination of length of pipe sections..........................................................................................28 Determination of heat transfer coefficients ......................................................................................31 Tabulated method for calculation of linear thermal transmittance ................................................33 Determination of average ambient temperature...............................................................................34 Determination of average hot water temperature of pipe section..................................................34

Annex E (informative) Calculation of thermal losses from user outlets .....................................................35 Annex F (informative) Calculation of auxiliary energy requirement of a circulation pump ......................36 F.1 Simplified method for calculation of auxiliary energy requirement of a circulation pump .........36 F.2 Detailed method for calculation of auxiliary energy requirement of a circulation pump ............36 F.2.1 Hydraulic energy requirement ...........................................................................................................36 F.2.2 Hydraulic power required by the pump.............................................................................................36 F.2.3 Duration of the provision of domestic hot water .............................................................................37 F.2.4 Pump performance coefficient...........................................................................................................38 F.2.5 Intermittent pump operation...............................................................................................................39 F.2.6 Expenditure value coefficient ............................................................................................................39 F.3 Auxiliary energy recoverable factor ..................................................................................................40 Bibliography......................................................................................................................................................41

3

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Foreword

This document (EN 15316-3-2:2007) has been prepared by Technical Committee CEN/TC 228 Heating systems in buildings, the secretariat of which is held by DS. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by April 2008, and conflicting national standards shall be withdrawn at the latest by April 2008. This document has been prepared under a mandate given to CEN by the European Commission and the European Free Trade Association (Mandate M/343), and supports essential requirements of EU Directive 2002/91/EC on the energy performance of buildings (EPBD). It forms part of a series of standards aimed at European harmonisation of the methodology for calculation of the energy performance of buildings. An overview of the whole set of standards is given in prCEN/TR 15615. The subjects covered by CEN/TC 228 are the following: design of heating systems (water based, electrical etc.); installation of heating systems; commissioning of heating systems; instructions for operation, maintenance and use of heating systems; methods for calculation of the design heat loss and heat loads; methods for calculation of the energy performance of heating systems.

Heating systems also include the effect of attached systems such as hot water production systems. All these standards are systems standards, i.e. they are based on requirements addressed to the system as a whole and not dealing with requirements to the products within the system. Where possible, reference is made to other European or International Standards, a.o. product standards. However, use of products complying with relevant product standards is no guarantee of compliance with the system requirements. The requirements are mainly expressed as functional requirements, i.e. requirements dealing with the function of the system and not specifying shape, material, dimensions or the like. The guidelines describe ways to meet the requirements, but other ways to fulfil the functional requirements might be used if fulfilment can be proved. Heating systems differ among the member countries due to climate, traditions and national regulations. In some cases requirements are given as classes so national or individual needs may be accommodated. In cases where the standards contradict with national regulations, the latter should be followed.

4

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

EN 15316 Heating systems in buildings Method for calculation of system energy requirements and system efficiencies consists of the following parts: Part 1: General Part 2-1: Space heating emission systems Part 2-3: Space heating distribution systems Part 3-1: Domestic hot water systems, characterisation of needs (tapping requirements) Part 3-2: Domestic hot water systems, distribution Part 3-3: Domestic hot water systems, generation Part 4-1: Space heating generation systems, combustion systems (boilers) Part 4-2: Space heating generation systems, heat pump systems Part 4-3: Heat generation systems, thermal solar systems Part 4-4: Heat generation systems, building-integrated cogeneration systems Part 4-5: Space heating generation systems, the performance and quality of district heating and large volume systems Part 4-6: Heat generation systems, photovoltaic systems Part 4-7: Space heating generation systems, biomass combustion systems According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

5

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Introduction

This European Standard is one of a number of standards that together describe methods for calculation of system energy requirements and system efficiencies related to domestic hot water systems. In particular this European Standard specifies methods for calculation of the energy losses of the distribution system. The user needs to refer to other European Standards or to national documents for input data and detailed calculation procedures not provided by this European Standard. Only the calculation methods are normative. Values necessary to complete the calculations should be given in a national annex.

6

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Scope

This European Standard is part of a set of standards covering methods for calculation of system energy requirements and system efficiencies of heating systems in buildings. In particular this European Standard is one of a number of standards dealing with domestic hot water systems. The scope of this specific part is to standardise the methods for calculation of: thermal losses from the domestic hot water distribution system; recoverable thermal losses for space heating from the domestic hot water distribution system; auxiliary energy of the domestic hot water distribution system.

These values are input data for calculation of the overall energy use according to prEN 15603 and EN 15316-1. This European Standard specifies the: inputs; calculation methods; outputs.

Normative references

The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. Not applicable

Terms and definitions

For the purposes of this document, the following terms and definitions apply. 3.1 auxiliary energy electrical energy used by technical building systems for heating, cooling, ventilation and/or domestic hot water to support energy transformation to satisfy energy needs

NOTE 1 This includes energy for fans, pumps, electronics etc. Electrical energy input to a ventilation system for air transport and heat recovery is not considered as auxiliary energy, but as energy use for ventilation. NOTE 2 In EN ISO 9488, the energy used for pumps and valves is called "parasitic energy".

3.2 building construction as a whole, including its envelope and all technical building systems, for which energy is used to condition the indoor climate, to provide domestic hot water and illumination and other services related to the use of the building

NOTE The term can refer to the building as a whole or to parts thereof that have been designed or altered to be used separately.

7

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

3.3 circulation loop part of the domestic hot water distribution system where the water circulation is maintained by a pump operating continuously or in cycles during a day

NOTE Where there is a circulation loop, there are heat losses from the pipes during the whole period of water circulation and not only related to hot water draw-offs.

3.4 calculation period period of time over which the calculation is performed

NOTE The calculation period can be divided into a number of calculation steps.

3.5 domestic hot water heating process of heat supply to raise the temperature of the cold water to the intended delivery temperature 3.6 domestic hot water distribution system distribution pipes installed between the heat generator or hot water storage vessel (if present) and the user outlet or outlets. The domestic hot water distribution system may include a circulation loop and individual sections 3.7 individual section of the domestic hot water distribution system part of the domestic hot water distribution system where the circulation of the domestic hot water is not maintained by a pump but only due to the draw offs

NOTE The heat losses occur due to the energy used in heating up the pipes and fittings of the distribution system.

3.8 energy need for domestic hot water heat to be delivered to the needed amount of domestic hot water to raise its temperature from the cold network temperature to the prefixed delivery temperature at the delivery point, not taking into account the technical building thermal systems 3.9 energy use for space heating or cooling or domestic hot water energy input to the space heating or cooling system or the domestic hot water system to satisfy the energy need for space heating or cooling (including dehumidification) or domestic hot water, respectively

NOTE If the technical building system serves several purposes (e.g. space heating and domestic hot water), it can be difficult to split the energy use into that used for each purpose. It can be indicated as a combined quantity (e.g. energy need for space heating and domestic hot water).

3.10 heating or cooling season period of the year during which a significant amount of energy for heating or cooling is needed

NOTE The season lengths are used to determine the operation period of technical systems.

3.11 heat recovery heat generated by a technical building system or linked to a building use (e.g. domestic hot water) which is utilised directly in the related system to lower the heat input and which would otherwise be wasted (e.g. preheating of the combustion air by flue gas heat exchanger)

8

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

3.12 recoverable system thermal loss part of a system thermal loss which can be recovered to lower either the energy need for heating or cooling or the energy use of the heating or cooling system

NOTE This depends on the calculation approach chosen to calculate the recovered gains and losses (holistic or simplified approach).

3.13 recovered system thermal loss part of the recoverable system thermal loss which has been recovered to lower either the energy need for heating or cooling or the energy use of the heating or cooling system 3.14 ribbon heating also called trace heating. Electrical resistance enveloping the pipes (one way) used to compensate the heat loss of the pipes in order to maintain the domestic hot water temperature in the distribution system at a required temperature 3.15 system boundary boundary that includes within it all areas associated with the building (both inside and outside the building) where energy is consumed or produced

NOTE Inside the system boundary the system losses are taken into account explicitly, outside the system boundary they are taken into account in the conversion factor.

3.16 system thermal loss thermal loss from a technical building system for heating, cooling, domestic hot water, humidification, dehumidification, or ventilation or lighting that does not contribute to the useful output of the system

NOTE 1 A system loss can become an internal heat gain for the building, if it is recovered.

NOTE 2 Thermal energy recovered directly in the subsystem is not considered as a system thermal loss but as heat recovery and directly treated in the related system standard. NOTE 3 Heat dissipated by the lighting system or by other services (e.g. appliances of computer equipment) is not part of the system thermal losses, but part of the internal heat gains.

3.17 tapping program 24-hour cycle that defines a number of domestic hot water draw-off requirements: succession of energy needs corresponding to uses of domestic hot water during a day 3.18 technical building system technical equipment for heating, cooling, ventilation, domestic hot water, lighting and electricity production composed of sub-systems

NOTE 1 A technical building system can refer to one or to several building services (e.g. heating system, space heating and domestic hot water system). NOTE 2 Electricity production can include cogeneration and photovoltaic systems.

3.19 technical building sub-system part of a technical building system that performs a specific function (e.g. heat generation, heat distribution, heat emission)

9

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

3.20 zone part of a building for which the energy need for domestic hot water is to be calculated

Symbols, units and indices

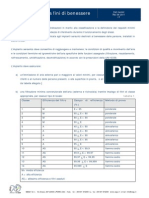

For the purposes of this document, the following symbols and units (Table 1) and indices (Table 2) apply. Table 1 Symbols and units

Symbol A b c e D f h L m n t Q Name of quantity area location factor specific heat capacity system performance coefficient (expenditure factor) diameter conversion factor height length mass number of operating times time, period of time quantity of heat, energy thermal power electrical power heat loss coefficient volume auxiliary (electrical) energy energy loss factor efficiency celsius temperature heat conductivity Unit m J/(kg K) m m m kg s J W W W/mK m J C W/mK

3 2

V W �

Table 2 Indices

amb avg B col dis e em f ambient average building circulation loop (collective) distribution external emission floor gen hs hydr in ind int ls nhs generation heated space hydraulic input to system individual internal losses non heated space nom on off out pmp rib tap W nominal circulation no circulation output from system pump trace heating deliveries domestic hot water

10

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

5

5.1

Domestic hot water system characteristics

General

The domestic hot water distribution system is given as one or more pipes installed between the heat generator or hot water storage vessel (if present) and the user outlet or outlets. The domestic hot water distribution system may include a circulation loop. The most basic system, for which this method is applied, consists of a single distribution pipe connecting a single heat generator, or a storage vessel, and a user outlet (e.g. tap or shower head). This is shown in Figure 1.

Key

1 generation 2 storage 3 distribution 4 emission

Figure 1 Basic domestic hot water system components If the building is used for different applications or is divided between different users, the method can be applied to the entire building or to part of the building, as required. The calculation method can also be applied to a building or to part of a building, where there is more than one domestic hot water system installed. For the

11

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

purposes of these calculations, the buildings are considered in terms of the number of zones into which they are divided and the number of domestic hot water systems within these zones. A zone is defined as a building or part of a building, for which the energy need for domestic hot water is to be calculated.

5.2

Single zone and single system

The simplest installation is a single system within a single zone (see Figure 1).

5.3

Single zone and multiple systems

This installation corresponds to a zone in which the energy need for domestic hot water is provided by means of more than one domestic hot water generator. In a domestic building, this may be one generator providing domestic hot water to a bathroom and another generator providing domestic hot water to a kitchen (see Figure 2). In non-domestic buildings, the installation depends on the building sector.

Figure 2 Domestic hot water system, single zone and multiple systems Calculation of system losses shall be carried out separately for each system. The total system loss for the zone is the sum of the system losses of each system. Each distribution system shall be kept separate in order to define the heat load on the heat generator along with the corresponding domestic hot water demand.

12

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

5.4

Multiple zones with single system

This installation corresponds to a building split into a number of separate zones, for which there is a common single domestic hot water system, e.g. a block of flats with a central boiler (see Figure 3).

Figure 3 Domestic hot water system, multiple zones and single system The total system loss is calculated for the system, and the total thermal loss is the sum of thermal losses of each zone.

6

6.1

Distribution thermal losses

Total distribution thermal losses

For the calculations, the distribution system is considered divided into two parts: a circulation loop, if present, and the individual distribution pipes to the user outlet or outlets. The thermal losses of each part are calculated separately. The total thermal loss part as follows:

QW ,dis ,ls of the distribution system is calculated by adding the thermal losses of each

QW ,dis ,ls = � QW ,dis ,ls ,ind + QW ,dis ,ls ,col

ind

(MJ/day)

(1)

where

�Q

ind

W ,dis ,ls ,ind

is the sum of thermal loss from the individual distribution pipes of the distribution system (no circulation loop), MJ/day;

13

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

QW ,dis ,ls ,col

is the thermal loss from the circulation loop of the distribution system (collective part), if present, MJ/day.

6.2

6.2.1

Thermal losses from individual distribution pipe section

General

Where there is no circulation loop, thermal losses occur due to the energy used for heating up the pipes and fittings of the distribution system. This contributes also to a delay in reaching the required minimum temperature of the domestic hot water at the user outlet. When the desired temperature is reached in the distribution system, thermal losses from the distribution system occur during the period of draw-off of domestic hot water. The heat content within the distribution system, after a draw-off of domestic hot water has been completed, is lost to the surrounding environment, i.e. heat content of the hot water in the distribution system and thermal capacity of the material of the distribution system. Insulation on the distribution pipes reduces the heat loss rate during a hot water draw-off and thus reduces the total thermal losses during a hot water demand period. Further, insulation on the distribution pipes reduces the heat loss rate regarding the heat content within the distribution system, after a hot water draw-off has been completed. The effect of the insulation in this respect depends on the time periods between consecutive draw-offs. If the time period is sufficiently long, pipe insulation does not affect the thermal loss of the heat content and the hot water temperature drops to the ambient temperature around the pipe. If the time period is short, pipe insulation reduces the thermal loss of the heat content, as the hot water temperature does not drop to the ambient temperature around the pipe. Thus, depending on the tapping pattern, the reduced thermal losses and effect of insulation should be taken into account. Different methods for calculation of thermal losses are described in the following. The methods differ in the detail of the calculations and the input data required. The method applied can be chosen based on the data available and the objectives of the user. The level of detail chosen should reflect the level of detail used in defining the domestic hot water needs. A national annex may specify which calculation method should be used for different types of buildings. A national annex may also specify which calculation method is applicable for the purpose of energy labelling or any other specific use. The calculations are based on daily domestic hot water needs. 6.2.2 Thermal losses from pipes based on dwelling area

This method is a simplified method relating the thermal loss of individual distribution pipes only to building floor area and, thus, detailed knowledge of the domestic hot water distribution system is not required for this method. This method can only be applied in a limited number of situations and is usually restricted to domestic buildings with a domestic hot water distribution system that does not involve a circulation loop. If this method is applicable, details for the calculation and limitations for its use shall be given in a national annex. Although detailed knowledge of the domestic hot water distribution system is not required, the pipe lengths shall be kept to a minimum. The maximum acceptable distribution pipe length for this method may be given in a national annex.

14

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

6.2.3

Thermal losses from pipes based on pipe lengths and number of tappings per day

This method takes into account the thermal losses from the pipes and the thermal losses from the water within the pipes. It is necessary to know the pipe diameters and pipe lengths for each individual section of the domestic hot water distribution system. This method is applicable only for domestic hot water distribution pipes that are not part of a circulation loop. The thermal loss is calculated by:

QW ,dis ,ls ,ind =

where

w * cw

1000

* VW ,dis * (W ,dis ,nom amb ) * ntap

(MJ/day)

(2)

w

cw

VW ,dis

amb

W ,dis,nom

is the specific mass of water (kg/m ); is the specific heat capacity of water (kJ/kgK); is the volume of water contained in the pipes (m ); is the average ambient temperature around the pipes (C); is the nominal hot water temperature in the pipes (C); is the number of hot water draw-offs during a day.

3

ntap

Details on this method shall be given in a national annex. It is possible to take into account other parameters, e.g. the thermal capacity of the pipes. An example is described in Annex A. It is possible also to include the thermal losses from the user outlets in this method. A reduction of thermal losses in case of short intervals between the tapping cycles is not taken into account in this calculation method. If this is to be considered, details shall be given in a national annex, and for this purpose, the effect of pipe insulation on thermal losses shall be taken into account. An example is described in Annex A. 6.2.4 Thermal losses from pipes based on pipe lengths and distribution efficiencies

This method is based on estimates of proportion of the heat energy reaching the user outlets for different pipe lengths. A distinction is made between supplies to kitchens and supplies to bathrooms. Detailed knowledge of the domestic hot water distribution system is not required for this method, however, an approximation of the length and diameter of each of the delivery pipes shall be made. The proportion of heat energy reaching the user outlets is tabulated against pipe lengths and diameters. This method is applicable only for domestic hot water distribution pipes that are not part of a circulation loop. If this method is applicable, details for the calculation and suitable tabulated values shall be given in a national annex. A table of default values is given in Annex B.

15

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

6.2.5

Thermal losses from pipes based on pipe lengths and tapping profiles

This method is based on estimates of the thermal losses expressed as a proportion of the domestic hot water energy demand at the user outlets. Data on domestic hot water energy demand is required for this method, but detailed knowledge of the domestic hot water distribution system is not required, as long as sufficient data is available to estimate the average pipe lengths. Additionally, data is required on the location of the domestic hot water distribution system, i.e. as to lengths of pipe sections installed within the heated space and lengths of pipe sections installed outside the heated space. This method is described in Annex C. Details on this method, including the equivalent energy loss factors, shall be given in a national annex. 6.2.6 Thermal losses from pipes based on pipe lengths and average temperature

This method is based on the same calculation principles as for the thermal losses from a circulation loop based on a physical approach (see 6.3.3). The only difference is the average temperature of the domestic hot water taken into account, which is normally lower for the individual section of the domestic hot water distribution system than for the circulation loop. Appropriate values shall be given in a national annex. An example is given in D.2. 6.2.7 Heat energy lost due to wasted hot water

For most uses, a minimum domestic hot water temperature is required at the user outlet, before it is considered useful. The energy content of the water tapped, until the water at the user outlet has reached the minimum required temperature, is wasted and is considered as a thermal loss. These thermal losses may be reduced if there is a high demand on the distribution system, i.e. a large number of hot water draw-offs occur over a short time period. If the domestic hot water demand is defined in accordance with EN 15316-3-1 on the basis of tapping programs, the conditions for the minimum domestic hot water temperatures and flow rates are given. If the domestic hot water performance of the generator unit is measured in accordance with EN 13203-2, the energy content of the wasted domestic hot water is also measured. If the domestic hot water performance of the generator is not measured in accordance with EN 13203-2, the energy content of the wasted domestic hot water may be calculated. A national annex should give details on this method and the assumptions to be made. 6.2.8 Time periods

The weekly, monthly or annual thermal losses are obtained by multiplying the thermal loss per day by the appropriate number of days.

6.3

6.3.1

Thermal losses from circulation loop

General

For a circulation loop, there are thermal losses from the pipes during the whole period of water circulation, i.e. not restricted to domestic hot water draw-offs. 6.3.2 Thermal losses from circulation loop based on pipe length and a fixed value of heat loss

A fixed value of heat loss from the circulation loop may be assumed. This method is applicable if exact design of the domestic hot water distribution system is not available or the pipe insulation thickness is not known. The value should be given in a national annex. If a national annex is not provided or does not include this value, a default value is given in D.1.

16

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

6.3.3

Thermal losses from circulation loop based on a physical approach

The general determination of thermal losses of a circulation loop comprising a number of pipe sections i is given by:

QW ,dis ,ls ,col ,on =

where

�Q

i

W ,dis ,ls ,col ,on ,i

=�

i

3.6 * U W ,i * LW ,i * (W ,dis ,avg ,i amb,i ) * tW 1000

(MJ/day)

(3)

QW ,dis ,ls ,col ,on ,i is the thermal losses of pipe section i (during periods of circulation) (MJ/day); U W ,i LW ,i

is the linear thermal transmittance of pipe section i (W/mK); is the length of pipe section i (m); is the average hot water temperature of pipe section i ( C); is the average ambient temperature around pipe section i ( C); is the daily utilisation period at the corresponding temperatures,

o o

W ,dis ,avg ,i amb ,i

tW

W ,dis ,avg ,i

(h/day).

The individual components of the equation are obtained from the method given in D.2. 6.3.4 Additional thermal losses from circulation loop during periods of no circulation

If the circulation loop is not operated continuously, the heat energy within each pipe section of the circulation loop is lost to the surrounding environment. This thermal loss is calculated by:

QW ,dis ,ls ,col ,off =

where

�Q

i

W ,dis ,ls ,col ,off ,i

�

i

w * cw

1000

* VW ,dis ,i * (W ,dis ,avg ,i amb,i ) * nnorm

(MJ/day)

(4)

w

cw

VW ,dis ,i

nnorm 6.3.5

is the specific mass of water (kg/m ); is the specific heat capacity of water (kJ/kgK); is the volume of water contained in pipe section i (m ); is the number of circulation pump operating cycles during a day. Total thermal loss from circulation loop

3

The total thermal loss from a circulation loop is the sum of thermal losses during periods of circulation and thermal losses during periods of no circulation:

QW ,dis,ls,col = QW ,dis,ls,col ,on + QW ,dis ,ls ,col ,off

(MJ/day)

(5)

The weekly, monthly or annual thermal losses are obtained by multiplying the thermal loss per day by the appropriate number of days.

17

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

6.4

Thermal losses due to accessories

The thermal losses from the circulation loop and from individual distribution pipes are increased by the thermal losses through fittings, i.e. valves and flanges, as well as thermal losses through pipe hangers. These thermal losses are estimated by introducing an additional equivalent pipe length. If these additional thermal losses are to be included in the analysis, details shall be given in a national annex.

6.5

User outlets

The domestic hot water is supplied to the user through a user outlet, e.g. a tap, showerhead or similar device. Depending on the design and the material of construction, the user outlet absorbs heat energy during the supply of hot water and causes a delay in reaching the required minimum hot water temperature at the user outlet. Depending on the characteristics of the user outlet, the user needs more or less time to adjust the required temperature (e.g. thermostatic user outlets). These delays increase thermal losses in the domestic hot water distribution system. The additional heat energy lost due to wasted hot water (according to 6.2.7) may be combined with the thermal losses due to user outlets and, thus, no additional calculation is required to take user outlets into account. If the thermal losses from user outlets are to be considered separately, the need for this calculation shall be indicated in a national annex. The basis of the calculation method is given in Annex E. These thermal losses are dependent on the number of hot water draw-offs. This dependence shall be detailed in the national annex. Default values for the thermal losses from different types of user outlets may be used in place of a calculation. If default values are applicable, these shall be given in a national annex.

7

7.1

Auxiliary energy

Total auxiliary energy consumption

For the domestic hot water distribution system, auxiliary energy may be used for ribbon heating and for pumps, and the total auxiliary energy consumption is determined by:

WW ,dis ,aux = WW ,dis ,rib + WW ,dis , pmp

where

(MJ//day)

(6)

WW ,dis ,rib WW ,dis , pmp

7.2

is the auxiliary energy consumption for the ribbon heater (MJ/day); is the auxiliary energy consumption for pumps (MJ/day).

Auxiliary energy consumption for ribbon heating

Where ribbon heating or trace heating is applied to reduce the heat losses, it is assumed that the auxiliary energy consumption for the ribbon heater is equal to what the heat losses from the pipe would have been without the heater. The ribbon heater does not contribute to the generation of hot water. The heat losses compensated by the ribbon heater shall not be added to the heat losses of other individual parts of the domestic hot water

18

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

distribution system, used to determine the heat demand and the load on the heat generator. The ribbon heater is supplied by electricity and should thus be considered as part of the auxiliary energy requirements. The auxiliary energy consumption for the ribbon heater is calculated by:

WW ,dis ,rib =

where

3.6 * LW ,rib * U W ,dis * (W ,dis ,avg amb ) * tW 1000

(MJ/day)

(7)

LW ,rib

is the length of pipe section heated by trace heating (m); is the linear thermal transmittance of pipe section (W/mK); is the average hot water temperature of pipe section ( C); is the average ambient temperature around pipe section ( C); is the duration of the provision of hot water (h/day).

o o

U W ,dis

W ,dis ,avg

amb

tW

It is assumed that the ribbon heater operates during the same time periods as the domestic hot water heating programme setting, if this is not continuous. The weekly, monthly or annual auxiliary energy consumptions are obtained by multiplying the auxiliary energy consumption per day by the appropriate number of days.

7.3

7.3.1

Auxiliary energy consumption for pumps

General

Electrical energy is required for the pump to overcome the hydraulic losses within the domestic hot water distribution system. A simplified method or a detailed calculation method may be applied to estimate the auxiliary energy consumption for pumps in domestic hot water distribution systems. The proportion of the auxiliary energy consumption for a pump, which is transferred as heat to the circulating water, should be given in a national annex. If a national annex is not provided or does not include this value, the default value given in Annex F may be applied. For the purpose of the calculations, the auxiliary energy recovered as heat to the circulating water is subtracted from the total thermal losses of the circulation loop. 7.3.2 Simplified method

The auxiliary energy consumption for the pump may be estimated from the pump power rating as follows:

WW ,dis , pmp = 3.6 * Ppmp * t pmp

where Ppmp tpmp is the power rating of the pump (kW); is the pump running time (h/day).

(MJ/day)

(8)

Values for tpmp should be given in a national annex. If a national annex is not provided or does not include this value, a default value is given in F.1.

19

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

The weekly, monthly or annual auxiliary energy consumptions are obtained by multiplying the auxiliary energy consumption per day by the appropriate number of days. 7.3.3 Detailed calculation method

If the design of the domestic hot water distribution system is available, a detailed calculation method can be applied. The auxiliary energy consumption for the pump can be calculated from the hydraulic energy requirement and the performance of the pump. The general calculation of the auxiliary energy consumption for the circulation pump is: WW ,dis, pmp = WW ,dis,hydr * eW ,dis, pmp where (MJ/day) (9)

WW ,dis ,hydr

eW ,dis , pmp

is the hydraulic energy requirement (MJ/day); is the performance coefficient for circulation pump (-).

Details of the method are given in F.2. The weekly, monthly or annual auxiliary energy consumptions are obtained by multiplying the auxiliary energy consumption per day by the appropriate number of days.

Recoverable, recovered and unrecoverable system losses

The calculated system losses are not all necessarily lost. Some of the system losses are recoverable for space heating and a proportion of these may actually be recovered and contribute to the space heating. The recoverable system losses are expressed as a fraction of the distribution thermal losses and a fraction of the distribution auxiliary energy consumption:

QW ,dis ,ls ,rbl = QW ,dis ,ls * fW ,dis ,ls ,rbl + WW ,dis ,aux * fW ,dis ,aux ,rbl

where

(MJ/day)

(9)

fW ,dis ,ls ,rbl fW ,dis ,aux ,rbl

is the fraction of distribution thermal losses recoverable for space heating; is the fraction of distribution auxiliary energy consumption recoverable for space heating.

The fractions depend on e.g. location of the pipes, location of the pump, duration of the heating season. If the pipes are installed in the heated space of the building, the thermal losses may be recoverable. However, recoverable losses can only be considered during periods of the year where there is a significant space heating demand. The proportion of the total recoverable system losses that can be recovered is determined according to other standards (e.g. EN ISO 13790 and prEN 15603) for which the total recoverable system losses are provided as an input. The fractions shall be specified in a national annex. If a national annex is not provided or does not include these values, it is considered that no system losses are recoverable for the space heating. ( QW ,dis ,ls ,rbl = 0). Under some circumstances, the recoverable system losses may add to the cooling load required in a building.

20

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

In some situations, the system losses may be reduced by an energy gain from the building to the cold water supply or by heat recovery from the wastewater. These energy transfers may be ignored, unless otherwise required by a national annex. Some of the auxiliary energy may be recovered as heat in the domestic hot water system, see 7.3.1.

21

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Annex A (informative) Calculation of thermal losses from pipes based on pipe lengths and the number of tappings per day

This calculation method takes into account the thermal losses from the pipes and the thermal losses from the water within the pipes. It is necessary to know the pipe diameters and pipe lengths for each individual section of the domestic hot water distribution system. This annex is only applicable for domestic hot water distribution pipes that are not part of a circulation loop. For every pipe section i, the maximum thermal losses are given by:

QW ,dis ,ls ,ind ,i = {

where

w * cw * VW ,dis ,i + c p * m p ,dis ,i

1000

} * {W ,dis ,nom,i amb,i } * ntap

(MJ/day)

(A.1)

w

cw

VW , dis ,i cp

m p ,dis ,i

is the specific mass of water (kg/m ); is the specific heat capacity of water (kJ/kgK); is the volume of water contained in pipe section i (m ); is the specific heat capacity of pipe material (kJ/kgK); is the mass of pipe section i (kg); is the nominal hot water temperature in pipe section i (C); is the average ambient temperature around pipe section i (C); number of tappings per day using pipe section i.

3

W ,dis ,nom ,i amb,i

ntap

A reduction of thermal losses in case of short intervals between the tapping cycles is not taken into account in this calculation method. Thermal losses due to energy content of wasted hot water at the user outlets, while the desired domestic hot water temperature has not been reached, are not included in this calculation method. If the thermal losses from user outlets, i.e. materials of shower heads or taps, are to be included, a further contribution is added to Equation (A.1) taking into account the mass and specific heat capacity of the user outlet material. Influence of pipe insulation in case of short tapping intervals In case of short tapping intervals, the effect of pipe insulation on thermal losses should be taken into account. The following calculation method can be applied.

22

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

For every pipe section i, the thermal losses for each tapping, which is followed by a short interval ttap, are given by:

QW ,dis ,ls ,ind ,i ,tap = {

and W ,i where

w * cw * VW ,dis ,i + c p * m p ,dis ,i

1000

} * {W ,dis ,nom ,i W ,i }

[MJ]

(A.2)

= amb,i + (W , dis ,nom ,i amb,i ) * e

( qi * Li * t tap ) / {( w * c w * VW ,dis ,i + c p * m p ,dis ,i ) * (W ,dis ,nom ,i amb ,i )*1000}

(C)

(A.3)

W ,i

qi Li ttap

is the final hot water temperature in pipe section i before the next tapping (C); is the density of heat flow rate of pipe section i (W/m); is the length of pipe section i (m); is the time interval before the next tapping (s).

The density of heat flow rate is given by:

qi = U R * (W ,dis ,nom ,i amb ,i )

where UR

(W/m)

(A.4)

is the linear thermal transmittance (W/mK) according to Equation (D.1).

23

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Annex B (informative) Calculation of thermal losses from pipes based on pipe lengths and distribution efficiencies

This method is only applicable for domestic buildings and domestic hot water distribution pipes that are not part of a circulation loop. It is based on estimates of the proportion of the heat energy reaching the user outlets for different pipe lengths. A distinction is made between supplies to kitchens and supplies to bathrooms. It is necessary initially to determine the length of the delivery pipes from the heat generator (or hot water storage vessel) or from the circulation loop to the kitchen and to the bathroom: Lkitchen and Lbathroom . The proportion of heat energy reaching the user outlet is termed

pipe,kitchen

and

pipe,bathroom , respectively.

Values for these parameters are to be obtained from tables. Default values are given in Table B.1. The combined efficiency of the domestic hot water delivery pipes is calculated by:

pipe =

� � f kitchen f � + bathroom � � � � pipe,kitchen pipe,bathroom �

(B.1)

where

f kitchen f bathroom

is the fraction of domestic hot water demand in the kitchen; is the fraction of domestic hot water demand in the bathroom.

Default values for

f kitchen and f bathroom are:

and

f kitchen = 0,2

f bathroom = 0,8 .

The total thermal loss from the domestic hot water delivery pipes is calculated by:

QW ,dis ,ls ,ind = QW *

where

(1 pipe )

pipe

(MJ/day)

(B.2)

QW ,dis ,ls ,ind

is the thermal loss of delivery pipes (MJ/day); is the energy need for domestic hot water (see EN 15316-3-1) (MJ/day).

QW

24

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Table B.1 Proportion of heat energy reaching user outlets Length of delivery pipe [m]

> 2 to 4

> 4 to 6

> 6 to 8

> 8 to 10

> 10 to 12

> 12 to 14

> 14

Kitchen dint < 8 mm for 2/3 of the pipe length dint < 10 mm for 2/3 of the pipe length

pipe,kitchen

1,00 0,86 0,75 0,67 0,60 0,55 0,50 0,46

1,00

0,79

0,65

0,55

0,48

0,43

0,38

0,35

Other pipes

1,00

0,69

0,53

0,43

0,36

0,31

0,27

0,24

Bathroom 1,00 0,95 0,90

pipe ,bathroom

0,86 0,82 0,78 0,75 0,72

All pipes

where dint is the internal pipe diameter of the delivery pipe.

NOTE These values are determined by assuming: - an average of 2 tappings of 1 litre in the kitchen and one tapping of 8 litres in the bathroom for every 10 litres of tappings; - complete loss of the heat energy of the water content in the pipes; - additional loss of the heat energy of the water content in the pipes and start/stop losses, at a rate of 0,7 of the loss of the heat energy of the water content in the pipes.

25

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Annex C (informative) Calculation of thermal losses from pipes based on pipe lengths and tapping profiles

This method is based on estimates of the thermal losses expressed as a proportion of the for domestic hot water energy demand at the user outlets. Data on domestic hot water energy demand is required for this method. If thermal losses from user outlets are taken into account, these losses should be added to the energy demand for domestic hot water. The energy demand for domestic hot water is based on the European domestic hot water tapping programs. Although these are not identical to the domestic hot water energy usage for all potential buildings and usage types, they do provide a representative mixture of small and large hot water draw-offs for different total energy requirements. The thermal loss

QW ,dis ,ls ,ind is expressed as:

(MJ/day) (C.1)

QW ,dis ,ls ,ind = W ,dis * QW

where

W ,dis

QW

is the energy loss factor as proportion of the domestic hot water energy requirement; is the energy requirement for domestic hot water (see EN 15316-3-1) (MJ/day).

Three values of

W ,dis

are required based on the three domestic hot water tapping programs:

W ,dis ,1 W ,dis , 2 W ,dis ,3

and

is the energy loss factor for domestic hot water tapping program 1, with 7,560 MJ/day (2,100 kWh/day); is the energy loss factor for domestic hot water tapping program 2, with 21,042 MJ/day (5,845 kWh/day), is the energy loss factor for domestic hot water tapping program 3, with 41,958 MJ/day (11,655 kWh/day)

QW ,1 equivalent to QW , 2 equivalent to QW ,3 equivalent to

QW ,dis ,ls ,ind ,1 = W ,dis ,1 * QW ,1 QW ,dis ,ls ,ind , 2 = W ,dis , 2 * QW , 2 QW ,dis ,ls ,ind ,3 = W ,dis ,3 * QW ,3

(MJ/day); (MJ/day); (MJ/day).

The three energy loss factors are given by:

26

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

W ,dis ,1 = 0,09 + 0,005 * ( LW , dis , hs , avg 6) + 0,008 * LW ,dis ,nhs ,avg W ,dis , 2 = 0,10 + 0,005 * ( LW , dis , hs , avg 6) + 0,008 * LW , dis , nhs , avg W ,dis ,3 = 0,05 + 0,005 * ( LW , dis , hs ,avg 6) + 0,008 * LW , dis , nhs , avg

where

LW , dis , hs , avg

is the average length of distribution pipe within heated space;

LW , dis , nhs , avg is the average length of distribution pipe in non-heated space (if appropriate).

For a specific level of the energy requirement for domestic hot water QW , the energy loss factor can be determined by interpolation as follows: If If

QW < QW , 2 QW > QW , 2

W ,dis = W , dis , 2 0,01 * [(QW , 2 QW ) / (QW , 2 QW ,1 )] W ,dis = W , dis , 2 0,05 * [(QW QW , 2 ) / (QW ,3 QW , 2 )]

Two higher European tapping cycles have been developed for larger energy requirements for domestic hot water. These may also be applied if the actual domestic hot water energy requirement is higher than QW ,3 .

27

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Annex D (informative) Calculation of thermal losses from circulation loop

D.1 Calculation of thermal losses based on pipe length

If a national annex is not provided or does not include a value for the thermal losses from the pipes of the circulation loop, a default value of 40W/m of pipe length may be applied.

D.2 Thermal losses based on a detailed calculation method

D.2.1 General

The variables required for calculation of the thermal losses from the pipes of the circulation loop can be obtained by the following.

D.2.2 Determination of length of pipe sections

For carrying out the calculations, the domestic hot water distribution system may be considered as comprising up to three different pipe sections. In general, these sections can be described as:

horizontal distribution from the heat generator to the main supply pipes (section LV); main supply pipes (section LS); individual branching pipes to the user outlets (section LSL).

In specific installations, all three sections may not be present.

28

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Figure D.1 Location of pipes The pipes of section LV (see Figure D.1) may be situated within an unheated space, such as a cellar or an attic, or they may be situated within a thermal skin of the building or the floor. The pipes of section LS may be vertical or horizontal or a combination of both. They are normally situated within the thermal skin of the building. Pipes of sections LV and LS may constitute part of a circulation loop. These are treated separately. Pipes of section LSL are not part of a circulation loop. For new buildings with an already designed domestic hot water system, as well as for new domestic hot water systems installed in existing buildings, calculations of thermal losses should be based on actual pipe lengths within each pipe section according to the design or actual installation. For new buildings in the early stage of design, where the exact design of the domestic hot water system is still not available, representative values of pipe lengths can be applied. These values are related to the effective floor area of the building, and default values given in Table D.1 may be applied. These default values are 2 based on an average floor area of 80 m and an average pipe spur length of 6 m.

29

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Table D.1 Default values for calculation of thermal losses from circulation loop and distribution pipes Parameters Ambient temperature outside the heating period Ambient temperature Length of circulation loop Length of main distribution pipe Length of individual branching pipe, only for transfer into adjacent rooms with a common installation wall Length of individual branching pipe, for all other cases Symbol Unit Section LV Section LS Section LSL

amb ,nhp

22 C

amb

L L

13 C in an unheated space and 20 C in a heated space 2LB+ 0,012 5LBBB LB+ 0,062 5LBBB

20 C in a heated space

m m

0,075LBBBnfhf 0,038LBBBnfhf

0,05LBBBnf

0,075LBBBnf

where

LB BB

nf hf

is the largest extended length of the building (m); is the largest extended width of the building (m); is the number of heated storeys; is the height of the storeys (m).

The length of the individual pipes is to be determined directly. If no detailed pipe network plan is available, the length can be determined from Table D.2 according to the number of tap points per individual branching pipe. The assumption is made that the individual branching pipes are all situated within the heated space.

30

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Table D.2 Default values for calculation of thermal losses from individual pipes Parameter Average ambient temperature Pipe length for one tap in a room, e.g. from under-sink heater to tap Pipe length for more than one tap in a room, e.g. in a bathroom Pipe length for more than one tap in an adjacent room with a common installation wall Pipe length for supply central within the home unit Symbol Unit C m

Section LSL

amb ,avg

L

20

�A � 1 � N � � 80 � �A � 3� N � � 80 � �A � 4� N � � 80 � �A � 6� N � � 80 �

where AN is the floor area in m . Decentralised domestic hot water systems provide individual rooms with hot water and do therefore not include a common distribution system or circulation loops. In this case, the only thermal losses from the distribution system are those associated with the individual distribution pipes. The heat generator may supply a single user outlet or a number of user outlets. In either case, the heat generator is installed within the heated space of the building and hence there are no distribution pipes situated in an unheated space. For calculation of the thermal losses from these pipes, the actual length of the pipes should be used. If details of the piping are not available, representative values for the pipe lengths can be used. These values are related to the floor area of the building and may be given in a national annex. If a national annex is not provided or does not include these values, default values given in Table D.2 may be applied.

D.2.3 Determination of heat transfer coefficients

D.2.3.1 General

The heat transfer coefficient for any pipe section depends on the diameter of the pipe, the location of the pipe (whether within the heated space or not), the type and thickness of any insulation and the age of the installation. Local or national requirements may define the level of pipe insulation to be used, and thus determine the heat transfer coefficients. Values for insulated pipes may therefore be given in a national annex. If a national annex is not provided or does not include these values, default values given in Table D.3 may be applied. D.2.3.2 Non-insulated pipes exposed

The thermal losses from a non-insulated pipe consist of losses through both convection and radiation. The heat transfer from the hot water to the pipe wall and the conduction within the pipe wall (for metal pipes) can be ignored. Where these pipes are exposed, the resulting heat loss coefficients are given in Table D.3.

31

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

D.2.3.3

Non-insulated pipes beneath plaster

For non-insulated pipes installed beneath plaster, a distinction is made between:

pipes in a non-insulated outer wall of an older building; pipes in an external wall insulated on the outside in an older or new building; pipes in a single layer external wall in a new building.

The resulting heat loss coefficients are given in Table D.3. D.2.3.4 Insulated pipes

The linear thermal transmittance can be calculated by:

U=

1 2 * insul D 1 * e + Dint * De

(W/mK)

(D.1)

where

insul

De

is the heat conductivity of the insulation (W/mK); is the external diameter of insulated pipe (including insulation) (m); is the internal pipe diameter (m); is the heat transfer coefficient (W/m K)

2

Dint

for insulated pipes

= 8 W/m K;

for non-insulated pipes

= 14 W/m K.

If information is not available for calculation of the heat loss coefficients, the values given in Table D.3 may be applied.

32

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

Table D.3 Typical values of linear thermal transmittance of pipes for new and existing buildings U [W/mK] Age/class of building From 1995 assumed that insulation thickness is approximately equal to the pipe external diameter 1980 to 1995 assumed that insulation thickness is approximately equal to half of the pipe external diameter Up to 1980 Section Lv Section LS Section LSL

0,2

0,3

0,3

0,3

0,4

0,4

0,4

0,4

0,4

Non-insulated pipes exposed A 200 m 200 m < A 500 m A > 500 m 1,0 2,0 3,0 1,0 2,0 3,0 1,0 2,0 3,0

Non-insulated pipes installed in external walls External wall non-insulated External wall with external insulation External wall without insulation but characterized by a low thermal transmittance (U = 0,4 W/mK)

a

total/usable 1,35 / 0,80 1,00 / 0,90

0,75 / 0,55

(total = total thermal losses of the pipe, usable = recoverable thermal losses).

D.2.4 Tabulated method for calculation of linear thermal transmittance

An alternative simplified method for calculation of the linear thermal transmittance may be applied. The simplified equation for the linear thermal transmittance is:

U W ,dis = AW ,dis ,U * d R + BW ,dis ,U

where

(W/mK)

(D.2)

AW ,dis ,U and BW ,dis ,U are coefficients depending on the pipe insulation class and dR is given in metres.

33

UNI EN 15316-3-2:2008

Licenza d'uso concessa a UNIVERSITA' CENTRO ATENEO DOC.POLO MONTE DAGO per l'abbonamento anno 2008. Licenza d'uso interno su postazione singola. Riproduzione vietata. E' proibito qualsiasi utilizzo in rete (LAN, internet, etc...)

EN 15316-3-2:2007 (E)

The coefficients

AW ,dis ,U and BW ,dis ,U may be given in a national annex. If a national annex is not provided or

does not include these values, default values given in Table D.4 may be applied. Table D.4 Parameters for calculation of the linear thermal transmittance of pipes Type of pipe insulation dR min (m) Class 2 Class 3 Class 4 Class 5 Class 6 0,010 0,010 0,010 0,010 0,010 dR max (m) 0,300 0,300 0,300 0,300 0,300 AW,dis,U (W/m K) 2,60 2,00 1,50 1,10 0,80

2

BW,dis,U (W/mK) 0,200 0,180 0,160 0,140 0,120

D.2.5 Determination of average ambient temperature

The average ambient temperature is solely dependent on the location of the pipe.

amb = int bW ,dis * ( int e )

where

( C)

(D.3)

int e

bW ,dis

is the internal temperature ( C); mean outside temperature ( C); location factor (-).

o

Values for the location factor are given in Table D.5. Table D.5 Location factor corresponding to the location of the pipes Location of the circulation loop Outside the building Outside the heated space, horizontal circulation Within the heated space Other (e.g. embedded pipe)

bW ,dis

1 0.8 0 to be calculated and substantiated

D.2.6 Determination of average hot water temperature of pipe section